Thermal insulation of walls with foam outside the house Thermal insulation of walls of a house from the outside is one of the important stages of construction work. Because most of the heat loss of any building, as a rule, occurs precisely through the walls of the building. Roughly, the numbers vary, ranging from 60-80%. As practice shows, excessive heat losses mean large expenditures on heating costs. Payment for heat, sometimes reaches 40% of the total amount of utility bills. Therefore, in order to somehow reduce the expense of the family budget, it is necessary to insulate the building. The most affordable and less expensive way is to insulate the walls of the house with foam outside with your own hands.

Thermal insulation of walls with foam outside - Advantages and disadvantages of the material

In order to determine whether it is possible to insulate a house with polystyrene foam, you need to thoroughly study the features of the material and this method. Polyfoam has, like other building materials, its own advantages and disadvantages. When deciding on the use, be sure to take this into account.

Cons of Styrofoam

Decorating the walls outside the house with polystyrene foam suggests the following disadvantages:

- The foam is poorly air-permeable. The material prevents the removal of wet steam from the room. This property, as a rule, leads to a violation of the proper microclimate in the room. An effective solution to the problem is a forced, exhaust ventilation device.

- A facade, waterproofing finish is required. Thermal insulation of walls with foam outside, without the use of facade decoration, is at least not practical. Of course, the styrene balls themselves do not absorb moisture. Their water permeability is very low. But between them, water is easily stored. In winter, during severe frosts, this moisture expands and leads to the complete destruction of the material. Facade waterproofing, however, will help to effectively solve the problem and avoid such incidents.

- Rather low mechanical strength. Using this building material, in the construction of the walls of a capital structure, such a quality of the product is not critical. For example, while laying the floor in a pie. But all the same, you need to take into account such a minus. If, for finishing the facade of the building, plaster is used, then it is recommended to strengthen the surface with a reinforcing mesh. If, however, it is planned to use foam for siding, then the material will come in handy, only as a component of a ventilated facade.

Insulation of walls with foam outside

Pros of Styrofoam

There are also quite a few significant advantages of this material. When constructing, insulation of the walls of a building with foam plastic with your own hands, it is important to know and use correctly, all the advantages of the product. Based on the positive qualities of polystyrene, it is possible to correctly determine whether to use the method in question for insulating external walls in private buildings.

Polyfoam has a number of positive advantages - these are:

- Relatively low cost;

- quite easy to install;

- relatively low weight of the product;

- small transportation costs;

- fairly high thermal insulation qualities;

- relatively high safety.

It is important to understand that foam is not resistant to fire. Therefore, when purchasing a product, you should pay special attention to its labeling. As a rule, a heat material has several degrees of fire resistance: from G1 to G4. The lower the number in the marking, the more fireproof. For complete confidence, when choosing a product, you can always consult the seller.

The use of polystyrene foam for insulating a wooden building is not recommended.Such a ban is caused due to fire safety considerations, and of course, due to the characteristics of the material. Wood breathes well, therefore, many homeowners prefer this building material for the walls of the building. Wall decoration with foam, for a capital structure made of wood, at the slightest violation of technology, can cause mold and mildew. This means that it will contribute to the progression of decay of the building as a whole.

For wooden buildings, it is wiser to use mineral wool as insulation. Warm product, vapor permeable enough. It will not be an obstacle for the ventilation of the building.

What is Styrofoam?

We insulate a private house with foam

First of all, I would like to draw your attention to the fact that foam is a material in which there is no vapor permeability; it is strictly forbidden to use it for cladding a room from the inside.

The density of the foam is also very important. The most suitable density option should be about 25. If you decide to insulate the walls with a less dense material, there will be a possibility of surface injury, and too dense material will lead to unjustified financial waste, because excessive density will not affect the thermal insulation characteristics in any way.

The third, no less important point is the thickness of the foam, on which the quality of surface insulation directly depends. It is best to use penoplex with a thickness of 50mm, but you can purchase thicker material, no one forbids you, and a thickness of 100mm also has a right to exist. By using thicker foam, be prepared to see a higher price point. In order to avoid rash and unnecessary financial investments, you can attract experienced craftsmen who will carry out the correct calculations and select the best option specifically for your climatic zone. When calculating, they will take into account the following indicators:

- average temperatures;

- the thickness of the walls that you plan to sheathe;

- the material from which those walls are made and much more.

Comparative characteristics of conventional foam with extruded are shown in the table below.

| Styrofoam characteristic | Styrofoam | Extruded Styrofoam |

| Water absorption in 1 month | 4% | 0,4% |

| Water absorption in 1 day | 2% | 0,2% |

| Vapor permeability | — | 0.018 mg / m.h. Pa |

| Thermal conductivity | 0.036-0.05 W / (m * C) | 0.028 W / (m * S) |

| Tensile strength | 0.07-0.2 kgf / m2MPa | 0.4-1 kgf / m2MPa |

| Compressive strength | 0.05-0.2 Mpa | 0.25-0.5 Mpa |

| Density | 15-35 kg / m3 | 28-45 kg / m3 |

| Working temperatures | -50о + 70оС | -50о + 75оС |

As can be seen from the table, it is more appropriate to insulate the house with extruded foam, the technical features of which are superior in many respects to ordinary foam sheets.

Thermal insulation of walls with foam outside - Preparation of materials

High-quality insulation of walls outside with foam, it is recommended to start with the preparation of construction tools and consumables. For construction actions, regardless of the finish (siding or plaster), the following should be prepared:

- Styrofoam - sheets or plates;

- to create a support, starting (bottom) heat-insulating profile;

- construction glue for fixing the material;

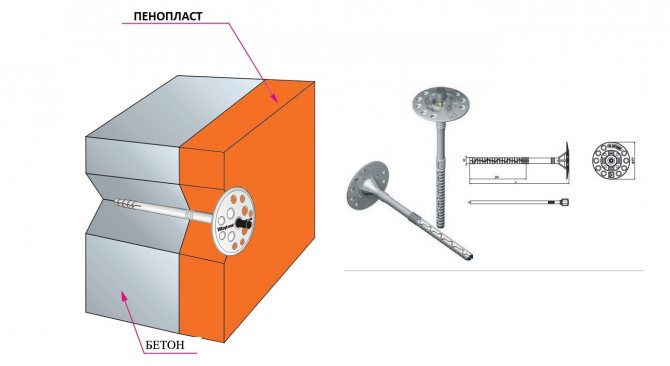

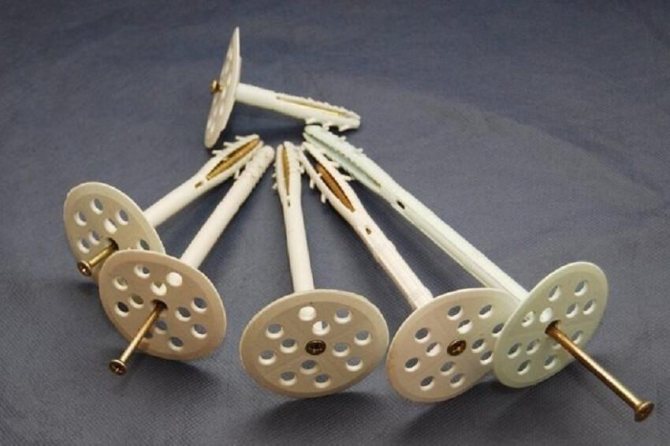

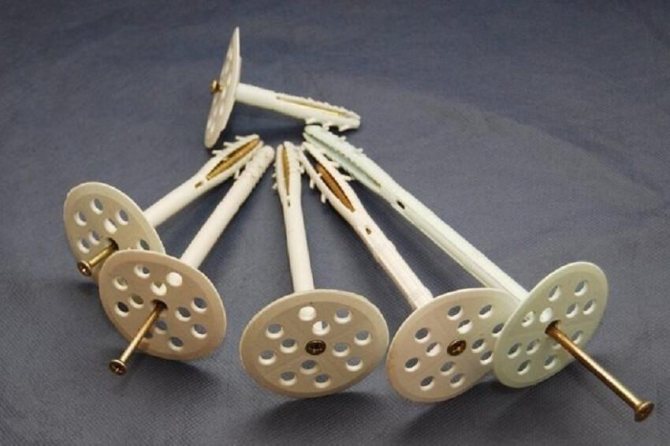

- disc or umbrella dowels.

Glue, for proper fixation of the foam, must be selected carefully. If you choose the wrong one, then defects will quickly appear on the surface of the product, which will significantly reduce the thermal characteristics of the material. The insulation needs to be attached to glue, which does not contain any solvent additives at all. Usually, on the packaging of the adhesive, there are explanations that say that the glue is well suited for such a warm product.

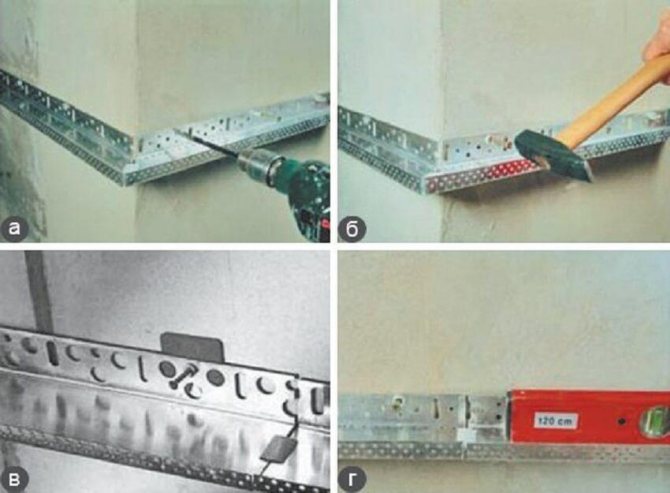

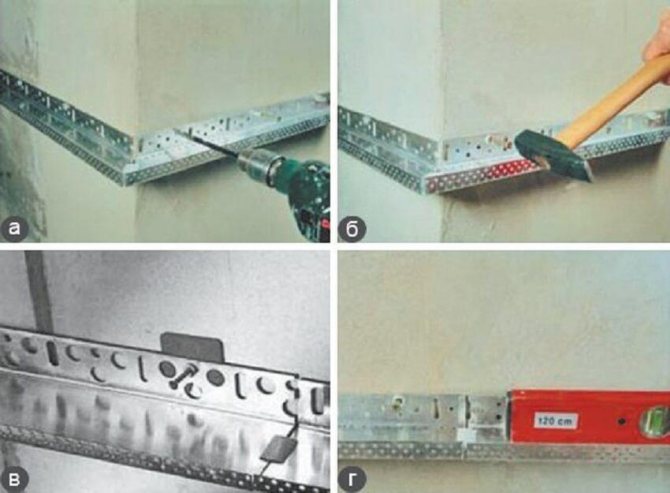

Installation of the starter profile

The length of the fasteners is selected based on the thickness of the heat product and the material of the walls. As a rule, the fixing of the dowel should be at least 50 mm. If, concrete base, then a minimum value of 40 mm is permissible. For brick walls, dowel fixings are recommended, 70 mm more than the thickness of the foam layer.

Fungus dowel, for fixing foam

Self-tapping screws and similar elements for finishing with foam plastic for siding or plaster are not advisable to use. Such latches provide a rather low grip reliability. In addition, they can cause serious damage to walls, capital structures.

What you need to work

Before proceeding with the installation of foam, the necessary materials and tools are purchased and prepared.

Materials:

- Styrofoam;

- Adhesive composition suitable for the material;

- Polyurethane foam;

- Dowels;

- Primer and plaster;

- Construction mesh for reinforcement;

- Starting bar.

Instruments:

- Drill (good if there is a mixer attachment);

- Notched trowel for applying adhesive;

- Conventional spatulas;

- Construction knife;

- Container for diluting glue;

- Roulette;

- Level;

- Drill;

- Graters with teeth of various sizes.

It is important to purchase the "correct" foam for wall insulation. For this, its density should be about 25 kg per cubic meter. The thickness of the slabs must be at least 8 cm, most often 10 is used.

Sometimes the building is sheathed with foam, 5 cm thick in 2 layers, making the seams offset between themselves for greater heat conservation.

You can fix the foam with glue or dowels. But as practice shows, both are better. The glued sheets are fixed with nails in several places for greater strength.

If desired, a starting strip-profile is installed at the bottom of the wall, which serves to secure the position of the sheets and does not allow them to slip during installation. It also prevents rodents from spoiling the foam, so if there is a problem of visiting uninvited guests, then it is better to use it.

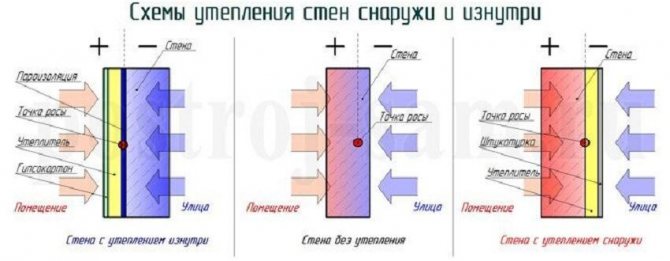

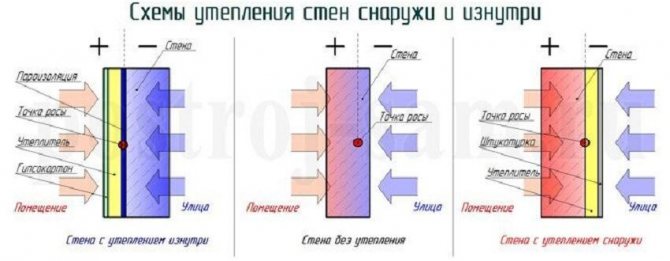

Why is the heat insulator placed outside

The technology of wall insulation with foam plastic from the outside, from the point of view of construction heat engineering, is considered correct. The number and order of layers, as a rule, does not depend on the type of finish (siding, plaster or panel). Thermal insulation from the street side is the most correct and practical solution. This is due to at least three reasons:

- The useful area of the building remains unchanged;

- Such thermal insulation protects not only the inner space of the house, but also the surface of the outer walls;

- Condensation (dew point) does not get inside the wall, but remains in the insulation.

Foam insulation outside and inside

The reasons for the insulation of the building from the inside can only be quite good reasons. For example, these can be:

- High building height. A similar problem suggests, for outdoor work, to attract industrial climbers. And this, as you know, is a rather expensive pleasure.

- Desire to preserve the existing facade of the building. The reasons are different, but the main, relatively common, are two. The first is if the exterior finish is recent. And the second, if the thermal insulation work is carried out only in one apartment, and there is no possibility or desire to do heat repairs in the entire multi-storey residential building.

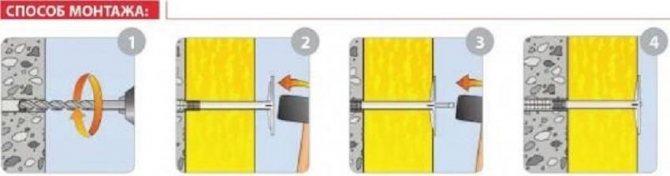

Additional fixation of foam

After the walls of the house have already been insulated, it is recommended to further strengthen the fixation of the material. For these purposes, a perforator and special fastening accessories are used - anchors with wide plastic caps, inside which a metal hairpin is driven.

When choosing the size of the fittings, you need to know that for high-quality fixation, the anchor is recommended to be recessed into the wall by 40 mm.If the thickness of the foam is 40 mm, the thickness of the adhesive layer is 10 mm, the length of the anchor should be 90 mm.

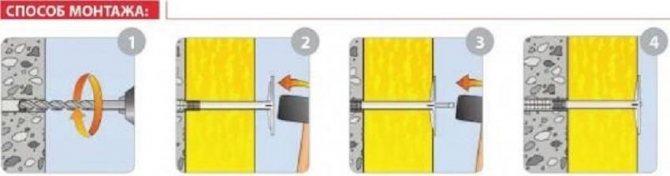

Step 1. It is desirable to fix the foam sheet with 4-5 anchors. For these purposes, holes are drilled in the insulation and the wall. The length and width of the drill must be equal to the dimensions of the fastening hardware.

Preparing the foam for the installation of the umbrella dowel

Step 2. After drilling, plastic fittings are inserted into the holes. The caps of the anchors need to be slightly sunk into the polystyrene in order to later hide them with a layer of plaster.

We fix the dowel

Step 3. Metal studs are inserted inside the plastic anchors and hammered with force until they stop.

Step 4. In this way, all sheets of foam glued to the walls are fixed.

Styrofoam plates

How to insulate walls outside the house with polystyrene - Plaster, as a facade finish

It is possible to independently insulate the walls of the house with foam plastic from the outside, using the technology that is known to many as the "wet facade". Top-beige, plaster, as a finishing of the facade of the building. It is worth noting immediately that with proper installation work, such a design option will become an acceptable protection from cold air, for any building and will serve in good faith for more than a decade.

Plaster, as a finishing of the facade of a building, is a fairly well-known and effective solution, which allows not only to minimize the costs for the improvement of the appearance of a capital structure, but also helps to qualitatively hide the external insulation of the walls from the negative effects of the environment. It is applied, as a rule, directly to the heat insulator itself. At the same time, construction work is carried out in the following order:

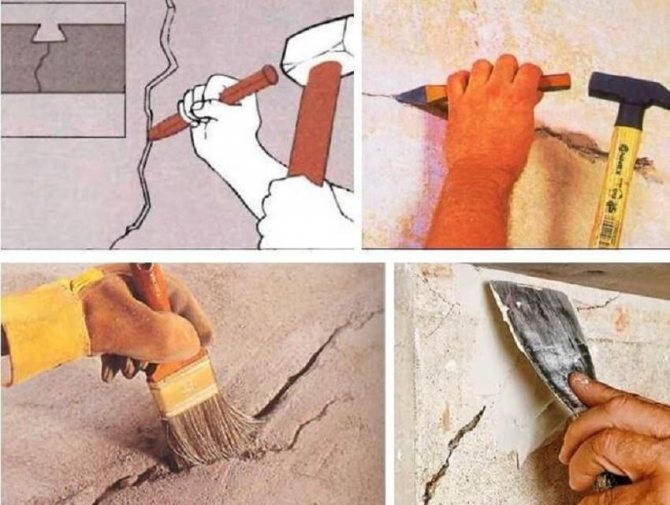

Cleaning the walls of the building, from dirt and dust

Cleaning the wall from debris

High-quality cleaning of the walls of the building, from various dirt and dust, although not difficult, but very responsible occupation. It is required to thoroughly, thoroughly remove, various debris deposits. Since then, putty will be applied. The durability of the entire thermal insulation structure depends on the quality of fixation, of this building material, no matter how banal it may seem.

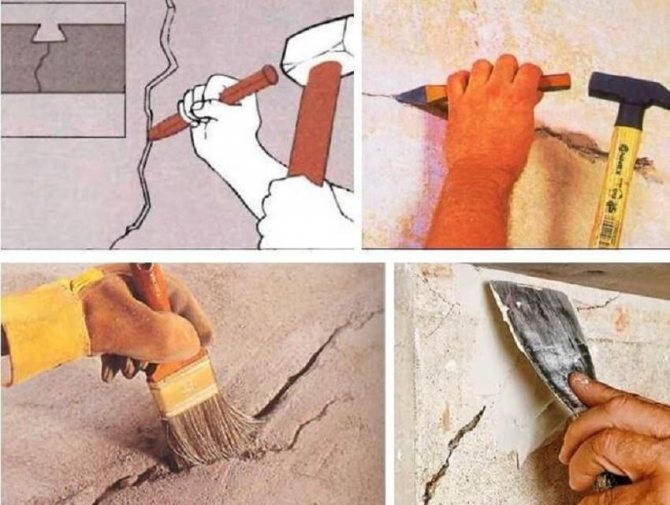

Puttying the surface

One of the equally important measures, which will further affect the durability of the thermal insulation structure, is surface filling. Or, in simple terms, the proper leveling of the surface. It must be understood that the fewer defects in the base, the lower the likelihood of rapid destruction of the heat-insulating layer. The work, I must say, although not very difficult, is quite laborious. The whole process of actions is shown in the picture below. It will not be superfluous, after the completion of the work, to check the evenness of the walls. The most affordable option, to correctly assess the plane of the walls of the building, is to use the building level.

Putty and crack filling

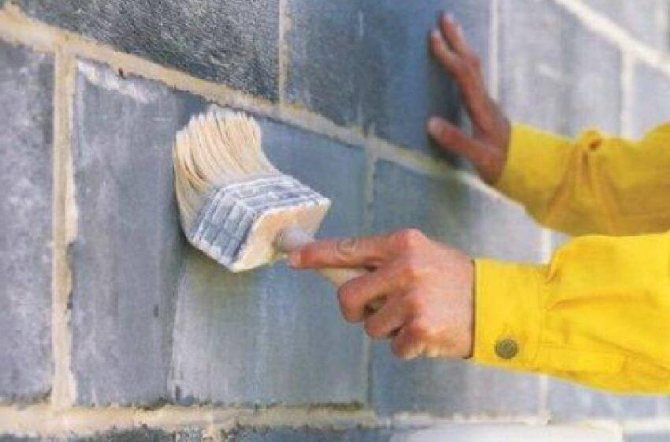

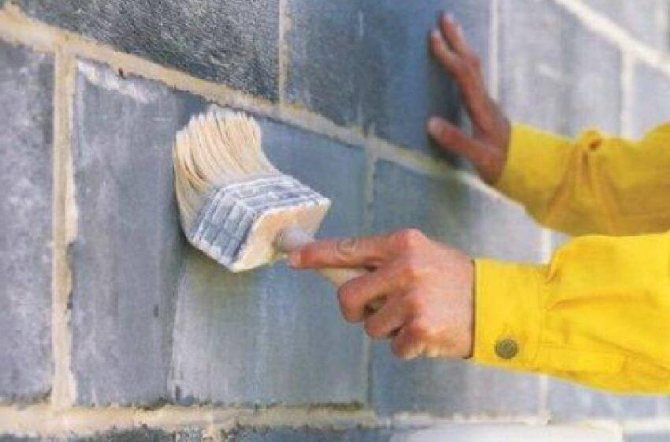

Surface priming

To ensure reliable, high-quality adhesion of building materials, it is required to prime the surface. In addition, the priming provides the coating with good antiseptic properties. To-bezh, provides proper protection to building materials from mold, fungus and other, no less harmful, microorganisms. Therefore, when choosing a primer, you need to pay special attention to the composition and antiseptic properties of the product.

Wall priming

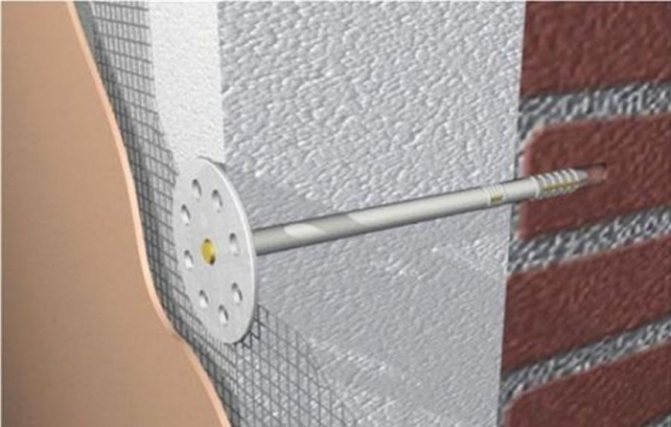

Fastening the foam

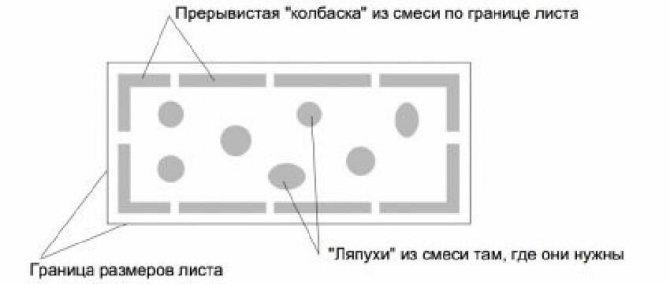

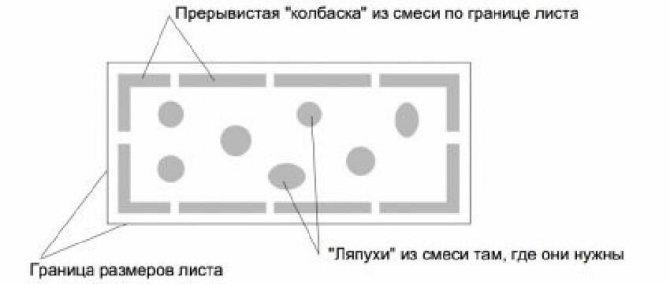

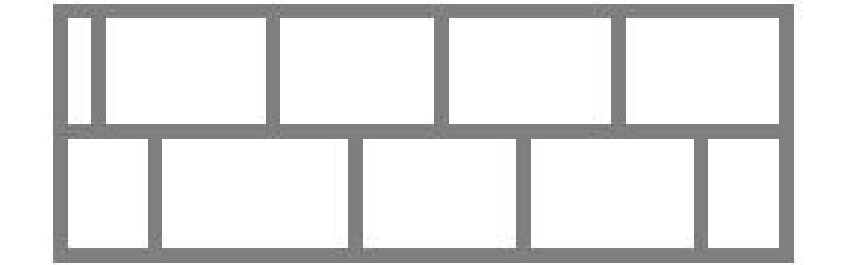

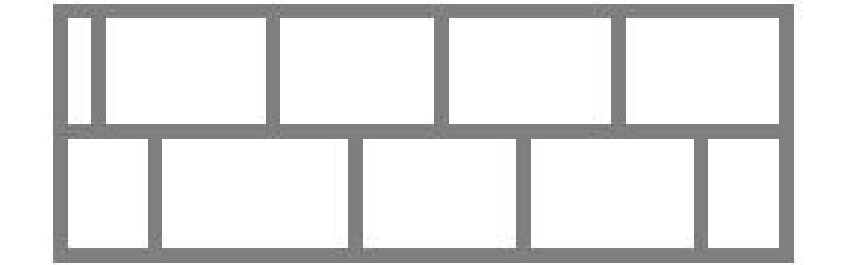

When used for exterior wall decoration, plaster, polystyrene sheets, it is necessary to fasten with a continuous layer, without a frame, having previously greased with glue. At the same time, vertical joints of the seams are recommended to be staggered. To-beige, each subsequent row, relative to the previous one, needs to be shifted by about half the width of the product sheet.

Glue application scheme

Styrofoam sheet stacking scheme

After completing the installation steps, the adhesive must be allowed to dry.The wait can last, depending on weather conditions, 2-3 days.

Fixing foam with dowels

After the adhesive has gained the proper strength, it is additionally carried out, fixing the foam with dowels. The process of fixing the insulation with dowels is well shown in the figure below.

Fastening the foam with dowels to the wall

Sealing joints with polyurethane foam

And at the end of the thermal insulation work, the joints are sealed with polyurethane foam. After the foam has hardened, the excess material is carefully cut off and cleaned with a float.

Foaming gaps between sheets

Plastering works

After the surface has been properly processed and prepared, plastering works are performed in compliance with the technology and using a reinforcing mesh. The action, I must say, is not an easy one, rather painstaking and laborious. Certain professional skills are required. Otherwise, the quality of plastering work will be poor.

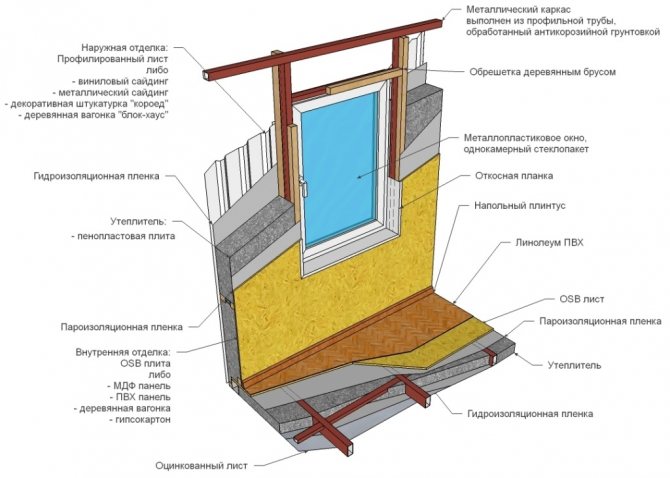

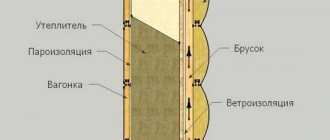

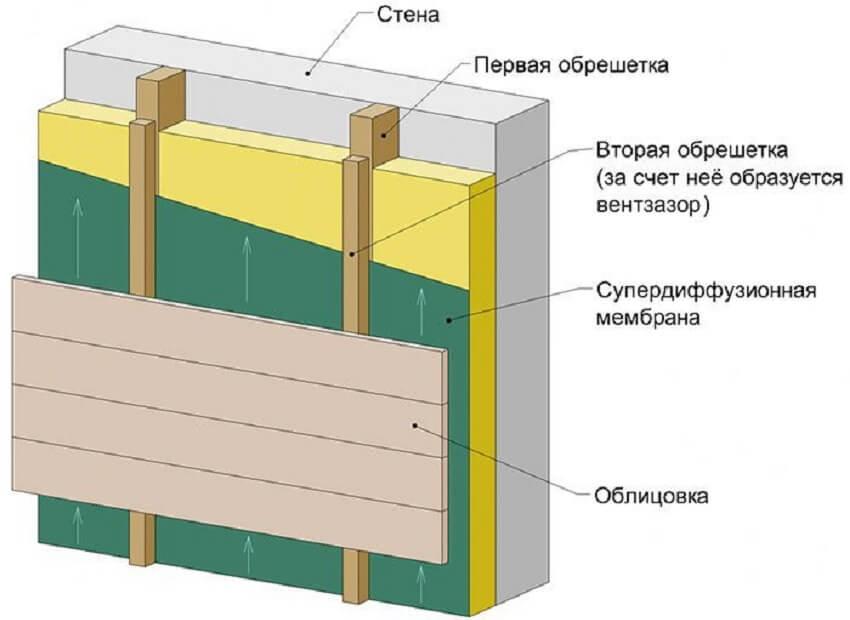

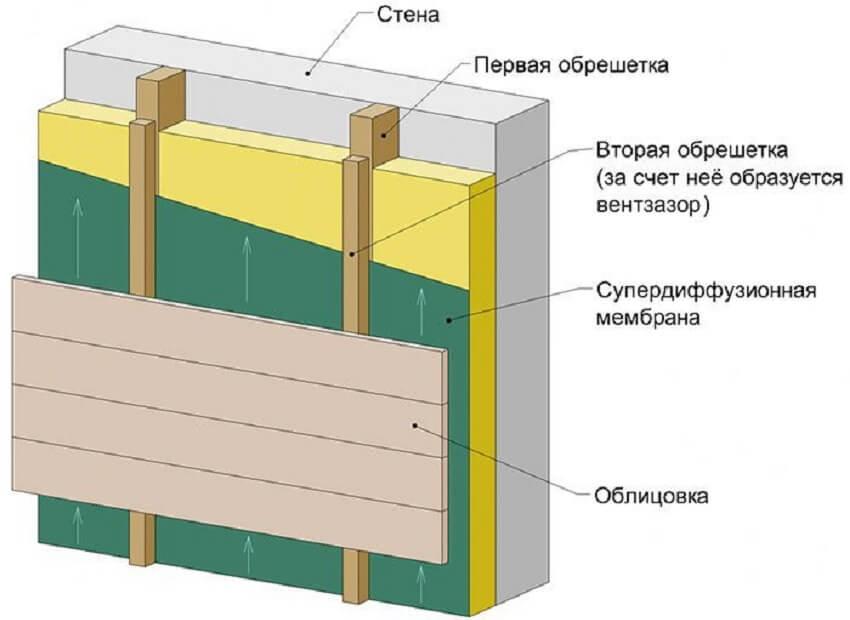

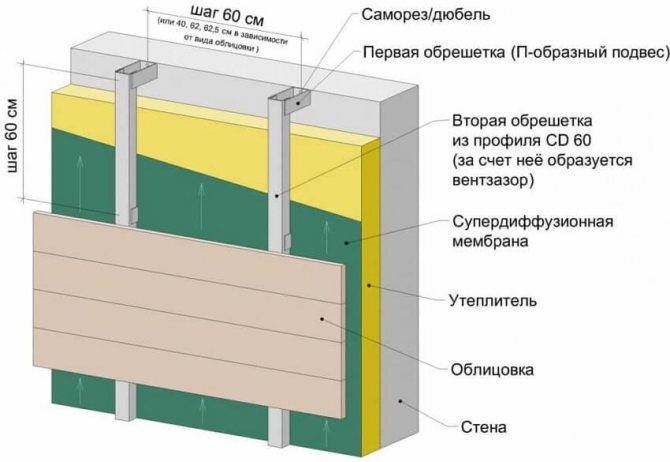

Layer diagram of the correct insulation

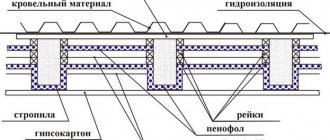

Insulation of a wooden house

Having examined the photo of the foam for cladding, you will understand that after the insulation work, it will be necessary to protect the walls and make them more aesthetically attractive. In the case of wooden houses, the technology for installing penoplex looks somewhat different. The technique involves the use of a frame structure. Installation is carried out between the elements of the crate. You can use glue as a fastener, but sometimes craftsmen get by with ordinary dowels.

The surface must be prepared by sealing the cracks and covering the material with protective substances. Next, a vapor barrier and frame elements are installed. The insulation is laid on the glue, in addition, after it dries, you can fix it on the dowels.

At the final stage, the second layer of waterproofing should be laid, only after that you can do the front finishing. Sheathing a wooden house with foam requires the installation of a frame for the reason that the described thermal insulation has poor vapor and moisture permeability. As a result, air does not enter the room.

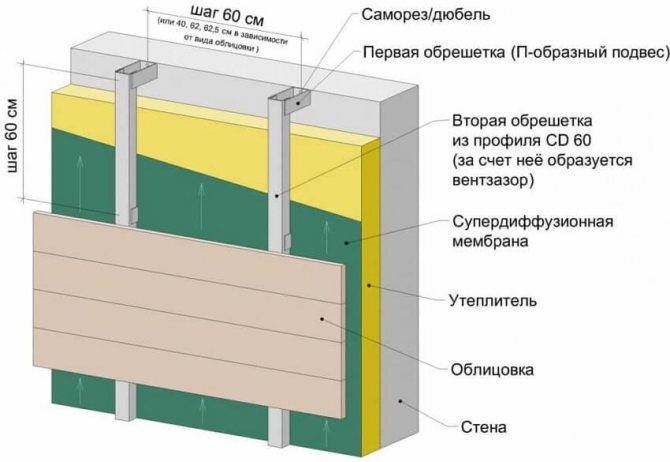

How to insulate the outside with foam plastic walls for siding - Step by step

If you plan to use siding as a finishing material, it is not very difficult to insulate the outside with foam plastic. In many ways, construction work is the same as the previous version. However, there are significant differences - it is required to provide a base for attaching the siding. Unlike the same mineral wool, the insulation of the walls of the house with foam outside does not require the mandatory arrangement of a ventilation layer. Nevertheless, it is more expedient all the same, to equip a ventilation layer. This approach will significantly and significantly increase the service life of the heat insulator.

Fastening siding through a wooden lathing

Fastening siding through a metal frame

To know and understand how to properly insulate a house with foam for siding, you need to study and perform the following order of construction work:

- High-quality surface cleaning;

- Proper alignment of the walls;

- High-quality application of the primer;

- Fastening brackets, for arranging frame racks, for siding;

- Foam bonding;

- Fixing with dowels;

- Laying a layer of waterproofing;

- Installation of frame racks;

- Fastening the siding.

Fixing with dowels, as in the previous case, is performed after 3 days of drying. In the general case, the fixing technique does not differ from the previously considered case.

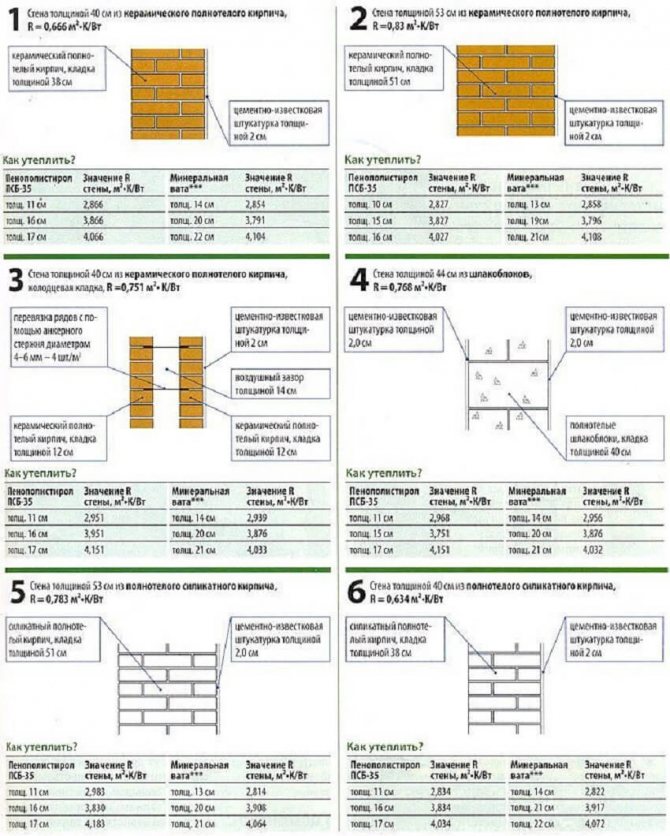

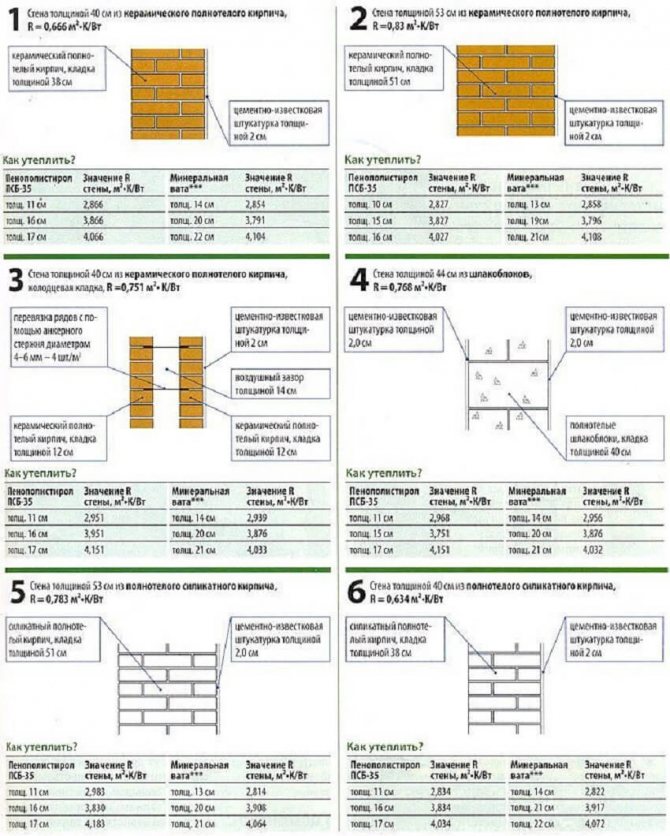

Wall insulation thickness

The proper thickness of the wall insulation is determined by the heat engineering calculation. For a private building, you can choose the thickness approximately. As a rule, it is equal to 100 mm. Determining the exact value depends on:

- Climatic features of the construction site;

- building material walls;

- the thickness of the wall structure;

- the purpose of the building - residential, economic or industrial, for each, special, its own requirements.

Foam thickness - table

For more accurate calculations, you can apply the Teremok program. It is not difficult and in Runet, freely available. For proper calculation, you will need to determine the composition of the wall. Its thickness and thermal conductivity of the building material. After the results are obtained, the specified value is rounded up.

P.S. Before you professionally insulate a house with foam with your own hands, you need to choose the right building material and carefully study, fully master, all the technology for performing construction work. It doesn't matter what is used for exterior decoration, siding or "wet facade", you just need to strictly observe the order of all layers, and most importantly, fix them reliably and with high quality. With proper thermal insulation, buildings, walls and decoration, and the structure as a whole, will last for many decades. And with proper, timely care, and several centuries.

SHARE ON SOCIAL NETWORKS

Features of the choice of material

Before sheathing the house with foam, you need to select the material. It is better to choose a canvas marked C-25, the density of which is mentioned in the title. Many consumers are wondering what it affects. The lower this indicator, the better the thermal insulation properties will be. For confirmation, it is enough to recall the school physics course, which talks about air - the best heat insulator.

Insulation with the mentioned density has closed cells filled with oxygen, which will prevent convection and reflect infrared radiation. But this belief should not be applied to foam with a density of 15 kg / m3. This also applies to mineral wool. These heaters are less dense, but they are not able to provide sufficient rigidity. It will be difficult to plaster the insulated facade without damaging the thermal insulation layer, and in the future it will be easy to wash the walls.

Photos of insulated facades

We invite you to take a look at twenty photos related to our today's topic.

Foreword... The characteristics of polystyrene foam (extruded polystyrene foam) have determined its popularity when carrying out insulation. In the article we will consider the material itself and its advantages, and also consider the issue of its application. In particular, how to insulate a house with penoplex from the outside with your own hands - installation methods, finishing insulation and we will show a video lesson at the end of the material.

What materials will be required

Let's start with the basic materials necessary for the purpose of insulating a house and a summer residence, regardless of the area of the building. Initially, of course, you will need the penoplex itself, then when purchasing the finishing material, along with it you need to buy glue-foam, which will hold your structure.

Brackets with metal profiles or even wooden slats cannot be bypassed, so don't forget about them. You need low steam permeability, in which case we purchase a film vapor barrier... Basically, houses are insulated from wood, and if you have such a case, then you need a protective impregnation under a tree.

The main characteristics of the foam

Most often, external insulation is carried out using sheet polystyrene, which for these purposes is recommended to be taken with a width of more than 10 cm.For those who know what kind of foam to insulate a house outside, it is worth understanding its types and features.

There are two types of foam:

- one is fragile even with little exposure;

- the second demonstrates high resistance to pressure and at the same time has a fairly light weight.

It is the second type of foam that is used for the most effective thermal insulation..

Note! Many, trying to save money, still use the first type of this material. However, this is a false economy, since the material does not differ in durability, and soon it will not be able to cope with the heat-insulating functions put on it.

There is an opinion that foam as an artificial material may be unsafe for human health. However, this is not the case, foam plastic has many positive properties, moreover, it is practically impossible to find a natural analogue, therefore, it is foam plastic that is used.

Styrofoam of different sizes

Foam plastic has a number of advantages:

- it does not rot at high humidity;

- easily mounted on the walls of the room to be insulated;

- besides, its price is very reasonable.