Penoplex, as the name suggests, is a penoplex made of extruded polystyrene foam. The company that produces this material in Russia appeared in 1998, when it was the only company that produced thermal insulation materials by extrusion. Later, the company expanded its capacity and product range.

Extrusion is the process of extruding molten material through a die (orifice in a die). Penoplex is made of polystyrene at high pressure and high temperature. The result is a relatively homogeneous structure with small pores (about a fraction of a millimeter).

The foam complex in the production process is light and durable, suitable not only for insulating a house, but also for insulating roads and airport runways. It absorbs water easily and has very good thermal insulation properties.

On the Internet you will find a large number of reviews on this material: is the foam complex harmful to health, is it flammable and is it durable? The points of view are very different and often contradict each other.

There are different types of foam plexus. Some of them are more durable, others are less heat conductive or less flammable, which is achieved by the introduction of special additives. (Read more about the universal foam form in this article.)

Here are some of the technical characteristics of this material (type 31):

- Density - from 28 to 32 kg / m3;

- Compression density - 2 kg / cm2;

- Water absorption per day does not exceed 0.004 of the volume;

- Fire resistance class - G1 (fire resistance), others - G3 (normal fire resistance);

- Thermal conductivity - 0.03 W / m˚C;

- Vapor permeability coefficient - 0.008 mg / m-h-Pa;

- The temperature at which this material should be used is between -50 and +75 degrees Celsius.

Detailed information on the technical properties of polyurethane foam can be found in this article.

Note: The foam complex is a two-phase material, i.e. consists of plastic and air, which makes it an excellent soundproofing material.

What should be the insulation?

Since there is no objective data on the allegedly harmful effects of penoplex on a person, we will figure it out ourselves.

Choosing a heater, many buyers, having familiarized themselves with the operational characteristics of the products of PENOPLEX SPb LLC, ask themselves the question: "Is penoplex not harmful to health?" Needless to say, there is a lot of talk about the harmful effects of penoplex, but let's try to figure it out. The selected insulation for structures or structures must meet the following requirements:

- the material used should not contain dust and small fibers, which confirms the inconsistency of statements about the dangers of foam for the house, since these factors are absent;

- phenol-formaldehyde resins and similar harmful substances are absent in the penoplex, which makes it possible to give a negative answer to the question: "Is penoplex harmful or not?";

- whether penoplex is not harmful to the environment and human health can be judged on the basis of the fact that during its production, means that destroy the ozone layer of the Earth are not used;

- when the insulation is operated from 50 degrees of frost to 75 degrees of heat, as recommended by the instructions for penoplex, there are no harmful emissions for humans, which is confirmed by the sanitary-epidemiological and environmental conclusion.

The harm of polystyrene to human health

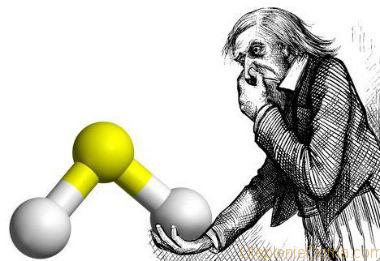

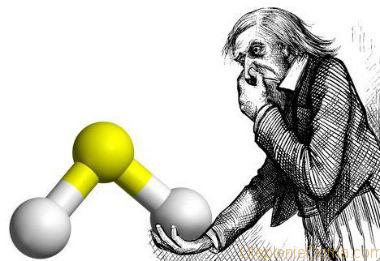

Styrene has a strong, pungent odor.

Today we will tell you how dangerous polystyrene is for health. The harm of this insulation has been proven by scientists who have conducted research in this area. Manufacturers insist that the foam is harmless, but the facts tell a different story.

It contains styrene (a strong poison), a highly flammable material that exacerbates the situation in the event of a fire.

The widespread use of this thermal insulation is explained either by the low awareness of people about its toxic qualities, or by a conniving attitude towards their health and their loved ones.

Styrene foam

Styrene is a toxic, colorless substance that is used to make polymers, particularly polystyrene. The harm caused by this poison to human health is very significant. In severe cases, everything can end with damage to the central nervous system, blood diseases, disruption of all organs, leading to death.

The manufacturing methodology of conventional foam and extruded foam is slightly different, as well as the characteristics of these materials. At the same time, the raw materials are practically the same, therefore, extruded polystyrene is harmful to health in the same way as foam.

Through the polymerization process, styrene is retained in the material. The problem is that it is impossible to achieve 100% polymerization, maximum 97%. Accordingly, the remaining 3% can freely leave the structure of the material.

In addition, after a fairly short time, the reverse polymerization process begins in the foams, as a result of which styrene is released. The following factors influence the intensity of the process:

- temperature;

- light, especially IR radiation;

- oxygen;

- ozone;

- water.

All of the above makes the depolymerization process more intense. There are established standards for permissible doses of styrene exposure. Scientists from research institutes carried out measurements and found that in rooms insulated with foam from the inside, at room temperature, the styrene level is 10 times higher than the permissible level. When the temperature rises to 75 degrees - the excess is 150 times.

Do not overheat the non-freezing liquid for heating a warm house, as this turns it into acid.

Read about how to choose a liquid for water heating in this article.

Even if you insulate the house with Styrofoam from the outside, some of the poison will still seep into the room. Based on the data of scientists, the harm of polystyrene to health is simply obvious, therefore it is better to insulate the house with mineral wool, it is harmless.

Low vapor permeability of polystyrene

For insulation materials, an important characteristic is their ability to pass steam, that is, breathe.

Foam plastic cannot boast of good vapor permeability, especially extruded, which is 10 times less breathable. Accordingly, the use of these materials entails a violation of air exchange.

As a result, there are places where moisture accumulates. Where it is humid and lacking ventilation, mold grows and grows quickly.

The air in such a room is filled with mold spores.

Walls accumulate moisture over time, regardless of the method of installing the foam. Is fungus harmful to health? Yes, it can cause serious illness.

The fact is that mold multiplies with spores, which it throws into the air.

There can be billions of spores in one cubic meter, therefore, being in a room where the walls are covered with fungus, it is impossible to avoid them entering the body through the lungs.

Disorders in the body caused by fungal spores:

- asthma;

- respiratory tract disease;

- disorder of the digestive system;

- migraine attacks;

- internal bleeding;

- damage to internal organs.

In fact, this problem cannot be underestimated. A childish, fragile organism is especially vulnerable.The solution to the problem is constant ventilation of the room, which is not always possible. For example, in winter you cannot open the window for the whole day. Therefore, it is necessary to use air recuperators. They take heat from the outgoing air streams and heat the supplied ones. So, heat loss is reduced.

High degree of flammability of foams

Fire safety comes first. Fire is the most destructive incident that destroys property and takes lives. According to statistics, most fire deaths are not from burns, but from asphyxiation by carbon monoxide. Therefore, this aspect should not be overlooked.

The facade, insulated with foam, flares up like a match.

As you know, polystyrene burns well and at the same time emits poisonous smoke. Extruded polystyrene foam burns a little worse, however, it cannot be called safe. Is styrofoam harmful? Of course, it significantly aggravates the situation when a fire occurs. It is especially dangerous to use flammable polymers to insulate a house using the ventilated facade technique.

It is worth noting that the manufacturers managed to slightly reduce the degree of flammability of the materials in question, but this is still not enough. On ignition:

- carbon monoxide is released;

- high concentration of toxic substances in the smoke;

- the flame is difficult to localize, the fire spreads quickly.

For comparison, mineral wool does not burn, does not smoke, does not emit poisons and may well be used to insulate a steam room in a bath from the inside. The only non-combustible polymer insulation is polyurethane foam, which is applied by spraying.

Outcomes

Styrofoam is widely used to insulate houses, although there is a safer and cheaper alternative - mineral wool. Polyfoam is harmful to human health.

Even during normal use, it emits styrene, and at high temperatures, the concentration of styrene increases exponentially. In addition, regular and extruded foams are highly flammable.

The process is accompanied by the release of thick smoke with a high content of toxins. Moreover, the cost of such heaters is twice as high as mineral wool.

Non-freezing liquid for heating systems warm house based on propylene glycol - it is not poisonous.

It is necessary to change the liquid for autonomous heating systems every two seasons. More details here.

That is, at a high price you get highly flammable, poisonous insulation, the only advantage of which is simple installation. Living in a house insulated with foam is harmful and this harm should not be underestimated. We strongly do not recommend using this thermal insulation for interior work.

Modern insulation Penoplex - myths and reality

The myths existing among consumers concern not only how much Penoplex is harmful to the human body, but also that a real house must "breathe". Unfortunately, only wood can provide natural microcirculation of air. A beautiful wooden house outside the city is wonderful, but how to build high-rise buildings from such material? In urban apartments - windows and supply and exhaust ventilation provide the necessary air exchange in the room. The alleged harm of penoplex in the house, which consists in the fact that it does not allow the walls of the house to breathe, only testifies in favor of its use, since a house built in accordance with modern requirements should be like a thermos.

But the "vapor permeability" of the walls is not only a myth, but a real misinformation, the harm of which is much greater than even talk about hypothetical harmful substances in the penoplex. It is simply impossible to imagine a multi-storey building, from the walls of which steam comes out on a frosty day.As a result, the walls would be covered with ice, and we would not have to talk about the harmful secretions of penoplex, but about the need to save residents from chronic colds.

A lot can be said about whether penoplex insulation is harmful to health. And we can only remember that the plates of expanded extruded polystyrene were used in the construction of a bathhouse at the international scientific station Novolazarevskaya in Antarctica, which indicates their environmental safety.

You can talk about the dangers of polystyrene for a long time

Most likely, scientists would give several more arguments in order to abandon expanded polystyrene. We will not load you with a whole list of negative factors, complex scientific phrases. After all, even those moments that we have cited are enough to think about the advisability of using foam for solving certain problems. And to understand: not in all cases it makes sense to use foam. Especially when the task is to equip residential buildings. And even more so indoors.

Do not forget that there are many other materials on the market that are capable of adequately replacing expanded polystyrene in some cases. And, at times, surpass it in some respects.

Choose your building materials wisely!

Vyborstm.ru

Interview

Is styrofoam harmful? How do you think?

Is it burning or not?

There is no doubt that modern insulating materials are subject to combustion. Consequently, there is a certain harmfulness of the foam to the body during the combustion of this insulation. At the same time, carbon monoxide and carbon dioxide are released, which poses a danger to humans. Ordinary solid fuel stoves in rural areas are just as dangerous, because in the absence of traction, carbon monoxide can cause death or severe poisoning. When using insulation in the middle of the brickwork or outside, reinforcing it on the walls, it is not necessary to talk about the health hazards of the insulation, since the question: "Is penoplex harmful during combustion?" it is possible to assert with full responsibility that burning penoplex is harmful, like wood, MDF boards, window structures. The statement that penoplex is harmful to the body, since when it burns, hydrocyanic acid and phosgene are released is not true.

Installation of house insulation can significantly reduce financial costs for space heating. Expanded polystyrene is especially popular among professional builders.

In everyday life, this material is most often referred to as foam.

The high popularity of this material makes one think about the question of whether expanded polystyrene is harmful to humans, especially when used as insulation indoors.

In order to understand whether it is dangerous for people to use this material as a heater, and what is its harm to the human body, one should figure out what it is and what the manufacturing technology is.

What are the disadvantages of using a heat insulator?

Back to the table of contents

Heat insulator expanded polystyrene: benefit or harm

Extruded polystyrene foam, like any other material, has its own pros and cons, which you need to know about those who choose this insulation. It must be emphasized that not only the positive, but also the negative aspects of any building material are based solely on its properties.

Extruded polystyrene foam consists of granules that are glued together at very high temperatures. The granules contain air. In this case, the structure contains the main quality of the material. The air contained in the cells is maximally capable of retaining heat, therefore, among all natural materials, it will be one of the best.

The high level of performance of expanded polystyrene is combined with its high protective characteristics, which help to protect the house from cold, insects, bacteria, and moisture. For insects, this material is not of interest, since it is inedible.

The cellular structure gave the material almost everything, but it is worth highlighting the main thing - the material perfectly performs the main task, while solving at the same time the difficulties that arise associated with protection in high humidity conditions or an obstacle to the destruction of wooden elements of houses from insect pests.

There are also certain aspects in the use of the material that you need to be aware of as it is not natural and prevents the surface of the structure from breathing. With normal ventilation, it is very easy to organize the necessary movement of air flows in the room, but the walls themselves will not "breathe". Here, first of all, the properties of the heat insulator play an important role, which do not allow it to pass air, which excludes its circulation.

Some believe that the material is capable of emitting dark smoke when burned. Although without a source of fire, this heat insulator will not burn, forming smoke, which can appear only with prolonged combustion of expanded polystyrene. Usually firefighters arrive much sooner than complete combustion of the material occurs. Most building materials can catch fire much faster than expanded polystyrene.

Back to the table of contents

Conclusions on the harm caused by polystyrene foam to the environment

It can be concluded that extruded polystyrene foam should not be afraid, because it is a modern, high-quality and harmless material.

Expanded polystyrene and all its varieties are quite popular. Is this material so safe when used for thermal insulation at home, as the manufacturers imagine it to be?

It was found that this material does not immediately have a harmful effect, but after a long period of time.

Normal temperature levels cause the material to disintegrate vigorously. In this case, a large volume of poisons and carcinogens are released, which are unsafe for human health. In particular, expanded polystyrene is unsafe in case of fires, since the smoke that is emitted contains a large amount of hazardous organic compounds.

Scientists have recognized expanded polystyrene as an extremely unsafe material when it burns, which has led to conflicting judgments on the part of manufacturers who seek to sell the material at low prices. In the event of a fire, a person is able to get poisoned by poisonous smoke together with volatile substances from the combustion of foam.

For example, foam is used as insulation. How safe is it for humans and can it be insulated?

Many users, in particular the owners of apartments on the upper floors, prefer to carry out thermal insulation work from the inside of the room. What is it fraught with? What insulation to give preference to and what is the difference between polystyrene and polystyrene? Is styrofoam harmful or not for human health? If it is dangerous, then why and what are the harmful properties of foam plastic?

Expanded polystyrene - its composition and production technology

What is Styrofoam and what is it made of?

Expanded polystyrene is a gas-filled material. Its production is carried out by steam heating of specially prepared polystyrene granules.

Polystyrene is preliminarily subjected to a special treatment - its granules are filled with gas.

Depending on the purpose of the final product, natural gas or carbon dioxide can be used.

Carbon dioxide is used in the production of fire resistant material.

In the process of heating, the gas begins filling the granules and expands, which leads to an increase in the volume of the latter. The volume of granules can be increased by 15-30 times.

If the process is not restrained, then at the end of heating, a friable material is obtained, which is used to fill frameless furniture and as a bulk insulation during construction work.

If it is necessary to obtain solid polystyrene foam, foaming is carried out in an appropriate closed form.

In this way, polystyrene foam plates are made, which are used for wall cladding when insulating buildings.

When foaming the foam in a closed mold, a variety of decorative elements are also produced. Boxes for packaging various household items, etc.

This heat-insulating material has a number of advantages, the main ones of which are the following:

- the presence of a high degree of thermal insulation;

- the presence of a long service life of the material;

- low coefficient of water absorption;

- the presence of a low coefficient of vapor absorption;

- high degree of biological resistance;

- lack of attractiveness for the settlement of rodents and various parasites;

- a small mass of finished insulation.

Another significant advantage of this thermal insulation material is its low cost.

Expanded polystyrene harm to health: expert opinion

Do you know how small children differ from teenagers? You ask how this relates to the question: is styrofoam harmful to health? Now you will understand everything. The fact is that young children perceive everything only as "black" and "white". For them, something is either good or bad. There are only two options. Teenagers, on the other hand, know how to distinguish between gradations.

As you probably already understood the harm of expanded polystyrene and its harmful properties - an ambiguous question. And yet, there are several important points to consider when considering whether to use this material during construction or not.

Let's look at the principles of foam production, the areas of its use and installation features, and after that, we will draw our own conclusions.

How "white" insulation is born

So, foam is, in essence, expanded polystyrene. The word "styrene" in the composition is already alarming, but more on that later. For the production of insulation, pentane and methylene chloride are used, among other things. These are high-temperature liquids that are needed for foaming polystyrene.

As a result of foaming, a large number of pores or balls are formed. To convert them into solids, a polymerization process is required. This process is carried out with the participation of toxic substances. By the way, this is where the well-known styrene mentioned above comes into play.

Polymerization - in simple terms, the gluing of molecules, as a result of which high molecular weight, solids are formed.

Clearly, polymerization is the reaction of several chemicals. At the same time, it is clear that no reaction ever goes 100%. It could be 95% -96% or even 99.9%. But, there is always some part of the substance that has not reacted. In our case, it remained a highly toxic substance.

So, to summarize: at its core, foam is made from hazardous substances. However, if all standards are met during the manufacture, this material complies with domestic and even international building hygiene standards.

The relative harmlessness of this material can also be said by the fact that it is used not only as insulation.

From the well-known, "white" material, substrates are made for various goods, including food, disposable dishes, and in some places there are whole foam houses.

Polyfoam is used not only in construction, but also, for example, in the food industry.

How is styrofoam used

Perhaps you remember from your school chemistry course that any chemical reaction, including polymerization, can take place in the reverse order, the so-called disintegration of molecules.

And this means that harmful substances, which once turned into harmless solids, can again be "free" in the form of vapors. For example, the release of substances such as benzaldehyde, formaldehyde and styrene can be harmful to health. But, of course, this requires certain conditions.

Therefore, never violate the foam installation instructions. The two main enemies of Styrofoam are:

- Ultra-violet rays;

- Heat.

The harm of extruded polystyrene foam to the body

The basis for the production of extruded polystyrene foam is the use of special installations - extruders.

This equipment operates on the basis of the use of the extrusion principle, which consists in forcing a heated source material through narrow slots; during the production process, a heater is formed in the form of a plate.

The use of extruded polystyrene foam can cause significant harm to health. Especially the harm of this material is manifested when exposed to high temperatures. This is due to the fact that such toxic compounds are released from it as:

- vapors of styrene.

- Benzene vapors.

- Soot.

- Carbon dioxide.

- Carbon monoxide or carbon monoxide.

The combustion temperature of the main component of expanded polystyrene - styrene is about 1100 degrees Celsius.

The use of this material in construction is also harmful to the environment, this is due to the long decomposition of polystyrene, which is more than a hundred years. During the period of intensive operation, which is about 20-25 years, the material undergoes significant wear and tear, which leads to a significant increase in the harmful effects on people.

During the period of intensive operation, the polystyrene board releases up to 60% of decomposed styrene.

Styrene released into the surrounding atmosphere interacts with oxygen, which leads to the formation of highly toxic compounds such as formaldehyde and benzaldehyde.

The resulting toxins have a critical effect on the body of pregnant women.

The use of this material for insulating a house from the inside is unacceptable due to the presence of a high probability of release of toxic compounds from it.

Expanded polystyrene is recommended for outdoor insulation of residential buildings and industrial premises.

Penoplex is best used to insulate the basement of a building, foundation and walls from the outside. It is permissible to use this material as insulation under the roofing material on the roof if the attic space in the house is non-residential.

In residential premises, it is allowed to use decorative elements made of expanded polystyrene.

Is styrofoam harmful?

Expanded polystyrene is called expanded polystyrene. The generally recognized abbreviated name of expanded polystyrene used in construction is PSB (suspended non-pressed polystyrene foam). Expanded polystyrene for SIP panels (PSB-S-25F) is 98% air and contains only 2% polystyrene. PSB is one of the most effective insulation materials, it is inexpensive, environmentally friendly and durable.

Styrene

- a substance of natural origin, which is part of some food products: cinnamon, coffee beans, peanuts, as well as strawberries, grapes, kiwi, and even orchid pollen contains styrene. The natural polymer of styrene is polystyrene. Utensils and packaging for food (for example, toys and household items) are made of polystyrene.

Polystyrene is widely used in the food industry, for example, polystyrene is used to make disposable cups and forks, lunch boxes, egg packaging and much more that comes into direct contact with your food.The walls of your refrigerator are insulated with expanded polystyrene, and the interior is made of polystyrene. Think - can there be a poisonous material from which all the world's leading manufacturers create their products?

When polystyrene is foamed, polystyrene foam is obtained - a material widely used in construction. The material has supporters and opponents. The latter argue their position with various myths about the dangers of polystyrene. Is styrofoam harmful to health? What facts are true? What you need to know about Styrofoam?

Dangerous and safe concentration of styrene

By itself, polystyrene is a safe substance. Styrene has a negative effect on the body only in very high concentrations.

According to GOST 10003-90: "Styrene in terms of the degree of impact on the body belongs to the 3rd hazard class in accordance with GOST 12.1.005 - moderately hazardous substances."

This 3rd class of hazard also includes such familiar substances as aluminum, copper, alcohol and even silver compounds. In experiments on rats, the lethal doses of polystyrene and alcohol are approximately equal. Like most other substances, polystyrene is dangerous only in huge concentrations. Styrene is as dangerous as strawberries, kiwi, nuts. If these foods are consumed in large quantities, they also become harmful, and in the usual dose, they are a healthy treat.

The safety of styrene is of concern to scientists from different countries. In the United States, a SIRC center has been established to study the effects of styrene on the state of nature and humans; this center has been operating for over 30 years. In Europe, the REACH regulation has been developed, according to which the impact of polystyrene on humans is thoroughly and comprehensively studied. The result of the study is as follows: polystyrene does not act as a carcinogen, does not cause gene mutation, does not affect health in general and the reproductive system in particular.

In our country, there are hygienic standards, according to which the maximum permissible concentration (MPC) of styrene in the air is one-time 0.04 milligrams per m3, and on average per day - 0.002 mg per m3. According to world standards, styrene is harmless at a concentration of 1 mg / m3. And styrene at a concentration of 84 mg per m3 can negatively affect a person - this is a very strong concentration, exceeding the maximum single dose by more than 2000 times! At a concentration of 34 mg / m3 and below, styrene does not have any harmful effect on a person at all - this level is called NOAEL, or "maximum inactive dose".

Myth number 1. Accumulation of styrene in the body

Another misconception associated with styrene is its buildup in the body. To test this theory, the condition of workers who worked an 8-hour shift at a styrene concentration of 160 mg / m3 was examined in the USA (this is 80,000 times more than the maximum concentration adopted in our country!). Studies have not confirmed the accumulation of styrene under these conditions. If we recalculate the conditions under which the studies were carried out for conditions with a normal concentration of styrene, then an 8-hour shift would stretch over 73 years. That is, even after 73 years of life with MAC, styrene will not accumulate in the body.

Myth number 2. Effect of styrene on liver function

The next myth is the toxic effect on the liver and, as a result, the development of toxic hepatitis.

Studies of the effect of styrene on the liver of humans and animals have been carried out repeatedly. No liver effects were observed at 160 ppm after 2 years of exposure under laboratory conditions at a styrene concentration of 160 mg / m3. It should be noted that 160 ppm styrene is 340 thousand Russian maximum permissible daily concentrations (MPCs). This is a huge concentration.

At the specified concentration, styrene has an intolerable odor, a person could not be in such conditions even for several minutes.Laboratory animals were kept in these conditions for 2 years, while no abnormalities in the liver function were found in them. The study period (2 years) when recalculated in conditions with normal doses of styrene (MPCs) is 680 thousand years - that much is needed to destroy the liver. During a person's life, in order to disrupt the functioning of the liver, one must not inhale styrene, but drink.

Myth number 3. The influence of polystyrene on the reproductive system

There is an opinion that polystyrene can influence the development of the embryo and stimulate miscarriages. However, numerous studies were carried out in different countries of the world, scientists examined pregnant women whose husbands or they themselves worked in the production of polystyrene, that is, in conditions with an increased concentration of styrene. There was no evidence of a negative effect of styrene on the condition and intrauterine development.

Myth number 4. Styrene vapor

The safety and non-toxicity of expanded polystyrene are hotly debated. Opponents of the material say that styrene is released from the insulation, however, styrene release is possible only at very high temperatures, which do not occur during the normal life of people. Yes, and PSB-S-25F consists of 98% of air and only 2% of styrene. In addition, in SIP panels, the insulation is sewn up according to the principle of a sandwich between OSB sheets. With an OSB board thickness of 12 mm, it prevents the passage of water molecules, and styrene molecules are much larger.

Myth number 5. Flammability of expanded polystyrene

- with equal weight, the smoke generation coefficient is 53 times higher than that of a tree, however, the smoke generation coefficient for PSB is 749 m2 / kg, and for a tree when smoldering - 345 m2 / kg, that is, the indicator is 2 times higher. But, you need to understand that with equal weight, the volume of expanded polystyrene will be 30 times greater, which means that the smoke from expanded polystyrene is ten times less than from wood;

- combustion of only 70 g of expanded polystyrene makes 1 m3 of air unsuitable for breathing (a "piece" of PSB-25 weighing 70 g is equal in volume to 5 liters, and not a matchbox, as one might initially think), but equal in volume (and not in weight! ) a piece of wood when burning makes 10 m3 of air unsuitable for breathing;

- expanded polystyrene ignites spontaneously like gasoline - yes, however, only the author of this myth confuses the ignition temperature of gasoline (about 400 degrees) and its vapors, in fact, for the spontaneous ignition of expanded polystyrene, a temperature is needed 2 times higher than for the ignition of a tree, while the expanded polystyrene on its own burns for no more than a second due to special fire-fighting additives - fire retardants. Due to the addition of fire retardants (special additives that prevent combustion) in the PSB composition, expanded polystyrene is essentially a non-combustible material and acquires the PSB-S marking, where beech C means self-extinguishing.

Myth number 6. Short service life

Tests indicate an 80-year (at least!) Service life of expanded polystyrene, during which it does not lose its characteristics. The material is not subject to decay, it does not deteriorate, it needs special disposal. So claims of 10 or 15 years of service life are untenable.

Myth number 7. Prohibition of use in housing construction

Contrary to popular belief, expanded polystyrene has good environmental performance. It is actively used in private and industrial construction. The share of private houses insulated with expanded polystyrene in France is close to 80%. In Germany, 87% of all buildings are thermally insulated with expanded polystyrene and only 12% with mineral wool. The spread of expanded polystyrene in housing construction in the West is very active. Expanded polystyrene has the highest A + environmental rating

Output

The conclusion is very simple - expanded polystyrene has excellent heat-shielding properties, it is an environmentally friendly, fireproof and durable material.Most of the myths regarding this material are created by unscrupulous competitors who know perfectly well that their products are inferior to expanded polystyrene in all respects. Friends, we urge you to check all the information regarding the materials from which your house will be built.

Don't believe the myths - check it out!

Styrene in polystyrene

In the composition of polystyrene, according to the standards of styrene, there should not be more than 0.05%, it penetrates through the respiratory system

The composition of the foam contains fire retardants (increase the resistance of the material to fire), plasticizers (with their help, the product becomes monolithic, resistant to deformation). Fillers give the polystyrene foam the required level of elasticity, resistance to moisture. Their number and composition depends on the purpose of the material. The extruded version of the product has more positive qualities than other types.

The main substance in the composition of the foam is styrene. It is he who is considered hazardous to health. The maximum concentration of this component in the product is 0.05%. However, manufacturers do not always comply with this standard and significantly exceed it.

Styrene is a toxic substance used in the production of polymers. With a direct impact on the human body, it causes blood diseases, functional disorders of the central and autonomic nervous system. But for such consequences a high concentration of the substance is required, although it is capable of accumulating in the body, into which it penetrates by inhalation.

Rules for the safe use of polystyrene

Walls with open sources of fire are not insulated with expanded polystyrene

When using expanded polystyrene, harm to health in an apartment can be reduced or eliminated altogether if the conditions for its installation and operation are observed:

- it is forbidden to use the material for insulating internal surfaces, especially in rooms with a high level of humidity;

- you should not use it when insulating metal or other types of roofs (it is possible when organizing ventilation);

- it is allowed to mount the material in places where there are no open sources of fire or the risk of ignition of the product is completely absent;

- do not use damaged sheets.

Despite the fact that expanded polystyrene is susceptible to inflammation and is capable of emitting toxic substances into the environment, it continues to be a popular material that retains heat in rooms. It can be used to insulate not only residential premises, but also industrial buildings and offices.

The main rule for the safe operation of the material is protection from the influence of external negative factors: wind, water, direct sunlight, some solvents. In this case, it will serve for a long time and will not cause harm.

Specifications

There are different types of penoplex. Some of them are more durable, others - less thermal conductivity or reduced flammability, which is achieved by introducing special additives. (Read about the universal form of penoplex in this article.)

Here are some technical characteristics of this material (type 31):

- density - from 28 to 32 kg / m3;

- compression density - 2 kg / cm2;

- water absorption per day is no more than 0.004 of the volume;

- fire resistance category - G1 (slightly combustible), others - G3 (normally combustible);

- thermal conductivity coefficient - 0.03 W / m˚С;

- vapor permeability coefficient - 0.008 mg / m · h · Pa;

- the temperature at which this material is recommended to be used is from -50 to +75 Celsius.

You can find out detailed information about the technical characteristics of penoplex from this article.

Take a note: Penoplex is a two-phase material, that is, it consists of plastic and air, which makes it an excellent soundproofing material.

High degree of flammability of foams

Fire safety comes first.Fire is the most destructive incident that destroys property and takes lives. According to statistics, most fire deaths are not from burns, but from asphyxiation by carbon monoxide. Therefore, this aspect should not be overlooked.

The facade, insulated with foam, flares up like a match.

As you know, polystyrene burns well and at the same time emits poisonous smoke. Extruded polystyrene foam burns a little worse, however, it cannot be called safe. Is styrofoam harmful? Of course, it significantly aggravates the situation when a fire occurs. It is especially dangerous to use flammable polymers to insulate a house using the ventilated facade technique.

It is worth noting that the manufacturers managed to slightly reduce the degree of flammability of the materials in question, but this is still not enough. On ignition:

- carbon monoxide is released;

- high concentration of toxic substances in the smoke;

- the flame is difficult to localize, the fire spreads quickly.

For comparison, mineral wool does not burn, does not smoke, does not emit poisons and may well be used to insulate a steam room in a bath from the inside. The only non-combustible polymer insulation is polyurethane foam, which is applied by spraying.