Types of batteries and accessories for them

Before installation work, you need to decide on the units that will be installed. To facilitate the choice of heating devices, we list their varieties with the main characteristic features.

Cast iron radiators

Devices of this type can be considered an integral part of the "Russian style". For more than a century, cast-iron sectional samples have been popular with consumers who try not to part with them when performing major repairs or, if possible, replace them with modern products made of similar material. The reason for this loyalty lies in the advantages of cast iron models:

- Corrosion, chemical resistance, as well as an increased internal section of the collectors make cast iron products unpretentious to impurities or foreign particles present in the coolant.

- The level of heat transfer is twice that of steel analogs.

- Long service life - up to 45-50 years.

- Due to the thick walls, the products retain heat for a long time, are resistant to water hammer, and withstand up to 30 atmospheres during operation.

- Versatility - suitable for centralized or autonomous heating systems.

Now about the disadvantages:

- The large weight of the assembled sections requires reinforced holders and fasteners. During transportation, installation, an assistant is required. It is necessary to install additional solid embedded products (when attached to a plasterboard wall), the use of special legs to support the floor.

- External unaesthetic products. True, this can be said about batteries in old apartment buildings, as well as about some modern budget models. In other cases, the appearance of modern cast iron samples is quite advantageous, even elite.

Modern cast iron creations

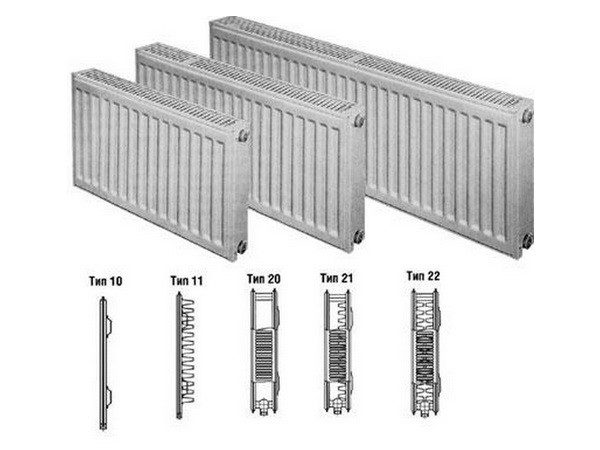

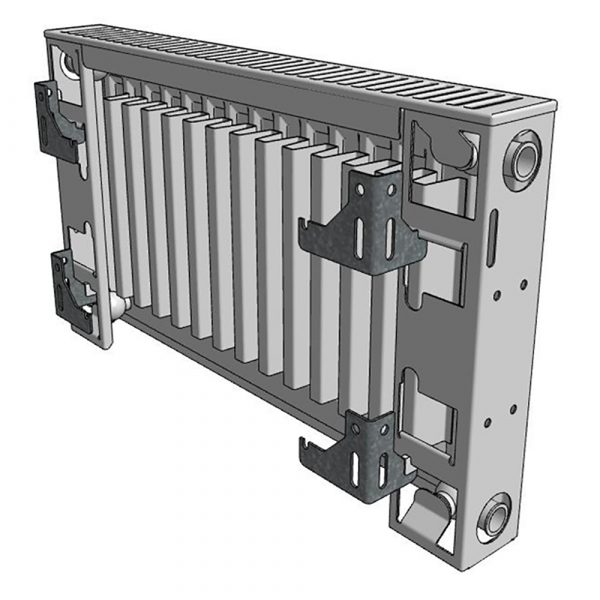

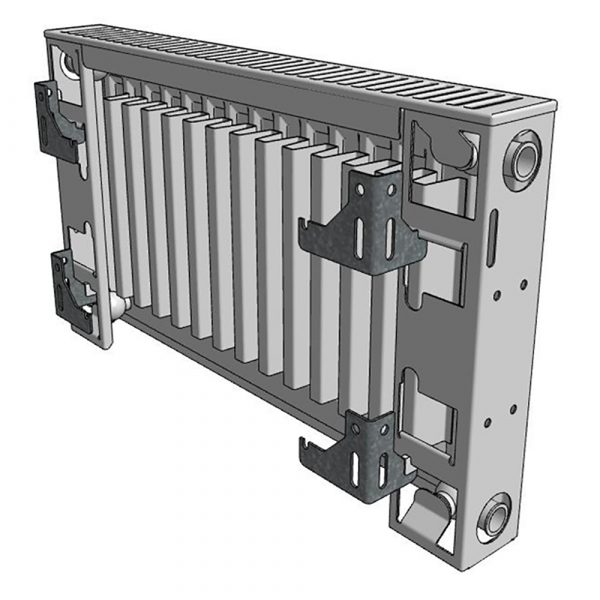

Steel batteries

Panel-type units are in demand when organizing heating of private and public buildings, apartments, offices. Price / quality is the main indicator that affects the prevalence of these models. Other benefits:

- Low weight.

- Ease of installation.

- Good heat dissipation due to the large surface area of the faceplates with coolant cavities, as well as the internal convector fins.

- The urban look of the products is combined with many design styles.

- Affordable price.

- A large selection of standard sizes (from 0.4 m to 3 m - in length; 0.2-0.9 m - in height) for rooms of various sizes.

- Compactness of the product.

Types of applied steel panel metal products

Main disadvantages:

- Reduced service life - on average 10-12 years.

- Vulnerability to strong water hammer of the general heating system.

- Susceptibility to corrosive processes.

- Possible difficulties in purchasing products of the right size. Since the panels are one-piece construction, not all models may be in the assortment of a particular outlet.

Aluminum appliances

This type can be considered the best option for heating a private house or apartment with an autonomous heating system. The main advantages of aluminum batteries:

- Lightness of the product, it can be easily installed by one person.

- Low price.

- Availability in the markets of building materials.

- High strength is achieved by the inclusion of silicon alloys in aluminum.

- Service life - up to 25 years.

- High heat dissipation of raw material.

- Austere, aesthetic appearance.

- Possibility of assembling models of any capacity by connecting any number of standard sections with threaded couplings (applies to cast products).

Samples of assembled sectional models made of aluminum

Important! With the necessary calculations, correctly determine the power of the assembled device, taking into account the fact that the manufacturer indicates in the documentation the power of only one section.

Of the negative aspects, we highlight the following:

- Uneven heating of the surface of the sections.

- Possible leakage due to sudden pressure surges in the system.

- Periodic airing of sections after chemical reactions of working fluid substances with aluminum.

- Susceptibility to corrosion at increased acidity, as well as the presence of solid particles in the working environment that violate the internal protective film.

Bimetallic radiators

From the name it is clear that two materials were used in the manufacture of the product: aluminum (the outer part of the sections), high-quality steel or copper alloy (inner pipes with a coolant). Outwardly, they are no different from aluminum units. But the characteristics are impressive:

- Due to the absence of contact of the working medium with aluminum, the likelihood of corrosion and airing of the sections is reduced.

- The service life is well over 25 years.

- They easily withstand water hammer, are designed for system pressures up to 40 atmospheres, and are fully adapted for connection to centralized systems.

The products retain all the advantages of aluminum models. The main disadvantage is the rather high cost.

More about the types of heating devices, their characteristics:

Fittings

Complete with a radiator of any type, the following fittings are supplied or purchased in a separate set: fittings with gaskets, cork, manual air vent (Mayevsky tap) equipped with a key. The set may also include pin brackets, dowels.

A complete set of necessary accessories

Other solutions

Other types of batteries - anode or copper - can be called exotic due to their rare use.

It is not always possible to bring pipes of the general heating system to certain places or rooms. Then electric heating devices come to the rescue - oil, infrared, ceramic, heat ventilation. They can have a stationary design, providing for wall mounting, as well as floor-standing, mobile devices. Suspended structures, as a rule, are characterized by a small thickness, but a larger area of heated plates. They do not take up space, being installed in narrow aisles, corridors. And they are conveniently located in small niches, behind furniture, under narrow window sills. Such models are sold complete with special fasteners, their installation is simple, it is performed without problems by every home craftsman.

Self-made units - welded registers can also be used. The material for their manufacture is steel pipes with a circular or profile section. These devices are included in the general water heating system, or they are made autonomous, equipped with a tubular electric heater. The efficiency of the register depends on its design, the correctness of calculations of the required parameters. For fixing the products, individual holders can be made or suitable standard products can be purchased.

Homemade welded round pipe registers

Gas

- Is it possible to hide gas pipes in an apartment

?

Where there are no threaded connections on them - of course. Gas-fired steel pipes, provided the paint is preserved on their surface, do not rust or wear out, their service life is practically unlimited.

Exception: do not close the steel gas pipe at the entrance to a private house. In winter, when the temperature outside is noticeably lower than in the house, cooling the bushing with gas consumption will cause condensation to drop out on it. On an open pipe, it will quickly evaporate, and on a closed pipe, it will eventually lead to rust.

- Is it possible to close gas pipes with plasterboard on a galvanized frame

?

The material of the box or niche at a distance from the stove does not matter. Absolutely any finishing materials can be used - gypsum board, gypsum plasterboard, wall panels, plywood, OSB, etc. But near the slab for the box, it is better to use non-combustible materials, including drywall.

- Is it possible to sew up a gas pipe at the connection with a gas meter

?

Not. All threads, taps in front of gas appliances and the meter itself must be accessible for dismantling and maintenance. If there is a leak at any connection, the accumulation of gas in the box is simply dangerous, and besides, it will interfere with identifying this leak and carrying out repair work. Do not forget about the need to check the meter: after a few years it will have to be removed.

Fittings for installation

The range of products for fastening heating devices allows you to choose the right option for each type of product from any manufacturer.

For mounting, metal pins with a bend in the shape of the suspended section can be used. They can be an independent product (they have a thread screwed into a dowel) or are fixed (with a weld seam) in pairs on a metal plate, which is then attached to the wall. For cast iron models, reinforced hooks or steel brackets are chosen.

Samples of the most used holders

In the steel panels, special brackets are welded at the back for hanging on metal corner brackets (right, left).

Canopy brackets for panel radiators

Knowing the parameters of the mounted battery, they calculate the number of anchor points required for its reliable fastening. According to the standard, for a 6-8 sectional device, three holders are required - 2 upper and 1 lower. Each next 5 sections imply a mandatory increase in the supports: one upper, one lower is added.

Helpful information! Often they use a floor mounting method using special brackets or supports. The main reasons for this decision: walls (made of plasterboard, sandwich panels, wood) do not have enough bearing capacity; panoramic glazing is used; lack of a suitable place; the floor bracket is a design accent; additional support for heavy products is needed.

Necessary tools and materials

To make a drywall box yourself, you must have the following tools with you:

- building level;

- drill with screwdriver nozzle;

- screws and dowels;

- metal knife;

- puncher;

- pliers;

- tape measure and pencil;

- ruler corner.

Required tools and materials

In addition, to close the radiator, you will need the following materials:

- drywall sheets. You can use both ceiling and wall;

- metal profiles with a U-shaped section;

- putty.

Wall mounting

Preparation for work, as well as the installation itself, must be carried out according to the general instructions. In practice, small amendments are possible due to the existing design features, differences in the weight of products. Wall mounting technology will be discussed using the example of an aluminum device.

Subtleties of installation

Some rules and recommendations help to avoid errors during installation, which may appear already at the stage of operation of the units that make up the heating system. You should pay attention to the following points:

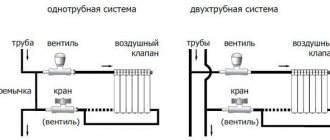

- Decide in advance on the option of connecting the radiator to the pipelines - saddle, diagonal, one-sided.

- The Mayevsky crane is always placed on the upper outlet on the opposite side of the pipeline supplying the coolant.

- The efficiency of heat transfer, as well as the correct circulation of heated air, depend on the correct location of the device. The usual place of attachment is under the window, in the center.It is necessary to expose the product taking into account the following distances: to the window sill - at least 100-120 mm, from the floor - at least 80-120 mm, to the wall - 30-50 mm.

- With a pipe side connection, it is advisable to provide a backup path for the coolant - a bypass, which makes it possible to turn off the device for various purposes without blocking the common heating riser.

Diagram of the correct arrangement of the bypass when connecting the radiator to the heating system

You will learn about the nuances of connecting batteries from the following video:

Radiator installation procedure

The main work is started, making sure that the necessary accessories, tools, devices are available. The order is as follows:

- Preparation process. The product is assembled from the estimated number of sections using gasket nipples, a special key. Pulling adjacent sections is carried out in stages, alternately pulling the thread up to the floor, then down - this is the only way to avoid distortions or jamming of the nipples. The end wrap should not damage the intersection gaskets. Now, having placed the finished product with the front side, it is necessary to screw adapters - futorki to the upper, lower, side outlets. According to the connection diagram, they first fix and then tighten the plug and the Mayevsky tap. There are two exits left - supply and return, on which they put an adapter-"American" under the tap. The assembled radiator is ready for installation.

- Marking for holders (brackets). We determine the distance from the top of the product to the seat, also between the sections where the brackets will be located. The dimensions of the sample are transferred to the wall, then the location of the first hole for the fastening is determined. With the help of the level, taking into account the results of the initial measurements, points are found for the rest of the holders. Holes are drilled according to the marks (displacements are not allowed) of the required depth, dowels are installed, and holders are screwed in.

- Installation and connection. The battery is placed on the fixed brackets. The "American women" and the cranes of the common system are pulled together. Testing of the system, checking the quality of the tightness of the joints. If leaks are detected, the device is disconnected from the system, the coolant is drained, then the connections are re-sealed.

On a note! When installing or replacing a radiator during the heating season, flaws are immediately identified, which are eliminated instantly (as long as the foreman with the tool is in place).

Knowing what is better to see once, we offer video instructions for installation:

Fastening a radiator is a simple process, if the necessary fittings with fasteners are selected, and the installation was carried out according to the rules. The main thing is that the location of the battery ensures maximum heat transfer.

Water supply

- Is it possible to sew up the pipes responsible for the water supply in the toilet

?

If you have a centralized hot water supply, then the same restrictions apply to the DHW riser as in the case of central heating. In no case should the steel risers of hot water and cold water be sewn up: after the first leak, you will have to make repeated repairs.

I will clarify: in cold water, to replace the riser, which will be removed into a niche, you can safely use any pipes with maintenance-free connections. Due to the peculiarities of the configuration of the cold water system, a water hammer is impossible in it: the air in the risers and connections during filling plays the role of a damper, while the hot water system at startup is often bypassed for reset.

If, at the same time, the permeability of the vent is lower than that of the valve element through which the circuit is filled, then a water hammer occurs at the moment when the remaining air is displaced from the circuit.

- And the pipes in the bathroom should be put in a box.

?

Again, in the event that all connections of the cold water supply and hot water supply are maintenance-free. Steel pipes cannot be sewn up with a non-separable box.

- How to sew up pipes in a toilet so that condensation does not collect on them

?

Install ventilation grilles above the floor and ceiling. Convection through them will provide heating of the air with a hot water riser.

Frame sheathing

First, a niche is sheathed for a drywall battery:

- Cut to size and sew up the side walls, cutting out, if necessary, holes for radiator pipes;

- If the window sill is not part of the box, then the top panel is cut out, with which the frame is closed from above;

- Cut out from the gypsum board panels for sheathing part of the facade around the screen and sew these zones.

Data-lazy-type = "image" data-src = "https://remontcap.ru/wp-content/uploads/2017/08/8086422_copy_1.jpg" alt = "drywall battery box" width = "500" height = "450 ″ srcset =" "data-srcset =" https://remontcap.ru/wp-content/uploads/2017/08/8086422_copy_1..jpg 300w "sizes =" (max-width: 500px) 100vw, 500px ">

After the corners are closed with a perforated corner, the joints are reinforced with a serpentine tape, primed, putty and cleaned the surface. The result should be a niche with a battery, which, after finishing, is covered with a decorative lattice screen. Thus, the problem "how to sew up heating radiators with plasterboard" can be solved independently.

The concept of modern home renovation implies the concealment of all utilities. But how to close the radiators and pipes with plasterboard, because according to the housing code it is impossible for them to be hidden in the walls, and the efficiency of the entire heating system will immediately decrease.

There are not so many options for hiding the batteries, tk. according to the housing code, they cannot be hidden in the walls.

The way out is to use drywall in combination with decorative grilles or other design elements of design.

Sewerage

- Is it possible to close sewer pipes in an apartment with a non-separable box

?

In principle, yes, but with a couple of caveats:

- Socket connections must be assembled on silicone. Rubber sealing rings dry out and leak when the drain system is idle for a long time without water, while the sealant will retain water;

- Siphon connections to plumbing fixtures must be accessible. Through the sockets, the sewage system is cleared when blockages.

In addition, SNiP 2.04.01-85 mentions another instruction: a hatch with a size of at least 30x40 cm must be installed opposite the revision in the sewer riser.

However: it is much easier to clean the fat plugs not with a cable, but simply by disassembling the pipes and shaking out the fat into the trash can. Of course, this can only be done with an open sewer installation.

- How to close pipes with plasterboard in a private house when they are long

?

The difference from the apartment is one: every 8-10 meters of the sewer bed, it should be torn by tees or revisions for cleaning, opposite which hatches are mounted in the box.

Design options

Before you close the battery with drywall, you should analyze the features of the placement of radiators and piping in the room. Depending on their location, you can choose one of two options for using drywall:

- covering the battery.

- False wall, hiding radiators and eyeliner behind its plane.

Options showing how to close the battery with your own hands with drywall are presented in the photo below. Both methods have their advantages and disadvantages:

- The installation of the box compares favorably with the smaller amount of required material. But such a design does not always fit organically into the interior of the room. In addition, pipes will have to erect their own boxes, which will further complicate the task. In addition, the presence of such protrusions will seriously interfere with the installation of suspended ceilings or laying laminate on the floor.

- The construction of a decorative wall will require more material consumption, but will allow you to get a flat plane that can be easily finished in accordance with the overall design of the room. In most cases, such a structure is even easier to build than a box that covers a battery.