How to install a smoke exhauster

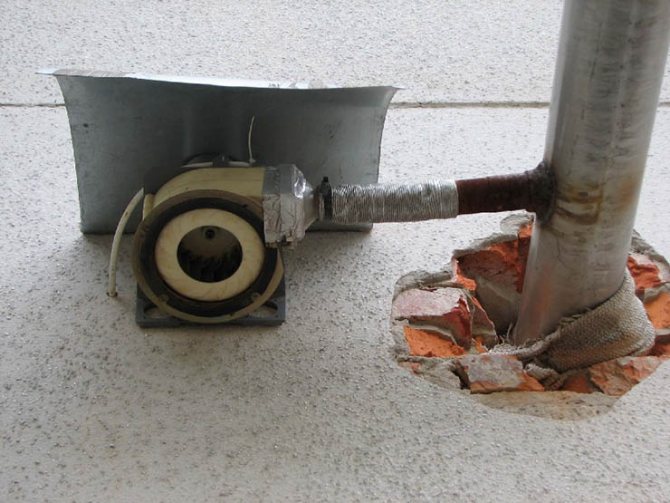

If you have a need to install a smoke exhauster on a chimney, which can not be removed or disassembled, and it is impossible to install a pump inside the room, then you have to install it outside. Although the best option for an electric motor is indoor installation. Smoke exhausters are usually sold with an impeller, impeller and electric motor with a boiler or pipe mount. It is necessary to choose a suitable exhauster, taking into account it:

- Dimensions;

- Power;

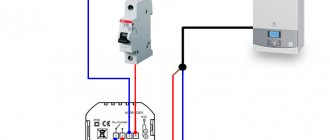

- Connection diagram.

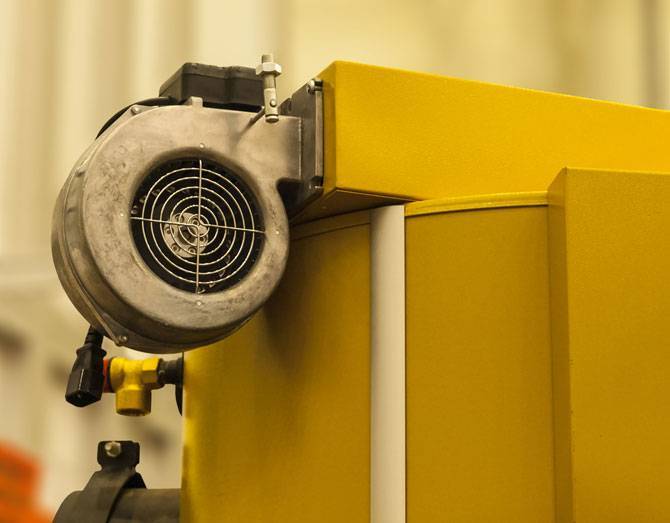

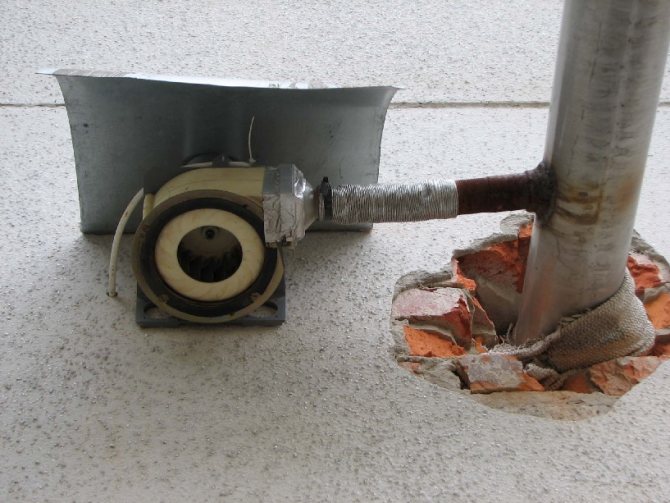

When there is a smoke exhauster and there is a chimney pipe, you need to figure out how to connect it all together. Most often, the engine is attached to a makeshift snail. And the snail is welded (attached) directly into the chimney. The connection slot must be equipped with a flap so that it can be opened or closed. Based on specific weather and other conditions - using natural or forced traction.

In principle, there is nothing complicated and supernatural in the installation of this device, and any home craftsman can handle it. Everything can be done with an ordinary grinder and drill at home. It is advisable to make a preliminary drawing of the connection, which will indicate the dimensions and diameters of the branch pipes and the main pipe. For example, if your chimney pipe is 159 mm, then the outlet from it for the smoke exhauster can be 110 mm in diameter.

Classification of smoke exhausters

Before installing the exhaust machine, you can try to do without it by increasing the traction with special devices that do not require forced air distillation and power consumption. Sometimes an elongated pipe or installing a deflector on top of it helps. If the problem persists, you can use:

- natural traction amplifier;

- flow-through smoke exhauster;

- centrifugal exhauster.

The first one consists of a fan mounted on the top of the chimney and connected to a control panel. The simplest and cheapest option, but its performance is low.

Smoke exhausters are of several types

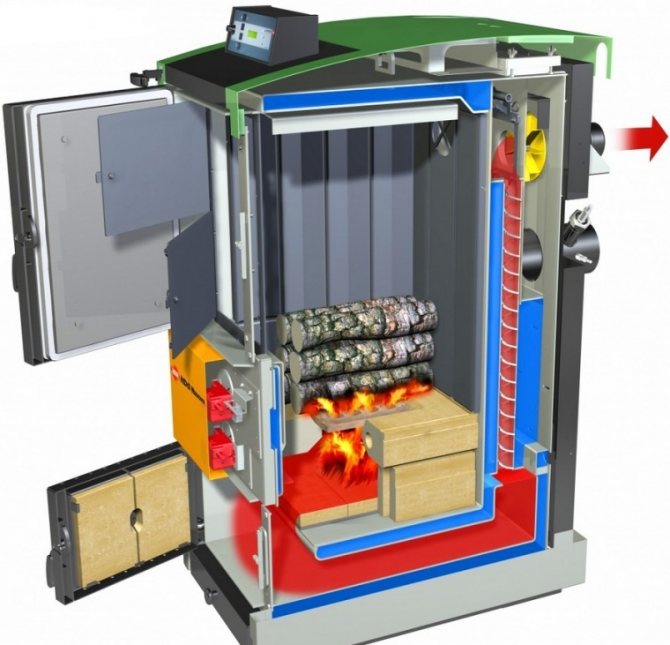

In the second design, the hood housing with the impeller is placed in the smoke channel, and the electric motor is installed outside. This configuration allows the use of engines and turbines of any power.

The highest performance of a centrifugal exhauster. This design makes it possible to service chimneys with the most complex configuration and large cross-section.

Interesting: do-it-yourself chimney.

In this video, you will learn how to make a smoke exhauster:

Good draft is the result of correct calculation and installation of the chimney

When asked which chimney is better for a coal boiler, and which is better for a diesel boiler, etc., the correct answer will always be different. Because a chimney made for a wood stove may be completely unsuitable for a gas boiler, for example. And there may be several reasons for this. At the same time, few people are able to lay out a new capital chimney instead of an ineffective one. That is why the existing chimneys have to be improved in one way or another. Often, the improvement involves the installation of a smoke exhauster for a new domestic boiler.

Everywhere, the chimney for a solid fuel boiler is made capital brick. If it has sufficient height and cross-section, then it always has excellent traction and no amplifiers of air movement are required. But there are also exceptions. For example, a brick chimney for a stationary solid fuel boiler cannot be brought to the required height.As a rule, a chimney for a solid fuel boiler is elementary made by hand, but it does not always do an excellent job with its function. And it often happens that additional traction must be provided using smoke exhausters for household solid fuel boilers, purchased or made by hand.

From what and how to lay out the chimney so that it effectively copes with the removal of smoke, this is a topic for a separate large article, and now we will not touch on it. A solid brick chimney is good for a solid fuel boiler or stove, but without additional inserts it cannot be used for modern boilers for other types of fuel. For example, a boiler smoke exhauster may be needed if the chimney was installed incorrectly from the very beginning.

How to make the correct connection to the chimney for a conventional solid fuel boiler? Highly qualified specialists know about this, but they are also mistaken, not noticing some local trifle in time. A good smoke exhauster for a solid fuel boiler or any other is able to eliminate all errors in the design and construction of boilers and chimneys. Especially if the chimney for the boiler is not brick, but metal.

This is a whole science - the device of a chimney for a solid fuel boiler. What can we say about more complex options for heating devices. Therefore, errors are often encountered, even simple brickwork is rarely ideal. Compliance with all technical standards for aerodynamics is still a challenge! And how to make a chimney if a brick boiler will be connected to it? Will your chimney be effective enough for a solid fuel boiler? Questions like these are often impossible to answer in advance.

Exhaust fan for a solid fuel boiler: purpose, varieties and nuances

A solid fuel boiler belongs to the autonomous type of organization of the heating system.

It is used in private houses, summer cottages, baths and cottages. The use of solid fuels implies that the boiler requires coal or wood to function. But the fuel does not always have time to completely burn out during the operation of the boiler.

This is uneconomical and requires constant cleaning of the heater. Combustion products must be discharged strictly into the chimney. With poor traction and low pressure, this is very difficult to achieve. To solve these problems, you should use special devices called smoke exhausters.

What is better smoke exhauster or blower

When the traction turbine is integrated into the heat generator by the manufacturer, such questions do not arise. Adding an exhaust fan to a conventional direct fired boiler is another matter. It must be understood that in this case the smoke exhauster solves only one problem - creating a vacuum in the furnace and increasing the draft. There are a number of negative points here:

- Without an electronic control unit, performance will have to be adjusted manually. Automatic maintenance of the coolant temperature is excluded.

- When air is supplied through the open ash chamber door, the fan will force the boiler to operate at maximum. Setting up a long burn mode will not be easy.

- In the event of an emergency stop of the impeller, the fuel combustion will not stop, since the gases freely pass through the volute or the smoke exhauster housing. Air enters the firebox, the probability of overheating increases.

- The impeller and the inside of the unit are covered with soot, which must be removed. The sticking speed depends on the moisture content and resin content of the wood.

The blowing machines always work in conjunction with the controller, so there are no problems listed above:

- the blower changes the capacity and turns off at the command of the control unit, the coolant heats up to the set temperature;

- during combustion, the ash pan door is hermetically closed, air is supplied through a separate channel;

- in the event of a power outage, the air channel is automatically closed by a gravitational flap;

- the impeller blades do not come into contact with hot smoke and soot.

Now let's compare the cost of a traction and blower fan, excluding the price of the controller. An exhaust fan for a TT-boiler up to 30 kW will cost 90 cu. e., supercharger - 60-65 cu. e. The difference is due to the design features of the exhaust unit - hot gases should not overheat the electric motor, plus the impeller is made of metal (when pressurized, it is made of plastic).

In terms of the complexity of the installation, the units are approximately the same. Installation of a pumping snail involves cutting out an opening in the ash pan door, a smoke exhauster - disassembling or cutting out a pipe. It is easier to install a roof hood, but you have to pull a long cable.

Types of smoke exhausters

There are several types of smoke exhausters, each of which has its own markings.

- "D" - small-sized units capable of providing one-sided air injection. Designed to create direct draft in boilers of various types: solid fuel, pyrolysis, gas, liquid fuel. Can be equipped with ash catchers. The impeller blades of a smoke exhauster for a domestic boiler are bent forward (to create a straight draft).

- "DN" - are intended for the same purposes as the devices of the "D" type, but the fan blades of these machines are bent back. This is necessary to create reverse thrust. The devices can be equipped with simple means of automation of control over the fuel combustion process.

- "DPE" is a fire-fighting smoke exhauster with an electric drive. Small-sized portable device, can be equipped with a centrifugal or axial turbine.

- "DPM" - stationary type unit, equipped with a motor. It is used during fires to remove smoke and provide fresh air.

- "DP" - smoke exhauster for fire-fighting purposes, is a trailed large-sized device.

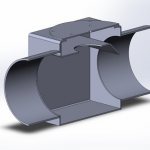

The smoke exhausters' marking consists not only of letters, there are also digital ones. The latter indicate the diameter of the wheel of the apparatus or fan. There are three options for the design of the smoke exhausters:

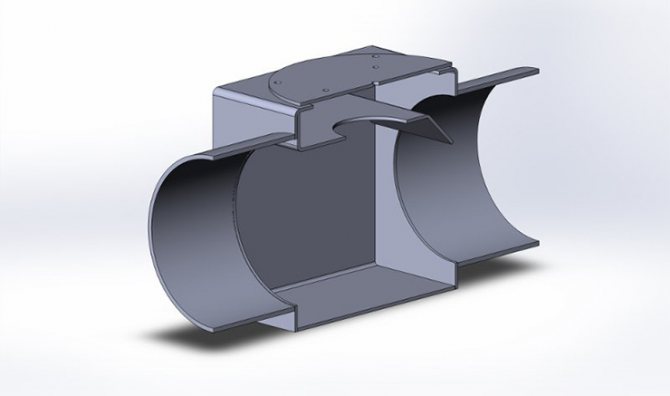

- with a wheel mounted directly on the motor shaft;

- with a wheel mounted on an intermediate shaft;

- with a wheel located in a separate chamber, connected to the drive shaft by means of a belt drive.

The chimney smoke exhauster is a small-sized device with one-way draft, which is placed in the chimney pipe. In the places where the device is installed, all gaps are filled with a heat-resistant sealant. To ensure effective removal of smoke into the atmosphere and a stable flow of air into the fireplace or stove, equipment such as a centrifugal smoke exhauster is recommended. Popular models of smoke exhausters for boilers:

- "DN-3.5" is a small-sized device installed in small boiler houses of private houses, mini-hotels, holiday homes, etc. It is designed to create traction in boilers of any type. The maximum permissible operating temperature of the device is +200 ° C. Regulation of pressure and capacity is possible by changing the engine speed.

- DN-6,3 is a more powerful device than the previous one. Equipped with an electric motor from 4 to 5.5 kW. Has different dimensions depending on the version. There are three design solutions for connecting the motor shaft and the fan: directly, through a coupling or a belt. In the third case, the dimensions of the unit are the largest, and the mass can reach 500 kg. The device is in great demand for equipping medium-power boiler houses.

- "DN-10" is an industrial-type centrifugal unit. It can perform two functions: to pump out combustion products of fuel from boilers and to be used for fire extinguishing purposes. Manufacturers offer three variants of the machine of this brand. The power of the units is 11–30 kW. Productivity is 13600–20450 m³ / hour.

Fan for solid fuel boiler

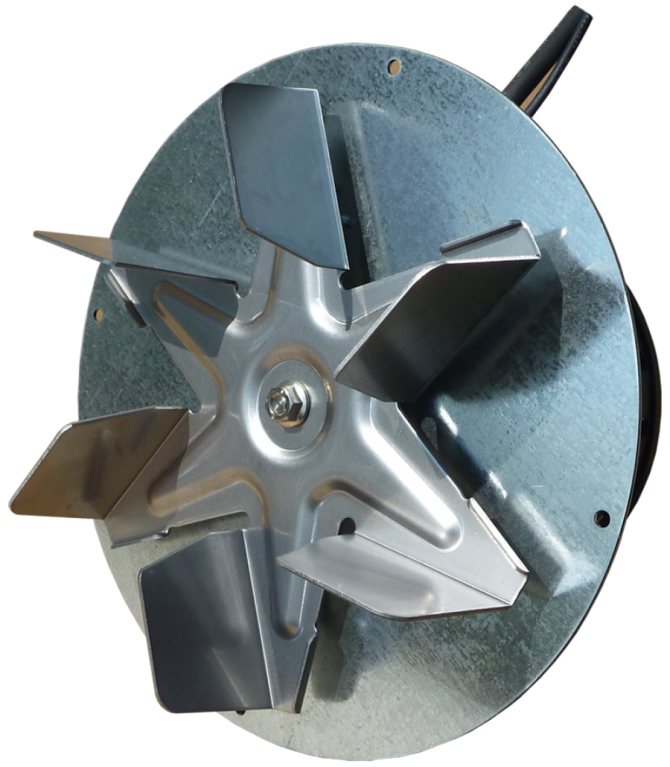

According to the parameters and functional characteristics, fans for solid fuel boilers are divided into the following types:

- devices with electrically commutated motors (EC);

- fans equipped with synchronous motors;

- asynchronous motor blowers.

Each type has its own advantages and disadvantages:

- Electrically commutated motor. This device is able to independently change the number of revolutions, having previously received a corresponding signal from the control unit, and also has a wide range of fan operation adjustment. However, the device also has a number of disadvantages - it is not compatible with most of the temperature regulators produced by domestic manufacturers, and besides, this technique has a high price.

- Fan with synchronous motor. The device is simple to manufacture and has a low price. But this type of fan also has a number of disadvantages. For example, a small adjustment range and minimum torque during start.

- An induction motor has many advantages. First of all, it is simple and easy to use. Secondly, it has a reliable design. However, there is also a drawback - high starting currents.

To remove smoke, smoke exhausters are used, which can be read about on this page.

Device

Any blower fan, regardless of which country it is produced in, consists of a metal case, and inside it there is an electric motor

Also, an important part of the blower fan is the blades, which are protected by a safety grid. The structure of the device is not complicated, but at the same time reliable

This is ensured by its robust housing, high operating temperature and reliable motor manufacturer. Vulnerable elements and parts are protected by a grill. The blower fan is lightweight, so there are no installation problems.

Fan for solid fuel boiler

On the Russian market, you can find fans for solid fuel boilers from the following manufacturers:

- Pressure centrifugal fan (turbine) WPA of various modifications. Manufacturer - Polish company MplusM. This company specializes in the production of turbines for solid fuel boilers. The model is in stable demand in the Russian market, as it is characterized by high quality and good reliability.

- NWS fan of various modifications. Production - Nowosolar (Poland). Purpose - forcing air into the combustion chamber. This increases the efficiency of burning fuel in the combustion chamber.

https://youtube.com/watch?v=8ZVXK4JcCNQ

How to choose the right

The performance of a solid fuel boiler is largely determined by a properly selected fan. What does this mean?

Let's consider several situations:

- If a fan is installed that supplies a lower volume of required air, then the fuel will not be burned completely. As a result, the boiler power decreases and the rated temperature is not reached.

- If a fan is installed that supplies a larger volume of the required air, then the solid fuel boiler will quickly gain temperature, and the fan will constantly turn on and off. As a result, fan breakdown is inevitable, the chimney will be constantly hot, and heat will go through it.

There is only one way out - choose the right blower fan.

The table shows options for installed fans on solid fuel boilers of various capacities.

| WPA X2 | 285 | 62 | 32 |

| WPA 07 | 160 | 35 | 18 |

| WPA 06 | 255 | 55 | 28 |

| WPA 117 | 180 | 39 | 20 |

| WPA 120 | 285 | 62 | 32 |

| WPA 140 | 395 | 86 | 44 |

| WPA 145 | 505 | 110 | 56 |

| WPA 160 | 600 | 130 | 67 |

| NWS 75 | 205 | 45 | 23 |

| NWS 79 | 205 | 45 | 23 |

| NWS 100 | 240 | 52 | 27 |

How to choose and install a smoke exhauster for a solid fuel boiler or fireplace

Previously, traction and blowing fans were used only in industrial boiler plants. The former are placed inside the chimney and create a vacuum, the latter pump air into the firebox. Gradually, the units migrated to the domestic sphere - manufacturers began to equip heaters with a closed combustion chamber with turbines.The idea was picked up by home craftsmen, because the smoke exhauster for the boiler helps to solve the problem of poor draft in the chimney pipe. Let's see if forced extraction of combustion products is always necessary.

Device application

It is important to synchronize the operation of the boiler and the fan during operation. Installing a smoke exhauster on a boiler without a control and automation unit is excluded, so you will have to buy and install all the electronics entirely from scratch.

Such fans are indispensable in the following situations:

- strong smoke in the room due to the opening of the firebox door, which can be facilitated by the design feature of the boiler;

- holes and cracks form in the brick chimney, so smoke is sucked through them;

- draft problems - complex chimney design, strong winds and other problems;

- insufficient chimney height.

How to install a smoke exhauster

Strengthening traction with a smoke exhauster also has a reverse side. If the natural pressure does not increase for a certain time after the fan has been running, then it is impossible to turn off the smoke exhauster, since asphyxiation by carbon monoxide can be a possible consequence. If the electricity is cut off at night, smoke will enter the room, and this cannot be avoided. While the chain thermostat closes the damper, the entire boiler room will be in smoke

In this regard, it is very important to do good natural cravings in order to avoid the occurrence of such cases.

Sources of

- https://teplofan.ru/sistemy-otopleniya/komplektuyushhie/ventilyator-kotla

- https://RSVgroup.ru/ventilyatsiya/dutevoj-ventilyator-dlya-kotla.html

- https://oventilyacii.ru/kondicionirovanie/kak-sdelat-dymosos.html

- https://svoimi-rykami.ru/stroitelstvo-doma/pechi_i_mangaly/ventilyator-dlya-kotla-svoimi-rukami.html

- https://klimatlab.com/otoplenie/tverdtoplivo/dymosos-dlya-tverdotoplivnogo-kotla-svoimi-rukami.html

Features of using smoke exhausters

When choosing a traction smoke extractor, it is necessary to calculate the cross-section of the exhaust pipe and the capacity of the exhaust unit. Unlike injection installations, they are more versatile and efficient, they allow you to lay firewood during the operation of the boiler, and do not allow combustion products to enter the room.

Forced exhaust of flue gases will help to make the stay in the room safe and reduce the risk of carbon monoxide poisoning to a minimum.

The use of smoke exhausters for pellet burners or boilers operating on sawdust, peat is the only possible way to organize the heating process. Under normal conditions, they burn badly.

Advantages of using a chimney hood:

- Improving the efficiency of heating devices, firewood burns almost without residue;

- Eliminates the accumulation of smoke in rooms, eliminates unpleasant odors;

- Exhaust gases do not flow back into the room when the firebox door is open;

- Reduce deposits on the walls of chimneys due to the filtration and separation system.

They have practically no drawbacks. If no mistakes were made during installation, then the service life of the smoke exhauster in the chimney is comparable to that of the boiler itself. In this case, regular maintenance should be carried out.

Device

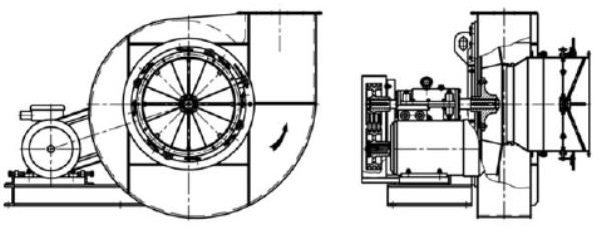

The smoke exhauster is a constructively simple device. It consists of several nodes, each of which has its own purpose.

- Housing.

- Suction pipe or suction pocket of the smoke exhauster.

- Guiding apparatus. There are right and left rotation, which is determined by the direction of the fan blades.

- Working wheel.

- Frame.

- Electric motor.

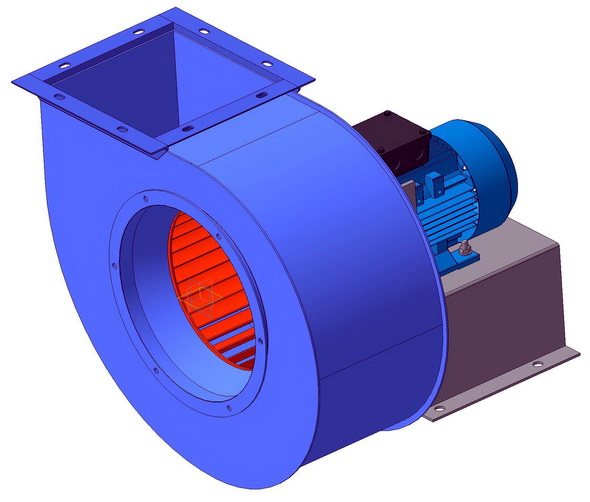

The body is made in the form of a "snail", which provides the required swirl of the air entering the unit. Made of heat-resistant steel, covered with thermal insulation.

The smoke exhauster guide device is located on the suction branch pipe, it allows you to regulate the air pressure using a swivel mechanism that unites the fan blades. Each blade is curved to allow the air flow to rotate in the same direction as the rotor. With the help of the rotary mechanism, it is possible to block the lumen of the nozzle to one degree or another.

The smoke exhauster impeller is a unit on which the fan blades are located. They are attached to it by welding or rivets. A rarefied atmosphere is created in the central part of the wheel when it rotates.For this reason, incoming air is drawn in here. Such small-sized devices as smoke exhausters for fireplaces work in a similar way.

The wheel docking unit can be located on the engine shaft or on the intermediate shaft, depending on the design of the unit. If it is a dust collection equipment, special filters with absorbents are included in the device. This is how all fire-fighting units are equipped. Ash collectors can be included in the design of boiler apparatus. The smoke exhauster device determines its purpose.

On the impeller, holes can be located, which are necessary for fixing the blades in a given position. Balancing can be done manually or by an electrical actuator. The direction of rotation of the fan blades can be distinguished by looking at the unit from the side of its electric motor. The axial guide device of the smoke exhauster ensures the rotation of the blades, regardless of their number and direction of the slope, at an angle from 0 to 90 °.

The blower fan and the smoke exhauster have a similar design, but differ in purpose. Devices of the first type provide air injection into the boiler furnace. The latter are designed to remove fuel combustion products and release them into the atmosphere outside the boiler room.

Fans and smoke exhausters of boiler installations have the same principle of operation, they can be left- and right-handed, with direct and reverse draft. These machines are designed for long-term, trouble-free operation over a temperature range of 0 ° C to +250 ° C. Fume exhausters are marked as "D" and "DN", fans - as "VDN". The latter are produced with the impeller landing on the motor shaft.

Repair of smoke exhausters and fans is carried out by persons who have passed the appropriate certification and instructed on the safety of the operation of electrical appliances.

Varieties

Manufacturers of heat-power equipment offer the following types of smoke exhausters: traction booster fans, flow-through units, centrifugal duct exhauster.

Natural traction enhancers

The devices are devices with an axial fan, the performance of which is regulated by a thyristor control unit. The unit is installed at the end of the gas-air duct, immediately in front of the chimney. The working mechanism is protected from high temperatures and volatile inclusions in the composition of combustion products.

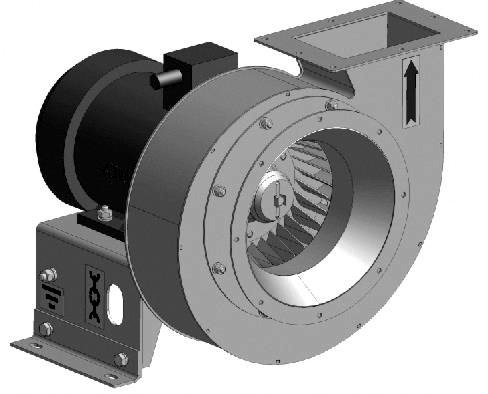

Continuous smoke exhausters for boilers

Structures serve to increase natural draft and are mounted on the outlet of the equipment. Due to the design features, the impeller of the flow-through smoke exhauster is not capable of developing high pressure. For this reason, it is used as an exhaust amplifier, and cannot always serve as a traction device. Only the housing with the impeller is installed in the smoke channel, and the electric motor and other elements of the unit are located outside, which allows you to turn on / off the equipment as needed. Manual control, if desired, you can connect the device to the automation of the boiler plant.

Centrifugal duct smoke exhausters for solid fuel boilers

Centrifugal units are capable of developing high pressure and creating a vacuum in the combustion chamber. To ensure the consistency of the operation of the entire heating equipment system, it is recommended to tie the functionality control to the electronic unit of the heat generator.

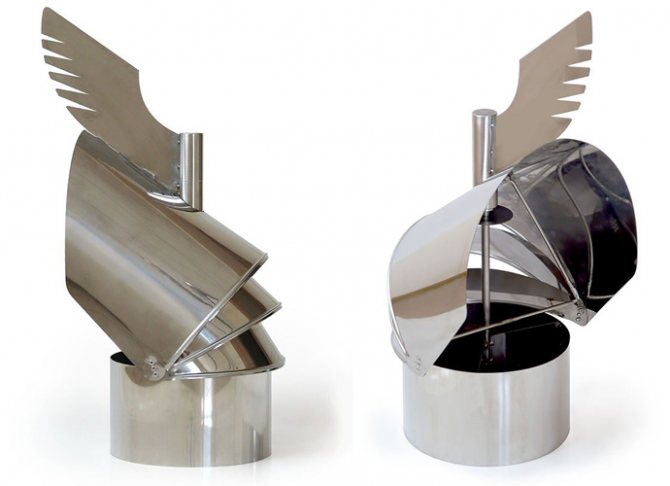

What is a fireplace smoke exhauster, and why is it needed

This device is a duct fan with an electric motor, which is mounted at the outlet of the chimney. The principle of operation of the device is simple - during the operation of the fan, the draft in the chimney increases.

Simply put, this device is a forced exhaust system, but they are not designed for full exhaust. They are used only to improve the (episodic) natural draft in the pipe, or during its repair.

Chimney hoods

For example, a chimney smoke exhauster is started as needed - at a time when the natural draft drops to a certain value.

When should you use it?

There are several indications for the use of a chimney smoke exhauster, which in one way or another are associated with impaired draft in the chimney.

Indications for use:

- When there is no draft in the chimney at all (for example, due to errors in the construction of the chimney, or because of its weakness in terms of exhaust). This often happens when the chimney height is incorrectly selected.

- In cases where the chimney is incorrectly positioned relative to the roof ridge.

- If a higher building was built nearby and, accordingly, the thrust fell because of this (due to the obstruction of wind flows).

- In cases where the chimney needs repair work (there are cracks, cracks, any protruding elements).

- In cases where the diameter of the chimney is not chosen large enough, or, on the contrary, is too large.

Pros and cons of using

Any device of this type has both a number of indisputable advantages and a number of disadvantages. This is also true for smoke exhausters.

Among the advantages of such a device, it is worth noting:

- you can not repair the chimney "right now" - the smoke exhauster allows you to postpone repair work for an indefinite period;

- the ability to create the necessary traction by strengthening it, in any weather;

- it is possible to significantly reduce the harm from the formation of condensation due to the fact that the thrust will be increased, and as a result less condensation will be formed;

- the ability to turn off the fan at any time when there is sufficient natural exhaust from the chimney.

List of disadvantages of using such a device:

- it is not always possible to install a smoke exhauster;

- additional consumption of electrical energy (however, in fairness, such fans consume relatively little electricity).

For which chimneys is it suitable?

You can use a smoke exhauster on chimneys for a stove, fireplace, various boilers (gas and solid fuel)

But there is one important condition - such a product can only be mounted on chimneys in which the temperature does not exceed +600 degrees

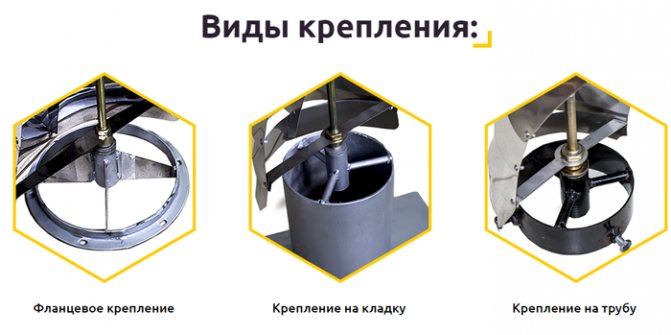

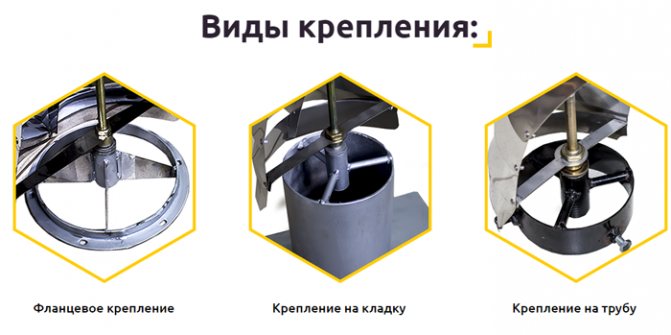

Types of fixing chimney hoods

This also applies to heat-resistant models. Although they are designed for high-temperature operation, they are not too high (therefore, they are used for a stove or fireplace, but not for industrial purposes). Moreover, +600 degrees is a very good indicator, many heat-resistant smoke exhausters are even designed for temperatures up to +350 degrees (average).

Smoke exhauster can be salvation

A small and useful fume extractor device is very useful to use with a pyrolysis boiler. Now on the market there are smoke exhausters with different performance, different brands, different quality and with different prices. Almost all of them are connected via a capacitor. For each such factory-made pump there is an instruction in which its parameters are indicated, often in the form of a plate, so that the buyer can independently connect it to any of the pyrolysis boilers.

You can make such a device yourself, under the section of the chimney. When installing the smoke exhauster, the gravity channel of the chimney must never be closed off, since the boiler in normal mode must operate on natural draft. An additional bridge must be created in the outlet pipe so that additional gas injection can be created only if necessary. Moreover, the design should provide an unobstructed flow from the air pump, while the performance of the exhauster itself will increase due to injection.

Purpose and device

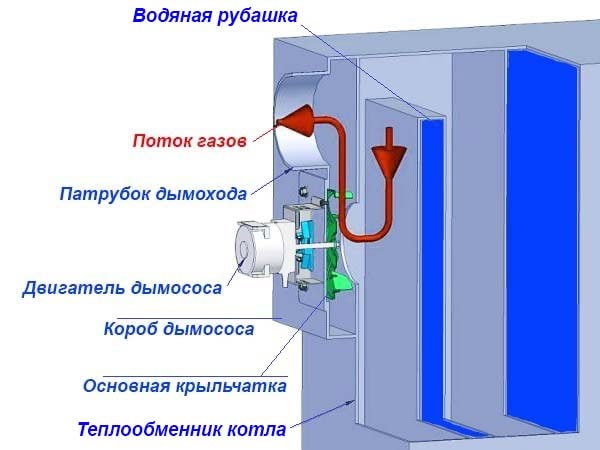

Blower fans are installed at the end points of the chimneys and facilitate the removal of combustion products by creating a strong vacuum that draws smoke and other gases out of the furnace and chimney system.The working conditions of the smoke exhauster are characterized by high temperature loads, contact with combustion products contributes to rapid wear and metal fatigue. The design of the smoke exhauster must correspond to the level of loads and ensure efficient operation throughout its entire service life.

The composition of the structure includes:

- heat-resistant fan (made of stainless steel, alloy steel or, less often, carbon steel)

- directing vane installed on the suction side and ensuring the correct direction of flow

- suction funnel connecting the guide vane to the fan inlet

- electric motor

The body of the exhauster, regardless of the material of manufacture, is covered with a protective polymer coating. It increases the service life of parts and helps to reduce thermal corrosion of materials. The direction of inclination of the impeller blades is used both forward and reverse. The first option is most often used on small boilers with relatively mild operating modes, the second option is used on powerful installations with high flue gas temperatures.

For use as smoke exhausters, not only radial, but also axial devices can be used. There are flow-through structures that are located at the outlet of the boiler. They are not completely located in the channel, but only the thrust-increasing part of the impeller. Such designs are not full-fledged smoke exhausters, but as traction amplifiers they are quite effective. The best option is to install a specialized centrifugal type device that gives the maximum effect.

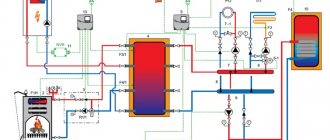

Design and principle of operation

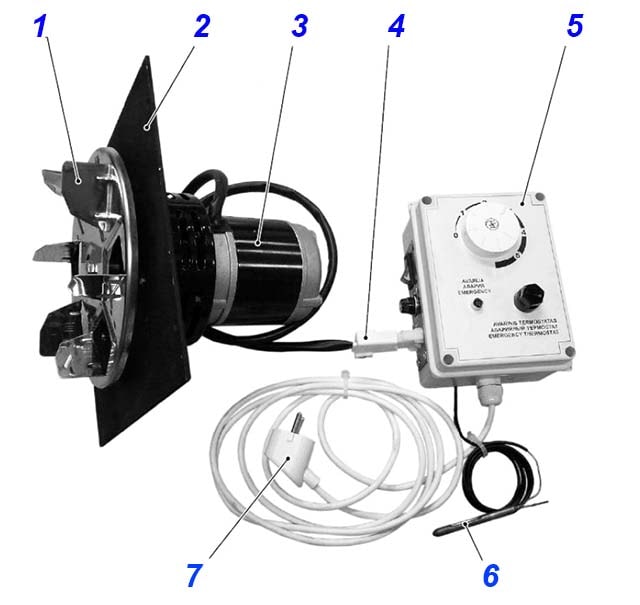

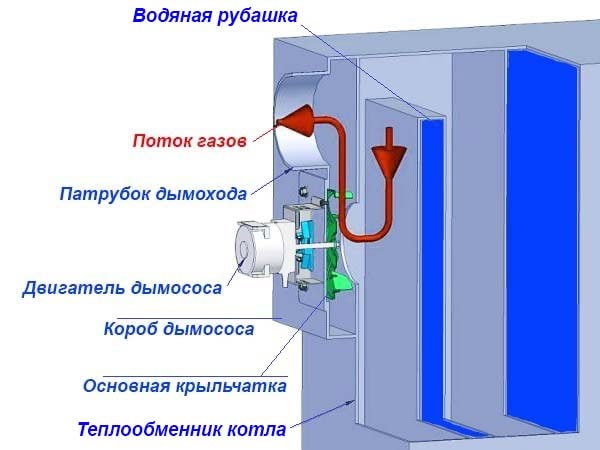

An exhaust smoke exhauster for a factory-made boiler includes the following elements (the device is shown in the diagram, the positions coincide with the points):

- Heat-resistant metal impeller with blades bent at 90 ° relative to the impeller.

- Fastening plate.

- Low performance electric motor (20 ... 50 W).

- Power cable connector.

- Control panel with controls and controls.

- Flask and capillary tube of the temperature sensor connected to the emergency thermostat.

- Power cord with plug.

Note. As an example, the DM-01 boiler smoke exhauster from Kalvis is taken. The design of other types of fans differs in the shape of the case - a snail, a box, a hemispherical landing area. The set of parts is similar.

The unit is attached to a special box located on the rear panel of the domestic TT-boiler next to the chimney pipe. The temperature sensor bulb is inserted into the immersion well of the water jacket, the control panel is placed separately.

The principle of operation of the smoke exhauster consists in the forced removal of high-temperature gases from the fire-tube heat exchanger of the boiler into the chimney. The algorithm looks like this:

- The firebox is filled with firewood, firing is performed.

- The loading door is locked, the blower door is opened. The fan is turned on with a key on the remote control, then the performance is adjusted.

- When the heating system and the chimney are warmed up, the speed of the impeller is manually reduced to a minimum. If the heat generator has enough natural draft, it is recommended to turn off the smoke exhauster.

- When the coolant heats up to a critical temperature of 100 ° C or more, at the command of the sensor, an emergency thermostat is triggered, turning off the fan automatically.

The scheme of the boiler smoke exhauster

Reference. On TT boilers equipped with an automatic draft regulator, the ash pan door does not need to be opened. The thermostat by means of a chain will open the air supply damper to the required angle.

High or low performance of the traction fan is set individually, depending on the quality of solid fuel, combustion mode and the degree of heating of the chimney. The main thing is to avoid the accumulation and seepage of smoke into the room.

It is also impossible to overdo it with revolutions - the lion's share of the heat will go into the pipe.Before opening the door and reloading, it is better to increase the rotation speed to the maximum.

A ready-made fan unit of the famous Russian brand Zota is mounted on wood-burning heaters with a rear gas outlet

Homemade constructions

You can make smoke exhausters for boilers with your own hands. This will save money on the purchase of a factory hood. To fold such a car yourself, you only need to purchase an electric motor. The rest of the components can be made from available tools.

Extraction from scrap materials

The set of tools required for the job consists of:

- grinders;

- welding machine;

- drills;

- locksmith tools;

- hammer;

- rulers;

- caliper.

Work begins with the manufacture of an exhaust fan. The impeller, matched to the chimney, is attached to the motor shaft. The engine is placed in the pipe with the help of fasteners equipped on its housing.

After connecting the motor to the wiring, during the first test run, it is imperative to check the direction of the air flow and, if necessary, correct the operation of the rotor.

The pipe for placing the turbine is selected with a diameter of 2-3 cm wider. Its length should protrude 3-5 mm beyond the fan. One end of the pipe is welded with a lid, a hole is made in the center of it for the chimney, and the side is equipped with another one, to which the outlet is attached.

During operation, the fan should not cause increased vibration of the hood housing. To prevent this from happening, it is installed using bushings to center the bearings.

The hood assembly is completed by welding the back cover to the tube and attaching the motor to the stand. After connecting the air ducts and electrical wiring to the unit, it is ready for operation.

Intermediate option

This version of the drawing machine assembly does not require special centering of the impeller, which is a rather delicate and difficult job for a layman. A factory-assembled mechanism is usually already centered and only needs to be checked during a trial run.

Sources of

- https://teplo.guru/kotly/tverdotoplivnye/dyimosos.html

- https://aquagroup.ru/articles/dymososy-dlya-kotlov.html

- https://kaminguru.com/dymohod/dymosos-dlja-kotla.html

- https://trubanet.ru/truby-dlya-otopleniya/prinuditelnaia-vytiazhka-dlia-dymohoda.html

- https://teplospec.com/tverdotoplivnoe-otoplenie/kak-vybrat-dymosos-dlya-tverdotoplivnogo-kotla-vidy-razlichiya.html

- https://otivent.com/dymosos-dlja-tverdotoplivnogo-kotla

- https://1poclimaty.ru/montazh/dymosos-svoimi-rukami.html

- https://klimatlab.com/otoplenie/tverdtoplivo/dymosos-dlya-tverdotoplivnogo-kotla-svoimi-rukami.html

- https://teplofan.ru/sistemy-otopleniya/komplektuyushhie/dymosos

Homemade unit

For those who feel sorry for money for a purchased smoke exhauster, there is an excellent alternative - you can make it yourself! Compared to purchased ones, such a unit costs mere pennies. A home-made smoke exhauster is usually made from a 230 mm worn diamond disc, to which the blades are welded. The motor can be taken from a flea market, for example, a motor from a washing machine of a two-speed motor. Such a simple device provides up to 3000 rpm in spin mode. You don't even need to connect through a step-down transformer, but you can immediately (or later) make a power regulator. Without too much overload, such a homemade device can work perfectly for several years.

Self-made snail-shaped smoke exhauster

A properly installed smoke exhauster, despite the fact that it is installed inside metal pipes, is practically inaudible during operation, it works even quieter than the blower fan. In this case, the "wind" speed reaches 150 meters inside the chimney. To check the operation of the device, there must be a revision hatch from the bottom, so that at any time you can see how the device will work when you open the loading door in the boiler.

How to choose a smoke exhauster for a solid fuel boiler - types, differences

The smoke exhauster is an electromechanical type device. It is designed to remove fuel combustion products from furnaces and boilers and is an exhaust fan mounted in chimneys. Such devices are indispensable elements of steam and water heating units for industrial use.

As for smoke exhausters for a solid fuel domestic boiler, they are installed only when it is provided by the manufacturers of heating devices. As a rule, such units function due to the presence of natural draft created by the smoke exhaust system. A gate is used to control the thrust force. If the chimney is designed correctly, there is no need to use the device.

It is necessary to think about installing a smoke exhauster for a solid fuel boiler when the unit does not function well, and the draft turns over in the chimney or its strength is not enough to remove the smoke, and besides that, the combustion products do not evaporate into the atmosphere, but penetrate into the interior of the house.

Only in this case there is a need to increase traction, select and install the device. The creation of conditions in the chimney for additional vacuum contributes to the complete removal of gases. But all the same, the use of a smoke exhauster does not completely solve the problem.

All questions regarding the functioning of the chimney should be solved in a complex. Installation of deflectors is considered to be a simple and common method that provides additional draft in a smoke exhaust structure.

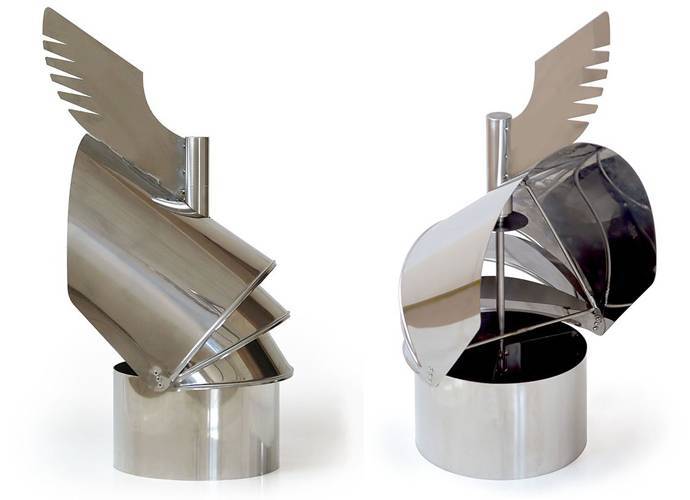

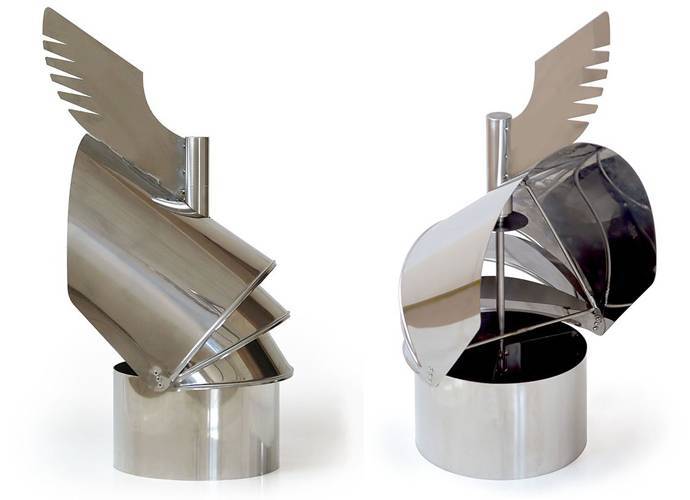

Types of traction fans

For solid fuel boilers and wood-burning fireplaces, several types of smoke exhausters are sold:

- boiler room (the design is discussed above);

- centrifugal duct;

- overhead;

- fireplace / stove (aka roof).

Various nozzles that improve natural draft should not be attributed to smoke exhausters - deflectors, round rotary elements and rotating weather vane. The effectiveness of these hoods depends on the wind speed, which changes with the weather.

The duct fan has its own casing with two connecting flanges or branch pipes. The unit is installed vertically or horizontally in the gap of the chimney. The device and principle of operation is similar to that of a boiler smoke exhauster.

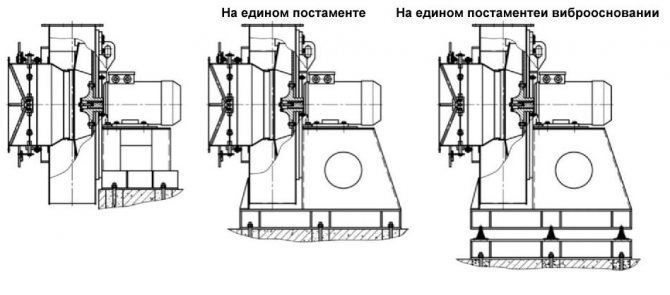

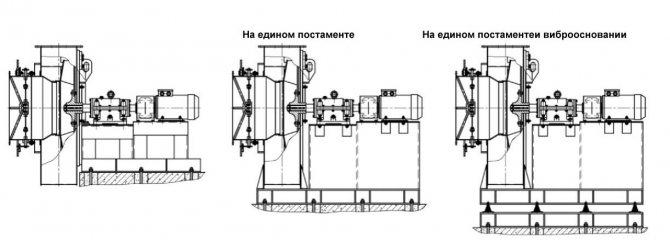

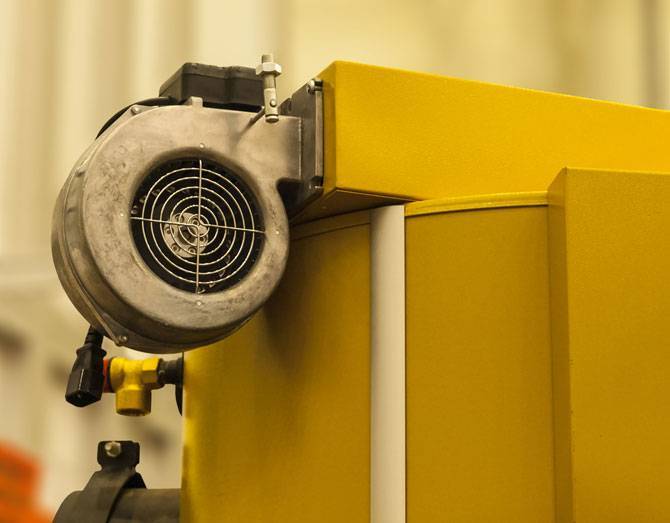

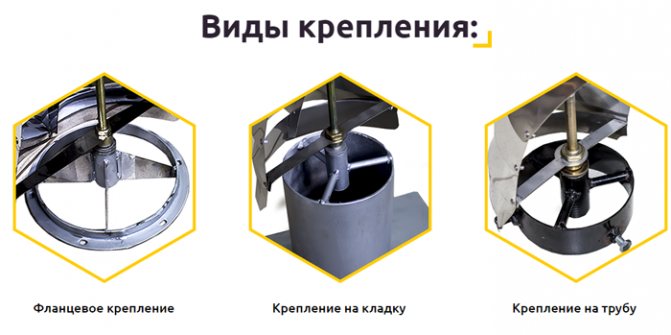

Surface-mounted smoke exhauster for a household boiler is equipped with a semicircular platform and clamps-ties. Installation is carried out on a vertical section of the chimney (not insulated):

- An opening is cut out in the pipe using a paper template.

- The impeller of the traction machine is inserted into the hole, the platform with the electric motor is pressed against the surface by the clamps.

- The connection is sealed with an asbestos cord glued to the inner side of the exhaust fan mounting platform.

Note. The overlay is matched to the diameter of the flue pipe. The installation process is demonstrated in the video.

Electric fireplace extractors are mounted on the head of a brick chimney and are fastened with expansion bolts. The power cable is routed through a pipe and inserted into the room next to the home stove.

To choose a traction machine, you need to be guided by 3 criteria:

- heat generator power, smoke exhauster models are designed for boilers performance up to 20, 30, 50 and 100 kW;

- the installation point is on the boiler itself, pipe or head;

- for overhead models - the diameter of the non-insulated gas duct.

Overhead (left) and roof exhauster (right)