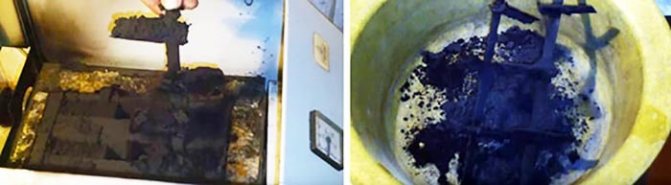

Consequences of a clogged heat exchanger

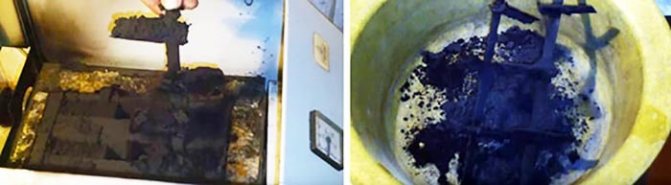

The heat exchanger of a gas boiler is a bent pipe made of metal or cast iron. It is heated by the flame of a gas burner, and then transfers heat to the heat transfer fluid, which moves throughout the heating system. If the heat exchanger is clean, it gives off heat efficiently. When salt deposits accumulate in it, its thermal conductivity decreases. Then the gas boiler has to heat the coolant longer, which entails an increase in fuel and electricity consumption.

In case of severe contamination of the element, in order to maintain the desired temperature, it must be in the maximum heated state for a long time - this leads to overheating of the heat exchanger and its failure.

Deposits and limescale also impede the movement of the coolant along the circuit. As a result, the load on the circulation pump increases.

Thus, a contaminated heat exchanger threatens failure not only of the element itself, but also of other important units of the unit. To prevent damage, the boiler should be cleaned regularly.

…

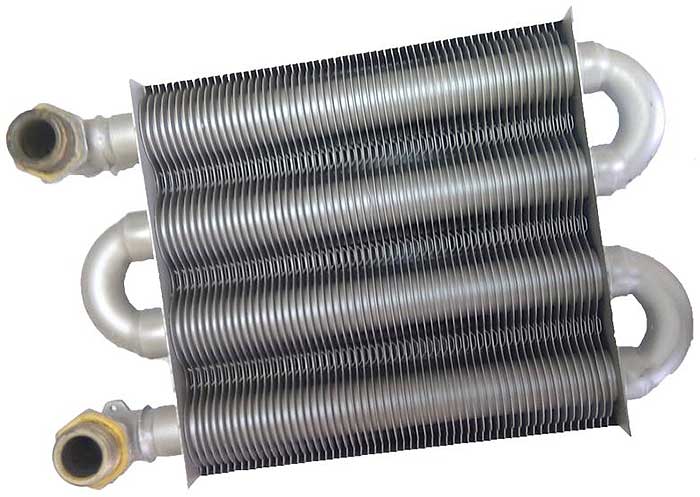

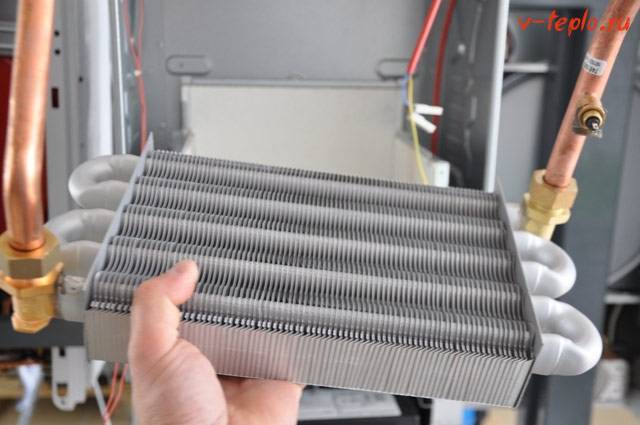

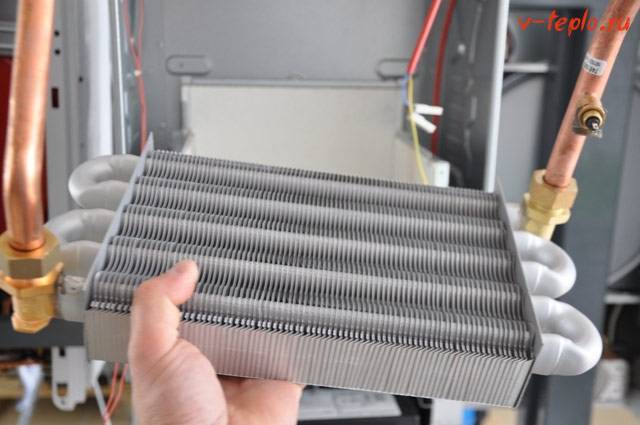

Note! In double-circuit models, the secondary heat exchanger, which works to heat hot water, often fails.

Heat exchanger material

The choice of a secondary heat exchanger for a gas boiler should be carefully so that it can work without interruptions for a long time.

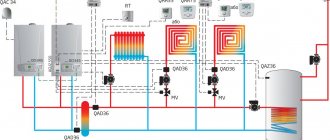

If the DHW tap is closed, then the coolant enters the primary heating circuit. The principle of operation of the secondary heat exchanger is as follows: when the hot water tap is opened, the three-way valve redirects the flow of the coolant from the primary to the secondary circuit; cold water begins to flow in and mix with the heated liquid, and then warm water comes out of the tap.

Secondary heat exchanger made from:

- copper;

- structural steel.

The copper heat exchanger has the following advantages:

- long service life;

- excellent thermal conductivity;

- low susceptibility to corrosion.

The disadvantage is its expensive price.

…

Steel heat exchangers are more common as they have the following advantages:

- sufficient thermal conductivity;

- cheap cost.

The downside is the susceptibility of the steel product to corrosive processes. However, in this case, you should pay attention to the quality of the material. Reputable gas boiler manufacturers manufacture heat exchangers from high quality structural steel with anti-corrosion coating. Such circuits can last long enough without breakdowns.

Note! The secondary heat exchanger is more prone to clogging with salt deposits due to the low heating temperature of 30-60 ° C. To avoid the occurrence of frequent blockages and extend the operating life of the circuit, it is imperative to put a filter on the cold water inlet.

How often should the heat exchanger be cleaned?

The frequency of cleaning the heat exchanger of a gas boiler is usually indicated in the operating instructions. If there is a filter on the water inlet pipe, then cleaning can be done less frequently. If there is no filtration and there is hard water in the region, then the heat exchanger will clog up faster.

Usually, without a water filter, cleaning is done once a year or two. If the tap water is filtered, it is sufficient to take care of the heat exchanger once every 4 years.

Exist signs that urgent circuit cleaning is needed:

- Fuel consumption has increased - with a clogged circuit, gas consumption can increase by 15-20%.

- The performance of the heating system has decreased.Signs of this may be as follows: poor heating of the batteries, the unit cannot reach the required temperature and works continuously.

- Weak water pressure from the DHW system or insufficient heating.

- Noises in the heat exchanger.

- An increased load on the circulation pump is created.

If at least one such "symptom" appears, the heat exchanger should be cleaned as soon as possible, otherwise inaction will lead to costly repairs.

Features of the secondary heat exchanger care

It should be noted that during the operational period it is necessary to monitor the state of the secondary circuit. It is more susceptible to clogging than the heating channel, therefore it is periodically necessary to flush the secondary heat exchanger of the gas boiler. This is most efficiently done with the help of special solutions. It is necessary to flush once a year or six months, depending on the rate of build-up of deposits.

If it becomes necessary to replace a broken circuit, it is recommended to choose a branded part. Then it will fit perfectly into the gas boiler device.

Gas boiler cleaning options

There are several basic methods for cleaning gas boiler heat exchangers:

…

- manual;

- chemical;

- hydrodynamic.

Which method to use depends on the degree of blockage. Let's take a closer look at each of the listed methods.

Manual cleaning

Not all users of gas boilers know how to clean the heat exchanger of a gas boiler themselves. The easiest way to do manual cleaning is to do it yourself. There are two ways to accomplish this method:

- mechanical - with a brush and a brush;

- flushing with active solutions is a more effective option, especially relevant for boilers with two circuits.

In case of stubborn dirt, two methods of descaling are used - first rinsing, and then mechanical cleaning. This process is carried out in the following stages:

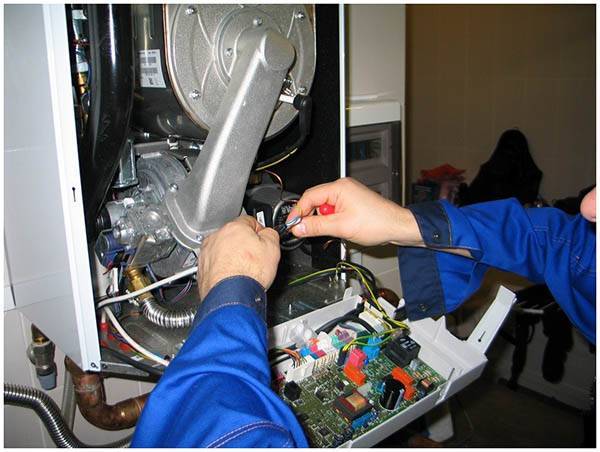

- turn off the gas and disconnect the unit from electricity;

- open the lid of the gas boiler;

- dismantle the heat exchanger;

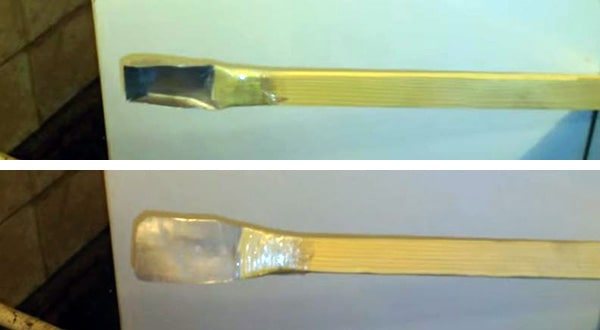

- place it in an active substance, for example, a solution of hydrochloric acid;

- pull the heat exchanger out of the solution and clean the dirt with a brush or brush;

- rinse the element with water outside and inside;

- dry and reinstall the circuit.

Dry cleaning

Chemical cleaning is characterized by the use of a booster or its analogues, as well as aggressive chemicals. An important condition for chemical cleaning is to maintain a safe concentration of the substance so that it does not corrode the surface of the heat exchanger.

Dry cleaning is carried out using a booster, but many craftsmen create its cheap analogue with their own hands. To do this, take a container of 10 liters and attach two hoses and a pump to it.

Find out here how to change a gas boiler - rules and responsibilities

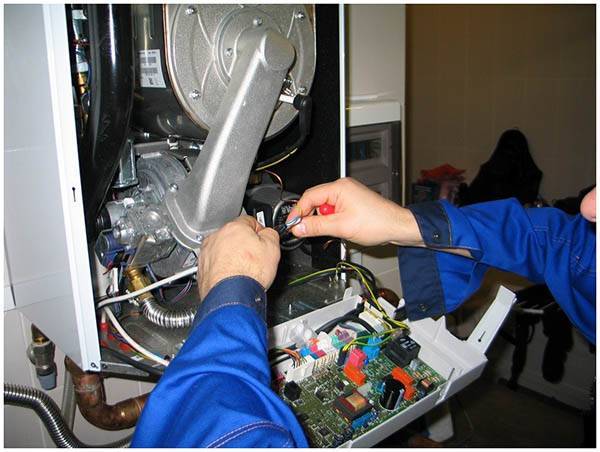

Maintenance and repair of gas boilers

Replacing the heat exchanger in a gas boiler with your own hands

If the limescale layer is too large, you can use a sulfuric or hydrochloric acid based substance for cleaning. The simplest cleaning solution is made from citric acid: 200 g of powder is diluted with 5 liters of water.

The chemical cleaning process is quite simple:

- the chemical solution is diluted in containers and poured into a booster;

- two hoses are connected to two boiler nozzles - inlet and return;

- turn on the device and run the liquid through the heat exchanger several times.

Factory boosters have a heating function, which allows you to flush the circuits with greater efficiency.

After the procedure, it is necessary to drain the reagent and flush the system again with a neutralizing agent or clean water.

Of course, dry cleaning is more effective than manual cleaning, however, the active substances contained in solutions can lead to corrosion.Therefore, this method cannot be used often.

Heat exchanger cleaning solutions

Some owners of gas boilers on the forums are interested in how to rinse a gas boiler from scale at home. Usually, the following agents are used for dry cleaning:

- Cleaning gel - This is considered to be the mildest cleaning agent. After that, it is enough to rinse the heat exchanger with running water. Despite the gentle effect, the gel copes well with scale and lime deposits.

- Adipic acid - in order to flush the heat exchanger of a gas boiler with acid, it is important to dilute it with water in the correct proportion, otherwise the substance will damage the metal surface. Adipic acid well softens all deposits inside the heat exchanger. After flushing the system with this agent, the neutralizing liquid should be driven through it.

- Sulfamic acid - good for dealing with tough dirt. The substance is diluted with water and filled into a booster. After the completion of the process, it is necessary to flush the heat exchanger with a neutralizing liquid.

Note! When performing dry cleaning, you should wear rubber gloves on your hands, and protect your body with overalls through which the acid solution cannot get on the skin.

Hydrodynamic cleaning

This method of cleaning the heat exchanger is carried out only by specialists. It is unnecessary to disassemble the boiler and remove the heat exchanger for its implementation. The principle of hydrodynamic cleaning is as follows: the liquid is pumped into the system and driven under pressure several times. For greater efficiency, abrasive cleaning agents are added to the water. It turns out that due to the rapid movement of water, scale disappears and contamination is washed off.

However, with this method, it is important to correctly calculate the pressure force - if it is too large, a pipe break may occur. Therefore, hydrodynamic cleaning cannot be performed on your own.

Do I need to conclude a contract for the maintenance of a gas boiler?

How to properly ground a gas boiler? -

https://oteple.com/kak-pravilno-vypolnit-zazemlenie-gazovogo-kotla/

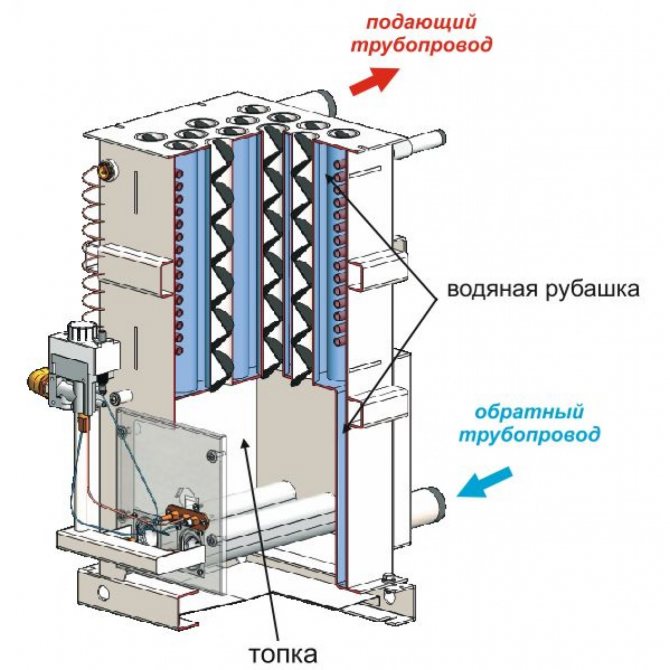

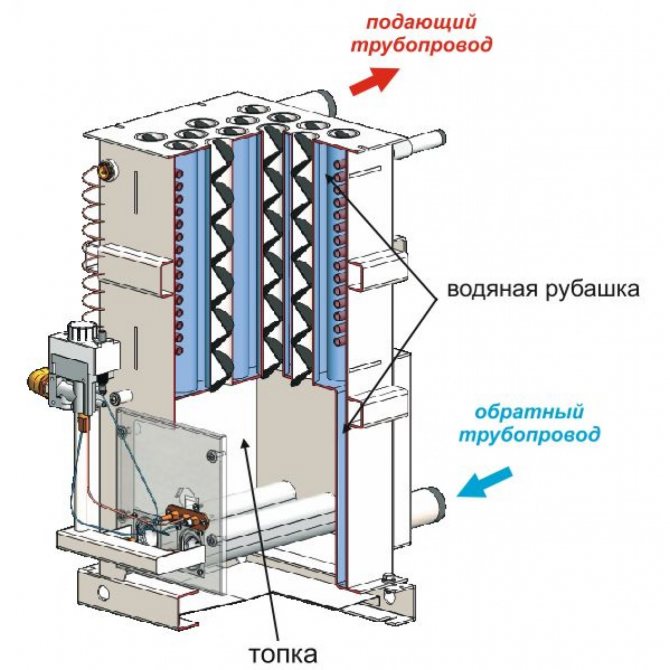

How to clean the heat exchanger of a floor-standing gas boiler

To disassemble the heating unit at home, you do not need any special tools, a simple set with screwdrivers, keys and pliers is enough. Preventive cleaning of the heat exchanger from soot and scale is carried out in the off-season, when the heating of the house is turned off. Having previously shut off the gas supply, we begin disassembling the boiler by removing the burner in the following sequence:

- Disconnect all wires from the gas valve.

- Remove the thermocouple from the combustion chamber, connected to the gas valve by a capillary tube.

- Disconnect the gas inlet.

- Remove the 4 nuts (or bolts) holding the burner plate. Pull the assembly outward as shown in the photo:

The burner can be removed with the safety valve and mounting plate

The gas boiler burner is cleaned without further disassembly using an old toothbrush. The igniter, piezoelectric ignition device and flame sensor (if any) should also be cleaned of soot. Now you need to get to the heat exchanger, for which you need to remove the top cover of the boiler, disconnect the draft sensor and the chimney.

In the opening that opens, you will see insulation covering the chimney casing. Carefully remove the insulation, and then unscrew the screws securing the casing and remove it. There is a heat exchanger under it, from which steel turbulators need to be removed, as shown in the photo:

When removing the turbulators from the heat exchanger, the soot spills down, so the first thing to do is remove the burner

It is not difficult to clean the turbulators; this is done with a regular metal bristle brush.But cleaning the heat exchanger of a floor-standing boiler is best done with the help of simple tools, made by hand according to the size of the smoke tubes. If they have a rectangular cross-section, then you need to bend a comfortable flat spatula and a small scraper in the form of a scoop out of thin metal, then nail it to a wooden handle.

For round flame tubes, the same tools are made slightly curved. First, the pipe walls should be cleaned with a scoop, after which the soot remaining in the corners should be removed with a spatula.

At the end of the work, all surfaces of the heat exchanger can be covered with a brush screwed to a long handle. The last step is to remove soot from the bottom, where it was poured when cleaning the smoke tubes. This is what a clean heat exchanger of a heating unit looks like:

You can take a closer look at how to clean a gas boiler at home in the video:

Note. In the video presented, the wizard violated the sequence of actions. He first cleans the heat exchanger and then removes the burner, which is covered with soot. It is wrong to do this, first you need to remove the burner, and only then clean off the carbon deposits from the walls of the flame tubes.

What are the differences between cleaning a double-circuit gas boiler?

How to flush the secondary heat exchanger of a gas boiler with your own hands? There are no fundamental differences between flushing the DHW circuit and the heating heat exchanger. It's just that in the case of a two-circuit model, you will have to clean not one, but two elements.

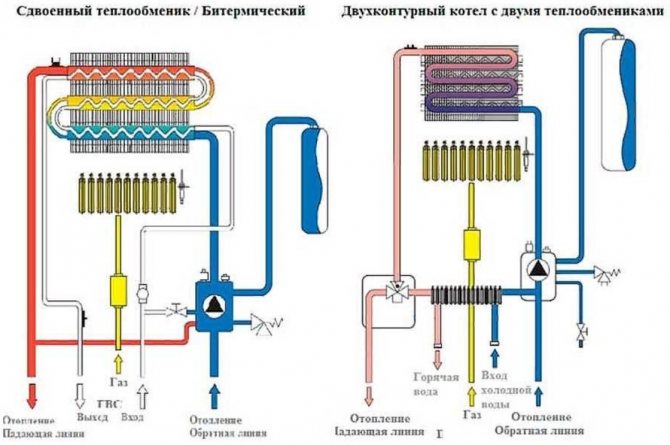

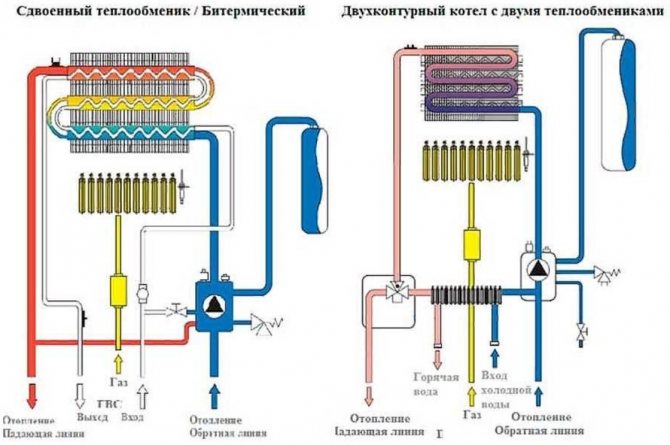

Double-circuit gas boilers can be equipped with two types of heat exchangers:

- removable secondary;

- bithermic.

The first option is cleaned in the same way as the primary circuit using manual or dry cleaning using a booster:

- connect the hoses of the booster with nozzles for cold water supply and hot water outlet;

- the apparatus is put into operation with heating of the reagent (t = 50-55ºC).

For manual cleaning, the secondary circuit is dismantled and immersed in a citric acid solution. Then brushed outside and dried.

A bithermal heat exchanger consists of two pipes inserted into one another: a coolant moves along one of them, hot water flows along the other. Its cleaning is much more difficult to carry out, especially since such a circuit cannot be dismantled as a separate analogue. Therefore, flushing of the bithermic circuit can only be performed using a booster. If such an element is heavily contaminated, then it is simply impossible to clean it. Then you will have to buy a new bithermal heat exchanger and install it instead of the old one.

When to clean up

There are 3 options for the development of events:

- Preventive cleaning of the boiler is done by the homeowner with his own hands 1 time in 2 years at the lowest cost.

- The procedure is performed as the heat exchangers become dirty with soot and scale, which reduces the efficiency of heating and heating water for hot water needs. In this situation, you can still clean the boiler yourself, although calling the master is also not excluded.

- The heat generator has stopped due to a breakdown, which often happens during the heating season. The malfunction is eliminated by the called specialist, who also cleans the heat exchanger from soot.

The last 2 scenarios are clearly unattractive for home owners, since they are associated with inconvenience and financial costs. You cannot do without a master even if a condensing boiler with a burner and a heat exchanger of a special design is used for heating. It is not recommended to climb there on your own, unless you are well versed in heating equipment of this kind.

Conclusion: Preventive cleaning and flushing of the heat exchanger of a double-circuit gas boiler is performed quite quickly and does not require costs, therefore it is the best solution.

What is the best way to flush the heat exchanger?

Some people get lost in the variety of contouring substances and often choose the most powerful ones that, with regular use, negatively affect the metal. Experts say that it is better to use such funds as a last resort, if more gentle solutions did not fit. The most versatile remedy is citric acid - it cleans scale no worse than all kinds of expensive products, but at the same time does not damage the surface of the heat exchanger.

If you rinse the circuit in time, and do not wait until the pipes are completely overgrown with salt deposits, then you will not have to use aggressive substances to clean a small layer of scale.

Basic flushing methods

To begin with, a heat exchanger is, first of all, a pipe system with a fluid moving inside. But the water used in the systems is usually not of high quality. Various metal salts present in it settle on the walls of the structure, become scale and narrow the passage. There are three ways to deal with limescale:

- mechanical;

- chemical;

- by pumping liquid into the system under strong pressure.

The article discusses only do-it-yourself cleaning, in connection with which we will not talk about the third method. It is definitely not possible to cope with it alone, since you will need a special compressor capable of creating a pressure of about 10 atmospheres. Only with this device can deposits on iron surfaces be broken.

Note! With the other two methods, you can easily cope with your own hands. Let's make a reservation right away that this is quite difficult, and the corresponding skills will be required.

Video - Cleaning of heat exchangers

Method number 1. Mechanical flushing

If this flushing of the gas boiler heat exchanger is used, do not forget that the exchanger itself takes up a lot of space in the heat generator. It is located above the combustion chamber, so it is not easy to get there. The algorithm of actions should be as follows.

Step one. The upper part of the case is removed. To do this, you must turn off the electrical power and gas supply (if all this is provided for by the boiler design).

Step two. The exchanger is disconnected from the heating main.

Step three. The fixtures of the device are removed.

After that, you can remove the heat exchanger from the heat generator and proceed directly to the flushing procedure. And what can you see after dismantling? As a rule, all internal cavities are clogged with scale - metal, calcium or sodium salts, and also trivalent ferum.

You will have to use metal tools for cleaning - pins, scrapers, and so on.

During work, special care should be taken so as not to damage the surface of the structure.

In some cases, the device is moistened in a container filled with a mild hydrochloric acid solution. And as soon as the scale softens, you can start removing it. At the end of the procedure, all internal voids are flushed with water under low pressure. For this purpose, you can attach a hose connected to the water supply system.

You will be able to see for yourself how much dirt will pour out. You need to wait until clear water begins to flow. Additionally, you can tap the surface of the device with a mallet (this is a special hammer made of wood or rubber).

Complete instructions for flushing a gas boiler

Earlier we talked about how to completely flush and clean a gas boiler with our own hands, we advise you to read this information

Method number 2. Chemical washing

Let's make a reservation right away that such a flushing is a rather complicated procedure. In the course of work, you will need a special device called a booster. And, despite the fact that this option is extremely simplified, to implement it, you still need to know about a number of important nuances.

What is the simplification of the technique? First of all, there is no need to remove the heat exchanger and dismantle some of the elements of the gas boiler. It is only necessary to disconnect a pair of nozzles (a special hose must be connected to one of them, through which the cleaning agent will be supplied to the inside of the case). Having passed through the body, the agent will come out through the second nozzle, to which a hose will also be connected. Therefore, both in the exchanger and in the booster, the agent will move in a circle.

Now let's look at what components the booster itself consists of. These include:

- container for a chemical;

- an electric heater (it is far from all models, but people with experience advise purchasing just such models; this way the reagent will heat up, and being warm, it removes salt and dirt scale more quickly and efficiently);

- pump.

Note! Such chemical reagents can be various kinds of solutions that are freely available on the domestic market. And the question of choosing the right reagent is the most pressing

In each specific case, it is necessary to take into account not only the degree of clogging, but also its type, as well as the material used in the manufacture of the heat exchanger.

Next, we will find out by what means the gas boiler heat exchanger can be flushed.

Stove with a heat exchanger for a bath

Earlier we talked about how to choose a good stove with a heat exchanger for a bath, we advise you to read this information

Cast iron heat exchanger

It does not corrode, therefore it is more durable than steel. Requires special attention to operating conditions. The most vulnerable point is the border between the hot and warm parts of the recuperator. Operational errors increase the risk of metal cracking in this area. To prevent this, you should regularly flush the gas heat exchanger. The installation on the return line near the heat exchange unit of a three-way mixer valve, which pre-mixes hot and already cooled water and supplies a medium temperature liquid to the cavity, will help to minimize the risks. It should be remembered that boilers of foreign manufacturers with cast iron recuperators are not adapted to Russian operating conditions, therefore they are very vulnerable.

Copper heat exchanger

Its advantages include low specific gravity and small capacity of the device, compactness, corrosion resistance, low fuel consumption for heating to operating temperature. The main disadvantages of such heat exchange equipment are high cost and insufficient reliability.

Classification, principle of operation

There are two media in a gas boiler - gas, liquid. In order to transfer the temperature of the air, obtained during the combustion of the gas, to the coolant, a heat exchanger is used. There are:

- primary;

- secondary;

- biothermal (combined).

Primary

Primary - heat exchangers that receive heat from a source. Included in the heating circuit. They are located in the boiler above the gas nozzles (coil overgrown with plates). A coolant, more often water, passes through the tubes. Hot gases passing through plates and tubes heat the water. It is driven by a pump, goes into heating. The gases are removed through the chimney.

Primary maintenance

Secondary

Secondary heat exchangers receive heat from the heated heat carrier. They are located outside the combustion chamber. Heating comes from the liquid. The simplest and most frequently used method is to use a plate heat exchanger. The sealed body is divided into two parts by a thin partition. On one side of the partition, a heated liquid flows, on the other - water, taking heat.

Sectional view of the secondary plate heat exchanger

There is another way. A coil passes through a large container filled with water.A heated coolant passes through it, giving off heat to the surrounding liquid.

Combined (biothermal)

Installed inside the firebox. Has four connections. One pair is connected to the heating circuit, the other to DHW (hot water supply).

Biothermal heat exchanger

The difference is within the structure. The heating circuit is heated by hot gases, the hot water supply circuit is heated by heating. Inside the tubes of the coil are tubes of a smaller diameter. Fastened with plates at an angle of 120 or 90⁰.

Cut tubing, contour slots

During the operation of the boiler, the liquid in the first circuit (heating) heats up and goes into the system. Preliminarily, part of the heat is transferred to the tubes of the second DHW circuit, where the heat carrier is also heated.

Differences between biothermal and two separate heat exchangers

When the analysis of water from the second circuit begins, the first circuit is closed so that the heat received from the boiler is transferred to the DHW. When the parsing of water from the hot water supply stops, the first circuit is connected, the heating starts to work.

Schemes in two modes

Steel heat exchanger

A widespread option due to its ease of manufacture and affordable price. Heat exchangers made of steel alloys are ductile, strong enough and resistant to mechanical stress. At the same time, their service life is short due to frequent corrosive processes, and their operation requires increased fuel consumption to heat the coolant and maintain the standard temperature regime.

How to make the right choice?

Above, we gave detailed information about what boilers with separate or bithermal heat exchangers are like, talked about the principle of their operation, listed their advantages and disadvantages.

Choosing a boiler model, you should start from the goals and operating conditions. You need to understand that no matter what choice you make, you will have to compromise with some shortcomings and get used to the peculiarities of servicing a particular model.

The bithermal heat exchanger is cheaper, and this fact attracts many buyers. If you use a high-quality heat carrier without a large amount of impurities, the boiler maintenance will be inexpensive, since its design is much simpler than that of boilers with two separate heat exchangers.

Choosing a boiler with a bithermal heat exchanger, it is easier to choose a reliable model, while equipment with separate heat exchangers requires a closer study of all characteristics and design features.

Wall hung boilers with separate heat exchangers

A standard boiler works as follows: with the help of a circulation pump, the heat carrier is constantly moving through the first heat exchanger, which is heated by the burner. Thus, hot water flows through the heating system from the heat exchanger to the radiators and vice versa.

When there is a need for hot water supply, a special sensor gives a signal and a three-way tap directs hot water from the first heat exchanger to the second. In other words, cold water in the second heat exchanger is heated not from the burner, but from the already heated coolant.

This method allows you to reduce heating costs due to more economical fuel consumption while consuming hot water for domestic needs.

Advantages of using boilers with separate heat exchangers:

- The maximum hot water temperature does not exceed 60 degrees. This is enough for any need. In this case, the likelihood of getting a burn while taking a shower is reduced to zero.

- The second heat exchanger has a long service life, as it is used less often.

- Uncomplicated design. Boilers with separate heat exchangers are easy to repair. In most cases, you can do it yourself, saving on the services of professional craftsmen.

- The risk of clogging is minimized.Practice shows that the need for maintenance for separate heat exchangers arises less often than for bithermic ones.

Important: While the split heat exchangers are easy to maintain, it is best not to do it yourself unless you have experience. It may be dangerous. In all documents supplied with heating equipment, manufacturers insist on refraining from DIY repairs.

Disadvantages:

- Separate heat exchangers take up more space, as a result of which the boiler may be larger than the purchaser requires.

- Boiler operation is impossible without a three-way valve. Its task is to automatically redirect the flow of water to a second heat exchanger when the residents of the house start using hot water. Such cranes often fail and need to be replaced, which creates great inconvenience.

- The price for boilers with separate heat exchangers may be higher due to the larger number of components.

As you can see, such boilers have not only positive qualities, but also disadvantages that you definitely need to know about before making a purchase decision.

As an example, consider the wall-mounted boiler Baxi Eco Compact 14F. This model is popular in the market due to its affordable price, compact size and good electronics.

The water heating temperature (DHW) is in the range from 35 to 60 degrees. The boiler runs on natural gas and consumes 1.6 m3 of fuel per hour. Its compact dimensions (700x400x298 mm) allow it to be installed in any room without any special site preparation.

The boiler with separate heat exchangers Baxi Eco Compact 14F is recommended for installation in rooms with a total area of not more than 140 m2. This equipment can easily cope with operation in Russian conditions, which is confirmed by many of our customers who have bought the Baxi Eco Compact 14F boiler.