Ceramic kilns

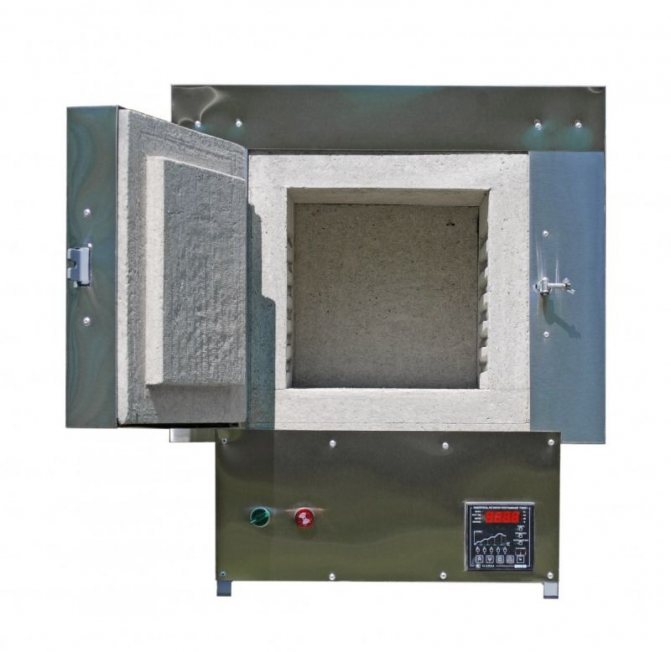

In this case, not ceramic kilns for firing are considered, but units specifically for ceramics. Products made from this material have high strength, which they acquire when exposed to very high temperatures.

This oven is a ceramic product specially designed for this type of heat treatment. They come in different designs, with different temperatures and may differ in thermal sources. You can buy them, but there are craftsmen who can make them on their own.

Types of ceramic furnaces

In total, there are two types of such structures:

- Wood-fired;

- Electrical.

The essential difference between them is only in the raw materials used in the work process. If you live in a rural area or you have the opportunity to regularly buy firewood, you should consider purchasing a wood-burning stove.

For residents of the megalopolis, pechnoy.guru recommends buying a small stove that runs on electricity - benefits, coziness and comfort will be equally provided by the model of both the first and the second type.

Firing equipment classification

Firing equipment can be classified according to several parameters depending on the user's requests.

Location of heating elements:

- chamber (heating elements inside the container);

- muffle (heating sources are located around the chamber made of a fire-resistant muffle).

Energy source type:

- gas (maximum temperature 1100-1300 0С);

- electrical (termodist 1200-1400 0С);

- using solid fuels.

Loading type:

- front-loading;

- top loading.

Type of environment inside the chamber (applies to industrial devices):

- general purpose (air environment);

- vacuum (as a medium - airless space);

- with a protective gas environment (gases such as hydrogen, helium, nitrogen, argon are used).

Chamber or muffle? Nuances of choice

When choosing a kiln for firing, usually take into account the expansion and production volumes. For more or less large-scale activities, camera equipment is used.

Ceramic muffle kilns have become more widespread. Let us dwell on them in more detail.

These devices are distinguished by their simplicity of design and reliability. The range of operations that can be performed using this simple equipment is wide:

- Remelting of valuable and precious metals and alloys. The muffle furnace guarantees no interaction with the flame and the introduction of impurities.

- Metal processing using high temperatures: aging, cementation, hardening, annealing, tempering.

- Working with ceramic products. In such a furnace, an even tone of the ceramic surface can be obtained. Relevant for art products.

- Drying of dielectrics inside the oven (microwaves are excellent for drying electrically conductive materials).

- A sad function is cremation. Yes, these are the ovens that are used for this purpose. They can be burned to mineral constituents (ash).

- Laboratory research and experiments.

- Medical use (for high temperature sterilization).

Muffle kilns for ceramics firing have long established themselves as unpretentious, ergonomic, with decent functionality. It is also possible to choose such a furnace in the case when the buyer has a lot of requirements for the firing device.

The main advantages of artificial turf

The stone for finishing the fireplace can be not only natural, but also artificial. This coating has the following advantages:

- Simple finishing work. You can do the cladding of the fireplace portal with an artificial stone with your own hands, which cannot be said about natural materials, for working with which you need to have not only a special tool, but also experience. This coating in its appearance resembles a simple ceramic tile or tiles. The method of fixing it to the surface is the same. It is possible to lay such a coating in the shortest possible time, and even without experience;

- Affordable cost. Artificial materials are distinguished by their affordable cost. Moreover, they are not much inferior to natural facings. In contrast, the composition includes various components, as well as artificially added impurities;

- Large selection of colors and surfaces. The finishing stone for the fireplace can be of different colors, due to the dyes included in the composition. The surface of the product is both a smooth and glossy structure and a rough refrained surface;

- Versatility. Facing stone for fireplaces is universal. It tolerates sudden temperature changes, strong heating, does not melt and does not deform. When heated, it does not emit harmful substances. Differs in its low porosity and does not absorb moisture;

- Low weight. Unlike natural coatings, which have a fairly large weight, this facing material is quite low. This allows it to be used for all types of structures and hearths. When finishing a suspended or built-in portal, the stone does not exert a significant load on the walls of the house.

Different-sized artificial stone for cladding

Inexpensive artificial turf for a large and massive wall fireplace

Imitation of a brick surface

Important: the disadvantages of artificial surfaces include the possibility of slight darkening, in areas of especially strong and intense heating, as well as where fire touches this material. Often quite rough and lumpy

fireplace stone texture, makes the care and elimination of various contaminants very difficult and not easy.

You can learn more about the varieties and features of such coverage by watching the video in this article.

Advantages of muffle kilns

The main feature of this type of equipment is the use of a muffle as an insulator for material (or product) and fuel (or products of its combustion). The muffle is the shell that protects the heated material and is the main working space.

Unit advantages:

- Wide temperature range (100 to 1450 degrees Celsius).

- Variety of used protection (air, atmosphere, or vacuum).

- Use of any energy carrier available to the buyer (you can connect to the power grid, you can use the gas main).

Such ovens can be of any size, with a different volume of the working chamber and with a different type of bookmark.

For travelers and for summer cottages

Electric ceramic stove is perfect for outdoor use. It is stationary and easy to carry with you. Heating occurs from an electric spiral due to heat transfer from the walls of the furnace. These days, these ovens come in a variety of designs. You can choose both a laconic style of execution and a design in an oriental way. The stoves have a high cost, but it is justified by at least two properties: high power (it all depends on the size, but even a small stove has good thermal characteristics) and environmental friendliness (ceramics is clay, a completely environmentally friendly material that does not contain impurities and synthetic additives) ...

In such electric ovens, you can cook barbecue, grilled chicken, bake fish, bread cakes and much more. They can even heat a small room. Summer residents will especially appreciate all the advantages of this device, because people spend a limited amount of time outside the city (season or weekend), and it is very convenient to take a small stove with you, which will both heat and feed.

For home comfort

The ceramic stove is an absolutely unique unit when viewed as an element of interior design. The lining of such a furnace can be made of various materials: natural or artificial stone, ceramics. These materials have decent heat storage properties. After heating, they will give off heat to space for a long time. Traditional metal stoves have 1.5-2 times less heat transfer than ceramic ones, and therefore cannot create such a unique, cozy, warm and attractive atmosphere in the house.

Variety of samples

The facing stone for the stove is presented for sale in a wide variety of colors and textures that imitate various types of natural stone.

Such an extensive choice allows consumers to create interiors and exteriors of the most varied designs, using one or another imitation of natural stone.

We offer to buy in Moscow the best samples of artificial facing stone for decorating fireplaces and stoves at a bargain price.

Here you can choose the color and texture you need, and if the samples presented in our catalog do not meet your requirements, you can order any color of your choice.

What is the difference from a traditional Russian oven?

Ceramic stoves for the home have absorbed all the best that the ancient Russian traditions of heating rooms can give. They warm up quickly, give off heat to the surrounding space for a long time, and have the function of preparing tasty and healthy food. But modern technology has gone very far. Now this device is more complete and supplemented with such functionality as a water circuit in the structure, ensuring absolute safety (excluding the occurrence of dangerous situations that cause smoke or fire), an additional stove or oven for cooking. Considering the sophisticated design, the ceramic stove has unrivaled aesthetics.

Variety of options

Manufacturers have taken care of the durability of such important equipment, but have not forgotten about the appearance. Yes, the basis is always safe and durable components: cast iron, stone, ceramics, steel. It's all inside. These materials are widespread because they are resistant to external factors, durable, durable and come in an affordable price range.

As for the outer cladding, it is quite interesting. The leading manufacturers of ceramic stoves for the home are Italian companies, and even Italians know a lot about art and sophistication. A lot of materials are used: tiles, fire-resistant glass, ceramics, environmentally friendly paints, unique tiles.

Customer reviews speak for themselves - everyone is happy. Yes, the price of such a device will not be low, but the high cost includes aesthetic pleasure, trouble-free operation of the stove without problems for many decades, safety, high quality guaranteed by European brands and extensive functionality.

Features of the decorative facing of the stove

A high-quality finish of a sauna stove must meet the basic operational requirements: withstand high humidity, temperature drops, ensure the durability and safety of the surface. The lined stove should quickly heat up the bath rooms and create a comfortable microclimate inside.

The lining of the stove in the bath has a number of advantages, among which are the following:

- fast and uniform heating of the premises;

- accumulation of heat for a long time;

- minimal risks of getting burned from a heated oven;

- there is no overdrying of air;

- simplicity and availability of maintenance of the finished cladding;

- attractive appearance of heating equipment;

- resistance to mechanical damage and deformation.