Cons of brick ovens

But before you make such a device for yourself, it is important to familiarize yourself with its shortcomings:

- If the size of the dwelling is large, brick stoves will have to warm up the cooled air for a long time. Therefore, in order to normalize the temperature while the stove is fully warmed up, it is recommended to purchase a heating device for gas or electrics.

- The design of the device itself is large, so it needs a lot of space, and such options are not suitable for all owners of a private home.

- If the construction of a brick kiln is not carried out correctly, the device will not function correctly. Therefore, there is no other option, how to completely redo the stove.

What is oven re-laying?

This is a service provided by professional stove-makers in relation to the existing stove or other hearth with controlled combustion, as well as the territorial arrangement of such within the already implemented communication engineering systems. The complex of works also includes a check of traction, as well as warranty obligations for the elimination of operating defects.

The guarantee for such work will be valid only if the input operating parameters are observed: the first kindling - 20% of the power, the second - 50%, the third - 70-100%.

For good burning of wood, it is necessary

- dry firewood (2-3 years old drying under a canopy) (standard: 6-7cm log thickness,

the length of the logs (written: up to 75-80 cm.) (Now everywhere I meet my local standard: the default is 50 cm)

—fuel space equal or more

fuel bed height

-high temperature (for the evaporation of volatile combustible substances from the fuel and the reaction of their combustion)

-Also, for combustion, air is needed in sufficient quantity (excess air drains out, and if there is not enough air, it smokes and clogs the channels)

- TIME: According to Podgorodnikov, 1-2 seconds so that all combustion processes take place in a hot furnace, and not be thrown quickly into the first cold channel or pipe.

This is why he always installed hilo.

Firebox length

- by the length of the wood + (7-10 cm.)

Firebox width

- for small ovens (in terms of power) 1 brick. = 25 cm.

In many ovens 32 cm (brick + 1/4 brick) (considered appropriate).

Usually 1.5 kirp. (37cm) -suits for almost all occasions.

Powerful stoves for individual use have a firebox width of 2 birks. (50 cm).

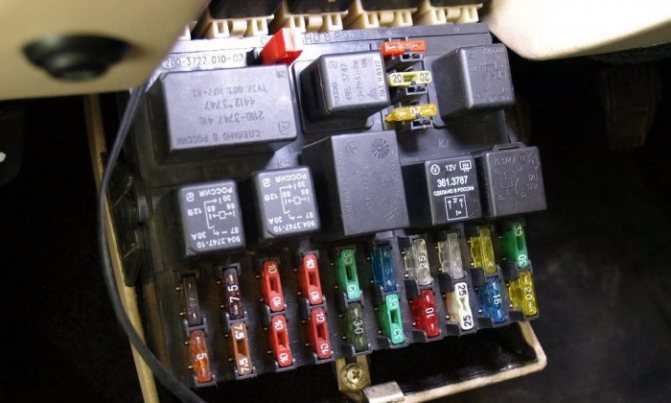

Block design

Now it is worth discussing the location and filling of the VAZ-2110 mounting block in more detail. Most of the safety devices are located in a small compartment to the left of the steering column. The unit is built into the dashboard, and you can get to it by unscrewing two fasteners on the side panel.

All fuses are numbered F1 to F20 and have a separate function. Protection marked F1, for example, is responsible for the license plate lighting lamps, lamps and electronics in the luggage compartment and devices that belong to the left side marker light; and F6 for electronics with cigarette lighter connection.

A more detailed picture will be shown in the table.

| Fuse number designation | Chain of protection |

| 1 | Bulbs that illuminate the rooms, VAZ trunk lighting. Electronic devices connected to the left dimensions. |

| 2 | Low beam headlamps, left side |

| 3 | High beam headlamp, left side |

| 4 | Front right fog light |

| 5 | Protection of electronic windows |

| 6 | Portable lamp or cigarette lighter protection, VAZ stove |

| 7 | Horn, cooling radiator fan |

| 8 | Heated rear view glass |

| 9 | Washer system, windshield wipers |

| 10 | Spare |

| 11 | Dimensions of the right side of the car |

| 12 | Low beam on the right |

| 13 | High beam on the right |

| 14 | Front fog light |

| 15 | Heated seats |

| 16 | VAZ-2110 signal protection for turning, turn signal alarm |

| 17 | Interior lighting |

| 18 | Glove compartment lighting |

| 19 | Reversing signals, instrument indication, door block. |

| 20 | Rear fog lamp |

Selecting the type of device depending on the operating conditions

When people have a choice between metal or brick stoves, they often forget to answer several important questions for themselves before purchasing:

- First of all, it is worthwhile to clearly understand what is the priority: the speed of warming up a room, house, or the time during which heat is transferred from the structure's firebox.

- Depending on the specific region of the location of the room, one of the devices will always be several points better in terms of operation, but in this matter everything is very individual.

- What are the technical features of the house, is it possible to build a foundation and other construction issues.

- Budget - structures made of certain types of metal can cost several times cheaper than brick structures.

If we compare and determine under what conditions it is better to build a brick oven, then first of all, such structures are installed in houses where the only source of heat will be just such a furnace: if it is well and correctly heated during the day, then the room will be provided with heat throughout all night.

Moreover, such structures must be monitored, and if it is not possible to periodically heat the chamber outside the heating season, then it is still better to opt for a metal product.

It is necessary to think over where the stove will be located and take care of the construction of the foundation. If all these conditions are met at home, then we can say with confidence that the choice was made correctly.

With what conditions provide for the construction of a stone furnace, everything is clear. It remains to consider the question of the advisability of installing a metal structure. Such a product can be installed in rooms where there is another source of heating, be it a central system or a boiler.

Considering that such systems heat up several times faster, they are recommended to be installed in rooms where it is necessary to warm up the air to a comfortable temperature as soon as possible, for example, if it is a country house that people come to in winter.

There is no need to build a foundation to install metal stoves, so they are suitable for installation on basement floors. A wide range of heating devices from modern manufacturers will help you choose exactly the option that fits perfectly into the interior.

The stove does not have to be a coarse solid cast iron stove. It can be represented by a steel structure with glass or ceramic firebox doors, which looks very stylish.

Good operating and saving functions are endowed with models in which a smoldering or long-term fuel combustion system is already installed. They allow you to use fewer materials to create a comfortable room temperature, but they are able to maintain it for a long period of time.

Summing up, we can conclude that metal stoves must be installed in those rooms where it is necessary to heat up the space faster, but at the same time there is also the main heating.

https://youtube.com/watch?v=GJHxuMkCD1w

Each homeowner must independently decide for himself what budget he has for equipping the heating system in the house, and also clearly understand whether he can independently carry out the construction of a brick stove, because this process is complicated, and if implemented incorrectly, the structure will be completely useless.

Sign in

Adblock detector

What kind of wood is more suitable for firewood?

Different types of wood differ from each other in calorific value and combustion characteristics. In this regard, when choosing a fuel, you need to understand the performance characteristics of firewood.

- Pine has a high burning temperature. The reason for this is the high resin content. This rock assumes many voids where resinous deposits are present. Burning down, they produce micro-explosions, sparks and burnt pieces of wood scatter.

- Spruce in the firebox is less efficient than pine. It contains less resin. Chopping wood is easy, but when burning, the tree smolders and smokes. These conifers can only be drowned in extreme cases.

- Alder. The main feature is the ability to burn without forming soot. At the same time, during combustion, deposits in the chimney will also be burned out. Such characteristics are inherent only in aspen.

- Poplar. It burns out quickly without giving enough heat. It should not be used to heat a bath, but it is quite suitable for a home.

- Birch. It burns hotter than beech with acacia and oak. But there is also a drawback, and a significant one. It is necessary that there is sufficient air flow into the combustion chamber. Otherwise, there will be no heat, but only tar and smoke on the walls of the chimney.

- Oak. Differs in high density and ability to generate heat. In terms of its characteristics, it is similar to ash and also resembles beech. In chopping, oak firewood is quite heavy.

- Maple. Its wood burns quickly without forming coal, as a result, it becomes necessary to constantly add fuel. It looks like a stove with linden wood.

- Apple trees. Like other fruit breeds, it pricks well, emits enough heat when burning. Apple wood is also preferred because of the pleasant smell in the room.

Here's what else the stove-maker told about.

Talking to colleagues about hobbies and staying on time: how to stand out at remote work

5 indoor plants that bring financial well-being to your home

6 Chinese zodiac signs will get rich and make a fortune in the next 10 years

Similarities and differences

When deciding which stove is better, the first step is to determine its functional tasks, because it will depend on them what is more suitable for the homeowner in each specific case.

All solid fuel designs have a number of identical parameters:

- In both metal and brick products, there will be an open flame inside the firebox.

- At the moment when the body of the structure heats up, the room is filled with warm air and a comfortable temperature is created in the rooms.

- Fuel combustion products are discharged through the chimney pipe.

- The correct draft must be realized in the chimney, otherwise the stove will not work correctly.

- The combustion process is possible only if oxygen is supplied.

The metal and brick oven have a number of differences that are worth paying attention to. First of all, the difference lies in the material of manufacture of the body of the heater.

In the first case, it can be cast iron or steel, and in the second - exclusively brick.

Many people wonder why iron stoves heat a room faster than brick ones. The answer to it is quite simple and lies in the thickness of the walls of the case: the smaller it is, the faster the structure heats up. Steel or metal can be very hot, while brick is an inert material and due to its greater thickness, it does not get very hot.

However, metal stoves have a significant advantage - in their furnaces there is a clear system for regulating the combustion process, which makes it possible not to overspend the material, respectively, the costs of maintaining a house during the heating season are reduced.

A brick heating device has a significant mass, so it can be erected only after the foundation has been poured.Metal structures do not require this, which simplifies the installation process, and to save space, such an oven can even be hung on the wall.

What kind of firewood is preferred?

It is best to take solid, hardwood firewood. When they burn, no resin is released, and the high combustion temperature is kept without problems. An additional plus is that soot remains to a minimum inside the chimney.

It is undesirable to heat the stove with garbage; it is also bad to use spruce and pine firewood. On the contrary, it is good to heat with sawdust. Briquettes are also used, they are made from peat or wood. The fuel should have a moisture content of about 20 percent. It is present if the wood is stored in a dry room for a year.

Playing chess helped an 8-year-old boy lift his family out of poverty

Multifaceted John Travolta spoke about his "second profession"

Conspiracy for money and wealth for the Ascension of the Lord May 28, 2020

ADVANTAGES AND PROS OF METAL FURNACES.

They are not afraid of temperature changes and long breaks in the firebox, they do not need booster heating after downtime. That is, for those who, in the cold season, come to a country house only for the weekend, this is the best option. Moreover, such ovens heat up the air very quickly.

TOOL FOR HOME AND GARDEN, NEEDLEWORK, ETC. PRICES VERY LOW

Another advantage is the relatively low cost (when compared with a brick oven). Again, to install such a "hot heart at home" you do not need to make a foundation or hire a stove-maker.

Compact size allows you to place a metal oven almost anywhere

But observe the fire-prevention indents, this is very important (the exact distances are indicated in the installation instructions). However, if the room is extremely compact, the margins are sometimes reduced

And fire safety is provided with the help of protective screens. The walls are fenced off with steel sheets, but not close, but with a 2-3 cm air gap. There is also a gap of 3-4 cm between the edge of the sheet and the floor. Thus, the metal, when heated, enhances the convective movement of air near the wall. This protects the wall from overheating.

Last but not least, a factory made metal stove can have a fire safety certificate. This means that it is much easier to obtain permission from firefighters to use it (provided that the installation was carried out exactly according to the instructions)

How is it heated correctly?

To reduce the consumption of firewood and improve combustion, the stove-maker advised to do the following:

- Logs should be placed in the stove, which are about 5 cm shorter than the length of the firebox. If, when storing firewood, you make them approximately the same size, it will be much easier to heat.

- The logs are laid in such a way that there are air gaps.

- Although the stove can, in principle, be heated with raw wood, this is fraught with the release of tar with smoke and in considerable quantities. In this regard, it is better to deal with dry fuel (no more than 25 percent moisture).

And in conclusion - about how to start heating the stove.

The husband and wife invested all the money in the house and made repairs: now they are selling for 6 euros

Briefly, clearly, in essence: micro-training of employees is the key to the company's success

Thanks to hackers, an early version of iOS 14 hit the net long before the release

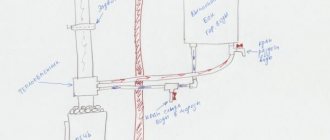

The place of the stove in the engine cooling system

The stove is part of a closed vacuum coolant circulation system. The main purpose of this system is to cool the engine. Thus, the device of the VAZ 2109 stove both helps to heat the interior in the cold, and cools the cylinder block when the engine is running. Completely SOD consists of:

- cooling jacket;

- radiator;

- expansion tank;

- water pump;

- radiator fan;

- thermostat;

- a heating radiator - a VAZ 2109 stove.

When driving, atmospheric air passes through the air intake into the radiator, in the pipes of which there is air that is too hot for the engine.These pipes are cooled by the fan, and the already cooled liquid through the water pump again enters the cooling jacket (cylinder block and cylinder head). The stove in this circulation of antifreeze performs the task of additional removal of hot liquid.

The heating fan VAZ 2109 maintains the desired air temperature in the cabin.

Stove wiring diagram and basic faults

In the "nine", the VAZ heating system operates with an electric drive. The operating manual for the VAZ 2109 high panel shows the wiring diagram of the stove. The wiring diagram for the interior heater consists of:

- fan motor;

- ignition lock, which turns on the stove;

- mode switch;

- additional resistor;

- mounting block of fuses (fuse F4 is responsible for the stove in the "nine").

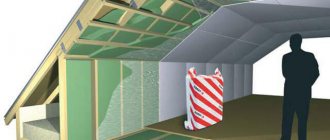

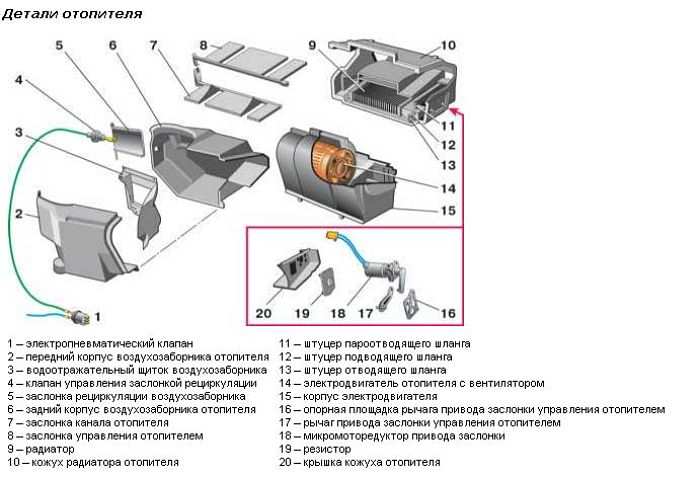

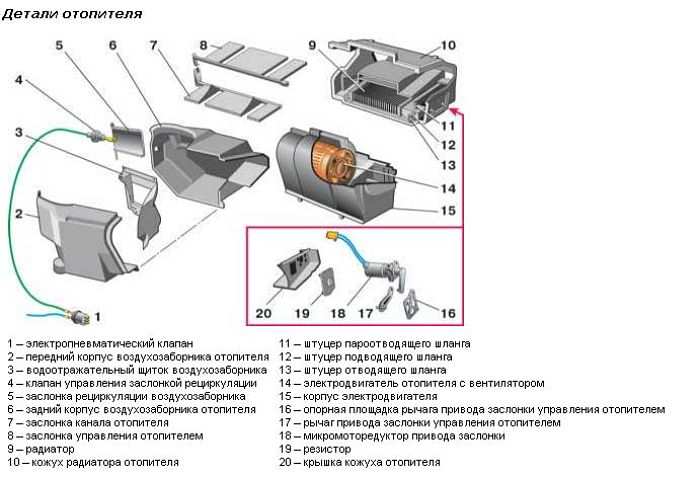

Heater design VAZ-21099

And then everything is simple: the created flow passes through the honeycomb of the radiator, where heat exchange takes place, as a result, heat is given off to the air, which then blows into the required zones through the air ducts.

The design of the VAZ-21099 stove includes several main components:

- stove body made of plastic;

- heating system radiator (connected to the cooling system);

- electric fan;

- air ducts;

- heater control mechanism.

Heaters of two modifications (old and new) were used on this car, which differed somewhat in design, but their component parts are completely identical.

Housing, radiator, dampers

Thanks to the housing, the required heating redirection is ensured, since the movement generated by the fan motor is immediately fed into it, and not dissipated. The body of the VAZ 2109 stove itself consists of two halves, interconnected with special brackets. To reduce flow losses, a seal is placed between its halves. Partitions are made inside both halves, which provide the correct direction.

Also, a niche is made inside this case, into which a radiator is installed. Initially, the radiator was made of brass, but now it is almost always made of aluminum. The device of the radiator of the stove 2109 is identical to the main one (it consists of two tanks, tubes through which the coolant circulates, and plates that form a honeycomb), but much smaller in size.

Video: The stove heats badly in the VAZ 2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, 2115

Air blowing is carried out due to stove dampers, also installed inside the body. These elements are movable, and thanks to them it is possible to block some and open other air ducts. There are three of them in total - the main one (heater control), the air duct that redirects between the leg zone and the supply to the passenger compartment, and the flow damper to the windshield.

Additional dampers are installed on the side and center deflectors. It turns out that, by default, air from the body constantly blows onto the deflectors and this is done so that the flow always has an outlet. Thanks to the existing dampers, it is possible to provide simultaneous supply of hot air to several zones at once (interior and windshield or windshield and leg zone).

The main damper of the stove provides air flow to the radiator or bypassing it. This is all done because the heater also plays the role of a ventilation system for the passenger compartment. This allows cool air to be supplied during the summer. And for this, it is only necessary to redirect the movement bypassing the heat exchanger, and the heated coolant will stop supplying the radiator itself. To disconnect the heat exchanger from the cooling system, a stove tap is used, which is located on the supply pipe in front of the radiator.