A single-circuit or double-circuit gas boiler is equipment that makes our life in a house or apartment more comfortable. Manufacturers now produce a huge range of gas appliances, differing in power, functionality, and installation method. However, even the most expensive and reliable models can fail. Agree, it is not very pleasant to stay on a winter evening without heat and hot water.

After analyzing the possible causes of breakdowns in gas equipment, we came to the conclusion that most often malfunctions occur due to the fact that the pressure in the expansion tank of a gas boiler or water heater is incorrectly set. In the article, we will figure out what an expansion tank is for, how to independently pump air into it and adjust the optimal pressure.

What is an expansion tank for?

In the process of heating, water tends to expand - as the temperature rises, the volume of the liquid increases. In the circuit of the heating system, pressure begins to build up, which can destructively affect the gas equipment and the integrity of the pipes.

The expansion tank (expansomat) acts as an additional reservoir, into which the excess water formed as a result of heating is squeezed out by pressure. When the liquid cools down and the pressure stabilizes, it is piped back into the system.

The expansion tank acts as a protective buffer, it dampens water hammers that are constantly formed in the heating system due to the frequent switching on and off of the pump, and also eliminates the possibility of air congestion.

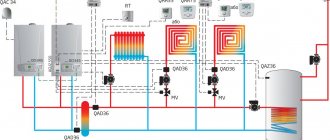

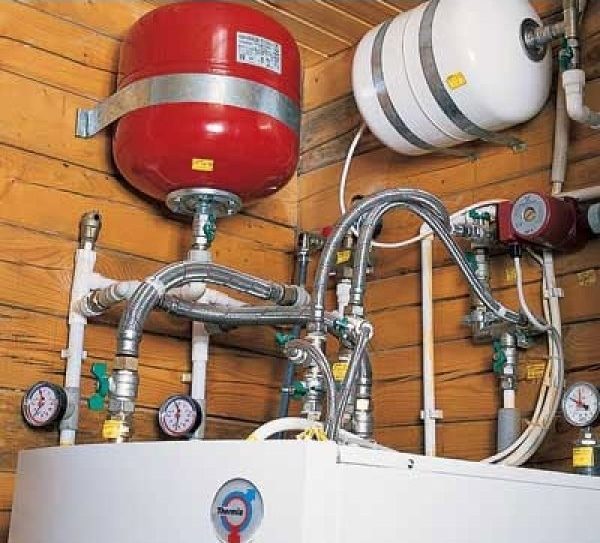

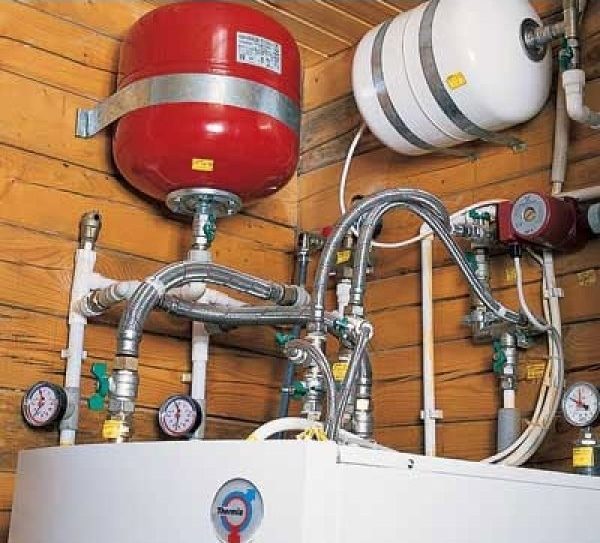

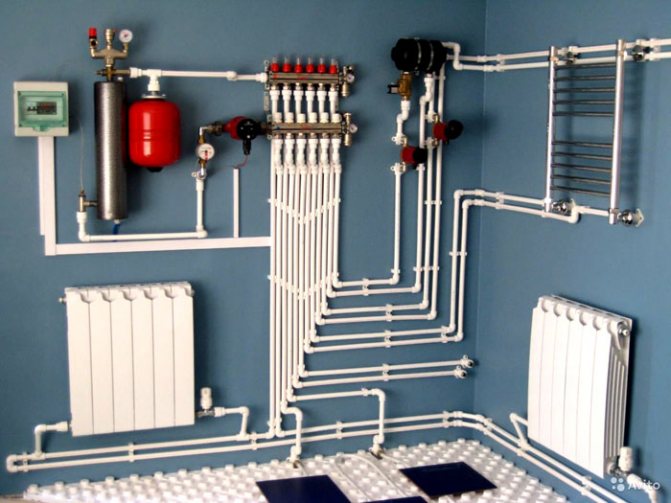

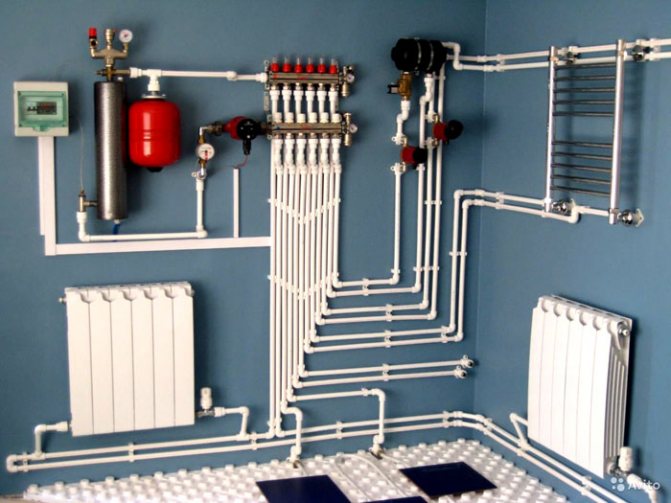

To reduce the likelihood of air congestion and prevent damage to the gas boiler by water hammer, the expansion tank should be mounted in front of the heat generator, on the return line

There are two different versions of the damper tanks: open and closed types. They differ not only in design, but also in the method, as well as in the place of installation. Let's consider the features of each of these types in more detail.

Expansion tank, open version

An open tank is mounted at the top of the heating system. Containers are made of steel. Most often they have a rectangular or cylindrical design.

Usually such expansion tanks are installed in the attic or attic. Installation under the roof is possible. Be sure to pay attention to the thermal insulation of the structure.

There are several outlets in the structure of the open-type tank: for water inlet, cooled liquid outlet, control pipe inlet, as well as an outlet pipe for draining the coolant into the sewer. We wrote in more detail about the device and types of an open tank in our other article.

Open tank functions:

- controls the level of the coolant in the heating circuit;

- if the temperature regime in the system has decreased, it compensates for the volume of the coolant;

- when the pressure in the system changes, the tank acts as a buffer zone;

- the excess coolant is removed from the system into the sewer;

- removes air from the circuit.

Despite the functionality of open expansion tanks, they are practically not used anymore. Since they have many disadvantages, for example, the large size of the container, the tendency to corrosion. They are installed in heating systems that work only with natural water circulation.

Closed expansomat

In heating systems with a closed circuit, a membrane-type expansion tank is usually installed, it is optimal for any type of gas boiler and has many advantages.

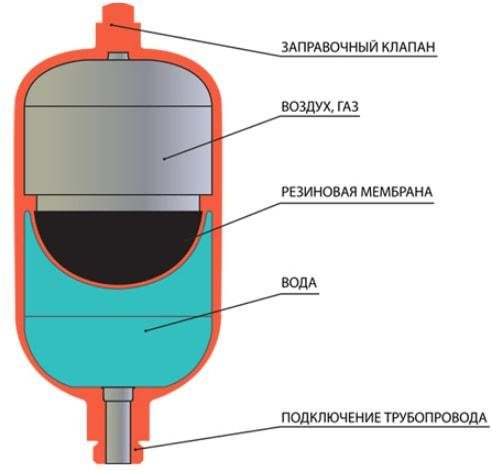

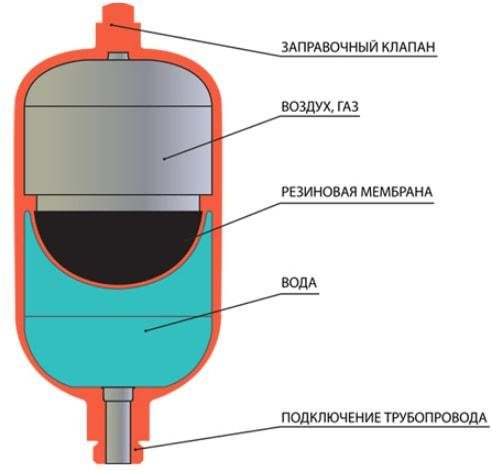

Expanzomat is a hermetic container, which is divided in the middle by an elastic membrane. The first half will contain excess water, and the second half will contain normal air or nitrogen.

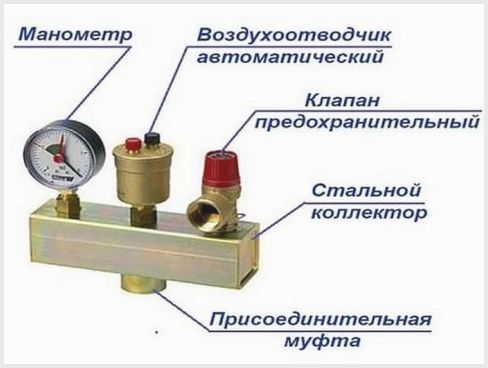

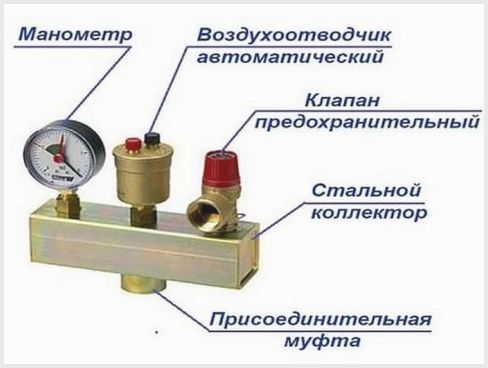

Closed expansion tanks for heating are usually painted red. There is a membrane inside the tank, it is made of rubber. Essential element for maintaining the pressure in the expansion tank

The expansion tanks with diaphragm can be produced in the form of a hemisphere or in the form of a balloon. Which is quite suitable for use in a heating system with a gas boiler. We recommend that you familiarize yourself in more detail with the installation features of closed-type tanks.

Advantages of membrane types of tanks:

- ease of self-installation;

- corrosion resistance;

- work without regular topping up the coolant;

- lack of contact between water and air;

- performance under conditions of increased load;

- tightness.

Gas attachments are usually equipped with an expansion tank. But the additional tank from the factory is not always configured correctly and can immediately turn on in the heating operation.

Tank in an open-type heating system

In such a system, the coolant - simple water - moves according to the laws of physics in a natural way due to the different densities of cold and hot water. The slope of the pipes also contributes to this. The heat carrier, heated to a high temperature, tends upward at the outlet of the boiler, pushed out by cold water coming from the return pipe from the bottom. This is how natural circulation occurs, as a result of which the radiators heat up. In a gravity system, it is problematic to use antifreeze due to the fact that the coolant in the expansion tank is open and quickly evaporates, but that is why only water acts in this capacity. When heated, it increases in volume, and its excess enters the tank, and when it cools, it returns to the system. The tank is located at the highest point of the contour, usually in the attic. To prevent the water from freezing, it is insulated with insulating materials and connected to the return pipeline to avoid boiling. In case of overflow of the tank, water is discharged into the sewer system.

The expansion tank is not closed with a lid, hence the name of the heating system - open. The water level in the tank must be controlled so that air locks do not appear in the pipeline, leading to ineffective operation of the radiators. The tank is connected to the network through an expansion pipe, and a circulation pipe is provided to ensure the movement of water. As the system fills up, the water reaches the signal connection, on which the

crane. An overflow pipe serves to control the expansion of water. He is responsible for the free movement of air inside the container. To calculate the volume of an open tank, you need to know the volume of water in the system.

Air pressure in the expansion tank

The indicator of air or nitrogen pressure in the expansion tank for different gas boilers will not be the same, it all depends on the type of equipment and design features. The standards are indicated by the manufacturer in the product passport.

Typically, the pressure in the new damper tank is 1.5 atm. But this setting may not be suitable for a specific heating system. Factory settings are easy to reset. For these purposes, there is a special fitting in the expansion tank housing (for some manufacturers it is a pumping valve), through which the air pressure is adjusted.

The nipple is located on the side of the cylinder air chamber. With its help, you can release excess pressure or, conversely, pump up the tank

For the normal functioning of a gas boiler, it is necessary that the pressure in the membrane tank is 0.2 atm less than in the system itself. Otherwise, the heated water that has increased in volume will not be able to enter the container.

In small houses and apartments for closed heating systems, the pressure in the expansion tank is usually permissible in the range of 0.8-1.0 bar (atm). But not less than 0.7 bar, since many gas boilers have protection and the device simply will not turn on.

Check the pressure level of the tank annually. If pressure surges are noticed in the heating system, it means that air has escaped from the damper tank and must be pumped up.

How does the system work and does it work?

Expansion tanks are tightly closed vessels that are divided into several fragments using membrane fabrics made of rubber material. This is an unusual rubber, because it must withstand significant heat, while remaining flexible and not losing strength.

The main thing: the pressure must be determined in the middle of the air void entering the empty container, strictly at a temperature of 20 degrees. It is equal to the static pressure of the fully filled heating system. Such a requirement makes it possible to achieve an equilibrium state of membrane tissues and compensate for the pressure exerted by the heat carrier.

In other words, by the time of start-up, the tank will be completely empty, and its entire volume can be used to correct the thermal expansion of water or antifreeze. If the gas boiler meter detects that the pressure in the heating system has dropped to 0.7 bar or less, it gives a command to turn off the heater. And the average value for normal operation is 1.2 bar. Because moving from a non-equilibrium position to an equilibrium one, the membrane tissue can raise the pressure even more, its initial level for an empty tank is taken to be an indicator of 0.3 bar (on average) higher than usual for a heating system.

Conclusion: with a closed heating circuit with a gas water heater, the pressure should be from 0.8 to 1 bar; the parameters of any system deviating from the parameters are calculated individually, taking into account:

- future volume of water or antifreeze;

- Tank efficiency;

- its required size;

- initial pressure at startup.

Tanks on boilers with two Baxi circuits, as follows from the instructions, must operate at a pressure of 0.5 bar. However, in reality, this indicator is minimal, and the same pressure of 0.8 - 1 bar allows to ensure good operation of the device. The built-in expander with a capacity of 6 liters does not stop working with heating systems with a capacity of 75 liters (on water). Or 50 liters (with antifreeze).

Is it necessary to apply additional expansion the tank, or the standard equipment is enough, is decided only by professionals at the time of project preparation.

How to set the optimal pressure?

There are pressure gauges on the heating system, with the help of which the pressure in the circuit is monitored. On the expansion tank itself, there is no fitting for the installation of the measuring device. But there is a nipple or spool for the release and pumping of air or gas. The nipple is the same as on the wheels of cars. Therefore, you can check the pressure level and adjust it using a conventional car pump with a pressure gauge.

For pumping air into the expansion tank, even the simplest car hand pump with a pressure gauge or an automatic compressor is suitable.

Before releasing excess pressure or pumping air into the expansion tank of a domestic gas boiler, it is necessary to prepare the system. The car pressure gauge shows the value in MPa, the data obtained must be converted to atmospheres or bars: 1 Bar (1 atm) = 0.1 MPa.

Pressure measurement algorithm:

- Switch off the gas boiler. Wait until water stops circulating through the system.

- In the area with a hydraulic tank, close all shut-off valves and drain the coolant through the drain connection. For boilers with a built-in tank, the return flow is shut off, as well as the water supply.

- Connect a pump to the tank nipple.

- Pump air up to 1.5 atm.Wait a little for the remaining water to pour out, let the air in again.

- Close the valves of the stop valves and pump the pressure with the compressor to the parameters indicated in the passport or to the level - pressure in the system minus 0.2 atm. In the case of pumping over the tank, excess air is vented.

- Remove the pump from the nipple, screw on the cap and close the drain nipple. Pour water into the system.

It is possible to check the correct adjustment of the air pressure when the boiler reaches operating parameters.

If the tank is inflated correctly, then the gauge needle of the device during measurement will show a smooth increase in pressure without any jumps and jerks.

If the air pressure in the expansion vessel is incorrectly set, the entire heating system may malfunction. If the expansomat is over-pumped, the compensating properties will not work. Since the air will push the excess heated water out of the tank, increasing the pressure in the pipes of the heating system.

And with underestimated pressure readings of the compensating tank, the water will simply push through the membrane and fill the entire tank. As a result, when the temperature of the coolant rises, the safety valve will work.

Sometimes in double-circuit gas boilers, fuses are triggered even with the correct setting of the pressure of the built-in expansion tank. This indicates that the volume of the tank is too small for such a heating system. In this situation, it is recommended to install an additional hydraulic tank.

Additional information

The expander helps to damp hydraulic shocks created by air locks and abrupt closing of the valve. The tanks will be able to perform a similar function if they are installed on the return path of the heat carrier directly in front of the boiler. Do not assume that the pressure set at the plant will be optimal for functional needs. Its readjustment is carried out by a spool.

The main thing: any device for determining the value of pressure when measuring the pressure in the expander registers only an excess value, to obtain the full figure, add 1 bar.

The pumped-over tank does not stop working badly, because the air will push the heat carrier out. If everything is configured correctly, but the fuses continue to discharge water sometimes, the fastest of all, the problem is the unnecessarily small volume of the expander. Therefore, it is necessary to select tanks that can accommodate 10% of the entire heat carrier circulating in the system, or even more. Since the tank does not include fittings for devices to determine the magnitude of the pressure, they must be connected to the nipple. It is located on the opposite side in relation to the contour filling the heat carrier.

Since automobile and bicycle pressure measuring instruments measure pressure in MPa, it is necessary to compare their readings with the pressure in the heating system (expressed in bar or kgf / sq. Cm). One bar equates to 100 kPa. When using a car meter, it is advised to wait 10 minutes after turning off the boiler so that the circulation stops. When the tank is mounted in itself boiler, it is supposed to close not only the shut-off valves, but also the supply of the heat carrier, and its return. By following these tips, you can make your life much easier.

Boiler expansion vessel pressure.

Appointment of an additional tank of a double-circuit boiler

As a rule, built-in expansion tanks in gas boilers have a volume of about 6-8 liters. They are designed to compensate for the expansion of 120 liters of heating medium circulating in the heating system. Under normal operating conditions, such an expansion tank is enough for a small apartment or house.

When installing radiators of non-standard shapes and sizes, the heating system must be equipped with an additional expansion tank. Since these batteries hold more water

If the heating area is large, a warm floor is installed or there are many radiators in the rooms, the volume of the standard built-in tank will be small, since more water is used.

When heated, the excess coolant completely fills the tank. And since there is no free space in the tank, the water pressure increases in the heating system itself and an emergency discharge occurs with a safety valve. After that, the gas boiler will hardly be able to automatically turn on.

To avoid such negative consequences, an additional expansion tank with a membrane is installed in the heating system in the design for a double-circuit gas boiler. When the standard tank is full, the water will drain into the spare hydraulic tank. After cooling, the liquid returns to the radiators.

Calculation of the volume of the expansion tank

It is not difficult to ensure the stable operation of the heating system, the main thing is to choose the right volume of the expansion tank. The calculation of the volume of the expansomat should be made taking into account the most intensive operating mode of the gas boiler. At the first start-up of heating, the air temperature is not yet very low, so the equipment will work with an average load. With the arrival of frost, the water warms up more and its amount increases, requiring more additional space.

It is recommended to select a tank with a capacity of at least 10-12% of the total amount of liquid in the heating system. Otherwise, the tank may not cope with the load.

You can independently calculate the exact capacity of the expansion tank. To do this, first determine the amount of coolant in the entire heating system.

Methods for calculating the volume of water in the heating system:

- Completely drain the coolant from the pipes into buckets or another container so that the displacement can be calculated.

- Pour water into the pipes through the water meter.

- The volumes are summed up: the capacity of the boiler, the amount of liquid in the radiators and pipes.

- Calculation by boiler power - the installed boiler power is multiplied by 15. That is, for a 25 kW boiler, 375 liters of water (25 * 15) will be needed.

After the amount of coolant has been calculated (example: 25 kW * 15 = 375 liters of water), the volume of the expansion tank is calculated.

There are many methods, but not all of them are accurate and the amount of water that can fit into the heating system can be much larger. Therefore, the volume of the expansion tank is always selected with a small margin.

The calculation techniques are quite complex. For one-story houses, use the following formula:

Expansion tank volume = (V * E) / D,

Where

- D - indicator of the efficiency of the tank;

- E - coefficient of liquid expansion (for water - 0.0359);

- V - the amount of water in the system.

The indicator of the efficiency of the tank is obtained by the formula:

D = (Pmax — Ps) / (Pmax +1),

Where

- Ps= 0.5 bar - this is the indicator of the charging pressure of the expansion vessel;

- Pmax - maximum pressure of the heating system, on average 2.5 bar.

- D = (2,5-0,5)/(2,5 +1)=0,57.

For a system with a boiler capacity of 25 kW, an expansion tank with a volume of: (375 * 0.0359) / 0.57 = 23.61 l is required.

And although the double-circuit gas boiler already has a built-in tank of 6-8 liters, but looking at the results of the calculations, we understand that the stable functioning of the heating system without installing an additional expansion tank will not work.

Installation question

How to install an additional expansion tank? First you need to calculate its volume. The most commonly used option is 10 liters. Often, its installation takes place with a reserve. And it turns out a volume of 12 liters.

Before installation, it turns upside down. The stub is removed. The nipple for the machine pump becomes open.

This pump is put to it, air is expelled.

Then air is pumped into the tank again. Its parameter is 1.8-2 kPa. This pressure must be in the expansion vessel of the boiler. The indicator in the network is inferior to these values by 0.2 - 0.5 kPa.

After these steps, you can install the tank.Only here another dilemma arises - where is the expansion tank installed in the heating system? The answer lies in the instructions for the RB: the most suitable place for installation is where the pressure is lowest.

But before that, the system is prepared:

- The boiler is turned off from it.

- The valves supplying water to the heating equipment are blocked.

- Water is removed from the batteries. For better draining of the liquid, Mayevsky's taps are opened.

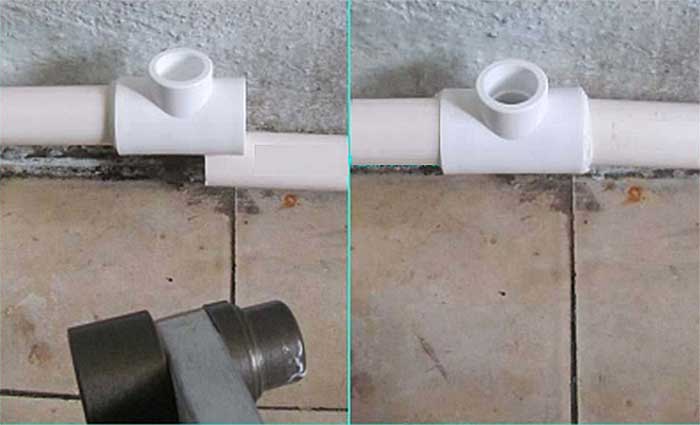

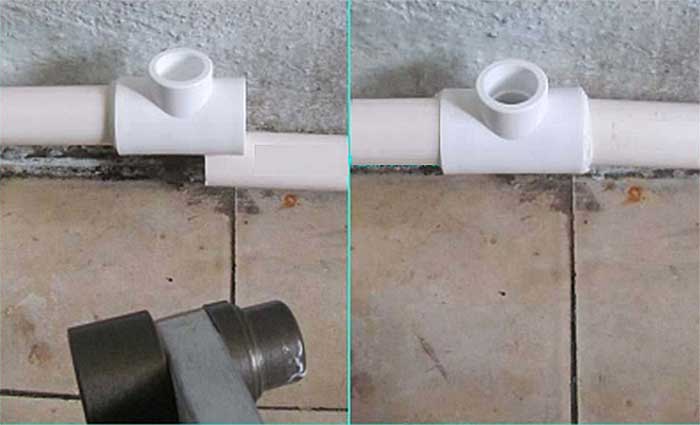

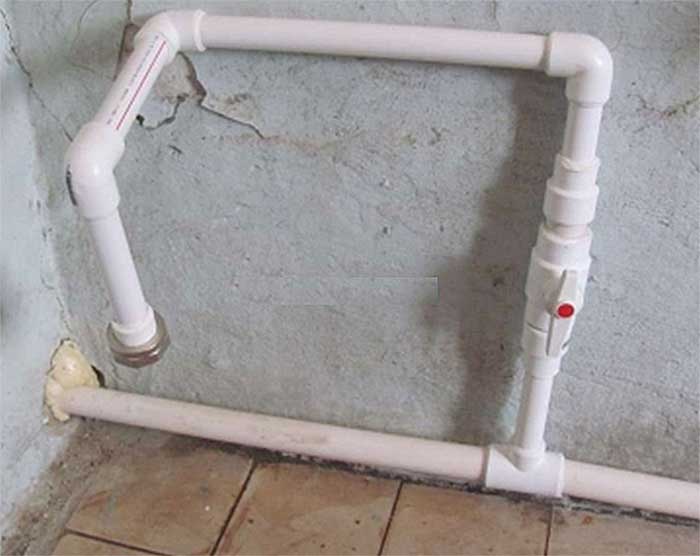

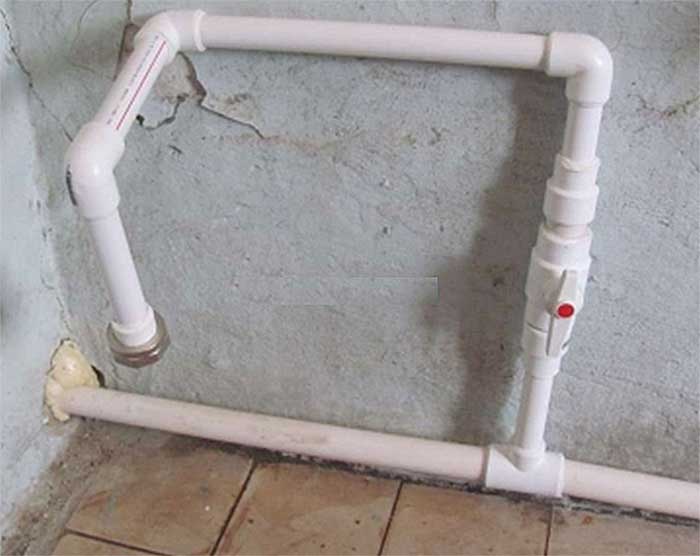

The following is an example with a network of polypropylene pipes. Here, to connect the RB, a pipe soldering unit, couplings, fittings and corners are required. It is optimal to use "American" here.

Before attaching it, a sealant is wound on its thread: flax and a special paste, for example, "Unipack".

The first part of this fitting is screwed in with a gas wrench.

Make sure there is no water in the network. Then the pipes can be mounted.

RB is put in the "return line". This is the path that fluid flows into the apparatus from the batteries.

The brazing unit starts up. The required temperature is fixed on it.

The pipe is cut in the area of the intended soldering. Special scissors are used.

When the unit heats up, the tee is soldered.

A pipe is soldered to it, then a shut-off valve. This will make it possible to repair the RB without draining the water.

After that, the corners are used. With their help, the pipes are soldered so that the final coupling is easily connected to the tank.

It is better to solder all components on the self-leveling floor. And then the formed structure joins the network.

After these actions, RB is connected. An American is screwed on it. The tank is placed in the lower corner, against the wall. This makes it easy to access.

While there is no water in the network, you can clean or change the filters.

Next, the water supply valves are opened. The radiators are filled up to the level of 1.2-1.3 kPa.

The pipes are free of air. Mayevsky's valves are being screwed on. The boiler starts up.

It would not hurt to check how the RB functions. It is filled with air up to 1.6 atm. The equipment turns on. Data in the network is brought up to 1.5 atm. Air is removed from the RB through the nipple. As an indicator, it will turn out to be less than 1.5 atm, water from the network will penetrate into the tank. This will be reflected on the thermometer: its arrow will fall. This is a sign that all operations were carried out correctly, and there are no errors in the RB connection.