Why do you need to insulate the chimney?

Effective insulation of the chimney will prevent its rapid cooling.

It also improves draft and reduces the likelihood of condensation.

Insulation of the chimney indirectly, but still prevents the heating of the building structures.

Basically, chimney insulation measures are carried out with chimneys of gas boilers.

Is it possible to use basalt insulation for a chimney

Basalt, used in the manufacture of chimneys, is one of the types of mineral insulation. Another name for the material is stone wool. Thermal insulation is made from gabbro-basalt rock waste. During the production process, the rock is crushed and melted, stretched into thin fiberglass.

The melting temperature in the furnace is 1500 ° C. The thickness of the pulled fibers is not more than 7 microns, the length is 5 cm. The resulting threads are passed twice through a press, preheated to 300 ° C. The resulting thermal insulation is distinguished by fire resistance, environmental friendliness, strength and other characteristics. It is not surprising that the largest manufacturers use fire retardant basalt insulation for chimneys.

Thermal insulation of the chimney with basalt wool, given the characteristics of the material, is quite justified. During the production process, the material acquires the following advantages:

- Low thermal conductivity - depending on the brand, the thermal insulation value of the material ranges from 0.032 to 0.048 watts per meter per Kelvin. Foamed rubber, expanded polystyrene, cork have the same characteristics.

- Hydrophobic - moisture settles on the surface and cannot get inside. Even in damp rooms or under the influence of atmospheric precipitation, stone wool retains its operational and thermal insulation characteristics. Therefore, the choice of basalt wool for insulation of a chimney installed outdoors is a really good solution.

- Fire resistance - basalt wool, without loss of strength, heats up to a temperature of 1114 ° C. At a higher temperature, the material begins to melt. This ability allows you to withstand even direct exposure to open fire. The temperature of the chimney, even when soot is ignited, does not exceed 1000 ° C, therefore basalt is suitable for insulating any smoke evacuation systems, regardless of the principle of operation and the type of fuel used.

- Strength and resistance to subsidence - the stone wool fibers are located both vertically and horizontally, which leads to the ability to withstand compressive loads from 5 to 80 kilopascals. During the entire service life, the material does not change its shape. Deformation is allowed no more than 10%.

Basalt wool for insulation of chimney pipes is recommended for use in the manufacture of fire-prevention cuts, installation in wet rooms, as well as outdoor decoration.

The characteristics of basalt fiber made it possible to significantly expand the scope of application, in comparison with conventional mineral insulation. In chimney systems, stone wool is used for the following purposes:

- Sandwich pipes - insulation of a steel chimney with basalt wool is carried out at the factory, which ensures high thermal performance and the absence of cold bridges. The construction of a sandwich pipe is distinguished by its light weight, heat resistance and good thermal performance.

- Ceramic pipes with an outer casing made of stainless steel - cylinders of basalt wool, 3-4 mm thick, are inserted into the structure. The absence of seams increases the already high thermal insulation characteristics.Ceramics installed in expanded clay concrete blocks are insulated during installation. You can wrap the chimney pipe with insulation with a thickness of 30/40/50 mm. Fix the cotton wool with clamps.

- Insulation of pipes of a single-wall steel chimney with basalt wool. For these purposes, it is recommended to use foil-clad basalt for the chimney. Foil stone wool reduces heat loss and protects the pipe from external influences of atmospheric precipitation.

- Insulation in penetrations - roof cutting for the chimney, as well as the passage in the floor slabs, in accordance with the requirements of PB and SNiP, is insulated with a non-combustible material. The gaps between pipes and structures are filled with stone wool. Fireproof foil-clad basalt insulation for chimneys is also used for the manufacture of fire-prevention cutting, protecting wooden elements of the building with it, located in the immediate vicinity of heating surfaces.

- Insulation of the chimney box - in order to prevent the appearance of oxides on brick channels, it is required to insulate the walls. For this purpose, rigid basalt slabs are optimal, allowing you to subsequently finish under plastering, laying ceramic tiles, etc.

Basalt is intended for insulation of chimney pipes located inside and outside the building, for the manufacture of fire breaks and chimney passage nodes through structures.

Shelter types

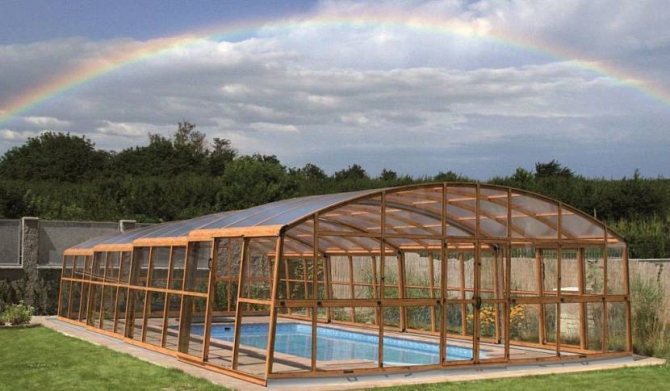

By purely design features, these structures are divided into two categories: awnings and pavilions. The first are roofs mounted on supports. The structure is open from the sides. The second is a closed type of building in the form of houses of various shapes.

Plain polycarbonate covered metal pool canopy

Immediately it is necessary to make a reservation that the design of the shelters does not impose any restrictions on them, but the properties of the materials used must be taken into account:

- The frame must be constructed of moisture-resistant materials. Today, preference is given to profiles made of aluminum alloys. Cheap, simple, plus long-term operation. At the same time, aluminum easily tolerates high humidity and temperature changes.

- Steel profiles. They are used only if the entire structure is eventually finished with moisture-resistant paint or other finishing materials. For example, ceramic tiles, which trim canopy racks.

- Lumber. Not the best option, but such shelters are still in use today. If wood is chosen as the frame, then it must be of high quality. Secondly, the tree must be treated with protective compounds that not only protect the material from moisture, but also prevent colonies of harmful microorganisms from forming on it. These are colorless varnishes, paint of different colors, antiseptic.

Outdoor pool wooden shelter

As for the transparent coating itself, there are only two options: glass and polycarbonate. The second option gradually pushed aside the first, because it has higher technical and operational characteristics. And the price of polycarbonate is much lower than that of glass. It is easier to work with, it is flexible, which makes it possible to install it on rounded structures. Its dimensions are larger, which means there are fewer joints.

Awnings

For many, a pool canopy for a summer cottage is an ideal option. It is simply easier to build with minimal costs, both financial and labor. The main thing is to choose the right sizes. As for the form, it all depends on the imagination of the customer.

It must be said that the sheds over the pools do not completely solve the problem of littering the water mass. From the sides, the structure is open not only to all winds, but also to foliage, insects and other troubles. In fact, the canopy serves only as a shelter from the sun's rays.

Shed pool cover

But as for the variety of design, there are no boundaries. Shed, gable, as well as several slopes are offered. Arched-type designs are very popular, which are increasingly appearing in summer cottages. Although this is justified by the flexibility of polycarbonate and the simplicity of the construction of this type of awning.

Purely structurally, these structures are a polycarbonate pool roof mounted on support pillars. There are no other elements in this design.

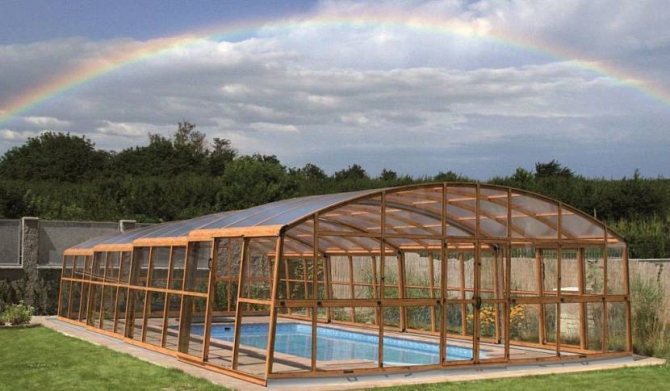

Pavilions

This is a completely different type of building, different from the previous one and performing slightly more functions. First, it should be noted that the pavilion completely covers the pool from all sides. Of course, there is a passage in it (with or without a door), there are window openings that open.

Swimming pool enclosure made of metal structures and polycarbonate

If we consider it from the constructive point of view, then all pool pavilions are divided into two groups:

- by height;

- by the way of closing.

The first group has two subgroups: low and high shelters.

- Low structures have a height of 1-1.5 m. Their main purpose is to protect water and structures from littering, atmospheric and sun rays. Usually in a building of this type, a small hole is made through which you can get into the pool itself, that is, into the water. This is the least expensive option. Some owners of such pavilions cover them with plastic wrap. The presentability of the appearance of such a shelter drops sharply, but in the summer it performs its functions one hundred percent.

Low type pool enclosure

- High. There is no height limit here. Anything above 2 m falls into this category. In principle, such pool pavilions are nothing more than a fairly large recreation area. And if you increase its width and length, without limiting only the boundaries of the pool itself, then inside the zone you can install furniture, household appliances, and even a barbecue. The main thing is to correctly install the smoke exhaust system.

High pool cover in the form of a large relaxation area

The very category of high shelters can be divided into two groups: completely enclosed and not completely. The second part consists of structures with a lower level of open space. A more economical option in terms of construction. But it loses to the models of the second group precisely by the absence of a part of the transparent fence, through which debris gets inside the structure.

There is another division into two groups:

- Stationary structures. This includes all the models discussed above. That is, they are installed in one place, do not move, do not carry over.

- Sliding. Canopies with a "telling" name - which can be moved and resized.

The sliding roof for the pool is, in fact, the same pavilion, only it is divided into several compartments that move on rails. Such a design can be clearly seen in the photo below.

Swimming pool with retractable polycarbonate roof

By the way, it should be noted that sliding models are not necessarily the designs shown in the photo. There is a different approach to the implementation of this method of covering hydraulic structures. For example, if the pool is round, then the pavilion above it is built in the same shape. This means that the sections will be displaced relative to each other along the circumference. For example, as shown in the following photo.

Round pool sliding roof

The sliding structure itself is uncomplicated. The main thing in it is to correctly install the rails along which the sections will move. Therefore, the very model of the shelter is selected according to the shape and size of the bowl. And here everything depends on whether the canopy will cover only the water surface, or a recreation area is organized under it. Based on this, the parameters of the sliding pavilion are selected.

The rails are attached to a solid foundation, usually concrete, with anchors. They are laid exactly according to the distances specified in the instructions. Changing the installation dimensions even by negligible values leads to incorrect operation of the sliding roof on the pool.

Types of basalt insulation for thermal insulation of chimneys

The choice of a brand of basalt wool depends on the desired thermal performance. The material is selected depending on the features of operation, the type of chimney design. You will also have to decide on the appropriate insulation for the manufacture of roofing cuts and nodes of passage through the wall, and floor slabs.

Heat-insulating basalt chimney shells are used in industrial and domestic smoke evacuation systems. By wall thickness, they are subdivided into several grades: 55, 75, 90, 110, 150, 200. The shells are supplied in lengths of 1 meter each.

We suggest that you familiarize yourself with: Installation of chimneys from sandwich pipes instructions

When installing pressed basalt cylindrical insulation, they are guided by the requirements set out in SNiP 2.04.14-88, and specifically, by the following instructions:

- The cylinders have a longitudinal seam for easy installation on pipes. The insulation is fixed with bands made of thin sheet galvanized or stainless steel, with a thickness of at least 0.8 mm. Alternatively, stainless steel or black steel knitting wires are used, with diameters of 1.2 and 2 mm, respectively.

- Non-combustible basalt heat-insulating elements of the cylinders are installed at intervals along the seams. The joints are insulated with aluminum tape.

- Installation work starts from the flange. Foil insulation does not need a protective coating. In other cases, a casing or metal casing is made for insulation.

The use of basalt insulation in the chimneys of a sandwich system, in the form of heat-insulating cylinders, is limited to pipes with a flue gas temperature of no more than 300 ° C.

Basalt mats are used to insulate heated surfaces at temperatures from 450-700 ° C. Operation methods are regulated by GOST-16381. Insulation is selected according to the following parameters:

- Density.

- The type of cladding.

- One or two-sided material stitching.

- Operating temperature limit.

First of all, you need to pay attention to the declared density of basalt wool. For connection to solid fuel units, stone wool with a coefficient of 30-125 kg / m³ is suitable. The material does not have a covering layer and is able to withstand a constant working temperature of 700 ° C.

Non-combustible basalt insulation of high density, used in the manufacture of nodes of passage, as well as insulation of chimneys of any design.

For external and internal insulation of single-wall pipes, a basalt mat with foil is used. When installed inside a building, there is no need for a protective sheathing. The foil layer is connected to the insulation by means of stitching.

It is not recommended to use stitched mats for the wall duct of the chimney. It is possible to install mats for insulating ceilings at the place of passage of chimneys, making fire-fighting cuts.

One of the novelties on the market for thermal insulation materials is basalt fiber board. The main characteristics of basalt cardboard:

- With a small thickness, it has a high density and is able to withstand temperatures up to 900 ° C.

- It is used as refractory coatings during the installation of wood and solid fuel stoves, boilers.

- Resistant to vibration and moisture.

- Service life is not less than 50 years.

- Basalt cardboard thickness: 5/10/14/19 mm.

- The creation of multilayer structures is allowed to increase the thermal insulation properties.

It is quite simple to insulate a metal chimney by wrapping it in basalt foil cardboard.The material bends well around the circumference. After wrapping the pipe, the insulation is fixed with clamps.

It is allowed to insulate the chimney with foil-clad basalt cardboard for all types of flue systems. After installation, there is no need to make an additional protective structure.

The basalt shield is installed as a fire cut, protecting the wooden walls adjacent to the heating pipe.

Why is it necessary to insulate the chimney

The use of heaters for insulating chimneys will prevent their destruction due to the formation of condensation on the inner surfaces and sudden temperature changes, violation of the tightness of the roofing cake due to increased heating and reduce the fire hazard.

Moisture on contact with the settled soot forms chemically active components, which negatively affects the properties of the materials. Oxidation processes are stimulated on steel structures, and brickwork collapses at the seams.

In addition, the presence of high humidity in the chimney significantly reduces the draft and worsens the combustion of fuel in the furnace. The result is a reduction in heat output from the oven and an increase in the time it takes to heat the room to the required temperature. Another negative factor is an increase in the amount of soot, which easily sits on moisture, and after drying forms a layer that is difficult to remove.

Laying the insulation will allow the dew point to be displaced from the main material of the chimney. Thanks to this, moisture will not accumulate in it and reduce the life of the structure. By insulating the chimney, heat loss from the stove will be reduced.

Basalt insulation brands for chimney insulation

Various manufacturers, the consumer are offered more than several dozen names of basalt heaters. Some are manufactured abroad, others at domestic enterprises.

Judging by customer reviews, the products of the following companies are popular:

- Basalt wool Rockwool is produced at the enterprises of the company of the same name, located in Denmark. In terms of its characteristics: hydrophobicity, sound and thermal insulation, as well as mechanical strength, Rockwool significantly outstrips analogues of other manufacturers. Basalt wool Rockwool is used by manufacturing companies for insulating finished ceramic chimneys Schiedel, Effe2 and others.

- Basalt wool URSA - originally made in Italy. Today the company has 14 large production centers located in Europe, the Middle East and Asia, which, as a result, could not but affect the quality of the products. The URSA company specializes in the insulation of industrial and domestic premises, and is popular due to the good price-quality ratio of its products.

- Izovat basalt wool is a heater made in the near abroad, in Ukraine. The product range includes mineral slabs with a density of 30 to 200 kg / m³. It is worth paying attention to a brand intended for insulating brick chimney ducts with subsequent plastering of the surface. The thickness of Izovat boards is from 30 to 200 mm.

- Paroc basalt wool is a Swedish company specializing in the production of stone wool since the 30s of the last century. Paroc production workshops are located exclusively in the EU countries, which allows maintaining a high level of quality and full compliance with safety standards in force in Europe. Paroc basalt cylinders can be used to insulate iron chimney pipes. To this end, the company has developed the Paroc Pro Section and Paroc Pro Bend cover layers, which provide maximum thermal insulation and protection for steel structures.

We suggest that you familiarize yourself with: How to impose a brick on a metal stove in a house: how to overlay a heating boiler, an iron stove, which brick is better to make

When choosing basalt for pipe insulation, it is mainly necessary to focus on the heat engineering characteristics specified by the manufacturer. On the basis of large concerns, modifications have been developed specifically for smoke extraction systems.

Gas boiler pipe insulation

In order to choose a heater for the chimney of a gas boiler, it is necessary to choose and use no less high-quality, non-combustible materials. The most common option is to use sandwich pipes. The design of which consists of two pipes with different diameters. This is necessary in order for a product with a large cross-section to enter the second, and thereby form an additional protective layer.

How to insulate a metal chimney pipe - materials and guidance:

- Small holes must be made on the roof slab. Their cross-section should exceed the diameter of the chimney by about 25-30 centimeters;

- We produce insulation using basalt wool. There should be no gaps after winding;

- We additionally fix the insulation with wire;

- Large pipe casing, must be fixed with tapes and ties;

- The metal sheet located near the riser must also be insulated with asbestos, expanded clay or clay.

Features of chimney insulation with basalt wool

In addition to the correct choice of basalt insulation, you need to worry about observing the installation rules. As practice shows, the following norms are especially often violated:

- The thickness of the layer of basalt wool in penetrations through wooden structures is at least 5 cm.The distance from the supporting beams is at least 1 m.

- If you need to lay the material in several layers, correctly lay out the fire-resistant basalt slab with an offset to overlap the joints of the lower sheet with the upper one. The same rule applies to the installation of a cylindrical insulation. The longitudinal seam of each subsequent shell is shifted 180 °.

- The device for the passage of the chimney through a wooden floor using basalt wool provides for the use of fire cutting. To combustible material, from the heating surface must be from 50-100 mm. The gap is filled with stone wool.

- The thickness of the basalt fiber in the chimney should be no more than 40 mm, for external insulation, up to 100 mm. The density is selected depending on the operating conditions. For insulation of ceramic chimneys connected to solid fuel boilers, basalt wool with a density of 100 to 200 kg / m³ is used.

- It makes no sense to use high-temperature basalt wool for thermal insulation of a chimney connected to a gas or oil-fired boiler, since the temperature of the flue gases rarely exceeds 200-300 ° C. Installation of a cylindrical insulation will be optimal.

- Calculation of the required amount of basalt wool for insulating a steel chimney. The required material thickness is selected. On the packaging of the insulation, the approximate consumption of cotton wool is indicated for different layer thicknesses. It remains to calculate the dimensions of the circle in centimeters and the length of the pipe. After that, the number of packages is calculated.

- After insulating a single-layer pipe with non-foil-clad material, it is imperative to manufacture a protective structure.

In some hardware stores, I can cut packages with basalt insulation in two, or sell mats individually. This allows you to purchase the exact amount of material and avoid overpayments.

The main disadvantage of basalt insulation is its cost. Otherwise, in comparison with any other types of thermal insulation, basalt undoubtedly wins. The advantages of the material include:

- Low thermal conductivity - even at an exhaust gas temperature of over 500 ° C, basalt wool heats up no more than 30 ° C.During a short-term ignition of soot and a temperature jump up to 900 ° C, the outer circuit of the sandwich pipe will not heat up more than 45 ° C.

- Non-combustibility - the material can withstand direct fire from a gas burner without igniting. Wool begins to melt after exceeding 1100 ° C. Therefore, you can lay the basalt insulation close to the chimney and not worry about the safety of the room during the entire period of operation.

- Easy installation - mats and sheets can be easily cut with a regular painting knife. The material is fixed with clamps or knitting wire. If you lay basalt wool with your own hands when installing chimneys, you can significantly save on work.

- The specific weight of even basalt refractory wool is 30 kg / m³, respectively, after insulation, the mass of the chimney structure does not increase much.

Basalt wool has no analogues in its characteristics and is the optimal solution when choosing a heater for a chimney. The only thing that limits the popularity of the material is the high cost associated with the peculiarities of the production process.

Warming rules

Depending on the material, chimneys can be:

It is imperative to insulate with non-combustible material only those areas that come into contact with cold street air.

It is also allowed to insulate parts of pipes running in unheated attics.

It is impractical to isolate the parts of the chimneys passing inside the heated premises, since they are an additional source of heat. An exception is made for metal pipes, which heat up so that you can burn yourself when you touch them. But even in this case, sometimes it is enough to fence such sections of chimneys with mesh screens. Such solutions are often used in country baths.

Steel chimneys must be insulated in any case, and the thickness of the layer of non-combustible thermal insulation should be as large as possible. Brick pipes with a wall thickness of a brick (25 cm) or more need not be insulated if the air temperature does not drop below -20 ℃.

Ceramic chimneys are usually a construction of products with a honeycomb structure. Such blocks are in themselves heat-efficient and do not need insulation.

For thermal insulation, only non-combustible heat-resistant materials are used, which ensure high fire resistance of the entire building. The value of the fire resistance of pipe insulation must be at least EI 45.

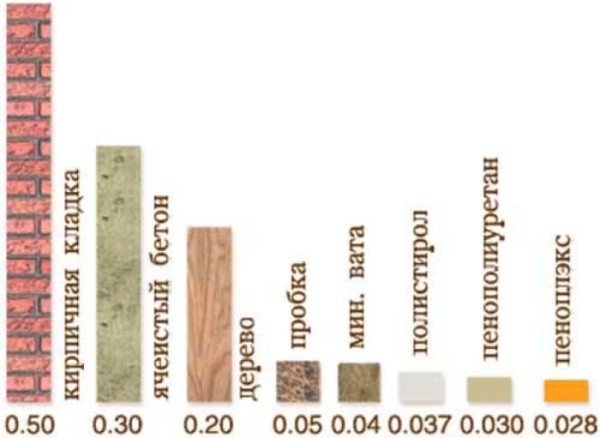

The main parameters of heaters

Thermal conductivity

When choosing a heater, the main attention is paid to its most important parameter - thermal conductivity, which does not at all depend on the density of the material, as many mistakenly believe. Heaters of the same density, but made using different technologies, may have different heat conductivity.

The lower the coefficient of thermal conductivity, the more efficiently and better the selected insulation material keeps heat in the house.

Coefficients of thermal conductivity of various materials (W / mK)

Water absorption

Another very important characteristic of an insulating material is the ability to absorb moisture. Water vapor is always present in the air. In a certain situation, it can turn into condensation inside the insulation, significantly reducing its thermal properties.

In this case, vapor barrier is required. This question becomes relevant if the loggia is also insulated.

Fire resistance

Insulation, like the entire structure of a house, especially a wooden one, must also have a fire-fighting property. This is especially important for insulating chimneys, fireplaces and other elements of the house, which are directly exposed to strong heating or direct contact with fire.

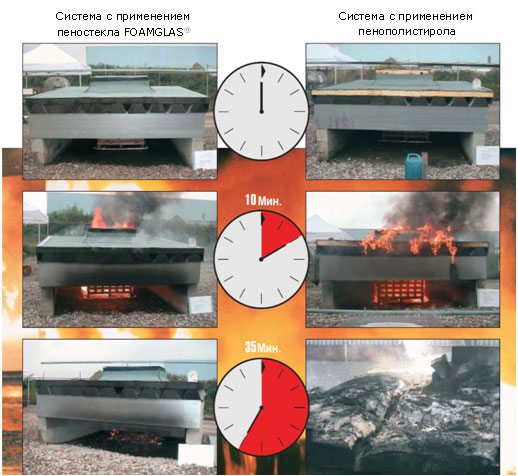

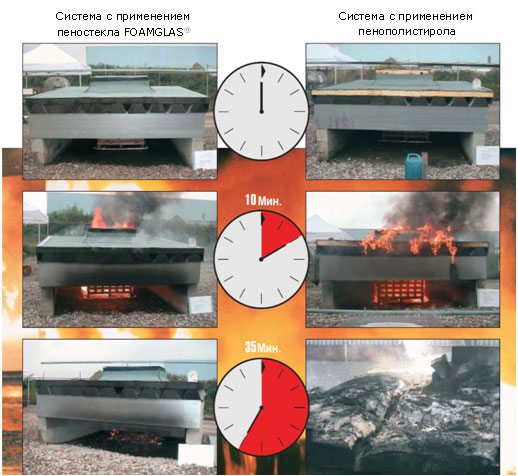

Comparative fire tests

Insulated chimney design

Qualitatively, the construction of a heat-insulated chimney can be described as a pipe in a pipe, in the space between which insulating materials are laid. That is, in fact, it is a multi-layer sandwich construction. A steel pipe, brickwork, a wooden box covered with asbestos plates can be used as external protection.

Heat-resistant insulation is located between the two pipe frames. Its fastening is carried out with glue, sealant or special fasteners. The inner pipe is the chimney itself for removing flue gases from the stove.

Types of fire insulation

Mineral wool

Photo of mineral wool

Mineral wool insulation is supplied in slabs or in rolls in the form of heat-insulating mats. Plates are more convenient and easier to use for insulation of roofs, floors and walls. Mats are more practical to use for pipes and various non-straight surfaces, as well as industrial equipment.

Cotton wool is made from sand, cullet, soda, and other components, which, after heating to a high temperature, turn into fiberglass. Then the material is impregnated with a special resin and pressed.

The most important advantage of mineral wool is its heat resistance. Cotton wool is a non-combustible insulation. Melting of the material begins when heated above 1000 ° C.

Therefore, such a fire-resistant insulation is effectively used by builders to insulate heat-resistant partitions, baths, chimneys and other structures.

Mineral wool insulation has also found application for the insulation of curtain facades and pitched roofs due to its excellent characteristics:

- low thermal conductivity;

- good sound absorption;

- high hydrophobicity (vapor permeability), which allows the building to breathe, thereby preventing the appearance of mold and mildew.

This refractory insulation consists of a layer of polyethylene foam, which is covered with polished aluminum foil on one side (or on both sides). It is a thin, very lightweight and completely environmentally friendly material with good flexibility.

Due to the low coefficient of thermal conductivity of foamed polyethylene, foil insulation is characterized by high resistance to heat transfer.

Polished aluminum foil is highly reflective. The reflection effect is up to 97%. Having the above properties, this type of insulation has excellent ability to reflect infrared (thermal) radiation, preventing heat loss to the outside.

Thanks to the use of foil-clad insulation, energy costs for heating a building or room are significantly reduced. For this reason, it has found wide application for thermal insulation of hot (cold) water supply systems, heating systems, systems intended for air conditioning.

With its help, the interpanel seams and window openings are sealed. It is excellent for thermal insulation of floors and walls in both residential and public buildings.

Non-combustible thermal insulation for horizontal slabs

Expanded clay can be placed under a wooden floor or screed.

When we talk about horizontal slabs, we mean:

The methods of installing insulation on these structures are the simplest, while no loads are applied to the materials. Therefore, any of the above materials is suitable as a non-combustible insulation for the floor. Preference is given to those in which mice do not start.

As you know, rodents bring a lot of problems, especially in the country. In the house where you live permanently, this problem can be solved quite simply - you need to get a cat. In a country house, it remains to either catch the mice with traps or poison.

Both options are losing.

Mice reproduce so quickly that they can be destroyed with traps for a long time.Placing the poison is fraught with the fact that the rodent dies in its hole, that is, under the floor, as a result of which a strong smell appears. Mice won't start in:

- vermiculite, perlite and expanded clay, even mixed 50/50 with sawdust; polyurethane foam and foam insulation; granulated foamed glass.

To choose non-combustible insulation for the roof, you need to build on the roof structure. If it is almost horizontal with a slight slope, then if you wish, you can even use bulk insulation. If the slope is significant, then only mineral wool or liquid insulation is suitable.

What are the requirements for insulation

The constant availability of water in the household not only ensures the comfort of living, but also avoids the additional costs required to restore a site that has failed due to freezing.

The following requirements are imposed on the material used as insulation:

- Simple assembly... This requirement is due to the lack of basic skills in the field of construction among homeowners, whose forces, in most cases, are laying insulation for heating or water supply pipes.

- The duration of the operational period... For high-quality insulation, its duration is longer, and the protection is more reliable.

- High level of fire safety... One of the main requirements for the material for insulation is its ability to self-extinguish, which minimizes losses in the event of a fire hazard.

- Tightness... If the material is permeable to moisture, it will not be able to protect the pipeline from freezing.

- Multiple use... This criterion directly depends on the duration of the service life.

- The cost... The price should be reasonable, but within reasonable limits. Excessive savings on insulation can lead to additional costs due to its poor quality. Replacement of cheap insulation may be required after a year of its operation.

Polypropylene

PP heating pipes are probably one of the most affordable and popular solutions. Among the advantages of polypropylene systems are low weight of the created structures, excellent hydraulic properties, no corrosion and a huge variety of fittings, adapters and special locking elements. Manufacturers produce this material with a series of all-plastic and multilayer PPR and PP-RCT pipes in the diameter range of 16-125 mm. All-plastic pipes are designed for systems with water temperatures up to 70 ° C. Their characteristic feature is a rather high rate of thermal change - 0.12 mm / m ° C. Shrinkage or expansion of pipes occurs due to temperature differences during operation and installation. Multilayer pipes are produced with a reinforcing layer of aluminum, glass or basalt fibers. This material is preferable for use in systems with a hot heat carrier (up to 90 ° C), while their coefficient of thermal change is much lower (0.05 mm / m ° C). It is recommended to lay the heating pipeline inside building structures, in the grooves of floors, walls, ceilings, or to cover it with a hinged decorative coating. In places where heating devices are connected, it is recommended to use more aesthetic metal fittings. During the operation of aluminum-reinforced pipes, swelling of the top layer of polypropylene may appear. This does not affect functionality and is not a reason for replacement. The minimum installation temperature is + 5 ° C. To connect the polymer system to a heating boiler or boiler, in order not to overheat the pipeline, it is recommended to install a metal pipe 1.5-2 m long. The parts are joined by polyfusion, electrofusion or butt welding. The homogeneous seam that occurs during the installation process is highly reliable, and, if properly performed, creates a monolithic structure.If it is necessary to create collapsible structures, you must use special threaded fittings. Self-threading of polypropylene heating pipes is not recommended. FUM tape is used to seal threaded connections.

Metal-plastic

Due to the multilayer construction, metal-polymer heating pipes are characterized as extremely durable and reliable material, while being available to a wide range of consumers. The pipeline consists of a one-piece, butt-welded aluminum foil with a polyethylene inner and outer layer. The layers are bonded to each other with glue, providing form stability and solidity of the structure. Manufacturers produce these products 16-50 mm in diameter and are delivered in coils or short sections. The maximum temperature of the carrier is 95 ° С, the limiting temperature is 110 ° С. When installing heating systems, the standard requirements for pipeline insulation are applied. The unit can be mounted openly or inside structures without the use of a protective shell. During installation, it should be borne in mind that the metal-plastic pipeline is afraid of sunlight. System elements are connected using several types of connectors. One Wavin company offers several fundamentally different sets of metal-plastic pipe fittings and each of them has an original design and advantages in use. Traditionally, press fittings are used in heating systems. The installation process using these connectors is simple, but requires a special tool. The body of the fitting is made of a material comparable in strength to metal - polyphenylsulfone. The press sleeve is made of stainless steel. In terms of physical properties, the materials of the connector work as a whole, even with significant temperature differences. During installation, the end of the pipe is calibrated, chamfered and inserted into the fitting. The tightness of the insert can be controlled through the technological windows on the press sleeve. For crimping, an electric or hand tool is used. The pipe bends easily by hand and retains its shape. In order not to create a crease, you need to use a bending spring or pipe bender. When laying long runs, allowance for thermal change in length must be taken into account.