DIY geyser repair

Gas water heaters with instantaneous water heaters, regardless of the manufacturer and model, do not differ in any way according to the principle of operation.

The difference lies only in appearance, design and a set of additional options, for example, automatic ignition of the burner, the error in maintaining the set temperature of the heated water, the presence of a digital display for setting and indicating the temperature of the water.

Any gas water heater works as follows. Water flows through the heat exchanger, which is a copper tube with fins. Gas burns, which heats up the heat exchanger and, as a result, heats up the water. Depending on the set water heating temperature and its pressure in the water supply system, the gas unit control system associated with the water unit ensures the safe operation of the gas water heater. In the absence of water pressure, or traction, the protection system automatically shuts off the gas supply.

Troubleshooting the gas column

No matter how reliable the gas water heater is, whether it is a domestic or foreign manufacturer, it does not matter, sooner or later it will break down and you will have to repair it.

Gas in the igniter of the gas column goes out

Such a malfunction is inherent only in gas water heaters with an automatic protection system. The gas in the igniter must always burn, regardless of the position of the handles or valves of the taps and water supply mixers. The simplest automatic gas column protection system consists of only three elements. Solenoid valve, thermocouple and thermal fuse. The gas column can go out during operation in the event of activation of the protection elements or a malfunction of the elements themselves.

The failure of the automation elements is evidenced by the extinguishing of the gas in the igniter, after stopping the holding of the gas adjustment knob. To repair the automatic protection system, you need to have a good understanding of how its components work. Therefore, it is worthwhile to get acquainted in more detail with the device and the principle of operation of the protection elements.

A thermocouple is two conductors welded together from different metals (I assume these are chromel and alumel), operating on the Seebeck effect and generating about 30mV EMF when heated. Serves to power the solenoid valve. Practically does not fail. The bottleneck is the unsecured center conductor coming out of the housing. Although it is insulated, the insulation can rub off over time, and the conductor can close to the case, while the gas column will go out. If the contact at the thermocouple welding site is broken, then it is not permissible to restore it by soldering with solder, since the junction in the thermocouple is a current generator, and not a simple eclectic connection of wires. The thermocouple should be replaced with a good one.

The solenoid valve of the gas column is a coil of copper wire, inside which there is a metal cylinder (solenoid), mechanically connected to the valve for shutting off the gas supply to the burner of the gas column. When a thermocouple is heated, it generates an electrical current that flows through the coil to create a constant magnetic field that pulls the solenoid into the coil. Since the solenoid is mechanically connected to the valve, the valve is displaced and gas enters the burner. If the gas in the wick does not burn, the thermocouple cools down and does not generate current, the spring-loaded solenoid returns to its original state and the gas supply to the gas column burner stops.In such a simple way, the safe operation of gas water heaters is ensured. If the wick does not burn, for example, the flame is blown out by the wind or the gas supply has been interrupted, then when the water taps are opened, gas will not be supplied to the burner of the gas column.

The thermal fuse is a bimetallic plate, which, when the temperature at the installation site of the thermal fuse reaches 90 ° C, bends so much that through the stem, breaks the solenoid power circuit. In addition, the thermal fuse itself is connected to the circuit mechanically, with terminals. Due to the complexity of the design and operating conditions, it sometimes fails. I had to replace it once due to the fact that the gas column went out haphazardly.

Checking the thermal fuse

It makes sense to check the thermal fuse, provided that there is good draft and sufficient air flow. If the plastic windows are tightly closed, and, in addition, the hood above the gas stove is turned on, then even with good traction, the gas water heater will overheat and just turn off the gas supply in this case and it is the task of the thermal fuse to protect the gas water heater from overheating, and the person from carbon monoxide.

Checking the solenoid valve of the gas column

If the paper clip did not help, then you need to check the functionality of the solenoid valve. The solenoid valve has a resistance of about 0.2 Ohm and consumes a current of about 100 mA in operating mode. You can check it by applying a voltage of 20-30mV to the winding at a current of 100mA. Such a mode can be easily created using any finger-type battery or accumulator and a 10 Ohm resistor. The battery must be fresh. The connection is carried out as follows. The negative terminal of the battery is connected to the column case (for the valve and thermocouple, one terminal is connected to the body, in the diagram there is a blue wire), and the positive terminal, through a 10 Ohm resistor, to the thermal fuse terminal (the terminals from the thermal fuse must be previously removed), the wire from which is not goes to the thermocouple (left red wire in the diagram). Light the wick and immediately remove your hand from the throttle control knob. The wick should continue to burn. If you disconnect the battery, the flame should go out immediately. If everything is so, the solenoid valve is working properly. Therefore, the thermocouple is faulty. If an external examination fails to find bad contacts or a short circuit in the wires, then the thermocouple will have to be replaced. It is sold complete with wires and terminals.

The geyser goes out during operation

No cravings

One of the most common cases with the arrival of autumn is a tightly closed sealed plastic window in the room where the gas water heater is installed. There is no air flow - the column overheats and the bimetallic relay of thermal protection of the column against overheating (self-healing thermal fuse) is triggered. If after 10-15 minutes the column lights up normally and does not go out with the window ajar anymore, then the reason is precisely the overheating of the column. If immediately after the gas goes out, you can light the wick, and it will continue to burn after you stop holding the gas regulator knob, then the draft is good.

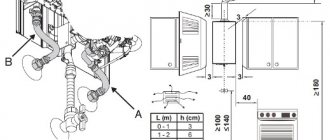

The draft may still be insufficient due to clogging with soot or foreign objects entering the ventilation duct, for example, bricks from which the duct is made. To check the draft, you need to remove the gas outlet pipe from the gas column from the channel and, with the window open, close the channel with a sheet of paper. If the paper holds, then the traction is sufficient. You can bring a lighted lighter and if the flame deviates to a horizontal position, then the draft in the channel is sufficient. Otherwise, cleaning of the canal is required.

Water unit malfunctions

Even the burners in the column, both with and without automation, can go out due to insufficient water pressure in the water supply system, or a malfunction of the water unit.

If the pressure of cold water has not changed, but the water coming from the column has become weak, then the mesh filter at the inlet of the water unit is clogged. This often happens after turning off the water and supplying it again. For cleaning, it is enough to unscrew one union nut on the water supply side, remove and clean the sieve and the differential pressure calibration hole.

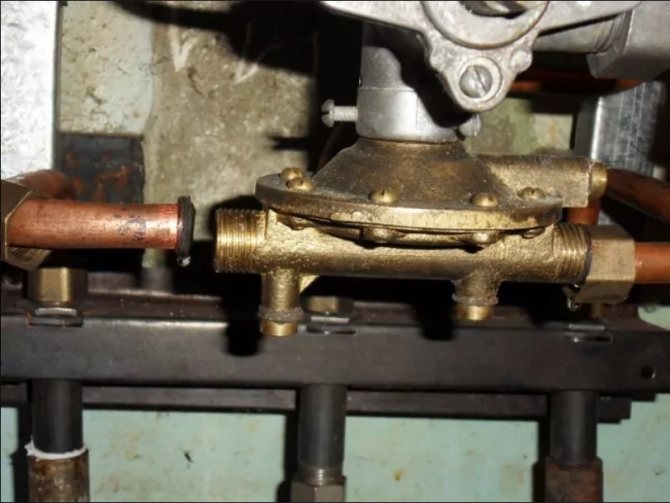

If a water unit is installed in the gas column as in the photo, and the water pressure has not visually changed, then it is necessary to check the condition of the rubber membrane in it. To do this, unscrew the two union nuts from the water unit, then unscrew the three screws that hold the water unit in the gas unit by the cone. Disassemble the water assembly by unscrewing the eight screws. Detaching the halves of the assembly from each other, you will see a rubber membrane. If the elastic is not flat, but deformed, with deflections, then this is the case and needs to be replaced. At the same time, you should clean the filter mesh and cavities of the water unit from dirt. I advise you to put a silicone membrane, it will last for many years. When assembling the water unit, first tighten the screws all the way, and then tighten diagonally to ensure that the rubber is clamped evenly.

In the old days, when I lived in an apartment on the top floor, where the water pressure was a sluggish trickle of water from the tap, I had to wash myself with a water regulator. With a round needle file, he increased the diameter of the calibration hole to 2 mm, removed the filter mesh, and annealed the conical spring of the gas unit. If he missed the size of the hole, then he inserted a copper wire into it to reduce it. Of course, this is a gross violation and it was necessary to constantly monitor the working column, but there was simply no other way out. But there was always hot water.

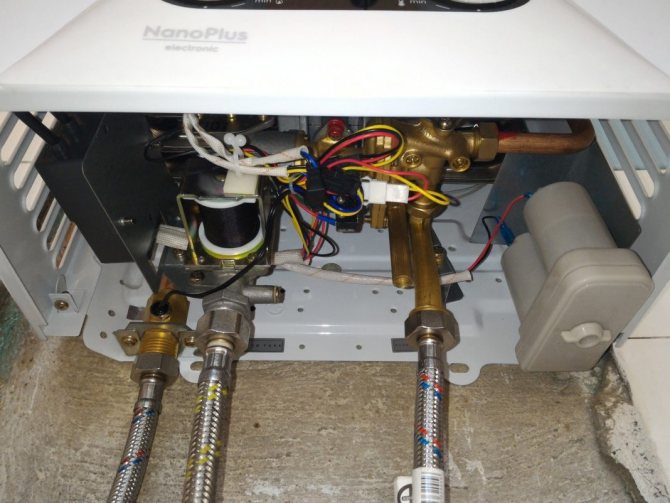

How to eliminate a leak in the gas column connections

The left pipe serves to supply water to the gas water heater, a tap is always installed on it to shut off the water supply to the column. This pipe is connected by a branch pipe to a water-gas regulator. From the regulator, water is supplied to the heat exchanger on the right side. Hot water is transferred through the middle pipe of the gas water heater to the water supply system and it is connected through a branch pipe directly to the heat exchanger on the left side. The right pipe in the gas column serves to supply gas and is connected through a copper pipe to the water-gas regulator. A gas shut-off valve is also mandatory installed on it. The water connections in the gas water heater are made by means of union nuts (American) with sealing with rubber or plastic gaskets. Over time, due to temperature changes, the gaskets lose their elasticity, become hard, crack and water leaks. To replace the gasket in the gas column, you need to unscrew the union nut with a wrench 24, remove the worn one and install a new one. Sometimes one gasket is not enough, the union nut is twisted all the way, but the water still oozes. Then you need to additionally install another gasket. Currently, silicone gaskets have appeared. They are much more expensive, but they last longer and more reliably.

Combined device

The need for maximum reliability has led to the invention of the Archives combined flame control relay, for example. The main difference from a conventional device is that the device uses two fundamentally different registration methods - ionization and optical.

As for the operation of the optical part, in this case it separates and amplifies an alternating signal that characterizes the ongoing combustion process. During the burning of the burner, the flame is unstable and pulsates, the data is recorded by the built-in photosensor. The fixed signal is transmitted to the microcontroller. The second sensor is of the ionization type, which can receive a signal only if there is a conductivity zone between the electrodes. This zone can only exist if there is a flame.

Thus, it turns out that the device operates in two different ways of controlling the flame.

Heat exchanger cleaning, descaling

One of the common malfunctions of gas water heaters is insufficient water heating

... As a rule, the reason for this is the formation of a thick layer of scale inside the heat exchanger tube of the gas column, which does not allow the water to warm up to the set temperature and reduces the water pressure at the outlet, which ultimately leads to an increased gas consumption of the gas column. Scale is a poor conductor of heat and, covering the heat exchanger tube from the inside, forms a kind of thermal insulation. The gas is open to its fullest, and the water does not warm up. Limescale forms when the tap water is harder. What kind of water you have in the tap is easy to find out by looking into the electric kettle. If the heating element or, in its absence, the bottom of the electric kettle is covered with a white coating, it means that the water in the water supply system is hard and the heat exchanger is also covered from the inside with scale, which becomes thicker over time, up to the complete overlap of the tube section. Therefore, it is periodically necessary to remove scale from the heat exchanger.

There are special devices commercially available for descaling and rusting hot water systems such as the Cillit KalkEx Mobile and flushing fluids. But they are very expensive and not available for private use. The principle of operation of the purifiers is simple. There is a container in which a pump is mounted, like in a washing machine for pumping water from a tank. Two tubes from the descaling device are connected to the tubes of the gas column heat exchanger. The flushing agent is heated and pumped through the heat exchanger tube, even without removing it. Scale dissolves in the reagent and the heat exchanger tubes are removed with it.

To clean the gas column heat exchanger from scale without the use of automation equipment, it is necessary to remove it, blow through the tube so that no water remains in it. The reagent for cleaning can be antiscale (sold in hardware stores), ordinary vinegar or citric acid (100 grams of citric acid powder is dissolved in 500 ml of hot water). The heat exchanger is placed in a container with water. It is enough that only one third of it is immersed in water. Completely fill the heat exchanger tube with the reagent through a funnel or thin tube. It is necessary to pour into the heat exchanger tube from the end, which leads to the lower turn, so that the reagent displaces all the air. Put the container on the gas stove and bring the water to a boil, boil for ten minutes, turn off the gas and let the water cool down. Further, the heat exchanger is installed in the gas column and is connected only to the water supply pipe. A hose is put on the outlet pipe of the heat exchanger, its second end is lowered into the sewer or any container. The valve for supplying water to the column opens, the water will displace the reagent with the scale dissolved in it. If there is no large container for boiling, then you can simply pour the heated reagent into the heat exchanger and keep it for several hours. If there is a thick layer of limescale, the cleaning operation may need to be repeated several times to completely remove it.

Control methods

Today, the variety of sensors allows for different control methods. For example, direct and indirect control methods can be used to control the combustion of fuels in a liquid or gaseous state. The first method includes such methods as ultrasonic or ionization. As for the second method, in this case, the flame relay control sensors will monitor slightly different values - pressure, vacuum, etc. Based on the data received, the system will conclude whether the flame meets the specified criteria.

For example, in gas heaters of small size, as well as in domestic heating boilers, devices are used that are based on a photoelectric, ionization or thermometric method of flame control.

Burning gas in the wick makes a loud noise

After installing the Neva-3208 gas column, an unpleasant phenomenon appeared that did not affect the quality of the column. The gas, when burning in the wick in standby mode, made a rather loud sound, which was unpleasant to the ear, and created discomfort. After thinking and experimenting, we managed to get rid of the noise in a simple way. He assumed that a jet of gas in the burner under pressure, escaping from the nozzle and hitting the wall at the bend of the burner, creates conditions for combustion with noise. To test this assumption, I put a strip of tin approximately 3 cm long and 5 mm wide into the burner, the main thing is that it would fit inside the burner. The noise disappeared. If your gas water heater is also noisy, then you can take any metal strip, for example, cut out a tin from a tin can, make a hole in it at the edge, put the strip on a paper clip aligned and bent at the end, and stick the strip into the burner of the gas water heater. It will look like a fishing lure. A paper clip is needed so that you can remove the strip of metal back from the burner if the noise does not disappear, although if it burns normally, then you do not need to remove it. This experiment can be carried out even without removing the casing from the gas column.

Device reliability

Reliability is a fundamental requirement for these instruments. In order to achieve maximum efficiency, it is necessary not only to choose the right equipment, but also to install it correctly. In this case, it is important not only to choose the correct installation method, but also the place of attachment. Naturally, any type of sensor has its own advantages and disadvantages, however, if you choose the wrong installation location, for example, then the probability of a false signal is greatly increased.

To summarize, we can say that for maximum system reliability, as well as in order to minimize the number of boiler shutdowns due to an erroneous signal, it is necessary to install several types of sensors that will use completely different methods of flame control. In this case, the reliability of the overall system will be high enough.

The water from the column is very hot

In the warm season, when the water in the water supply system is quite warm and its pressure is small, a problem arises, seemingly associated with a malfunction of the gas column. When the gas supply knob is set to the position of minimum water heating, the water from the column is still very hot. This is not a malfunction of the gas water heater, it is just that this model of the gas water heater is not designed for such an operating mode. The operating instructions usually indicate the minimum water pressure at which the gas water heater ensures normal operation.

It is very simple to solve the problem, it is enough to limit the gas supply by slightly shutting off the gas supply valve installed on the gas pipe in front of the entrance to the gas column.

SL-90 marking sensors

Today, one of the fairly universal photosensors that can register infrared radiation from a flame is the SL-90 flame control relay. This device has a microprocessor. A semiconductor infrared diode acts as the main working element, that is, a radiation receiver.

The element base of this equipment is selected in such a way that the device can function normally at temperatures from –40 to +80 degrees Celsius. If a special cooling flange is used, then the sensor can be operated at temperatures up to +100 degrees Celsius.

As for the output signal of the SL-90-1E flame control sensor, it is not only LED indication, but also dry-type relay contacts. The maximum switching power of these contacts is 100 W. The presence of these two output systems allows this type of fixture to be used in almost any automatic control system.