The diameter of the nozzle and stop valves d, m, for draining water from the sectioned section of the pipeline of water heating networks, which has a slope in one direction, should be determined by the formula

(1)

where dred, ∑l, ired are the reduced diameter, m, total length, m, and the reduced slope of the sectioned pipeline section, respectively:

(2)

(3)

where l1, l2,… ln are the lengths of individual sections of the pipeline, m, with diameters d1, d2,… dn, m, with slopes i1, i2,… in;

m is the valve flow rate, taken for valves m = 0.0144, for valves m = 0.011;

n is a coefficient depending on the time of water discharge t:

at t = 1 h. n = 1;

t = 2 h. n = 0.72,

t = 3 h. n = 0.58,

t = 4 h. n = 0.5,

t = 5 hours n = 0.45.

When placing drainage devices at the lowest point of the heating network, the diameter of the choke and shut-off valves def, m, should be determined by the formula

(4)

where d1, d2 - diameters of fittings and valves, m, determined by formula (1) separately for each adjacent to the lower point of the heating network pipeline section.

The minimum permissible indicators of the probability of failure-free operation should be taken for:

heat source Рit = 0.97;

heat networks Ртс = 0.9;

heat consumer Рпт = 0.99;

MCT as a whole Pstst = 0.9 × 0.97 × 0.99 = 0.86.

The customer has the right to establish higher indicators in the design specifications.

With underground laying of heating networks in non-passable channels and channelless laying, the amount of heat supply (%) to ensure the internal air temperature in heated rooms is not lower than 12 ° C during the repair and recovery period after a failure should be taken according to Table 1.

Reservation of heat supply through heating networks laid in tunnels and passageways may not be provided.

For consumers of the first category, provision should be made for the installation of local backup heat sources (stationary or mobile). It is allowed to provide for redundancy, providing, in case of failures, a 100% heat supply from other heating networks.

Table 1

| Heating network pipes diameter, mm | Heat supply recovery time, h | Estimated outside air temperature for heating design tо, ° С | ||||

| minus 10 | minus 20 | minus 30 | minus 40 | minus 50 | ||

| Permissible decrease in heat supply,%, up to | ||||||

| 300 | 15 | 32 | 50 | 60 | 59 | 64 |

| 400 | 18 | 41 | 56 | 65 | 63 | 68 |

| 500 | 22 | 49 | 63 | 70 | 69 | 73 |

| 600 | 26 | 52 | 68 | 75 | 73 | 77 |

| 700 | 29 | 59 | 70 | 76 | 75 | 78 |

| 800-1000 | 40 | 66 | 75 | 80 | 79 | 82 |

| 1200-1400 | Up to 54 | 71 | 79 | 83 | 82 | 85 |

AIRCRAFT

Nominal bore of the union and shut-off valves for air discharge

table 2

| Conditional passage of the pipeline, mm | 25-80 | 100-150 | 200-300 | 350-400 | 500-700 | 800-1200 | 1400 |

| Nominal bore of fittings and shut-off valves for air discharge, mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 |

AIRCRAFT, DOWNLOADS, JUMPER DIAMETERS

Nominal bore of the union and fittings for draining water and supplying compressed air

Table 3

| Conditional passage of the pipeline, mm | 50- 80 | 100-150 | 200-250 | 300-400 | 500-600 | 700- 900 | 1000-1400 |

| Nominal bore of nozzle and fittings for water discharge, mm | 40 | 80 | 100 | 200 | 250 | 300 | 400 |

| The same for compressed air supply, mm | 25 | 40 | 40 | 50 | 80 | 80 | 100 |

| Conditional passage of the lintel, mm | 50 | 80 | 150 | 200 | 300 | 400 | 500 |

DESCENDANTS

Nominal passage of the nozzle and stop valves for draining water from sectioned sections of water heating networks or condensate from condensate networks

Table 4

| Conditional passage of the pipeline, mm | Up to 65 incl. | 80-125 | 150 | 200-250 | 300-400 | 500 | 600-700 | 800-900 | 1000-1400 |

| Nominal bore of the nozzle and stop valves for draining water or condensate, mm | 25 | 40 | 50 | 80 | 100 | 150 | 200 | 250 | 300 |

The smallest inner diameter of pipes should be taken in heating networks at least 32 mm, and for circulation pipelines for hot water supply - at least 25 mm.

General Provisions

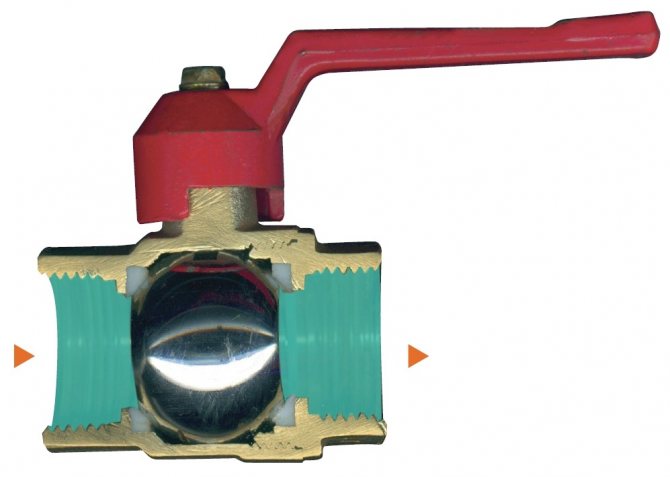

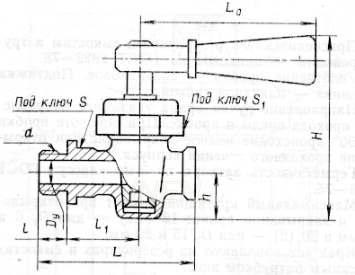

Schematic drawing of a pinned crane 10b9bk1 with direct descent

In order to correct the movement of liquids and gases in the circuit itself or to release them outside, two types of structures are used:

| Design | Description and purpose |

| Checkpoint | They are mounted directly into the pipeline itself, for which they have two special connecting pipes. Designed to isolate individual sections of the system. |

| Trial and drain | They are equipped with only one connection pipe and are usually installed on containers or reservoirs for the possibility of draining the liquid filling them. |

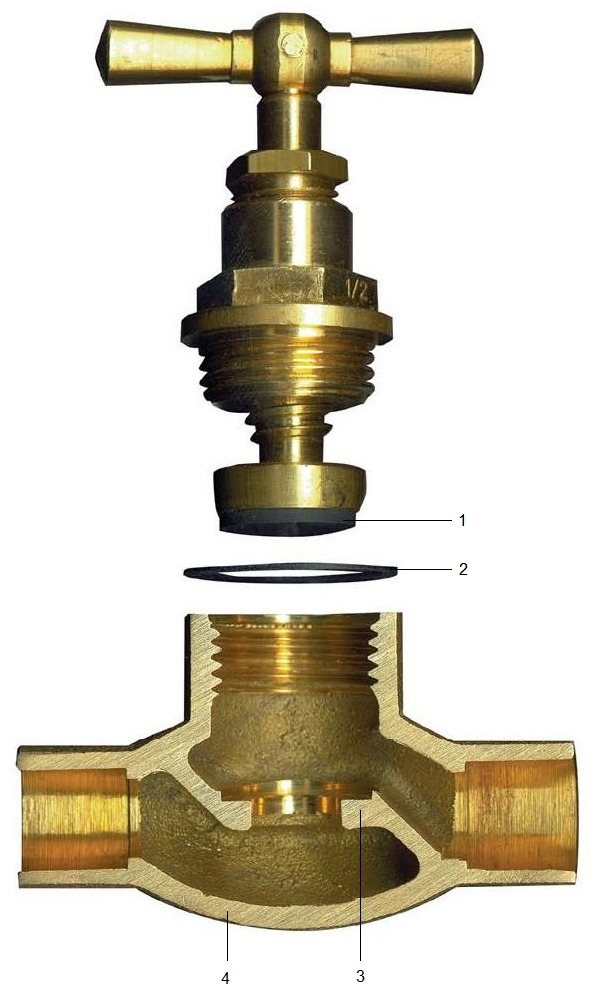

Tap 10b8bk1 for draining liquid

Domestic use

So, what is a ball valve with a drain used for in everyday life?

- Straight through design will allow to shut off a section of the pipeline during repair or installation work without the obligatory shutdown of the entire heating system.

- Trial and drain - will help to eliminate the formation of air pockets in the pipeline, which impede the uniform distribution of heat.

With this arrangement, the radiator can be completely insulated with your own hands.

Advice: brass valves for venting STD 7073V do their job perfectly, thanks to the ideal combination of price and quality. They are also called Mayevsky cranes.

Conventional valve for venting STD 7073V

It is also very convenient to use straight-through ball valves with an additional trigger mechanism. We will consider them further in more detail.

Easy-to-use ball valve with drain valve

Shut-off valves. Valves and sealing systems

In order to stop the water supply, various plumbing fixtures are used. A variety of rubber gaskets, spherical plugs and ceramic discs are also used in plumbing sealing systems. All these elements need regular care and prevention.

Water valve device. Shut-off valve. 1 - gasket; 2 - sealing washer; 3 - saddle; 4 - case.

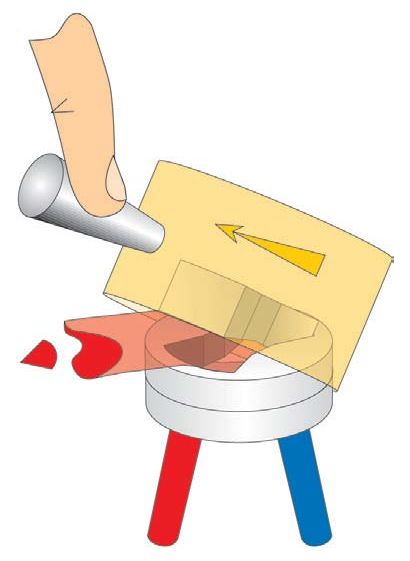

Valves and shut-off valves

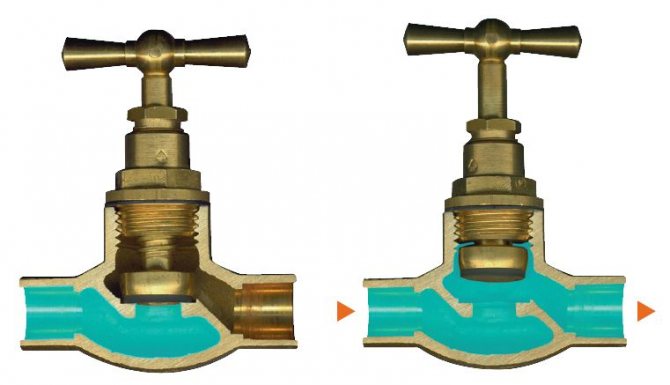

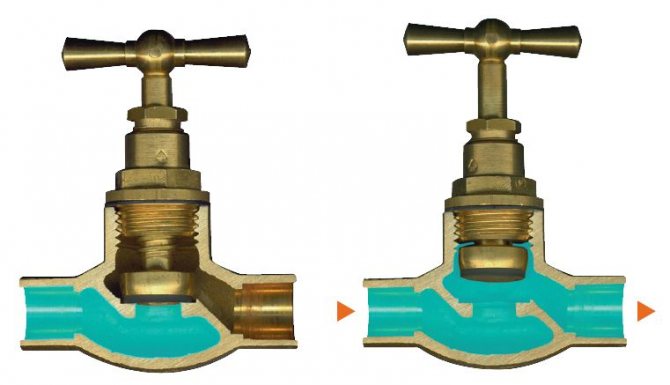

Valves and shut-off valves are the most common and inexpensive representatives of plumbing shut-off valves that are used in everyday life. They are quite durable, but parts of them can quickly deteriorate. An integral rubber pad rests on a flat part of the valve called the seat. As a rule, such gaskets are installed in brass distribution taps, as well as in cheap mixers. When installing a shut-off valve, you must observe the direction of movement of the water.

Closed tap (left), open tap (right)

Ball valves and valves

Taps and ball valves, or ball valves, are typically used in distribution plumbing systems. Compared to conventional faucets, ball valves are more efficient, more wear-resistant and less noisy.

A ball with a hole, made of stainless steel, is fixed between two gaskets. When the ball valve is closed, the ball blocks the flow of water. When the valve is opened, the ball lets water through the hole in it. A feature of ball valves is that they are not suitable for repair, if the valve fails, it must be replaced with a new one.

The tap valve is closed |

Ball valve open |

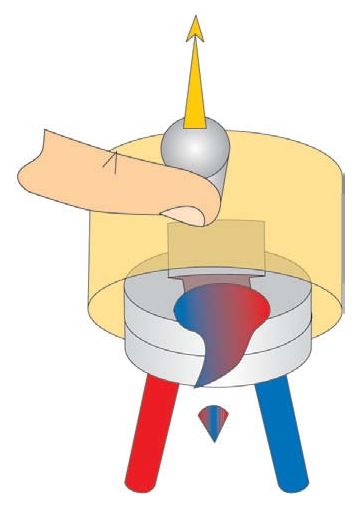

Ceramic discs for taps and mixers

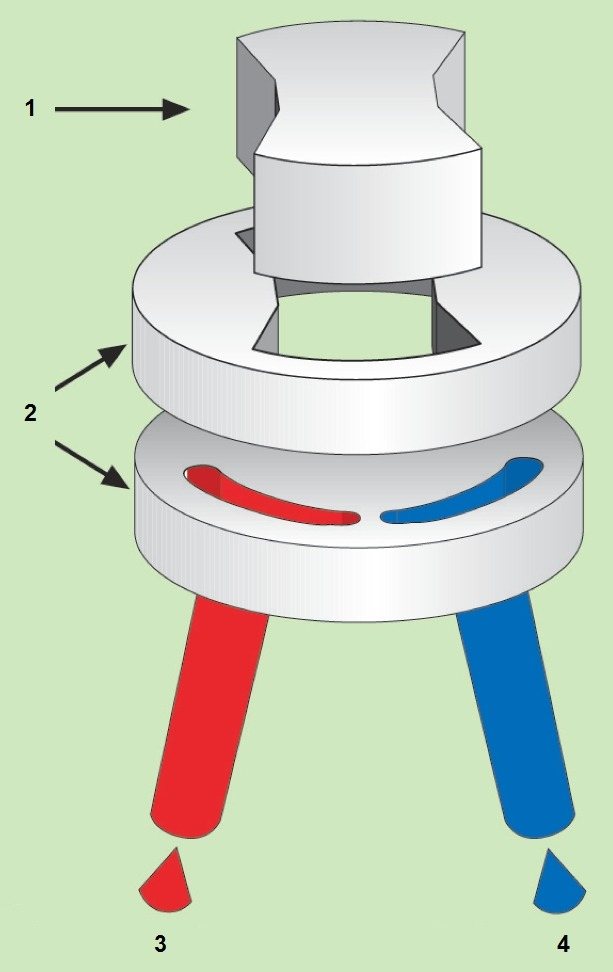

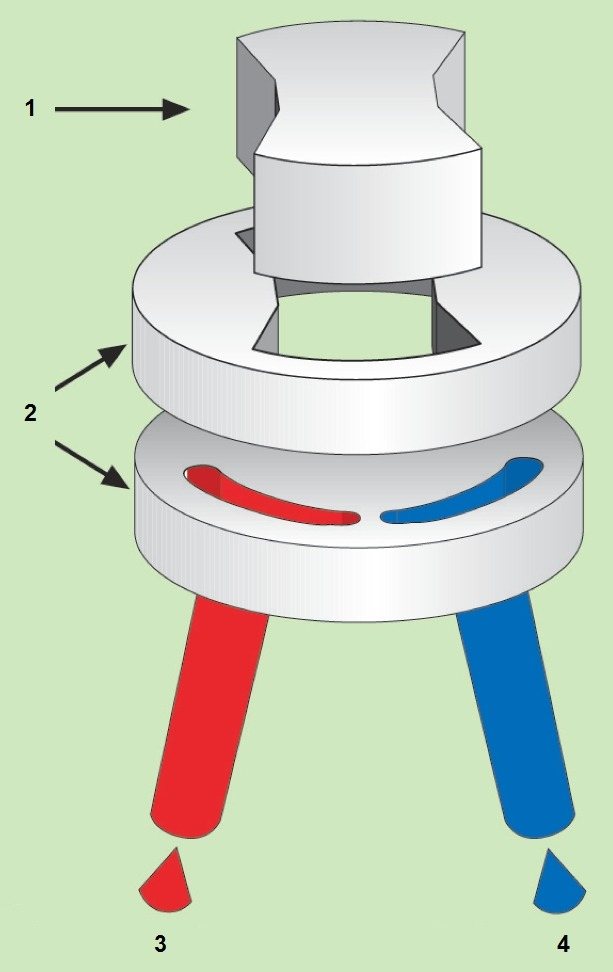

Ceramic discs for taps and mixers provide the ability to open, close and mix water. The ceramic disc system is used in high quality faucets. The use of ceramic discs makes it easier to open and close the faucet, allowing the water temperature to be regulated. Ceramic discs are more reliable and significantly less susceptible to limescale build-up.

Schematic diagram of the mixer with ceramic discs. 1. Water shut-off system; 2. Ceramic discs; 3. Hot water supply; 4. Cold water supply

Depending on the design of the system, the ceramic discs can be in direct contact with each other or in a special built-in cartridge. If necessary, the ceramic discs can be replaced with new ones.Care and maintenance of mixers with ceramic discs consists in replacing seals and lubricating rubbing parts. In this case, it is strictly forbidden to lubricate the ceramic discs themselves.

The principle of the mixer with ceramic discs.

Warm water supply | Water supply shut off |

Dispensing hot water |

Cold water supply |

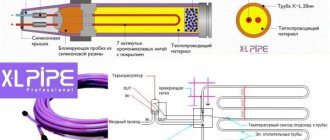

tap for draining water from the heating system

Shut-off systems play a significant mission in any pipeline. Previously, ordinary valves were installed everywhere, but now ball valves are of great preference. Ball valves for water have proven themselves at the highest level. These designs are of excellent quality and have the highest reliability and are used both in everyday life and in an industrial pipeline system. For example, in everyday life, such taps are installed when washing and dishwashers are connected to the water supply system. The work of such a crane is based on an iron ball. A ball valve is used to completely shut off or completely supply water. It is unrealistic to regulate the water flow with such a tap. The cranes have a variety of dimensions, which one is suitable for you depends on the size of the pipe. For problems and questions related to the tap for draining water from the heating system, you can get advice from the employees of our company by sending a letter by email, or in the feedback form on the site, as well as by dialing the phones indicated on the website. There are several types of ball valves. Coupling. Such a crane is usually small and small in size and is installed on a pipe with a diameter of no more than 45 mm. Flanged type. This ball valve is suitable for pipes with a diameter of more than 45mm. When installing it, additional gaskets are used to increase strength and tightness. If you are interested tap for draining water from the heating system, then write to us by email on the website, either in the feedback form or by calling the contact indicated on the website. Shtucherny. It is used in industrial sectors. Such a crane can be repeatedly dismantled and reinstalled. Welded. Installed by welding. Dismantling of such a crane is not possible. Blinker taps for water are very easy to use. They have good strength, tightness and are compact in size. the convenience of using ball valves is that when opening or closing, you do not need to turn the valve for a long time, but just turn the handle 90 degrees. The ball valve for water is highly resistant to corrosion, and can be easily dismantled if desired. But in order for the ball valve to really serve for a long time and reliably, choose it carefully. When choosing a water ball valve, ask the sales specialist for a quality certificate and annotation. Each crane must be labeled. There should be no cracks or sagging on its surface. Branded cranes have all walls of the same thickness.