One of the main functions of any real estate object is to maintain a normal temperature regime for human life. Thermal insulation of buildings and structures is a necessary measure for the effective implementation of this function. There are many methods of thermal insulation, we will list the most effective ones.

Thermal insulation of the facade is an important part of construction activities.

Not sure which insulation to choose? We will help you!

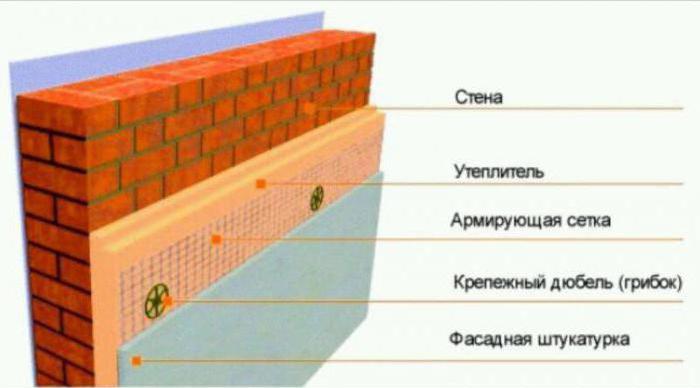

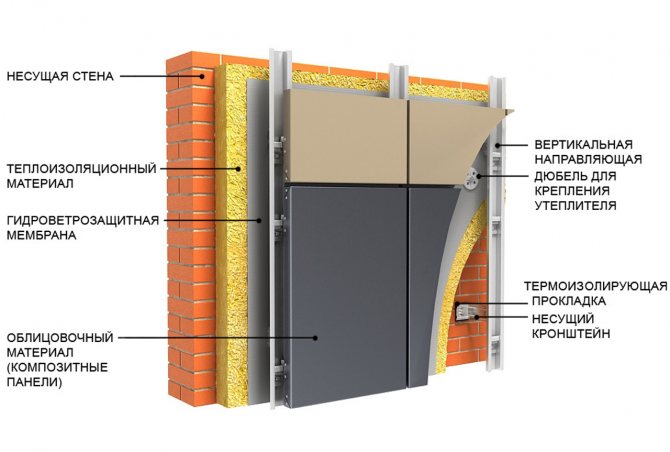

The difference between two insulation systems ("wet" and "ventilated facade")

- Thermal insulation of the facade using the technology "wet facade»Has no restrictions on the building envelope, be it from a monolith, brick of any kind, aerated concrete, moisture-resistant materials, wood, etc. due to the lightness of the constructed system "wet type" in contrast to the "ventilated facade".

- Thermal insulation of the facade using the technology "ventilated facade»Has limitations due to the weight of the system. To start the production of work, it is necessary to conduct surveys for the strength and endurance of the existing facade due to the weight of the subsystem being constructed and the cladding of the building with porcelain stoneware or other facing material.

The main methods of insulating the outer walls of buildings from the company's craftsmen:

- a lightweight method of insulating the facade of an apartment using plaster;

- heavy plastering method of wall decoration;

- ventilated version of the facade surface finish;

- installation of foam or polystyrene plates with their subsequent plastering;

- thermal insulation of the structure using mineral wool.

To achieve the maximum efficiency of the thermal insulation of the outer walls of the house, the company's specialists pre-examine the object in order to identify the most vulnerable places and zones. After that, our masters determine the most suitable insulation installation technology and the best way to isolate the structure. An integrated approach to carrying out all the necessary work guarantees high quality, reliability and efficiency of our services.

Are you planning facade insulation?

We have been installing insulation on facades for 20 years!

↘Thousands of objects handed over.

↘Hundreds of grateful reviews.

↘ Dozens of awards and certificates.

- Departure of our specialist to study the building,

- Identifying the causes of heat leaks,

- Drafting a commercial proposal and project design,

- Execution of work according to the submitted estimate.

We are ready to perform all these types of work and services with high quality and with a good warranty period.

+7

Multichannel telephone

We will be happy to carry out any facade work for you.

Liquid heaters

Liquid thermal insulators such as polyurethane foam are the best thermal insulation materials that are used for external insulation of facades. The polyurethane foam heat-insulating layer creates a double monolith with the walls of the building, the insulation has high adhesion, which provides it with reliable adhesion to any surface.

During the installation of polyurethane foam, there is no need to install steam and waterproofing, since the structure of the insulation allows air to circulate freely in the heat-insulating layer, providing it with excellent ventilation and preventing the formation of condensation on the walls of the building.

Liquid heaters are easy to install, they can be used to insulate large areas in the shortest possible time. The heat-insulating layer obtained by applying a liquid heat insulator is monolithic, has no joints and gaps, therefore, prevents the formation of cold bridges and heat leakage from the room.

The main

Insulation of the facade by industrial climbers working within the walls of the CityAlp enterprise is carried out using high quality tools, equipment and materials. Turning to the technologies of industrial mountaineering helps us get an effective and safe result of the renovation of residential or commercial buildings.

Thermal insulation of facades "ventilated facade"

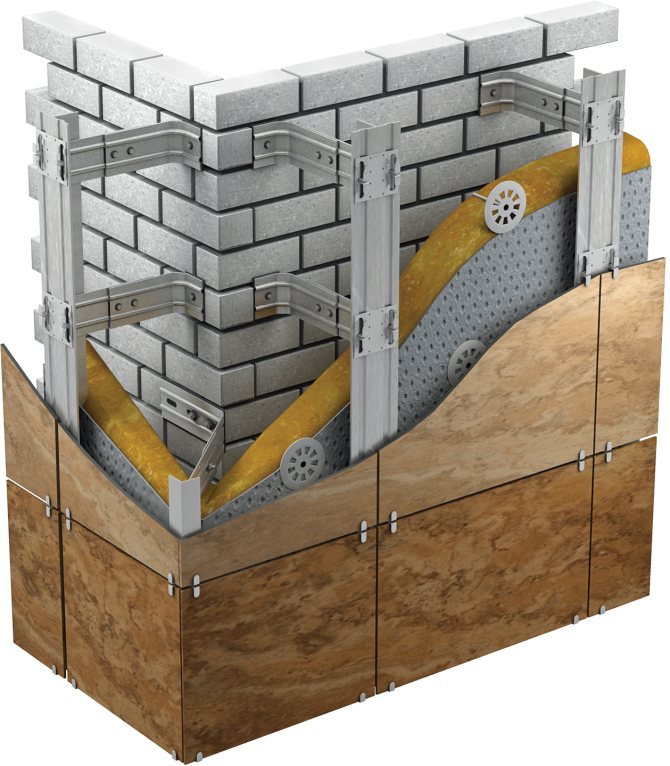

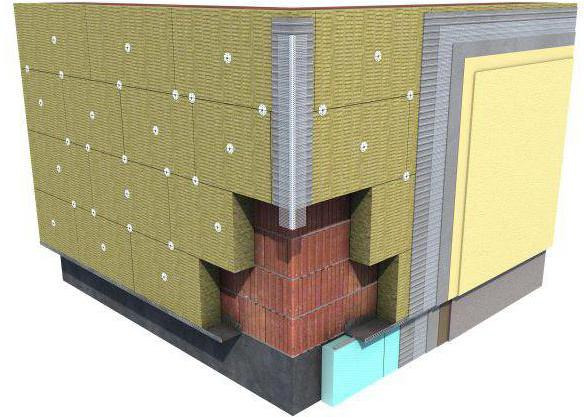

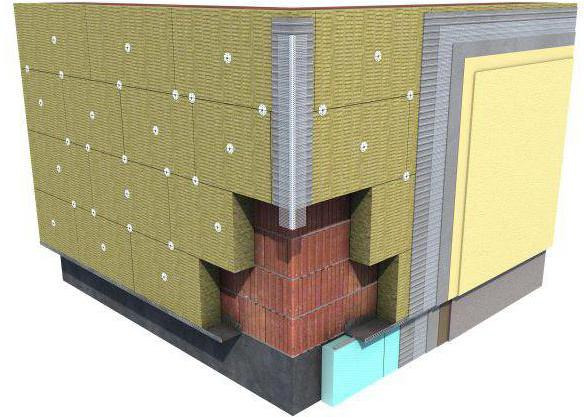

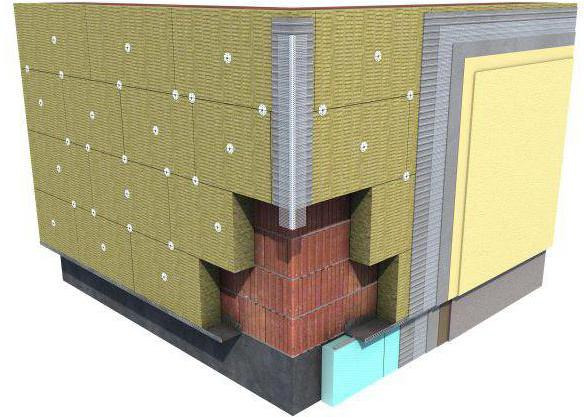

Suspended facade systems with an air gap are used for cladding and insulation of external walls of industrial and civil buildings and structures, as well as for high-tech residential buildings and various complexes.

Curtain facades represent a structure of varying complexity, consisting of cladding materials, heat-insulating material and a subsystem on which the curtain facade cladding material is attached.

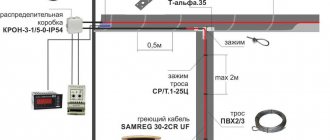

How do we install "ventilated facades"

1. A subsystem consisting of metal guides is set on the level, fastened with anchors.

2.With the help of a dowel, an insulation (mineral wool plate) is attached to the wall

3. Then the facing material is installed on the support subsystem with an air gap.

As facing materials used are porcelain stoneware, fiber-cement panels with a decorative coating, cassettes made of composite materials or steel.

Examples of our work on the "ventilated facades" system

Insulation works using mineral wool

Methods for installing thermal insulation using mineral wool are similar to those for using basalt slabs and cellulose heaters.

- To securely hold mats and sheets of mineral wool, on the wall is made installation of a frame system and lathing made of wooden beams... In this case, the width of the lathing should be 2-3 cm less than the mineral wool sheet. In this case, its tight entry between the bars will be carried out.

- In addition to the lathing, installation of anchorson which sheets of mineral wool are put on. In case of unevenness of the wall, it is better to use two-layer mineral wool. The layers of this wool differ in density. Cotton wool is applied to the wall with a soft layer, which ensures reliable adhesion of the material.

- Minvata is a versatile option in the case of external cladding. Most types of mineral wool allow plastering with reinforcing mesh.

- There is a possibility fastening the material with an external horizontal crate... A windscreen is laid under it. It is a dense plastic film. In this case, different types of cladding are used. In this case, a three-layer ventilated insulation is obtained. This insulation is used for most climatic conditions.

How much does it cost?

| Name of works | Types, list of works | Unit | Price, rub) | ||||||||||

| Device - "Wet facade" Expanded polystyrene PSBS-25F - 100mm watch an example | Facade preparation, cleaning, priming, installation of thermal insulation boards, dowelling, applying a reinforced layer, priming, applying a thin layer of finishing decorative plaster. | m2 | 1290 RUR | ||||||||||

| Device - "Wet facade" Mineral Wool Slab -100mm watch an example | Facade preparation, cleaning, priming, installation of thermal insulation boards, dowelling, applying a reinforced layer, priming, applying a thin layer of finishing decorative plaster. | m2 | 1290 RUR | ||||||||||

| The device of the hinged ventilated facade - 120mm watch an example | Installation of a subsystem, fixing a slab insulation, installation of porcelain stoneware slabs or other | m2 | 2000 RUR | ||||||||||

| Insulation installation | Installation of thermal insulation boards - leveling on a plane using facade glue | m2 | 350 RUR | ||||||||||

| Facade reinforcement | Leveling the facade with an adhesive in two layers, with the application of an alkali-resistant mesh | m2 | 350 RUR | ||||||||||

| Decorative plastering | Application of finishing decorative plaster on the prepared base | m2 | 380 RUR | ||||||||||

| Wall priming watch an example | Cleaning the facade from dust, priming with a deep-penetrating primer | m2 | 60 RUR | ||||||||||

| Dowelling | Fixing the insulation after gluing, using dowels | m2 | 120 RUR | ||||||||||

| Reinforcement of window slopes | Leveling the slope with an adhesive in two layers, with the application of an alkali-resistant mesh | mp | 270 RUR | ||||||||||

| Facade painting watch an example | Painting the wall surface in one layer on the prepared base | m2 | 90 RUR | ||||||||||

| Insulation of window slopes | Priming, installation of insulation, reinforcement, priming, decorative plaster on the slope | mp | 320 RUR | ||||||||||

| Insulation of the basement watch an example | Surface priming, installation of insulation, dowelling, reinforcement, priming | m2 | 850 RUR | ||||||||||

Insulation works using expanded polystyrene, EPS

- The bottom of the wall is equipped with a special shelf from the corner... It is necessary in order to align the first layer of expanded polystyrene sheets. The heat insulator is attached to a special adhesive solution. The sheets are applied to the wall and pressed down. With the help of a grid, level and plumb lines, the evenness and correctness of the installation is controlled.

- Installation of the next layer of foam is made after the previous layer has set. During installation, it is desirable to displace the next layer relative to the first by half the sheet. Thanks to this, a bunch of sheets is carried out. After gluing, the sheets are fastened using special fastening anchors. Fastening is carried out by five mushrooms, four at the edges and one in the middle. Due to the offset of the rows, the corner anchor of the sheets will also fix the middle of the upper and lower sheets.

- The corners of buildings, as well as the places of window openings fixed with metal corners. With the help of reinforcing plaster tape, all joints between the sheets of material are glued.

- A reinforcing mesh is attached to the EPS or expanded polystyrene on top... Plaster is applied on top of the mesh.

- Insulation of monolithic concrete or brick buildings best done with expanded polystyrene. In this case, the only significant drawback is the low vapor permeability of the material. This interferes with the normal drainage of condensation from the walls.

- Before using styrofoam necessary thoroughly dry the walls... Otherwise, it is better to use ventilated facades or partially ventilated facades. In this case, moisture retention will not occur on the surface of the main walls. This will preserve their mechanical properties.

- After the completion of all work, there should be no gaps and places open to the foam... Thanks to this, the material is protected from various rodents.

Varieties and characteristics of mineral wool

There are several varieties of mineral wool, which differ in their characteristics and scope:

- Basalt... It is made from gabbro-basalt fibers with a thickness of 5-15 microns, does not contain mineral or binding additives, therefore it can withstand temperatures from -190 C to +1000 C, is characterized by minimal hygroscopicity, is used for insulation of facades;

- Stone... For manufacturing, diabase and gabbro fibers are used, 5-12 microns thick, similar in performance to basalt, but slightly inferior to it in resistance to freezing, not suitable for regions where the temperature drops below -45 C;

- Slag... It is produced from metallurgical waste, the fiber thickness is 4-12 microns, it is not suitable for the insulation of metal surfaces, for example, pipelines, since it can contribute to the development of corrosion;

- Glass wool... The most budgetary option with a fiber thickness of 5-15 microns, contains formaldehyde, therefore it is used for insulating non-residential premises (warehouses, workshops).

Basalt wool is most often used to insulate facades.It is one of the most versatile insulation materials due to its characteristics:

- Thermal protection (thermal conductivity). With a 10 cm thick insulation slab, this parameter for mineral wool ranges from 0.036 to 0.042 W / K * m.

- Density - 40-300 kg / m³.

- Resistant to fire. Refers to the category of non-combustible facade materials. Does not light up even at a temperature of 1000 C.

- Soundproofing level. The noise absorption coefficient of the material is 0.95.

- Water vapor permeability. Allows excess moisture to freely leave the room. The vapor permeability coefficient is 0.49 - 0.6 Mg / m * h * Pa.

- Hygroscopicity. Moisture saturation is not more than 1-1.5%.

It's important to know!

When working with mineral wool, it is imperative to follow the safety rules. Protect the hands and face of the fitter with protective clothing. You need to wear glasses on your eyes. A respirator should be used to prevent mineral wool fibers from entering the respiratory system. Micro-dust from the insulation, when it gets on the mucous membranes or skin, can cause allergies (itching, redness).

Price list

Popular turnkey works

| Description / Thickness of thermal insulation | 50mm | 100mm | 150mm |

| Turnkey ventilated facade, rub / m2 | 3330 | 3440 | 3550 |

| Wet facade "turnkey", rub / m2 | 2340 | 2560 | 2780 |

| Insulation name / thickness | 60mm | 80mm | 100mm |

| "Turnkey" installation of thermal panels faced with artificial stone, rubles / m2 | 3300 | 3450 | 3550 |

| Name | Price |

| Treatment of seams of a panel house using warm seam technology | RUB 300 / m. |

Ventfacade

| Name | Price |

| Heat engineering calculation | Is free |

| Pull-out test of anchors | Is free |

| Geodetic survey of the facade | 20 rub / m2 |

| Design work | 70 rub / m2 |

| Installation / dismantling of frame scaffolding | 120 rub / m2 |

| Wall markings for brackets | 50 rub / m2 |

| Installing brackets | 150 rub / m2 |

| Attaching extension cords | RUB 100 / m2 |

| Installation of the first layer | 200 rub / m2 |

| Installation of the second layer | RUB 100 / m2 |

| Installing the guides | 200 rub / m2 |

| Fastening the facing layer | RUB 600 / m2 |

| Subsystem device for parapet cover | RUB 500 / m2 |

| Installation of a parapet ebb, m. | 400 rub / m. |

| Installation of ebb, slopes, drip, m. | 350 rub / m.pog |

Facing with thermal panels

| Name | Price |

| Heat engineering calculation | Is free |

| Leveling plaster (with a difference of over 30 mm) | 520 rub / m2 |

| Frame device (with a difference of more than 30 mm) | RUB 300 / m2 |

| Fastening thermal panels | 800 rub / m2 |

| Grouting | RUB 300 / m2 |

| Slope device, m.p .: | |

| Plastering | 650 rub / m. |

| Steel | 350 rub / m.pog |

| From clinker tiles | 800 rub / m. |

| Installation of ebbs | 350 rub / m.pog |

| Installation of spotlights | RUB 600 / m2 |

| Fastening the end plate | 350 rub / m.pog |

| Installation of a drainage system | 350 rub / m.pog |

Masonry

| Name | Price per rub / m2 |

| Rough laying of partitions (thickness up to 200 mm for blocks and 120 mm for bricks) from: | |

| Foam blocks | 400 |

| Gas silicate blocks | 400 |

| Expanded clay blocks | 400 |

| Bricks | 450 |

| Rough wall masonry (thickness over 200 mm for blocks and 120 mm for bricks) from, m3: | |

| Foam blocks | 2600 |

| Gas silicate blocks | 2600 |

| Expanded clay blocks | 2600 |

| Bricks | 2800 |

| Fastening of thermal insulation with disc dowels | 200 |

| Facing brick walls with a thickness of half a brick | 800 |

Material selection

Before purchasing your favorite mineral wool, be sure to pay attention to where it will be installed and whether it is intended for this. So, if the installation of mineral wool will be carried out outside the building, then the material should also be facade, since it has a higher hydrophobicity, repels moisture and has a good density. Insulation intended for indoor installation has lower properties and will not cope with its purpose if installed outside the building.

Unfortunately, mineral wool, like any building material, has more than just advantages. He also has disadvantages - the need to strictly adhere to the technological process. If the manufacturer's recommendations for installation are violated, the insulation will lose its thermal insulation properties.One of the options for violating the technology is the rejection of the reinforcing layer. Such a decision will lead to the fact that cracks will appear on the facade and, over time, expand.

Professional finishing and insulation of the facade surface

LLC CityAlp specializes in qualified high-rise work and offers its customers the most attractive prices for facade insulation. The cost of finishing the exterior walls of residential buildings and other types of buildings is affordable for all Moscow customers.

Adequate prices for the entire range of services to ensure high-quality thermal insulation of the object will help you significantly reduce the cost of repairing and finishing your home. To clarify the prices for the work performed by us, study the price list presented on the company's website. A more accurate amount will be announced by our specialists after inspection and study of the object, taking into account the customer's personal preferences for the finished result of the finishing work.

Our projects

all implemented projects can be seen live

The BauGroup company insulates office buildings and country houses, shopping malls and multi-storey residential buildings, social facilities and special-purpose buildings.

We have extensive experience in tight deadlines and in winter conditions, in the implementation of projects with increased requirements for documentation and organization of work.

Country houses

Residential complexes

Cottage villages

40% of energy resources in the modern world are spent on heating and cooling buildings. Previously, a comfortable temperature was achieved by increasing the thickness of the walls - today, with the advent of modern heat-insulating materials, this is no longer necessary.

Europe has long adopted stringent requirements for the use of energy-saving technologies in construction and thermal insulation. Russia, following the Western countries, adopted a number of regulatory and technical documents in the field of construction and insulation of buildings ("On the adoption of amendments to SNiP II-03-79" Construction heat engineering "+ the program for reforming housing and communal services), aimed at solving the problems of energy saving and reducing operating costs in construction.

In accordance with the requirements established in SNiPs, traditional building materials (reinforced concrete, brick, foam concrete, gas silicate, wood) are not capable of providing the required thermal resistance in a single-layer enclosing structure. It is possible to achieve standard indicators for the insulation of houses with the help of a multi-layer enclosing structure, where an energy-efficient heat-insulating material is used as a heater.

Selection basics

But in order for the material to really perform all functions and keep the house warm, it must only be of high quality. Not all types of heaters that are currently on sale in the construction market can be said to be of high quality. However, there are companies that produce mineral wool that meets all the requirements and has all the necessary properties. These are Beltep, IZOVOL, Paroc and others.

Rockwool tops the list of the best manufacturers. This is a subsidiary of a Danish firm. Moreover, he is not alone: throughout the country there are factories of this brand that offer high quality products without price markups.