If water from a heating boiler (its temperature often reaches 90-95 ° C) is directly fed into the circuits of the underfloor heating system, it will be too hot in the room. According to the standards, the coolant entering the circuits must have a temperature within a certain range of 40-45 ° C. To provide such operating conditions, a special device is used - a three-way valve.

The purpose of the valve for underfloor heating and its types

The design of the auxiliary heating system can include the installation of a two-way or three-way valve on underfloor heating in a mixing unit. Both types of devices provide continuous thermoregulation of the liquid heat carrier. The water floor can be connected to both centralized and autonomous heating. In both types of systems, the temperature of the coolant is 650C-850C. If such hot water gets into the contours of the warm floor, it is impossible to create an atmosphere on the surface of the floor covering that is comfortable for walking barefoot and being in the room.

The floor screed perfectly accumulates heat, so the temperature on the floor surface will be over 450C. Which is unsafe for the flooring itself. The permissible surface temperature should range from 180C to 330C. To ensure such conditions, it is necessary to cool the heated liquid before it is introduced into the system circuits. This procedure is carried out by a mixing valve for underfloor heating, which can be bought in specialized stores.

If one cannot do without them in auxiliary heating systems, then which one to choose - two- or three-way? It is very simple to decide:

- The supply, or two-way valve for a warm floor is a simpler, and therefore more resistant to loads, device. Installing it will not overload the system. The device takes care that sudden and unstable surges of the flow are excluded. It is used in systems for heating air masses from the bottom of small-scale rooms (maintenance of an area of no more than 190 m2). In this case, a high-temperature heating system must provide heating of a liquid heat carrier exclusively for the circuits of a warm water system. In fact, a two-way thermostatic valve for underfloor heating performs an increase in the temperature of the coolant by mixing hot liquid coming from the boiler to the cooled one coming from the return line.

- Structurally, a more complex three-way tap for underfloor heating is a device that performs the function of mixing hot and cooled streams, and then dispensing. It is used in heating systems for objects with an area of more than 200 m2 and when connecting a water-heated floor to a centralized or autonomous heating network. Its principle of operation is described above.

Since a three-way mixing valve for a warm floor (it is called a thermostatic, thermo-mixing valve) is a more versatile device, it is used in 8 out of 10 cases. However, if the device is installed incorrectly in the system, emergencies may arise.

Features of automatic devices

To ensure efficient operation of the thermo-mixing valve, the formation of a mixed liquid flow must be continuously monitored. It is better if this is done automatically.

Automatic control devices are controlled by electrical or pneumatic components.

- Electric actuators are relatively inexpensive and easy to connect.This largely explains their popularity and wide distribution. On the other hand, their dependence on power supply and the need for periodic maintenance make them insufficiently reliable.

- Pneumatic actuators are more expensive and the wiring procedure is more complicated. However, these shortcomings pay off with a long service life and complete autonomy.

We recommend that you familiarize yourself with: How to choose a needle valve for a pipeline?

Additional components of the mixing unit

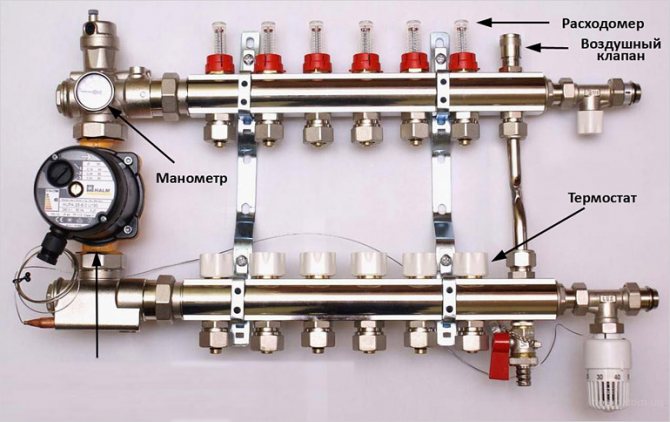

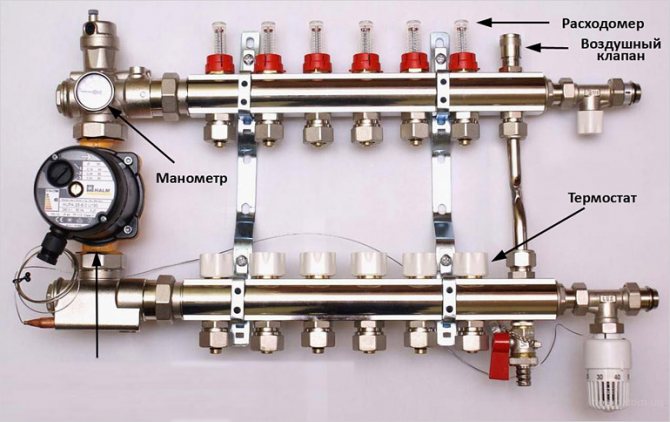

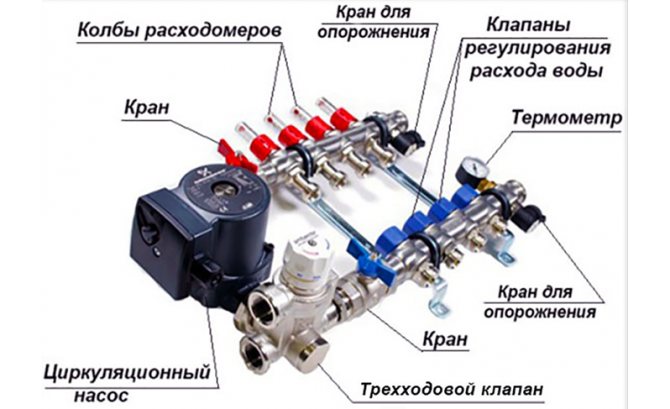

It is not only the three-way thermostatic mixing valve for underfloor heating that ensures the efficient operation of the system in every single room. The node includes:

- Thermal head. Ensures the continuity and automatic operation of the auxiliary heating system for air masses. If the purchased two- or three-way valve is already equipped with a thermostatic element, then it is not necessary to install it additionally.

- Servo. They produce electrical and mechanical devices, as well as equipment with a remote control method. The device is designed to physically influence the thermo-mixing valve for underfloor heating, giving a command to open and close the damper. Thanks to him, it is possible to supply a coolant with different temperature characteristics to different rooms of the house.

Equipment characteristics

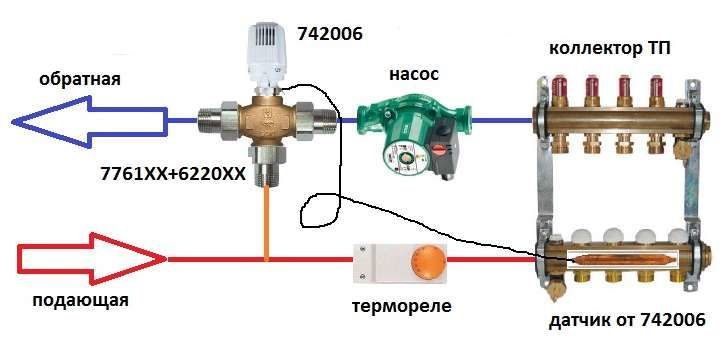

The coolant from the boiler passes through the pipe line to the collector. From it, the liquid enters the floor pipeline. Giving off heat, it returns back to the collector, which has a separate return outlet for the cooled heat carrier. The circulation pump pumps water back into the boiler.

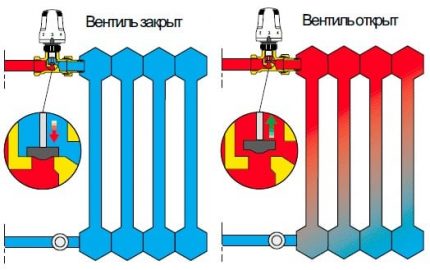

With manual control of the temperature regime, valves are installed on the circuit with cold water and a high temperature coolant. If the room has warmed up well enough, then the hot water valve is closed. If the room is cold, then the valve is opened.

For automatic regulation of the heating mode, a three-way mixer with a thermostat and an external temperature sensor is installed. This system forms a thermostatic valve. It is installed at the inlet to the manifold. The equipment is made of brass or bronze.

- The three-way valve has 3 outlets for hot and cold water and for the heating medium, which is supplied to the floor line. On the body, markers indicate the direction of flows of different temperatures.

- A mixing chamber is provided for mixing liquids of different temperatures.

- A thermostat with a temperature controller is located on the body.

- The temperature sensor is located on the thermostat.

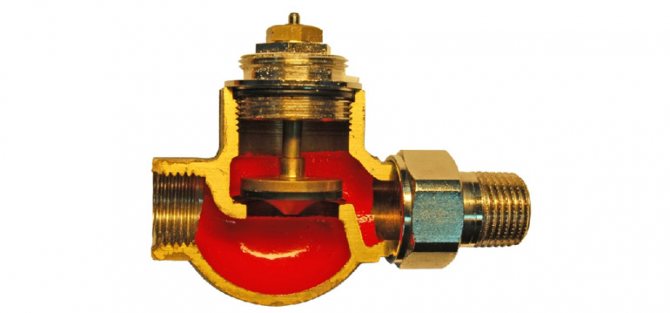

- The valves close off the cold and hot flow outlets. They can be disc-shaped or needle-shaped. Their work depends on the thermostat.

- The thermostat is a system that consists of a liquid capsule and a spring-loaded stem. Valves are attached to it.

- The temperature sensor has a digital panel on which the heating modes are indicated.

We recommend: What can be the base for underfloor heating?

The thermostat can be located in the thermal head or in the actuator. The devices have a different circuit, but the same principle of operation. The thermal head is a thermostat, which works with the help of a liquid: it is sensitive to temperature changes.

The servos are powered by the electrical network. The liquid is contained in a container. It contains a heating plate. The servo is installed on the manifold.

The three-way mixer is designed for heating systems of large areas. In separate rooms or in country houses, a two-way valve is connected to the collector. It is installed on a circuit with a high temperature coolant. Water flows through it in only one direction.

How to choose a valve for a warm floor?

The popularity of water floors, which are increasingly used to heat private houses and country cottages, has given impetus to the emergence of a huge selection of models on the market. But then the question arises, which three-way tap to install on the warm floor, which manufacturer to prefer. After all, the abundance of goods complicates the purchase. When selecting a device, experts recommend determining in advance what type of device is needed - two- or three-way. Then choose a manufacturer:

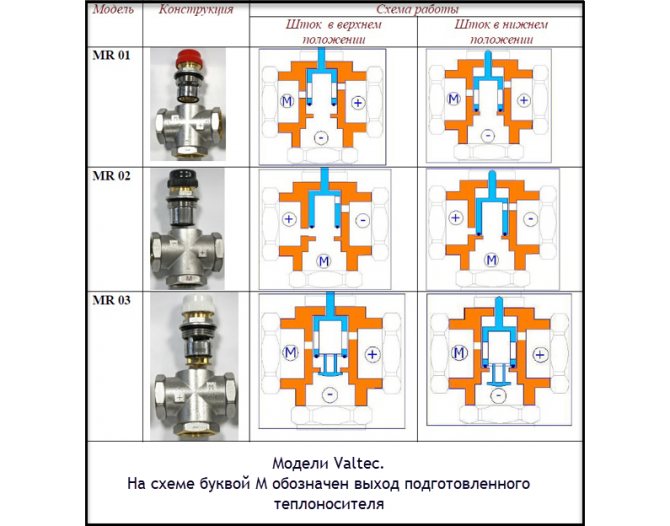

- Valtec. The company presents Russian-Italian products on the market. Their main advantage is a budget price with excellent physical and technical qualities. The manufacturer gives a 7-year warranty on the purchased three-way tap for underfloor heating with a thermostat. Products are supplied with quality certificates, a technical passport, a recommendation sheet for installation and a warranty card.

- Esbe. The Swedish company offers high quality floor heating taps made of innovative materials. The devices are maximally resistant to operating conditions, reliable and visually attractive. When buying Swedish devices, it is recommended to carefully consider the technical characteristics of the equipment. There is a small chance of parameter mismatch. The cranes are supplied with certificates and warranty cards, the operational period is over 5 years.

- Honeywell. The thermostatic mixing valve for underfloor heating of the American company Honeywell is distinguished by its high manufacturability and excellent design. The main advantages of its products are practicality and simplified installation. The design is designed in such a way as to facilitate the installation of equipment as much as possible. Errors are excluded. The company is proud of its innovative developments, which it implements in the manufacture of devices. This makes them more efficient and reliable, but also more costly.

From the listed manufacturers, consumers buy three-way valves for underfloor heating that have already been tested by time. But do not rely only on the quality of the equipment, because even the most stable and reliable device will not be able to protect the system if it is installed incorrectly. In this case, the choice should also be based on the throughput of the unit. This parameter should be clarified in the technical documentation for the equipment. When designing a system for auxiliary heating of air masses from the bottom of the room, its power, throughput, heat loss, etc. must be calculated.

Principle of operation

In the case of the device, in the front and right branch pipes, the coolant circulates until its temperature reaches the set value. The thermostatic valve is installed in order to maintain the set outlet temperature by mixing cold or hot water into the liquid. If the parameters do not converge, then the external drive of the device acts on the stem. When it starts to move, all 3 channels in the body open. And, as soon as the temperature parameters stabilize, the front inlet is closed.

There is a wide variety of thermostatic valves and 3-way valves. One of the varieties is similar to a ball valve. In this model, the diverter valve consists of a sampled ball rather than a cone seat. To redistribute the coolant, the actuator acts on the stem with a fixed ball, rotating it. Such valves have a low flow capacity, therefore they are used only in domestic heating systems. In short, a thermostatic valve sets the required water temperature.

Installing a thermo mixer for underfloor heating

Correct installation of a three-way valve on a warm floor consists not only in connecting the equipment to the pipeline, but also in carefully checking it. Mistakes can lead to big trouble.Installation of the device is carried out when connecting the collector and before pouring the concrete underfloor heating. At this stage, complete assembly of the system is performed and its check is performed at the temperature of the carrier not higher than 22-250C. The build quality testing period must be at least 24 hours. After making sure that the system is working correctly and there are no leaks, you can complete the installation.

To connect a three-way valve for heating with a thermostat for underfloor heating, use ordinary wrenches. With their help, the internal / external thread of the device is screwed onto the fitting or pipe union nut. The tightness of the connection will be ensured by sanitary flax, FUM tape or other materials. Special silicone gaskets are supplied with the tap. When working, you need to make sure that they were laid in the socket, otherwise a tight connection cannot be achieved.

During installation, avoid:

- excessive impact on the threaded connection;

- distortions of pipes, especially at the joints;

- loose or loose screwing.

The installation of the crane is a crucial moment, since its operation and the threaded connections obtained during installation will be exposed to moisture and high (fluctuations) temperatures. Therefore, all work must be carried out carefully and accurately. The process of assembling the mixing unit is completed by adjusting the three-way valve for underfloor heating using a head. If you are not confident in your own abilities, it is better to leave the installation and purchase of the necessary equipment for assembling the system to professionals. Remember: a warm water floor can cause not only damage to the flooring, but also the inability to create optimal comfortable living conditions in the rooms. For all questions of underfloor heating, please contact our specialists.

Expert advice

A few tips from professionals will help the apartment owner install and configure the thermostatic valve with his own hands and according to all the rules:

- It is important to mount the device in such a way that the direction of movement of the water coincides with the direction shown by the arrow shown next to the marking on the body, otherwise the operation of the thermostatic valve will be incorrect.

- For underfloor heating systems, it is better to choose thermostats with a side valve - this makes it easier to access the setting.

- In public areas, thermostatic valves with remote control or presetting must be used for installation to protect them from outside influences.

- To seal the threaded connection, do not use fum tape, but polymer or linen threads with heat-resistant paint. With heating and significant temperature differences, thermal expansion of the pipes occurs, the density of the tape laying may be disturbed, which will lead to the formation of a leak.

- It is more expedient to place the valve on the supply pipe.

- The distance from the floor to the installation site of the thermostatic valve should be at least 40-60 cm. Initially, manufacturers set them up to capture temperature changes at this level. If it is necessary to change this parameter, then additional configuration of the device is performed.

- The thermostatic head must be installed horizontally on the valve and turned towards the back of the room. If the thermal head is installed vertically, the warm air from the riser will interfere with the normal operation of the sensor.

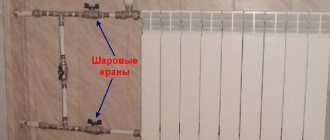

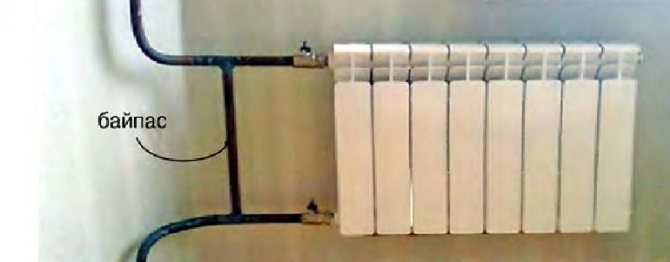

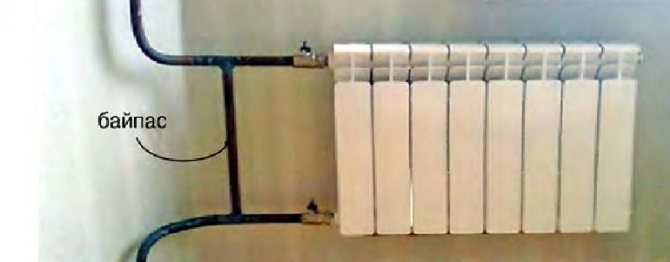

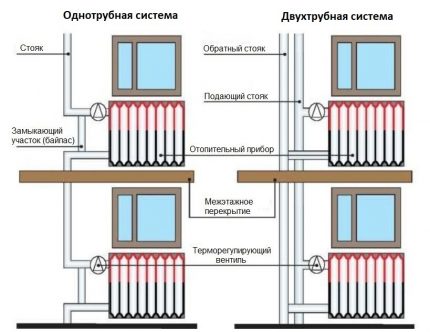

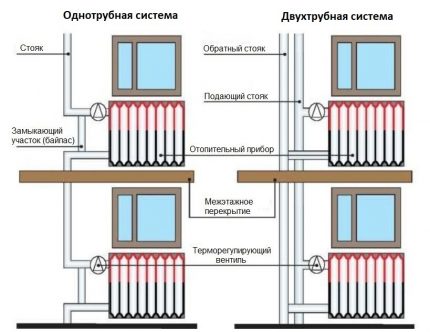

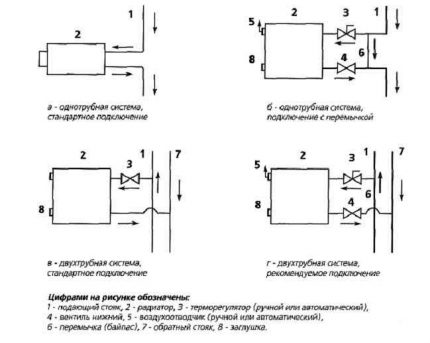

- When installing a thermostatic valve in a one-pipe heating system, it is necessary to install an additional bypass section - a bypass. It should be located between the pipe sections entering and leaving the heater (as in the photo below).

Thermostatic valve: principle of operation, types, adjustment

A standard heating system is not flexible. To adjust the parameters of the battery, various devices have been invented.

One such device is a thermostatic valve for heating radiators. It is used to regulate the heat dissipation of the system depending on the weather conditions. In this article, we will analyze the device and the principle of operation of the thermal valve, get acquainted with the existing varieties and main manufacturers.

We will also give recommendations for installation, providing the material with visual photos and video reviews on the installation and response speed of devices of various brands.

The content of the article:

Why do you need a thermostatic valve?

The valve solves two tasks: maintains the room temperature at a comfortable level plus saves energy.

But in order for it to really cope with such functions, you need to understand in which cases the device is appropriate and how to install it correctly.

If in the middle of winter there is a need to open windows so that the temperature in the room drops to an acceptable level, a thermostat is definitely needed. But it will not help when the batteries are barely warm - it may become even colder with it.

In the second case, it is better to try to adjust the temperature in the room differently: change the volume of the coolant in each radiator, correct the operation of the boiler (for a large area), select the optimal circulation pump or adjust the operation of an existing one.

The price of a thermostat fluctuates in the range of several hundred rubles (200-600), so re-equipment of the heating system will be inexpensive. But there are also expensive models.

Control valves can be used as a temporary measure. But it is not recommended to use ball valves for these purposes.

Device and features of the device

Let's consider how the thermostatic valve works and how it works.

How does a thermal valve work?

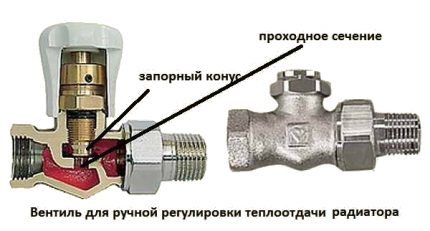

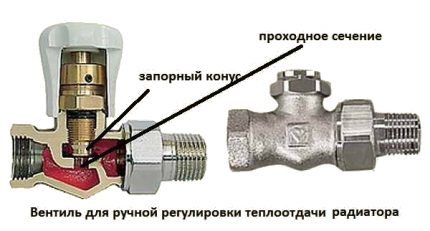

The device consists of two main working elements - a valve and a thermostatic head. The first is most often made of brass, sometimes nickel-plated, its lower part blocks the pipe, and the top continues the push rod and spring.

Valves are also bronze (nickel-plated or chrome-plated), as well as stainless steel. The latter are rare and expensive.

What happens inside the valve? There is a sensing element in the head device. It is located in a cavity with a gas or liquid (bellows).

Heating provokes expansion in this environment, the element is pushed forward, presses on the stem, spring, and later on the valve. The force of pressure determines the degree of overlap.

The figure shows a device with liquid in a bellows. Gas thermostats react faster to temperature changes (5-10 minutes), but they are also more expensive. There is not much difference from this during operation.

An additional part of the thermostat is a plug or a knob with a scale. Some appliances have electronic controls.

The principle of operation of the device

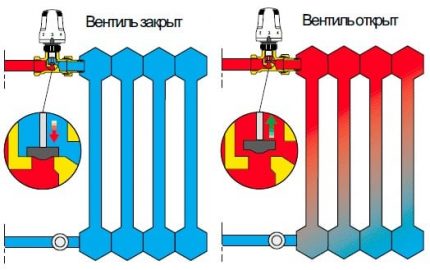

Let's take a closer look at the principle of operation of thermostatic valves for batteries. The mechanics of their action schematically looks like this: when the temperature of the coolant or the environment changes, the gas or liquid in the head reacts to these fluctuations.

The sensing element acts on the pressure rod, and it goes up or down. When the stem moves down, the valve blocks the flow of the coolant, which stops the flow of heat and slows down the circulation rate. No heat is supplied to the battery, so the room temperature does not rise.

And here it is important to distinguish between a thermostatic valve and a control valve. The latter can reduce the throughput of the valve and so regulate the temperature of the batteries.

When you turn the knob or enter a digital value on the panel, the user sets the initial pressure value in the thermal head, to which it "adjusts" during operation

The control valve does not have a thermal head.The thermostat is open or closed, it is controlled by a thermal head, it does not change the volume of the coolant, but only turns on and off its supply

Let's analyze the principle of operation of a thermal valve using an example. So, we set the device to the recommended temperature of 20 degrees. This is usually a triple or the largest point on the scale of the regulator.

What's going on inside the device? If the ambient air heats the head to 21 degrees, that is, increases the set temperature by 1 degree, it presses the stem, the coolant supply to the battery is completely blocked by the valve.

The radiator does not heat up, the room temperature starts to drop. When the ambient temperature drops to 19 degrees, the thermal valve will open and the battery will begin to heat up.

We deal with the types of devices

By the way of adjustment, the valves are divided into mechanical and automatic... The former require manual rotation of the mechanism for narrowing the duct in the pipes.

Both devices perform the same function - they adjust the supply of coolant to the radiator in accordance with the parameters set by the user, but the use of automation is less troublesome

Automatic models do not need manual adjustment. When the temperature around the thermostat decreases, they independently record this and adjust the coolant flow.

Manufacturers also offer different designs of thermostats:

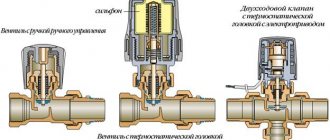

- Common for two-pipe systems - the simplest device. If you need hydraulic balancing of radiators on one branch, it is recommended to add a shut-off and control valve on the supply (return) to the circuit.

- With hidden and open hydraulic superstructure - in such devices there is a coupling with an internal rod, therefore hydraulic adjustment is possible.

- For one-pipe, gravity systems - due to the increased passage, the throughput of these devices is increased to 5.1 m3 / h, so they can be installed in non-pressure systems.

- 3-way for bypass applications - know how to regulate and distribute the coolant in conjunction with the bypass. When the set temperature reaches the valve, the coolant is sent to the bypass, when it drops, the bypass is partially closed.

As a percentage, there are much more thermo valves for two pipes than for single pipes, and the latter in our country are about 80%.

This is due to the fact that the device was originally invented for the first, where the coolant is distributed among the devices forcibly under high pressure. Presetting by valves and is designed to evenly distribute the pressure throughout the system.

Valves for single pipes are available only from some manufacturers - Heiz, Danfoss, Heimeier, Oventrop.

In single-pipe circuits, conventional "two-pipe" thermostats cannot be used.: they have a lower throughput, they are able to work only with a large pressure difference between the supply and return, so there will be a risk of redirecting the coolant to the bypass.

Externally, "one-pipe" valves are larger in size.

Three-way valves are appropriate in schemes with a solid fuel boiler, as well as for flow separation, bypass piping of radiators. The device can also be used in one-pipe distribution

Also thermostatic valves differ in shape. They are straight, angled, or fit into headsets with pipe bridges. Straight lines are appropriate for conventional batteries. Corner ones are needed in schemes with lower piping, when CO is partially disguised under the floor.

A separate type of thermal valves is electronic. They have wider functionality than the usual ones. With their help, you can set a different temperature in the room for each day of the week and even hourly.

Electronic thermal heads are more expensive and larger than usual ones: inside the case there is a compartment for two batteries. There are models with removable and built-in control units

Electronic thermostats provide significant savings in heating medium consumption.If there is no one in the apartment or house from 8 am to 6 pm, the device will regularly maintain the minimum temperature. And by the arrival of the owners, it will heat the premises to a comfortable level.

There are also valves with an anti-vandal cover on sale. They are reliably protected from unskilled interference and are suitable for installation both in a home with small children and in kindergartens and schools.

Features of installation and connection of the valve

The device itself is simple, but special attention should be paid to the installation and calibration of the thermostatic valve on the radiators. Correct installation will ensure accurate operation of the device.

What factors are considered during installation? A kind of thermal valve - for one-pipe or two-pipe. Plus the direction of movement of the coolant - it comes from below or from above.

On the valve itself, the direction of movement of the coolant is indicated by an arrow. According to this marker, it is necessary to install thermostats on radiators, otherwise the device will not work correctly.

Hot water pipes are supplied to the battery in different ways. It depends on the heating scheme. The locations of the plugs and thermostats are also different. The general recommendation for most thermostat models is to be placed within 40-60 cm of floor level.

The installation algorithm is approximately as follows:

- Disconnect the radiator from the heating system and drain the water.

- We remove the section of the horizontal pipe and the crane too.

- The thermostat can also be mounted in the radiator cap if a shut-off valve is installed in front of it. Or make a tie-in into the horizontal part of the pipe in front of the battery.

- The tightness of the joints is important. We provide it with the standard winding of the FUM tape on the threaded section.

The traditional connection scheme is as follows: bypass - ball valve - thermostat.

Another point: there are systems where the coolant moves in different directions in different rooms. This is especially true for U-shaped risers.

Installation nuances for one-pipe and two-pipe systems

In a single pipe, hot water circulates through one pipe with radiators connected in series. The pipe with the coolant goes into the upper part of the batteries. The latter runs through the installation, comes out from the bottom on the same side and goes to the main highway.

One-pipe CO is considered ideal for private buildings and an apartment building up to 5 floors. In other cases, it is recommended to equip a two-pipe CO

In a one-pipe system, the thermostat is placed on an unregulated bypass. This jumper connects the straight pipe and the return pipe, so hot water moves freely after the pressure is blocked by the valve.

Such a jumper can be welded to the pipe on your own, for which a piece of pipe with a diameter of no more than 8 cm is suitable. In this case, you need to prepare holes in the appropriate places.

Standard and recommended thermostat installation schemes for one-pipe and two-pipe CO. The figure shows how to connect a jumper (bypass) valve with a bottom valve

In a two-pipe, the coolant enters the radiator through one pipe, and is removed through the other. The bypass is not needed, the thermostatic valve must be installed on the water supply pipe.

Rules for adjusting the operation of the device

After installation, you need to adjust the operation of the device. To do this, we first close the windows and doors - we isolate the room to prevent heat leaks.

Then we act like this:

- We turn on the heating.

- We set the valve to the position of maximum heat transfer, measure the temperature.

- We are waiting for the room temperature to rise by 5 degrees and become constant.

- We close the valve and wait for a comfortable temperature.

- Then we open the thermostat a little bit until we hear the noise of passing water. The body of the device itself should warm up.

- The last position must be remembered.

In a private house, before adjustment, air must be deflated from the batteries.In this case, it is necessary to observe the maximum accuracy so that there is no ejection of hot steam.

When more than three batteries are connected to the boiler, each thermostat must be opened to a different level so that the heat is evenly distributed throughout the rooms.

The adjustment starts with the coldest room. It needs to be warmed up well in order to move to other rooms.

Frequent installation errors and possible problems

The first mistake is the vertical position of the thermal head. The problem is with the hot metal valve under the head: hot air is blowing upward from it.

This air heats the head, and it turns off the radiator by mistake. As a result, the battery is almost always disconnected, the room does not warm up. The device must be installed horizontally ("head" into the room).

In the instructions for the thermostat, the diagrams show how and where to install it in different cases, but there is not a single diagram with a vertical arrangement. If it does not work vertically, you need to use devices with remote sensors.

The second mistake is the location of the thermostat where the temperature differs from the real one in the room. Example: in a niche with a battery. In this variant, the head will always be "hot".

A significant failure in its work will also be present when placed behind a dense fabric of curtains, under window sills, at the edges of window openings.

If the thermostat cannot be positioned differently, the model with an external sensor will help out again. They differ from conventional devices by the presence of a capillary tube of about 2 meters with a temperature sensor at the end. You can attach such a device to the wall away from the window and the battery.

Models with a remote element more accurately than conventional devices determine the temperature due to their location at a distance from the radiator, but they also cost much more.

Heads with remote controls are also on sale, which can be installed anywhere at a distance of up to 15 m from the battery and valve. There are also electronic heads that are controlled by thermo-computers.

The thermostatic valve completely shuts off the heating medium flow. If in a radial heating system all devices do this at the same time, there will be problems with the boiler. A possible solution is bypass valves on the circuits.

If there are 2-3 radiators in a room, does it make sense to put thermostats on each battery? Will there be a conflict between them? In this case, balancing must be done with adjusting valves (ball valves).

Conclusions and useful video on the topic

What is a thermal head, what is it for and how it works.

Analysis of the finished system with a thermostatic valve.

Experiment on the response speed of thermal heads from 4 manufacturers.

The use of thermal valves for radiators allows you to make the heating system as flexible as possible.

With their help, it is possible to regulate the temperature of individual batteries so as to constantly maintain a comfortable microclimate in the room. But at the same time, it is important to consider the appropriateness of the installation of such devices, to correctly carry out their installation and configuration.

Thinking about installing a thermal valve, but want to clarify a couple of points on installation? Ask your questions under this article - our experts and site visitors using such temperature control equipment will try to answer you in as much detail as possible.

If your heating system is equipped with thermostatic valves, please share your opinion with other users. Tell us which manufacturer's equipment you prefer, is it convenient to use, are you satisfied with the result? Write your recommendations in the comment block, add unique photos of the thermal valve.