Reliable fastening of the insulation is a mandatory step in creating thermal insulation for a room. Soft, loose and porous sheets or mats, which are easy to fix, are chosen as the insulating material. For small volumes, they are fixed on glue or simply placed between the bars. In the case of large-scale construction work, it is necessary to use special fasteners - dowels. They differ in the method of fastening, material of manufacture, length and diameter. Before starting work, it is necessary to choose the right holders for thermal insulation.

Types of retainers

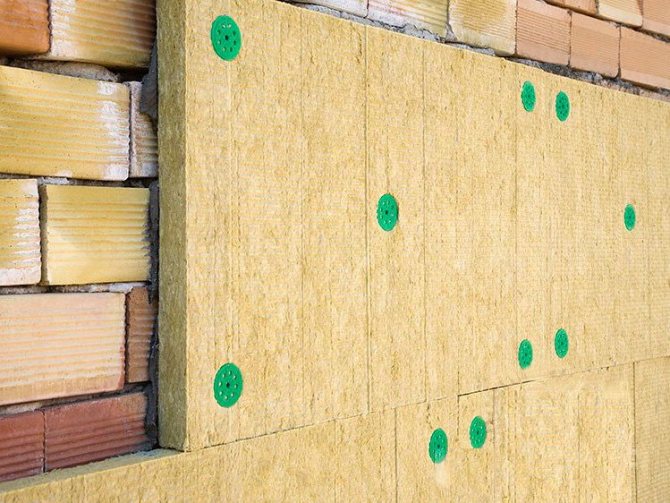

For the facade and roof, different types of dowels are used, differing in the size of the cap

Insulation is a heterogeneous multilayer material, often with a porous structure. The complexity of its fastening lies in the risk of violating the integrity of the structure, especially when using waterproofing and vapor barrier. For this reason, retainers are divided into two main groups:

- dowels for facade work and wall insulation;

- dowels for roof insulation.

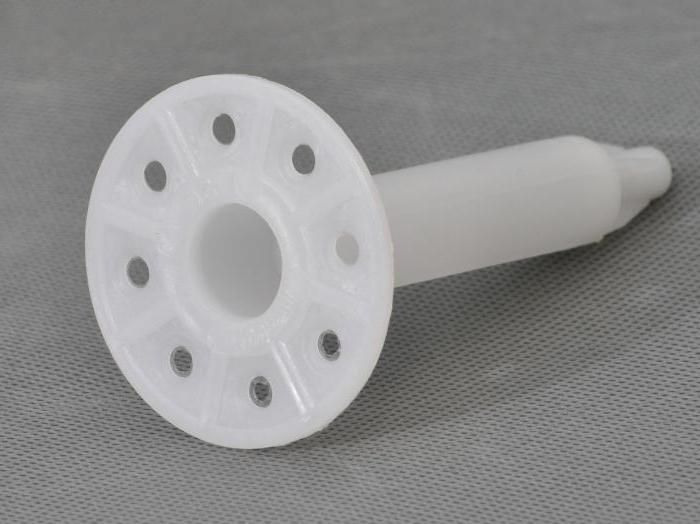

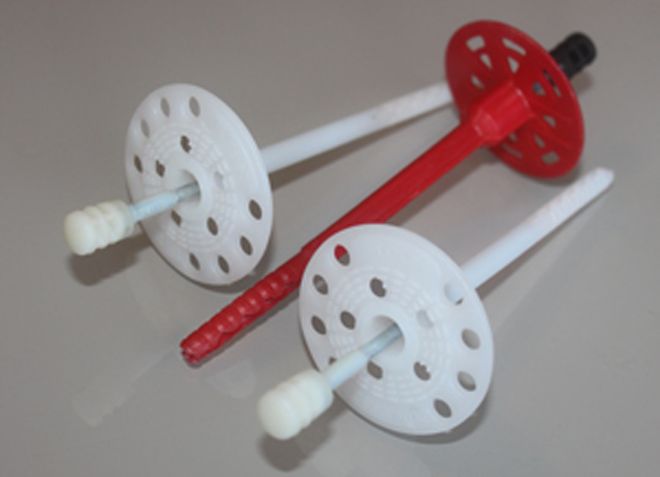

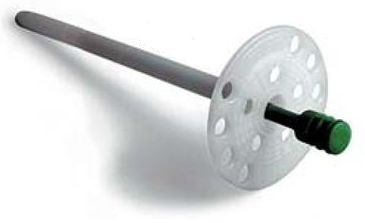

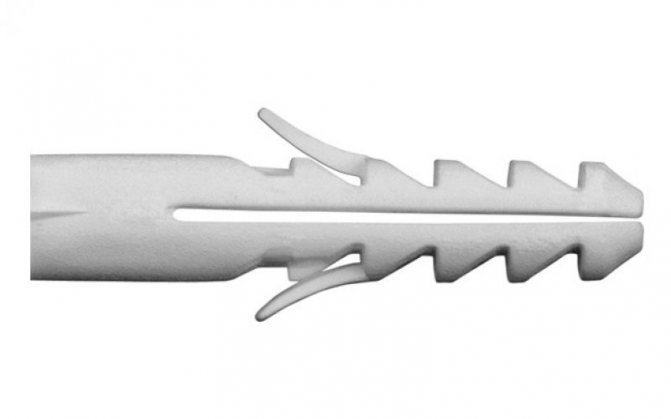

The first type of fasteners is an integral or collapsible structure in the form of a mushroom. The collapsible one consists of a sleeve with a spacer part, a head in the form of a pressure disk and a rod. The dowel for insulation differs from the usual only in the increased volume of the head. The disc diameter is 45-90 mm. Made from various types of plastic and metal.

The second type of dowels is a hollow plastic rod with a wide clamping disc. It has a special way of installation - into the body of the heat insulator. The nail goes through and sinks into concrete or other dense material.

Criterias of choice

When choosing dowels for insulation, its density matters

The quality of fastening the material to the surface depends on the correct choice. When choosing dowels, you need to pay attention to several factors:

- Length. It depends on the thickness of the insulator and other layers, the deviation of the wall from the vertical, the minimum allowable deepening.

- Pull-out load.

The shape also depends on the material. Lightweight heat insulator does not withstand rigid attachment.

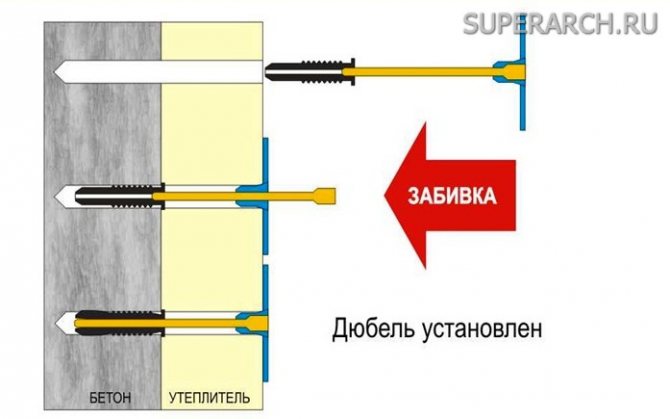

The process of fixing the insulation with a dowel

Directly installing insulation dowels is simple and consists of just a few operations.

- Marking the places of the proposed installation.

- Drilling holes for fasteners through the thermal insulation layer.

- Installing the dowel: it is pressed into the hole until the cap is firmly pressed against the insulating material.

- Installing a spreader nail and hammering it in until it is completely seated.

- Attaching the protective cover of the nail head.

When attaching the insulation, be sure to remove the old plaster (if any) or increase the drilling depth. Fastening of dowels means that the anchoring element fits into the load-bearing layer of the wall exactly along its entire length. By reducing the length of the spacer on your own (which happens quite often), it is imperative to sharpen the cut end. To install the dowel, make a hole with a diameter of 10 mm (± 0.3 - 5 mm). In this case, its depth in the bearing wall should be 55 - 60 mm - for an anchor element with a size of 50 mm, 105 - 110 mm - for an anchor element with a size of 100 mm.

After that, a dowel is placed in the hole, and the disc and anchor elements are preliminarily put on a fiberglass rod. Using a hammer, the protruding part of the rod is hammered to the level of the flange.At the same time, an interference is created in the anchor element, which ensures the reliability of adhesion in the "wall - anchor element - rod" system. For standard fastening, use five to six dowels per 1 sq. m walls. The exact amount of required fasteners is determined by calculation based on the area of the insulated surface.

Dowel for fixing insulation

Currently, there is a huge assortment of different types on the market. dowels for heatersdesigned for various thermal insulation materials, taking into account their thickness, weight and other characteristics. The main producing countries of such hardware are Russia, Germany, China and Poland. The price range ranges from 3 to 30 rubles. per piece (the cost depends on the materials from which the dowel is made, as well as on the manufacturer's brand).

These articles may also be of interest to you:

- Installation of facade blocks

- Modern fasteners for all occasions

- Replacing the siphon and sink drain

- Insulation of walls outside with mineral wool. Step-by-step instruction

Varieties of dowels

Dowels can be classified according to several criteria - by design, material and design. The choice depends on the characteristics of the insulation itself.

Design

There are two main methods of fastening:

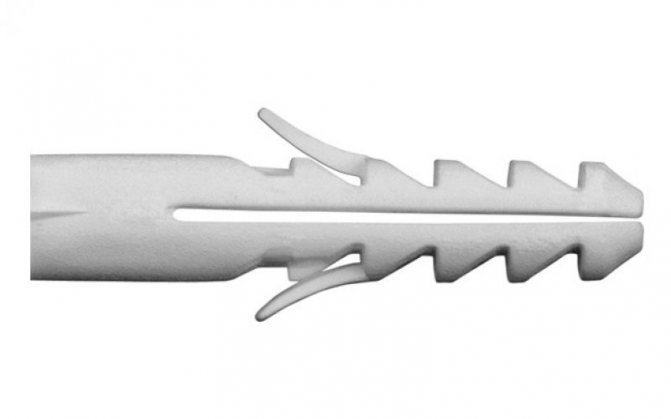

- Spreadless. The dowel does not need hardware. The fasteners are installed in a pre-drilled hole through the insulation.

- Spacer. A nail or screw is driven into or twisted into the body of the rod. A hole is pre-made under the rod, into which it must be placed.

Spacer

Spreadless

The first option is used for aerated concrete, and the second for dense materials (brick, concrete).

Manufacturing material

Glass fiber reinforced polyamide nail has the strength of metal

The dowel itself is made from different types of plastics. It is forbidden to use metal due to its high thermal conductivity. A screw or nail is made of plastic or metal.

The main types of plastics for dowels:

- Nylon or polyamide. It is a lightweight material with a high degree of strength. It can be used to mount to any surface. The maximum permissible load on the fasteners for the insulation is 120 kg. Working - 30 kg.

- Polypropylene. Differs in increased strength and hardness. The load reaches 150 kg.

- Glass fiber reinforced polyamide. It is a new material that has the same strength as metals. It has low thermal conductivity, which makes it a material of higher priority than metal parts.

The spacer rod can be made of the same plastic as the mushroom dowel for thermal insulation, or from metal.

Stainless steel is a more durable material than galvanized steel

The following materials are used from metals:

- Cink Steel. The thickness of the zinc layer must be at least 6 µm. It is used in normal conditions with normal humidity levels.

- Stainless steel. This is a more expensive fixative, but it does not corrode. The main area of use for steel holders is in places with high levels of humidity.

By design, they are distinguished:

- The nail and the dowel are made of the same type of plastic. It is not advised to use different types, since their coefficients of thermal expansion will differ. The thermal insulation dowel with a plastic nail is used in almost all climatic conditions.

- The dowel is made of plastic, the rod is made of metal. The fastening is improved, but the metal conducts heat. This leads to the formation of a cold bridge.

- Plastic dowel fungus for insulation and a metal rod with a thermal head. This design avoids the appearance of a cold bridge. The screw head is covered with a nylon cap and the nail is inside.

Each of the combinations of dowel-nails for thermal insulation has its positive and negative sides, as well as its own cost. The choice depends on the climatic characteristics of the room in which the insulation is carried out.

Benefits of poppet fasteners

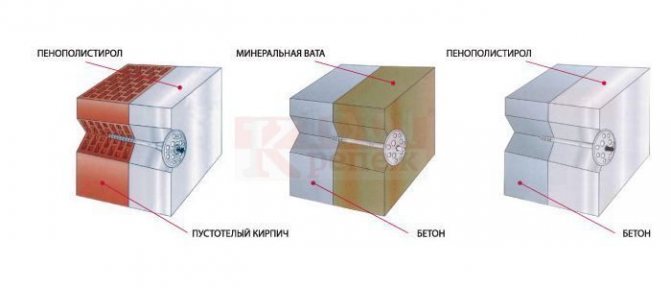

For fastening any type of heat-insulating materials, special dowels are intended - the so-called mushrooms for insulation, or umbrellas. They can hold even loose and fragile material. With these dowels, you can attach thermal insulation to concrete, brick, foam and aerated concrete and even stone.

Disc dowel design

The main material for the manufacture of fungi is HDPE (low pressure polyethylene), and the wedge can be made of galvanized steel or glass-filled polyamide.

- This type of fastener is widely used due to its design: the outer cap is wide enough, which allows even mineral wool insulation to be well fixed.

- Thanks to the long leg, the dowel can withstand a large bearing load. In addition, the fixation is enhanced by a long spacer zone, consisting of three sections. The surface of the cap is rough and has special holes on it.

- Fungi not only help to keep warm, but also have high anti-corrosion properties. Unlike outdated wooden corks, polyethylene does not deteriorate or rot.

- Plastic does not create additional cold bridges; it is a durable, reliable and inexpensive material.

- Due to their high flexibility, plastic "umbrellas" allow leveling expansion and contraction of materials, preventing damage to the insulation.

- For reliable fixation, you need to unfold the dowel inserted into the hole with a special wedge, screw or screw. At the same time, it expands in several directions, which enhances adhesion to the wall.

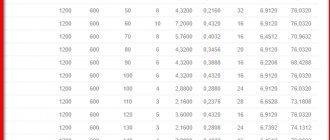

Product dimensions

There are no GOST standards for plastic dowels, but they exist for polyamide products. The document states which brand of plastic can be used and in which macroclimatic conditions.

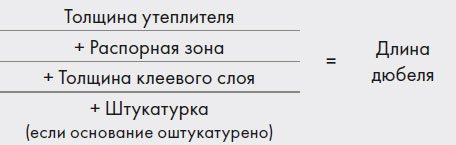

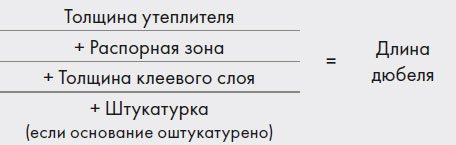

The formula for calculating the length of the dowel for different thicknesses of insulation

The insulation fasteners must be of sufficient length. This is due to the deepening through several layers of thermal insulation. The sizes of other parts vary within a small range:

- head diameter - from 45 mm to 90 mm;

- 2 rod diameters - 8 mm and 10 mm each;

- length from 40 mm to 400 mm.

The bearing capacity depends on the strength of the retainer and the material of the walls. The load can be from 0.3 kN to 23 kN.

The length can be calculated using the formula L = H + I + K + W. L - dowel length, H - insulation thickness, K - thickness of plaster or glue layer (if any), I - additive for fixing into concrete / brick / wood (50 mm), W - stock.

When using 50 mm foam, mounted on a 5 mm adhesive layer, a 110 mm dowel is required. In the case of a curved wall with a skew of 50 mm, the dimension will increase to 160 mm by the corresponding value. A dowel of 210 mm is required for a double layer of insulation.

Excessive length will not always be a positive factor. This must be taken into account when insulating thin walls in an apartment.

Famous manufacturers

The leading manufacturers of insulation dowels are companies from Germany, Russia and Poland. The most famous firms include:

- Termoklip. The company supplies products to Russia and the CIS countries made of anti-rust coated carbon steel. Dowels are produced in several series, made of block polymer. Some models have a heat-insulating cover.

- Isomax. Produces disc dowels with a diameter of 10 mm. The nail is made of zinc coated carbon steel. It is possible to install a thermal head.

- Tech-Krep. The Russian manufacturer supplies plastic fasteners in different versions. They can have a plastic or metal nail, thermal cover.They have a complex chemical composition. The steel nail is galvanized.

All products have the necessary certificates and licenses for installation work.

Dowel for thermal insulation with a plastic nail

Plastic crepe parts eliminate the disadvantages that a dowel with a metal nail has due to the fact that they are made of nylon or propylene. Such a dowel can be purchased in various sizes, from 7 centimeters to almost 40 centimeters. The diameter of the base is approximately 6 centimeters, the diameter of the rod is about one centimeter.

The nail for such an attachment is also made of nylon with the addition of fiberglass. This provides the structural part with lightness and strength at the same time, and increases the ability to support heavy loads.

Installation work

The number of dowels is calculated based on the presence or absence of additional fasteners, for example, glue

First of all, you need to calculate how many dowels you need, what length and diameter they should have. It depends on the insulation. Its weight is practically irrelevant, the thickness and degree of looseness are important.

The length of the fasteners for the insulation mushroom depends on several parameters. The thickness of the insulation sheet, adhesive layer, vapor barrier, waterproofing. It is also necessary to take into account the deviation from the vertical and the maximum possible deepening into the wall. All these criteria must be specified in the documentation and the size is selected according to them.

The diameter of the cap is determined by the degree of looseness of the thermal insulation. This criterion is approximate, the exact values are not indicated anywhere. If the insulation is light and loose in structure, the diameter should be large. In the case of styrofoam installation, you can choose dowels with a small head. For laying mineral wool, choose the largest hats.

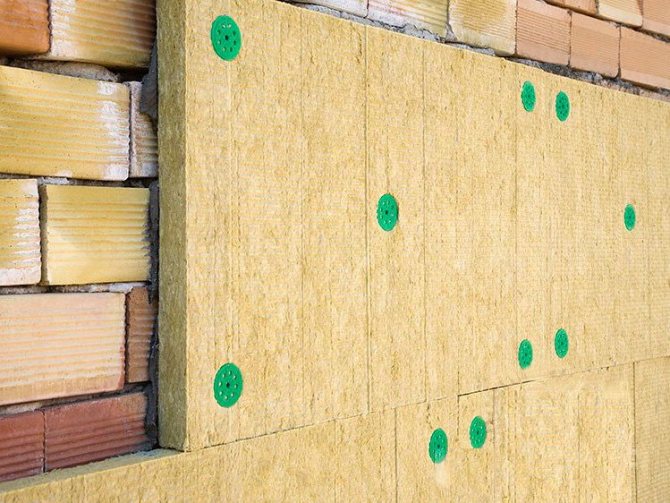

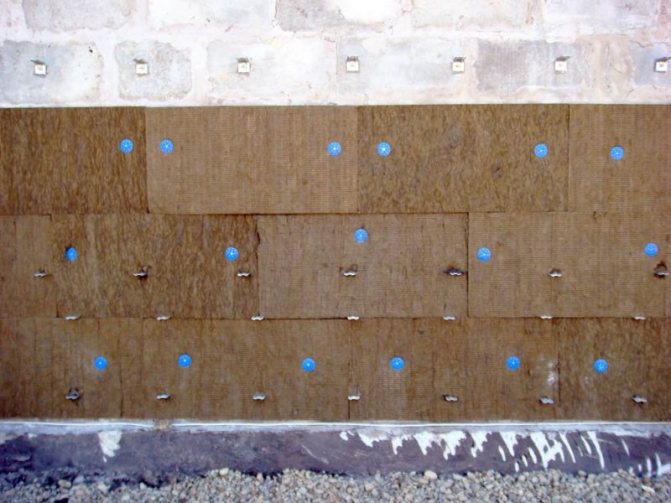

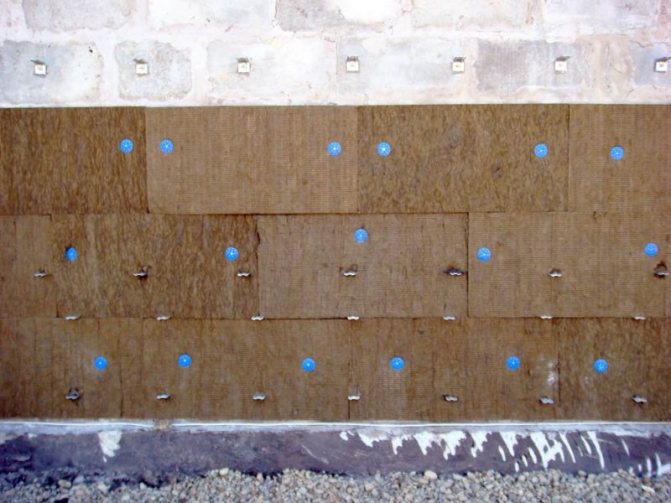

The number of fasteners depends on the weight of the insulation boards and the possible load of the disc dowel itself for fastening the insulation. There should be at least 5 of them per plate - 4 are attached in the corners, 1 in the central point.

All these values are applicable if the interior of the house is insulated.

If the insulation is to be attached to the façade, the wind load must be taken into account. The number of bindings is increasing, there should be at least 6 of them, located in two parallel rows. If the building has a height of up to 20 meters, 1 sq. M. there are 7 dowels. At a height of more than 20 meters, the consumption of fasteners increases to 9 pieces.

Subtleties and nuances of installing thermal insulation

Basic methods mounting thermal insulation for various materials, such as polystyrene, expanded polystyrene or expanded polystyrene, are identical. All work is reduced to a general algorithm, which has several stages:

- Preparation of the surface on which the material will be installed.

- Installation of sheet thermal insulation on an adhesive solution.

- Fixing the panels with fasteners.

- Refinement of panel joints.

- Installation of waterproofing film.

- Sheathing of the insulated surface with decorative materials.

All work must be started with preparation work surface, with the removal of old paint, wallpaper or plaster, as well as eliminating imperfections of the wall. Further, the selected material for warming the room is planted in a specialized solution that should not contain toluene and acetone. The adhesive mixture must be distributed evenly over the entire area of the element to be installed.

For additional fixation and prevention of displacement of sheets, the first level from the ceiling consolidatet per metal profile. After the specified period for the adhesive solution to set, you can proceed with the installation fastening fungi... When drilling holes for them, the drill diameter is used, which corresponds to the diameter of the mushroom leg. The hole should be ten millimeters deeper than its length, so that debris after drilling is finished does not interfere with the installation of the fasteners.

Building standards, norms and regulations

If you pay attention to the current legislation in the construction sector, then in it installed standards and requirements for the installation of thermal insulation:

- When installing thermal insulation indoors or on the facades of residential one-story buildings outside, for one square meter of the insulation surface, it is required to place 4 elements for fastening in the corners and one in the center.

- At the corners of the walls, you will need to additionally fix it with 6 fasteners.

- Provided that the height of the facade is from 8 to 20 meters, you will need 7 fasteners at the edges and one in the center.

- For installation work at a height of over 20 meters, the rules require one square meter of the insulated surface to be fastened to 9 elements.

The best option is to strengthen the fungi at the joints of foam panels or a similar material, since this method optimizes the number of holes in the insulation, which, as a result, will not affect the overall effectiveness of such measures.

If the fastening element needs to be fixed on a metal surface, for example, on a corrugated board, then a self-tapping screw is attached to the dowel leg and, together with the insulation, is pressed against the wall, after which the self-tapping screw is screwed into the metal. The screw tightening depth must be at least 15 millimeters. Further, the joints of the insulating panels are additionally glued with aluminum reinforcing tape, and the corner joints between the walls, ceiling or floor are sealed with polyurethane foam.

Calculation of the required number of fasteners

For a high-quality and durable installation of insulation, you need to use fasteners made in accordance with GOST, but not forgetting also about calculating the required number of such parts. To do this, the following formula will help:

D = T + K + I + Z, where:

- T - The thickness of the insulation to be installed.

- K - The thickness of the layer of adhesive solution used for fixing the panels

- I - The depth of screwing the self-tapping screw into the wall, not less than 45 millimeters.

- Z - Possible inclination of the wall relative to the vertical, this parameter is optional.

The length of the dowel anchor for use on brick or concrete walls must be at least 60 millimeters. And if the brick or foam concrete block is hollow, then in this case, at least 100 millimeters.

When choosing a fungus for installing thermal insulation, you need to take into account the features of a particular insulation and surface.