Types of roof boiler rooms

The most acceptable option for placing such a boiler room is considered to be a flat roof structure. For these sources of heat supply, installations are provided: built-in and block-modular boiler room (BMK).

BMK

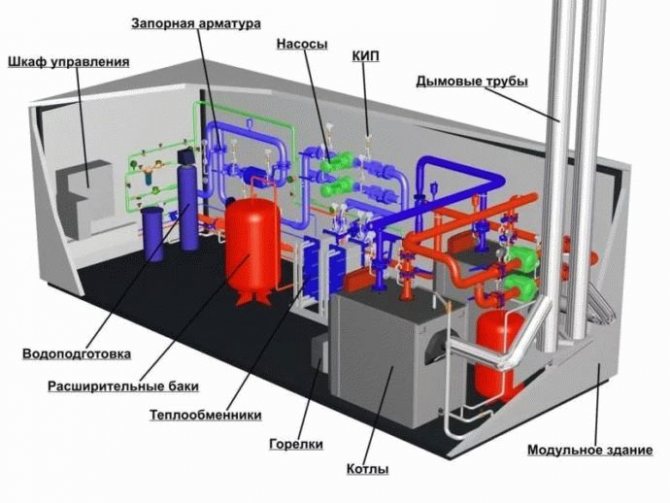

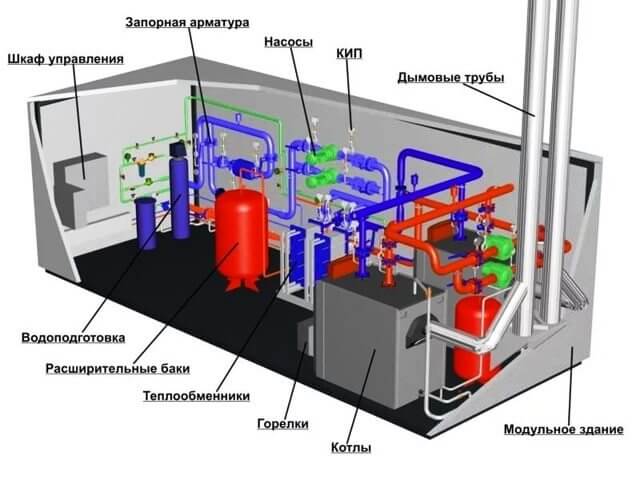

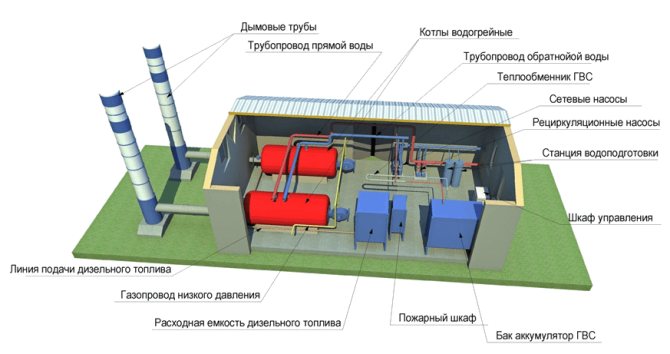

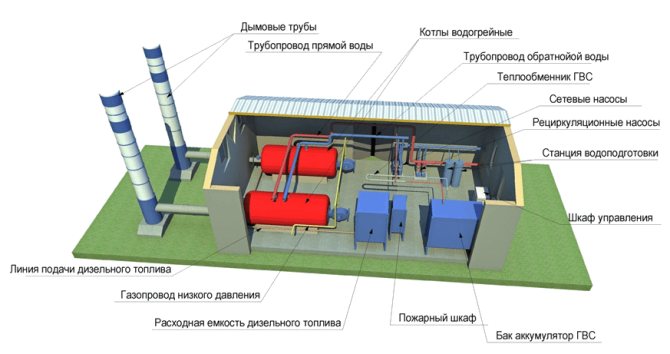

Block-modular gas-fired boiler houses are supplied in full factory complete set. They arrive to the customer essentially with 100% readiness, therefore they are launched as soon as possible. Modern roof-top boiler houses operate throughout the year in automatic mode for heating and hot water supply and do not need permanent operational personnel.

All boiler equipment is selected for the design technological parameters and complies with the current legislation in terms of ensuring safe operation. The block includes boilers taking into account the peak power, pumps for heating and hot water supply, fans and smoke exhausters, chimneys, primary devices for controlling thermal processes and an automatic control system. BMK is equipped with high-quality insulation and reliable supply and exhaust ventilation.

Built-in

The built-in roof-top boiler room in an apartment building is built according to an individual project, in which each element of the thermal circuit is carefully calculated in order to create a safe and efficiently functioning heating system.

The boiler room is most often made of prefabricated sandwich structures or standard reinforced concrete products. The assembly of the heating scheme of the boiler house is carried out on site, using precisely selected equipment, developed schemes of the built-in boiler house, in accordance with the design specifications for equipment and materials.

Completion is carried out by the customer of the object or, under a separate agreement, with the installation company. The scheme of a roof boiler room in an apartment building of built-in type includes gas boilers taking into account a reserve, pumping equipment, a smoke exhaust and ventilation system, chemical water treatment and instrumentation.

Usually, such boiler houses are installed within a few days, then the process of setting up the boiler equipment and the final stage of accepting the boiler house into operation begins.

Norms and requirements for operation

There are requirements for the design and installation of roof-top boiler houses, but they are minimal. All of them are based on ensuring safety during the operation of the structure.

In particular, the following should be done regularly:

- It is necessary to constantly check the supply and exhaust valves, due to which the boiler room is ventilated.

- At the design stage, it is necessary to provide for the installation of sensors that detect any fires, gas leaks and other emergency situations. In addition, a gas-insulating flange must be installed that can shut off the entire system in the event of a fire.

- The roof of a multi-storey building should be equipped with an alarm, which will immediately begin to notify others with sound and light signals about a fire in the boiler room.

- The boiler room should be equipped with windows and doors leading directly to the roof. You also need a dedicated fire lift and a service exit. The lighting of the boiler room must comply with the standards.

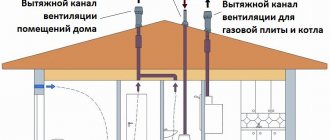

- A separate chimney must be designed for each gas boiler, and they must all be of the same height. The distance between the pipes can be any.

To ensure more stable and safe operation of the boilers on the roof, a separate branch of electricity should be connected to them.This will allow to neutralize possible voltage surges around the house, which can lead to the failure of the entire heating system.

It is also desirable to provide an alternative power supply option, in particular, to purchase a diesel generator.

According to safety regulations, the chimney pipe must be at least 2 meters higher than the height of the roof of the boiler room itself.

It is forbidden to install a gas boiler room directly above residential apartments. Between them and the roof, you need to make a technical floor in order to comply with the mandatory list of conditions regarding boiler rooms. Gas units can only be placed on a floor made of reinforced concrete slabs.

Remember that the boiler room is quite noisy, so it is important to soundproof it.

Once the boiler room is designed and installed, it is necessary to organize periodic maintenance. It is enough to hire one or two people for this. Gas service workers will also periodically come with inspections to monitor the condition of the equipment being operated.

Advantages and disadvantages

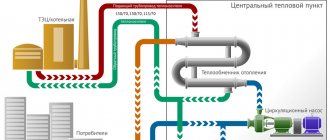

The main advantage of a rooftop gas boiler house is its autonomy, as a result of which heating and hot water supply is supplied directly to the house on which it is installed. This helps to reduce heat losses, in connection with which the cost of a unit of heat energy KKg is significantly reduced to a minimum indicator.

At the request of the customer, it is possible to conclude an agreement with the operating organization, which simultaneously serves several similar objects.

The beginning and end of the heating season begins as needed, and not by the decision of the municipal authorities. A high level of operational safety is guaranteed by modern thermal management systems.

Roof-top boiler houses have a number of negative qualities:

- Installation restrictions, such equipment can be installed in a house no higher than 9 floors.

- Increased vibration due to the operation of circulating pumps, smoke exhausters and fans.

- High price for the production of the project, the purchase of equipment and installation and construction work. Depending on the capacity and completeness, the approximate investment in such a heat supply scheme will be 5-18 million rubles.

Some features of the device of autonomous boiler rooms

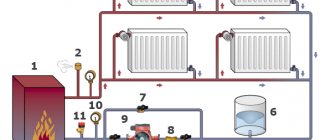

In order to comply with safety requirements, no more than two boilers are placed inside the boiler rooms - one is the main one, the other is backup. Installation is carried out in the central part of the room, then the least problems arise with maintenance and repair.

For wall cladding, be sure to use materials that do not support combustion. An example of a great option is steel sheets. The floors are poured with a concrete screed, the non-combustible coating is laid from above. The main requirement is a non-slip coating.

Natural gas is the composition that is processed during the operation of autonomous boilers. Units with automatic operation contribute to a smooth flow. If a leak or breakdown is detected, special sensors simply block the operation of the system.

For developers, one of the most profitable options will be the acquisition of block autonomous boiler houses. Delivery and installation of such installations takes a minimum amount of time. The equipment also differs at an acceptable level of prices. In the future, such a purchase will help protect against the shortcomings of centralized systems.

An analysis of typical mistakes in the installation of boiler rooms can be found in this video:

See also Phones for consultation 13 Dec 2020 Victoria M. 216

Share the entry

Discussion: there is 1 comment

- Ivan says:

21.12.2019 at 18:23Such a boiler room certainly provides significant savings. District heating is now very expensive.Do the manufacturers of such self-contained boilers give guarantees that the boiler will work without interruptions in a house with a large number of floors?

Reply

House requirements

It is allowed to install such boiler rooms on the ceilings of buildings, except for buildings for explosion and fire hazard with categories A and B. Their placement directly on the ceiling is not allowed. The maximum permissible thermal power KKg for houses is 3.0 MW and for industrial facilities - 5.0 MW.

There are several prohibitions when installing rooftop heat sources:

- The height of the boiler room together with the object cannot exceed 26.5 m, which is equal to a 9-storey typical house.

- The dimensions of the combustion room should not be larger than the plan of the house.

- It is not allowed to increase the width of the walls, and to carry out retrofitting of the roof to reduce the load on the basic supporting structures.

Installation of heating equipment is carried out only after the project has been appraised.

Roof requirements for installation

When building this type of boiler room, it is necessary to provide for an exit directly to the roof. The exit to the boiler room from the entrance of the house must be carried out along a marching staircase. With a slope angle of more than 10% on the roof of the house, they equip navigation bridges of 1 m in size, with a railing height of at least 0.9 m.

The constructions of ladders and handrails should be foreseen from fire-resistant building materials. The total load of the boiler equipment should not exceed the calculation of the loads on the roof.

The position of the boiler building should be built taking into account the wind loads in the climatic zone of the location and take into account the specific stresses laid down in the design of the house.

Design standards for roof gas boilers

The design of the KKg is carried out by companies licensed for the corresponding type of work. Prior to approval, the project must be coordinated by the architectural supervision, the SES, the fire inspection with the operating organizations that formalized the technical specifications in the design process.

Since the design services for boiler houses are quite expensive, it is recommended to pay for the work performed after the project has been agreed with all regulatory authorities and approved. This will become possible only if the design documentation meets the requirements of SNIP, VSN and the rules for the operation of boiler equipment.

The KKg floor is made with waterproofing, capable of providing a flood of water up to 100 mm high. Window openings must provide natural illumination, and therefore they are installed from a ratio of at least 0.05 m2 per 1 m3 of the total volume of the heat supply facility.

The piping scheme for in-house heating and ventilation networks is carried out according to a dependent scheme, through a mixing unit for supplying heat energy, and the hot water supply system - according to a closed circuit through a heat exchanger.

Heating systems are divided in front, with an individual unit for commercial metering of heat energy. A chemical water treatment system must be installed in the boiler room to supply soft water to the boiler and the heating circuit. These requirements are met in order to prevent scale formation on heating surfaces.

What boilers to use

As sources of thermal energy in KKg, automated hot water boilers are used, capable of heating water with a coolant to 95 C and a pressure of up to 1.0 MPa.

For example, modular boiler room ARGUS TM-1000.00.PR.10 with a capacity of 1050 kW, equipped with:

- Gas boiler PROTHERM 120 SOO with a capacity of 105 kW and an efficiency of -90%, 10 units.

- Pump group with centrifugal pump WILO HWJ 202 EM 20L.

- Expansion membrane tank REFLEX N 200/6.

- Automation and regulation system.

- Group of instrumentation and primary sensors.

- Chemical water treatment unit.

- Smoke ventilation system.

How to supply gas

The gas pressure in the gas pipeline for KKg should not exceed 5 kPa.

The external wiring of the gas pipeline to the boilers is carried out in places that are convenient for performing subsequent maintenance and exclude the possibility of its rupture. Connection of other consumers to this gas pipeline is not allowed.

The gas pipeline should not pass through ventilation systems, windows and doors. The internal gas pipeline in the boiler room is laid openly, while there should be free access for control and technical inspection of safety and automation devices.

Shut-off and control devices on the gas pipeline are installed at the inlet to the boiler room, at each branch to the boiler unit, in front of the ignition devices, on the purge gas pipelines and drainage fittings.

In addition, a safety shut-off valve (SSV) with an electromagnetic actuator is installed on the gas line in the safety system, which cuts off the gas in an emergency.

Roof power supply

Electrical equipment KKg must comply with the PUE, as an object of the second category of electrical supply reliability.

The building should be provided with lightning protection and a gas pipeline grounding system. The illumination of the premises must comply with the requirements of SNiP 23-05-95. Electrical equipment must have automatic protection against overheating and overloads in the network.

The power supply scheme should provide for the possibility of switching on backup electrical equipment when the main device exits, for example, a pump, a fan and a smoke exhauster.

Safety automation should ensure that the gas supply to the boiler is turned off in case of an emergency: high gas pressure, separation of the torch from the burner, gas contamination in the boiler room, low draft in the furnace, high temperature and pressure of the coolant.

Fire safety

There are a number of important security fire requirements for KKg in a multi-storey building:

- The location of the boiler room directly above the apartments is prohibited.

- The boiler facility is assigned a category of class "G" for explosion and fire hazard.

- The height of the ceilings of the object must be higher than 2.65 m.

- Door width over 0.8 m.

- Fireproof partitions must be installed in the building.

- The room must have a separate emergency exit.

- The facility is equipped with fire-prevention sound and light alarms and emergency fire extinguishing systems.

Block-modular types of boiler rooms

They do not require a large area due to their compact size. The construction site is first filled with special blocks. Then they are combined into a structure that maximally preserves performance under any conditions.

The entire system is assembled at the factory with elements that are important for operation. At the final stage, normal operation is ensured by adding the necessary equipment.

After the completion of the assembly stage, the station is ready for further operation. The manufacturer foresees the assembly, mounts the necessary modules. Separate rooms are equipped for staff service.

Under such circumstances, one cannot do without high quality insulation, ventilation systems with sufficient reliability. It is permissible to create an unusual design, an attractive appearance. Manufacturers foresee in advance that the installation of the unit will be carried out on the roof.

The main thing is to determine the bearing capacity of the building based on the results of the examination. If necessary, organize events and measures to increase the indicator.

A corresponding platform will be supported on the supporting elements of the building. Only in this case the block retains maximum stability. Further, a fire-resistant block is created under the gas boiler room.

Usually a concrete layer is poured to solve the problem. Railings should be installed around the perimeter of the roof for maximum safety.

In some cases, you cannot do without measures to increase sound insulation.

Block boiler rooms are an excellent option for buildings that are initially connected to centralized heating. But the equipment in this case must have acceptable technical conditions. Be sure to create a project.

Boiler room commissioning

The procedure for receiving the roof boiler room is determined by the PTE. The main stages of putting the KKg into operation:

- Project development.

- Approval of the completed project and its coordination with the municipal profile departments - architecture and housing and communal services.

- Performing technical expertise.

- Purchase of equipment and materials according to the section specifications and materials.

- Manufacturing of a boiler room and its installation on the roof of the building.

- Commissioning of boiler equipment.

- Creation of a commission for acceptance of the boiler house into operation. The commission should include representatives of the customer, the design and installation organization, the gas company, as well as municipal departments for capital construction, housing and communal services, SES and fire inspection.

- After the signing of the act by all members of the commission, they issue a permit for operation in the gas supply organization.