Where is the material used

TechnoNicol Rocklight, as already mentioned, is a semi-rigid mineral slab. It can be used in:

- Vertical;

- Horizontal;

- Inclined surfaces.

BUT! No external load. According to the data on the website of the TechnoNicol company, the material has a compression rate of 30%, and the density varies between 30 and 40 kg per m3. This density will be quite enough to withstand the vertical load under its own weight when the insulation is used in frame structures. But, it will not be enough with additional load. Therefore, this thermal insulation is not used in wet facades, but only in hinged ones.

If you give more specific examples of the use of Rocklight, you can highlight:

Sound and thermal insulation of interior partitions;

Insulation of the facade for siding and other hanging systems;

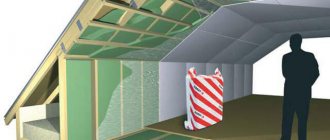

Creation of an attic microclimate.

For example, in the video below, TechnoNicol representatives recommend Rocklight as insulation for the attic.

Installation rules Rocklite TechnoNIKOL

This thermal insulation is used for insulating floors on the first floors, attic floors, pitched and flat roofs, for insulating facades for siding, etc. As you understand, Rocklight mineral wool has excellent characteristics. Let us further consider how to correctly install basalt thermal insulation slabs from the Technonikol company when independently finishing the roof and facade for the winter.

Insulation of house facades

Insulation of the facade of the house with mineral wool Rockwool

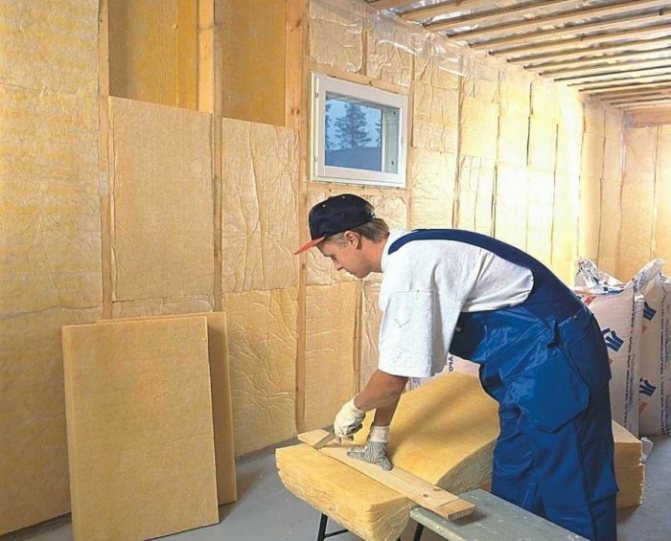

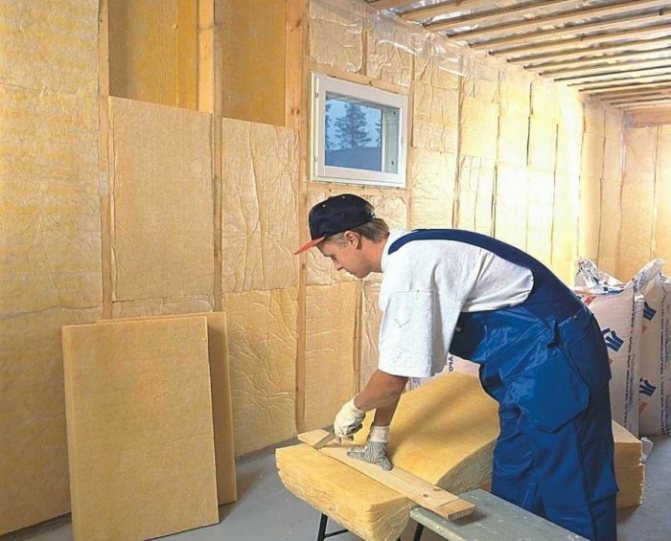

For thermal insulation of the facade, it is necessary to mount a frame made of metal profiles or beams. The width of the bars should be equal to the thickness of the thermal insulation - 50, 100 or 150 mm. On top, the entire structure is closed with a waterproofing material so that the insulation does not absorb moisture from the walls of the building. The overlap of the vapor barrier should be at least 15 cm, the joints should be glued with tape.

Next, TechnoNIKOL thermal insulation is placed between the guide bars. It is important when installing the lathing to make the distance between the bars 1-1.5 cm less than the width of the mineral wool slabs. Rocklite, like Rockwool mineral wool, should sit tightly between the bars. After laying the thermal insulation, it should be protected with a vapor barrier membrane, laying the film with the smooth side towards the insulation.

Upon completion of all work, wooden blocks 20-30 mm wide are stuffed onto the structure. It is such a gap that the manufacturer recommends to make so that moisture from the surface of the waterproofing film can be weathered without interference. Well, at the end of the work on the counter-lattice bars, the facade cladding is being installed. You can choose from vinyl siding, OSB boards or PVC panels.

Pitched roof insulation

Attic insulation with Rockwool thermal insulation

To begin with, you should fill the crate from the inside of the rafters with a small step. Insulation slabs will be laid on the boards, and if you make large gaps between the crate, then the mineral wool can sag. Also, when laying insulation, make sure that all joints are tightly pressed without gaps. Insulation is often put in two layers so that the second layer overlaps all the joints of the first layer.

This is followed by a layer of wind-waterproofing, the film is attached to the rafters with a slight sagging so that the condensate flows down like a groove. It is important not to confuse which side to the insulation to lay the waterproofing. The upper side should protect the insulation from moisture, and the lower side should be free of steam from the insulation. The vapor barrier is laid with an overlap between the sheets of at least 15 cm.

Further, as with the laying of Izorok mineral wool, it is necessary to create a ventilation gap using a lathing of wooden bars.This must be done so that the condensate formed on the surface of the film can be freely weathered. You can find out more about how to independently insulate the roof of a house with mineral wool or polystyrene foam on our website in the section "Do-it-yourself roof insulation".

As you can see, TechnoNIKOL products are in demand in the construction market for a reason. Ease of installation, long service life, low cost and excellent technical characteristics of rocklight TechnoNIKOL insulation predetermined the high popularity of the material among developers. In the video posted on the page, you will find additional information on the topic in question.

Basalt material characteristics

Mineral wool perfectly resists cold, significantly superior to any other natural or artificial insulators. But when choosing a Rockline insulation from the manufacturer Technonikol, you should start from personal needs, weighing all the technical advantages and disadvantages of the product.

The thermal conductivity of the material is 0.036W / m. This indicator is consistent with all the standards that are necessary for the device of thermal insulation in cold climates.

The density is 30 kg per cubic meter. m. The indicator is not very high, but it is perfectly combined with the compression ratio, which plays a significant role when using insulation indoors and in attics as thermal insulation. Thanks to him, it will be seen how much it is possible to pull off the cotton wool without deforming it, because by reducing the efforts, it will return to its original shape. The 30% figure is a significant result, which will be quite enough for an easy process of installing mineral slabs into roof or wall frames.

The products are produced in packs with sheet sizes 1200 × 600 × 50 mm and 1200 × 600 × 100 mm. These dimensions are the most demanded, since they are conveniently installed in frames, having a low weight. But at the same time, such a thickness of cotton wool is quite enough to provide the structure with the proper degree of thermal insulation in a cold winter. In the case when the layer is not enough, for example, when insulating an attic, then the material can be combined with each other or placed in several levels.

Specifications

Rocklight slabs are supplied in thermo packing. The standard size of one Rocklight slab is the same as that of Penoplex 60 × 120 cm. This simplifies the handling of the insulation, since there is no need to make any changes to the crate when facing the house with siding or other finishes. The thickness of the slabs varies depending on the needs and can be from 50 to 150 mm. The size of the "Rocklight" package does not change, so its quantity will be smaller with greater thickness. For example, for the minimum thickness, the package can hold 12 boards, and for the maximum thickness only 4. This should be taken into account when planning the delivery of material to the construction site.

Insulation TechnoNIKOL "Rocklight" has a thermal conductivity of 0.039 W / (m2 × K). In terms of technical characteristics, this is an excellent indicator, which is many times superior to other heaters. The density of the insulation is also at the proper level. It can vary from 30 to 40 kg × m3. It is the density that explains the stability of the form of insulation to various influences. The color of the insulation is closest to greenish-yellow. A video about Rocklight insulation can be seen below.

Application

Insulation "Rocklight", reviews of which, perhaps, will allow you to understand which type of insulation to make your choice, has found its widespread use. It is the ideal material for private construction. Stone wool is used for inclined, horizontal and vertical surfaces, as well as for the insulation of corner elements, floor slabs, pitched roofs, foundations and basements.You can purchase this insulation in the event that there is a need to insulate the attic or frame house. For the reason that the density of the material is not so high that it can be used as a supporting structure, it is best to use additionally more durable building elements for this.

Customer Reviews

Below are real reviews of buyers who used TechnoNIKOL Rocklight insulation.

“A significant share of the family budget was spent on the purchase of heating media. This was due to the rapid cooling of the house. Initially, the walls were designed and kicked out correctly, so the reason lay elsewhere. It became clear that the problem was in the roof. It was decided to use Rocklight stone wool. Insulation of various thicknesses was purchased. It was laid in 2 layers to eliminate gaps in the seams. After installing TechnoNIKOL "Rocklight" and it was possible to reduce heating costs in half. The house is cooling down more slowly. There are plans to carry out the same insulation procedure in the country. I liked that the insulation quickly pays for itself and is fireproof. "

Mikhail, St. Petersburg

“I love working in the workshop, so I had to warm it up for the winter. At the first stage, extruded polystyrene foam was selected. Due to the lack of proper ventilation, condensation accumulated and flowed down the walls. To eliminate the consequences, it was necessary to remove all the insulation. It was decided to finish the exterior, but not with expanded polystyrene, but with Rocklight insulation. The result was very pleasing. With the same ventilation, it became warm and dry. At the same time, the usable space inside has slightly increased. "

Oleg, Novosibirsk

“We bought a house several years ago. In winter, the temperature dropped quite low and some walls began to become covered with condensation and dampness. It was necessary to insulate the house, which was done at the first opportunity. The choice of thermal insulation took a long time, but, focusing on the price and characteristics, the TechnoNIKOL Rocklight insulation was chosen. For a good finish, we had to dismantle some elements, we were surprised that the insulation did not lose its shape and was as good as new. "

Yaroslav, Moscow

“Before that, I had never used mineral wool as a heater, so there were doubts about the reliability and quality. Reviews played a role, it was decided to purchase TechnoNIKOL "Rocklight". The first thing that caught my eye was the excellent vapor permeability of the material. The dwelling was built of wood, so it was necessary for the insulation to breathe and remove moisture in a timely manner. The second nuance, which bribed, was the thermal conductivity coefficient, which is comparable to penoplex. After the first winter, the results were tangible. Heating costs have been significantly reduced, and the house keeps warm for longer. ”

Konstantin, Moscow region

Installation features

Basalt insulation "Rocklight" allows you to save not only at the stage of purchase, but also during installation. Any home craftsman will be able to carry out installation work to install this thermal insulation. The material can be glued or screwed on, filling the resulting joints with construction foam. In this case, the walls are pre-treated with a primer, as an alternative solution is the laying of waterproofing

If we are talking about a pitched roof, then it is important to leave a ventilation gap between the insulation and the structure itself. For this "Rocklight" is mounted directly on the frame beams, which are reinforced from the inside at a distance of 30 centimeters from each other.

THERMAL INSULATING MATERIALS PRODUCED BY TECHNONICOL FOR DEVICE OF BUILDING STRUCTURES

WALLS, COVERINGS, ROOFS, FLOORS, PARTITIONS, FRONTING THE MANSARD STRUCTURES AND ATTIC COVERINGS USING TECHNO MINERAL WOOD BOARDS AND TECHNONICOL EXTRUSIVE FOAM POLYSTYRENE BOARDS XPS TECHNONICOL. Part 01. GENERAL PROVISIONS

Part 01. GENERAL PROVISIONS

1.1. The manual contains materials for the design and working drawings of the nodes of three-layer walls, basement walls, coatings, attic floors, partitions, enclosing structures of attics and floors of heated buildings for various purposes with thermal insulation from mineral wool slabs: ROCKLIGHT, TECHNOROOF N PROF, TECHNOVENT EXTRA, TECHNOROOF V PROF, TECHNOENT N PROF, TECHNOLIGHT, TECHNOROOF V OPTIMA, TECHNOENT N, TECHNOBLOCK, TECHNOFLOR PROF, TECHNOFAS L, TECHNOENT, TECHNOROOF V EXTRA, TECHNOSANDWICH, TECHNOROOF PROF, TECHNOROOF N 30, TECHNOROOF N OPTIMA, TECHNORUF N 30, TECHNOROOF N OPTIMA, TECHNORU N TECHNOFAS COTTAGE, TECHNOROOF 45 GALTEL, TECHNOROOF V PROF c, TECHNOROOF N VENT, TECHNOROOF V EXTRA c, TECHNOFAS, TECHNOROOF PROF c, TECHNOFAS EXTRA, TECHNOROOF V OPTIMA S, TECHNOFAS EFFECT, TECHNOROOF DEFAULT 45, TECHNO , 7%), TECHNOROOF N PROF KLIN (4.2%), TECHNOFAS OPTIMA and TECHNONICOL XPS CARBON extruded polystyrene foam.

The following materials are provided as roofing materials:

- polymer membranes "Logicroof" of the RP, R2P, SR, P, PMV brands;

- bitumen-polymer surfacing roll materials of the following brands: TECHNOELAST, UNIFLEX, BIPOL, TECHNOELAST SOLO RP1, TECHNOELAST FIX and other waterproofing materials produced by TechnoNICOL.

The following are provided as hydro, wind and vapor barrier:

- TechnoNICOL vapor barrier film for flat roofs; universal vapor barrier film;

- superdiffusion membrane TechnoNICOL.

2 THERMAL INSULATION

2.1. Depending on the physical and technical properties of the slabs are intended:

2.1.1 Mineral wool for use as heat and sound insulation:

- ROCKLIGHT - in frame walls, including external ones with various types of finishes (for example, siding);

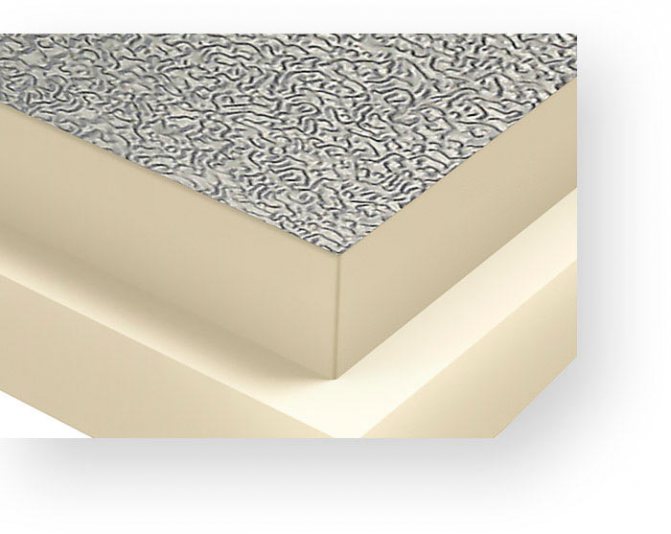

Fig. 1 - ROCKLIGHT. Insulation for private housing and partitions.

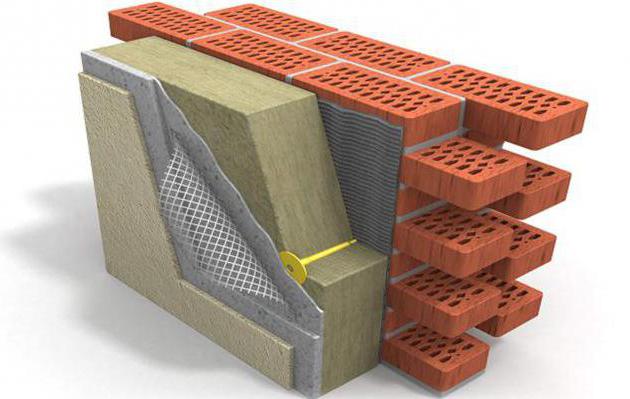

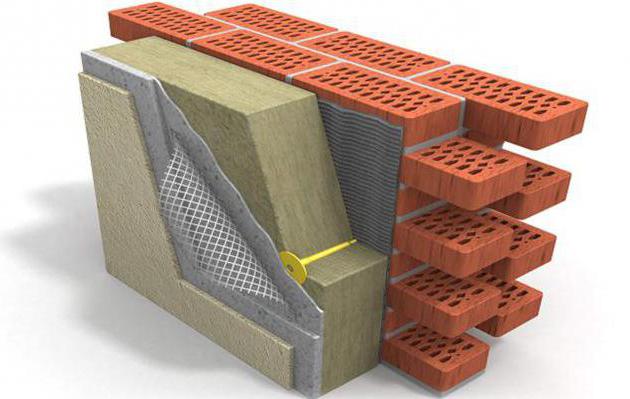

- TECHNOFAS, TECHNOFAS OPTIMA, TECHNOFAS EFFECT - in walls with a finishing layer of thin-layer plaster;

- TECHNOLAYT EXTRA, TECHNOLIGHT OPTIMA, TECHNOLIGHT PROF - in frame walls, attic floors, in floors along logs, partitions, enclosing structures of attics and roofing on corrugated board with a profiled sheet roof;

- TECHNOBLOK STANDARD, TECHNOBLOK OPTIMA, TECHNOBLOK PROF - middle layer in three-layer walls with a finishing layer of brick (layered, well masonry) or plaster;

- TECHNOVENT STANDARD, TECHNOVENT OPTIMA, TECHNOVENT PROF - in walls with a ventilated air gap;

- TECHNOROOF N30, TECHNOROOF V60 - in coatings with a reinforced concrete base or with steel corrugated board;

- TECHNOFLOR STANDARD, TECHNOFLOR PROF - in the walls of the basement and floors on the ground.

2.1.2. From extruded polystyrene foam for use as thermal insulation: TECHNONICOL CARBON ECO FAS, TECHNOPLEX, TECHNONICOL CARBON ECO, TECHNONICOL CARBON PROF, TECHNONICOL CARBON ECO SP, TECHNONICOL CARBON PROF SLOPE, TECHNONICOL TECHNO SOLID CAR for flat roofs (inversion, operated, under screed), plaster facades, layered masonry, foundations (plinths), floors on the ground, on reinforced concrete, incl. loaded, floors of refrigerating chambers.

Fig. 2 - ROCKLITE. Thermal insulation material based on stone wool produced by TechnoNICOL.

TECHNONICOL systems based on ROCLIGHT basalt insulation produced by TECHNONICOL:

TN-WALL Balcony Internal thermal insulation system on a double frame with ROCLIGHT mineral wool

System composition:

1. Internal cladding (gypsum board, OSB-3, lining, panels) 2. TECHNONICOL vapor barrier 3. TECHNONICOL butyl rubber connecting tape for gluing vapor barrier 4.Counter batten 40-60 mm thick 5. Slabs made of ROCKLITE stone wool 6. Lathing (wooden beams 50 X 50 mm with a step of 600 mm) 7. Insulated balcony wall 8. Finishing floor covering (parquet board or laminate) 9. Substrate under the finishing coating floor (cork or foam material) 10. Subfloor (plywood, boards) 11. Wooden logs 100 X 50 mm

TH-WALL Bathhouse The classical system of thermal insulation of the wall and ceiling of the steam room of the bath (steam room).

System composition: 1. Wall made of timber, bricks, blocks 2. Lathing, frame made of timber 50X50 mm 3. Lathing, frame made of timber 50X100 mm 4. ROCKLIGHT stone wool 5. Aluminum foil 50 microns 6. Aluminum tape 50 mm X 50 m 7. Counter batten 20 X 30 mm 8. Inner lining (lining made of linden, aspen, Canadian cedar)

In order to read the entire instruction, follow the links below: Part 1 Part 2 Part 3 Part 4 Part 5 Part 6 Part 7 Part 8 Part 9 Part 10 Part 11

You can purchase all the required materials for organizing roofing carpet and repairing roofs by calling us, or by making an application in the online store on our website. You can also pick up the material from our warehouse. Helpful !!! In conclusion to this material, we recommend watching on our YOUTUBE channel a series of detailed videos on the organization of installation work on the installation of thermal insulation using thermal insulation mineral wool boards ROKLIGHT, TECHNOFAS, TECHNOFAS OPTIMA, TECHNOFAS EFFECT, components for facades, roofs, installation equipment, etc. materials produced by the TechnoNICOL corporation. Organization of installation work for the installation of mineral wool boards ROCKLIGHT, TECHNOFAS, TECHNOFAS OPTIMA, TECHNOFAS EFFECT: www.youtube.com/TK CentroStroy / Thermal insulation TechnoNICOL ROCKLIGHT

The main characteristics and properties of TechnoNIKOL insulation

So, if we talk about such a characteristic of the TechnoNIKOL insulation as thermal throughput in relation to various types of products, then it has a value from 0.028 W / m • K to 0.035 W / m • K.

Judging by the given values, we can conclude that this type of plate copes well with the influence of infrared rays, regardless of which side of the room it was installed on. The use of such stoves allows maintaining a constant thermal regime in the room at any ambient temperature.

If we consider such a characteristic as water absorption, then for TechnoNIKOL slabs it has a value of 0.2% of the volume. This allows the material to perfectly resist moisture and at the same time prevent unpleasant neoplasms on the structures of objects, primarily mold and mildew.

If we talk about vapor permeability, then this parameter has a very insignificant indicator, which is 0.011 mg / (m × h × Pa). The density of this insulation is at a fairly high level and is 26-32 kg * m3. At the same time, certain types of products can be found on sale, for which the value of this parameter can be 60 kg * m3. Such heaters are characterized by the presence of an even and rigid base.

Plates manufactured by TechnoNIKOL Corporation have a fairly high strength. Their value is sufficient to cope with compression from 250 to 1000 MPa. The peculiarity of the production process of the plates is that it takes place without the use of freons. This fact gives grounds to assert that Technonikol heaters are environmentally friendly and safe.

A characteristic such as the fire safety of rocklight slabs can be judged by the following indicators:

- according to the degree of flammability, these plates belong to the G3 group, which allows them to be considered normally flammable;

- in terms of flammability, these heaters can be included in group B2, which speaks of their moderate flammability;

- according to the ability to generate smoke, it is appropriate to include this material in group D3, implying a high ability for this parameter;

- according to the level of toxicity of emissions during combustion, TechnoNIKOL stoves belong to the T2 group, which includes moderately hazardous materials.

Such heaters are able not to lose their performance when interacting with temperatures ranging from - 70 to + 75 degrees. This feature expands the possibilities of their use.Therefore, when building any objects, it is permissible to use such a material. TechnoNicol Rocklight slabs are chemically resistant, so they feel great even in direct contact with any other compounds and surfaces used in the construction of objects.

Main characteristics

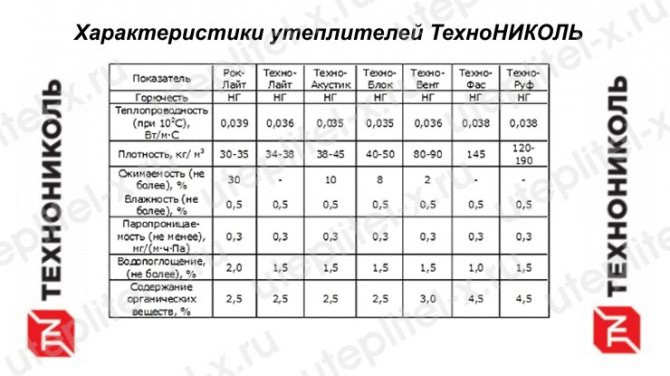

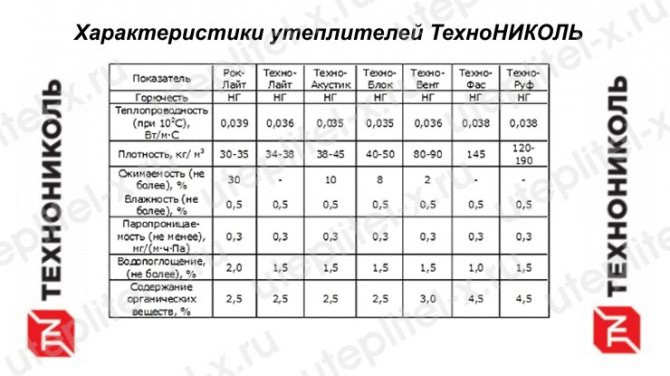

Below in the plate are all the main technical characteristics of the insulation for those who like to know all the subtleties.

TechnoNicol Rocklight Specifications

| Indicator name | Unit measurements | ROCKLIGHT |

| Compressibility, no more | % | 30 |

| Flammability | power | NG |

| Thermal conductivity | λ 10 | W / m S |

| λ 25 | 0.039 | |

| λ A | 0.04 | |

| λ B | 0.041 | |

| Water vapor permeability, not less | mg / (m h Pa) | 0.3 |

| Moisture by mass, no more | % | 0.5 |

| Water absorption by volume, no more | % | 2 |

| Organic matter content, no more | % | 2.5 |

| Density | kg / m 3 | 30-40 |

You can see that Rocklight's density is slightly lower than that of Technoblock Standard. And the compressibility is 3 times or more inferior. But, this cannot be a disadvantage in itself, rather, it all depends on the approach and application.

Features of the

The features or advantages of this insulation follow from the definition, namely:

- Fire safety. The insulation has a class NG, which means it does not contribute to the spread of fire. For many consumers, this factor is decisive when choosing a heater made of stone wool. The latter is preferred over polystyrene, which emits toxic substances when burned.

- High vapor permeability. The thermos effect is good only in the case of tea in winter. But the room to a reasonable extent should not only preserve, but also REMOVE heat or moisture. Otherwise, over time, a living room or office would turn into a steam room.

- Convenience and simplicity when insulating. Minwata Rocklight provides for wet-free styling. And this type of installation is faster, more convenient and simpler.

- Low thermal conductivity. For the central regions of Russia, a 50 mm insulation is recommended, although there are much denser options.

Rocklight vs. Styrofoam

Since the price of polystyrene is much lower than the cost of mineral wool from Technonikol, many often choose a cheaper option for insulation material. Of course, it is more profitable to pay 200-300 rubles for a package than 600-800 rubles. But how will the foam behave in practice and what is Rocklite capable of giving?

The strengths of the foam include its lightness, ease of installation and affordable cost.

But Rocklite, as opposed to foam, provides important advantages:

- The material is not subject to combustion. The mineral wool will not spread the resulting fire, but will simply start to gradually melt. Styrofoam ignites and burns very actively;

- Duration of service life. Polyfoam can effectively serve for 10 years, after which its gradual process of destruction begins. Rocklight mineral wool has been in service for over 50 years while maintaining its original technical characteristics;

- Polyfoam is simply adored by rodents. In many houses, they gnaw through the insulation and settle under the ceiling or in the walls. Mineral insulation is not characterized by such features;

- Providing wall ventilation. By insulating rooms with mineral wool, they can breathe. If you use polystyrene foam, the room will turn into a kind of thermos. The moisture removal will have to be carried out through a specially installed ventilation system. This is unnecessary financial costs and time.

disadvantages

It cannot be said that the product of the TechnoNIKOL company is an ideal insulation, better than which nothing exists. This is not true. Each insulation shows its negative qualities to one degree or another. If you use mineral wool correctly and for its intended purpose, you will not find out about the shortcomings. But if you violate the recommendations, the cons will surely come out.

Mineral wool does not absorb moisture, but due to its effect, the material is still capable of gradually deteriorating.When working with mineral wool, it is imperative to use waterproofing materials. These are additional costs and labor. Is this a disadvantage? For some, yes. I combine thermal insulation from Rocklight mineral wool with waterproofing materials, you need to carefully evaluate the properties of the latter. Some insulators are capable of keeping out moisture and air at the same time

Therefore, an important advantage of mineral wool is lost due to improper insulation design. So, by insulating the floor and ceiling at the same time, it will be just as hard to breathe inside the room as if you were using polystyrene foam.

https://youtube.com/watch?v=JYHrMfDMNkM

Distinctive features and properties

Today, in order to meet the needs of buyers, construction companies are trying to produce lines of goods that are of high quality. Firms are trying to come up with something new to attract as many consumers as possible. This is not surprising, because insulation is the key to an excellent completion of construction.

Also, many construction firms produce materials that are versatile and suitable for other purposes. One of these building products is Rocklight basalt thermal insulator from Technonikol. Due to its excellent technical parameters, the product can be used for various purposes.

Rocklight contains mineral wool, which is one of the best thermal insulation products.

The mineral wool itself is made of basalt fibers. Basalt fibers are obtained by melting mineral rocks.

Basalt fibers

Thanks to such production, a dense material is produced, which has a huge operational life. Rocklight has a low level of thermal conductivity.

Rocklight's competitor can only be products made of expanded polystyrene from the manufacturer Rockwool. However, expanded polystyrene has its own pros and cons.

In any case, foam plastic has a much lower cost than stone wool from TechnoNIKOL, because the process of producing stone wool is long and complex and requires much more time, effort and money.

Styrofoam has a big disadvantage - it can burn. Expanded polystyrene is 90% air, therefore, during contact with fire, it begins to instantly collapse.

Expanded polystyrene

The product does not burn at all, which increases its level of reliability. Therefore, it is recommended to purchase Rocklight from the manufacturer TechnoNIKOL.

The thermal insulator is guaranteed for forty years. Expanded polystyrene lasts a maximum of twenty years.

Reference! Rocklite does not suffer from the problems associated with mineral wool. Rocklite does not swell upon contact with water and is not interesting to rodents.

Minvata begins to swell due to the fact that water instantly accumulates in it. It is incredibly difficult to dry mineral wool, and it is very difficult to immediately notice this problem. Plates from TechnoNIKOL do not absorb moisture or water.

Technonikol plates do not absorb water

Due to this advantage, this heat insulator can be used not only for insulating internal walls and floors, but also for roofs and facades. Reviews indicate that there are no problems during mount. And thanks to specially designed processing, rodents and small insects do not prefer to "dine" with this thermal insulator. They don't contact him.

In addition, Rocklight is an environmentally friendly material and does not harm the human body. Let's briefly list the main advantages and disadvantages of this insulation.

Main advantages:

- huge operational life (40 years);

- high level of reliability;

- does not react to moisture, practically does not absorb water;

- belongs to the class - NG;

- the presence of protection from rodents and small insects;

- good thermal insulation parameters;

- the possibility of application for all building sites;

- ease of mounting material;

- small weight in comparison with other thermal insulation products;

- the presence of vapor permeability.

The main disadvantage is the rather high price in comparison with expanded polystyrene.

Minuses

Although, in general, TechnoNicol products have established themselves in the market, as you know, there are no ideal things. This means that Rocklite has its own "dark" sides.

Firstly, users note that mice do eat it. And if they don't eat, then they gnaw for sure. Therefore, like polystyrene, insulation needs to be erected with a dense frame, through which the unexpected inhabitants of your house cannot get to it.

Secondly, is it worth attributing to the shortcomings of the insulation itself ... or, rather, the approach to choice is flammability. Although TechnoNicol cotton wool itself does not burn or melt, you should not expect that in case of a fire, the insulation will do a miracle, say, in a wooden house. Walls made of wood, OSB or other combustible materials will burn and mineral wool, although it will not promote combustion, will definitely not be able to stop a huge fire.

Thirdly, we have already spoken about the release of harmful substances (unconfirmed!).

Fourth, consumers complain about poor adhesion or contact with alkaline-based wall finishing materials.

In addition, they report the hydrophobicity of the insulation, the fragility of the sheets, and some say that even when buying, the sheets in the package are deformed and dented, which makes it very difficult to install the plates.

Thermal insulation Technonikol

In the Russian market, TechnoNIKOL has long gained popularity with a wide selection and quality of thermal insulation materials. The range of produced stone wool is produced on the basis of basalt rocks. Basalt fibers are mined by remelting mineral rocks. As a result of production, a very dense and durable material with low thermal conductivity is obtained.

Currently, there are a huge number of different types of materials. Most insulating materials are not only intended as heat insulators. They also have sound insulating properties and help protect structures from damaging influences. The company strives to produce the highest quality product lines.

Types and features of Rocklight heaters

Although the Technonikol company also has an extensive assortment, there are only 2 types of the Rocklight brand: with 50 mm and 100 mm thick. Cotton wool differs from each other only in insignificant overall parameters, in particular the diameter of the layer, in all other respects it is an absolutely identical material in its properties. From 50 mm sheets, you can make a surface thickness of 50, 100 and 150 mm by combining several coatings into one. The size of one slab is 0.72 sq. m, and each package contains from 4-12 pieces.

Mineral wool has many advantages, thanks to which it is quite in demand among numerous buyers, having characteristics that are no worse, and in some places even better than the main competitor - polystyrene.

- Resistant to fire. This insulation prevents the spread of ignition over the surface, thanks to which many buyers prefer it, because when the foam burns, poisonous substances are released that can cause serious harm to health. During a fire, people inside the building will have enough time to evacuate and call the firefighters. The melting point is in the region of 1000 degrees, so the mineral wool does not burn, does not smoke and does not run off in scalding drops.

- A low level of moisture absorption is achieved with a preliminary perfect vapor and waterproofing during installation.This property is a tangible advantage and the only disadvantage of the material. If it is used indoors, it should not cover all surfaces, providing fresh air.

- Mineral wool has a long service life, which reaches 50-60 years. Foam sheets begin to deteriorate after 15-20 years.

- Due to its structure, it has excellent sound absorption characteristics and can be used to provide a structure with an effective degree of sound insulation.

- Low biological activity does not contribute to the emergence of harmful fungi and microorganisms, as well as various rodents.

- The material has significant indicators of hardness and rigidity, which is why it is capable of giving in to enormous loads. Even after a long service life, Rocklight insulation is not prone to shrinkage, retaining its original slab shape and efficiency.

- The insulator does not corrode and is resistant to alkalis.

- Basalt wool is absolutely environmentally friendly. It does not contain components harmful to human health.

- The available vapor permeability allows passing and retaining the required level of heat and moisture, producing ventilation of the room.

Rocklight TechnoNicol and its technical characteristics

Rocklight TechnoNICOL mineral wool is a non-combustible slabs 50 or 100 mm thick, made from rocks. The material is intended for thermal insulation of building structures in residential or industrial premises. Ease of installation and excellent material characteristics are appreciated in construction companies and among private developers.

Table. TechnoNICOL technical characteristics of basalt wool