A Russian brick stove, folded according to all the rules, gives half of the heat given off to the room into the room. However, this amount directly depends on the material covering its surface. Moreover, a rough surface gives off heat more than a smooth one. Since ancient times, stoves have been painted with lime in villages. The owners of the rich houses decorated the stoves with tiles, turning them into real works of art.

Currently, the best design for a brick oven is also its painting. But what is the best way to paint a brick stove?

The amount of heat that a brick stove gives off to a house also depends on the material with which the stove is painted.

Painting with chalk or lime

A brick oven or brick fireplace can be painted with lime wash. Its consistency should resemble liquid sour cream. Before painting the stove, it is necessary to carry out preparatory work: to clean the stove surface from dust, dirt and clay. This can be done with a scraper or iron spatula. Residues should be brushed off. For 100 g of lime, you should take 35-40 g of salt dissolved in water. The resulting paint is highly durable. If it is painted on the surface, it does not leave marks.

You can paint a brick-built stove with chalk, which should first be sifted through a sieve, diluted with skim milk and stirred thoroughly. If the resulting solution has a yellow tint, you can add a little blue to it.

Before painting the surface of the stove, it must be moistened with water. This solution is applied in a very thin layer 2-3 times. Moreover, the next layer is applied to the well-dried previous one.

Metal oven painting

It should be understood that there are several reasons when you can resort to painting a brick stove. So you can approach this issue from the aesthetic side, from the practical and for the sake of safety. As for aesthetics, a stove in a house is needed not only to heat the house and be comfortable in it, but also to maintain the interior and create special coziness. On the practical side, after the fireplace is painted, the heat output increases and the stove surface is leveled.

Note! From a safety point of view, thanks to staining, it is possible to prevent the appearance of microcracks on the brick and, as a result, prevent the fire of the home.

There are several options for painting a structure. You can do this:

- enamel;

- oil paint;

- drying oil;

- heat-resistant varnish.

As for the enamel, it is strong, moisture resistant, interacts well with other materials and has increased durability. Experts cite the following figures: about 200 sudden changes in temperature can be endured by enamel. It should be noted that the color choice is very scarce.

Heat-resistant oil paint for ovens is the best solution, since there is a large selection of colors, the paint can withstand temperatures of 600 degrees Celsius, it is guaranteed to protect the brick from oxidation, has increased resistance and durability. In addition, it is easy to apply and does not need any additional priming on the outside. However, there are disadvantages in the form of unpleasant odor, toxicity and long drying times.

Drying oil is a material that is not able to change the color of the brick, but only slightly make it darker. As for the positive qualities, this coating is reliable and safe. The only drawbacks are the price.

Heat-resistant varnish is a coating that can improve the technical characteristics of a brick surface.

Note! The peculiarity in its use is that it can be diluted with gouache to acquire the desired color with a shade.

Metal furnaces are highly susceptible to oxidation degradation due to their molecular composition. Metal trace elements react with air and, as a result, lead to oxidation. Due to the high temperatures, this process is significantly accelerated. As a result, the service life of the furnace equipment is reduced.

Cast iron is a sufficiently strong metal that is favorably able to withstand prolonged exposure to high temperatures. According to some sources, it is possible not to resort to painting the metal, but it is better to do it. An excellent option for a cast iron stove is the use of water-based acrylic or polyurethane paint, which has already proven itself excellent. In addition, the cast iron alloy will be able to withstand even disturbances during painting more favorably.

The painting process itself looks like this. First, the surface is pre-cleaned with a metal brush. Next, the oxidations are sanded with sulfuric acid five percent, and the mixture is washed off with a soap solution. Then the metal is degreased with a solvent and covered with paint. This is the whole dyeing technology. In this case, the painting of the metal furnace should be uniform. All seamed corners should be reworked as much as possible.

Note! If you do not want to drip onto the surrounding elements of the oven, you must use cellophane with masking tape.

Brick stoves

You can paint a brick stove using enamel, oil paint, drying oil and heat-resistant varnish.

In the first case, the structure will be protected from moisture, will have good strength and durability. In the second case, the plastered and painted surface will be able to withstand high temperatures, and in the latter cases it will be able to impart strength to the brick.

Brick kiln paints and how to use them

The main criterion when choosing a paint for a brick oven is its heat resistance.

A finishing method such as painting a brick stove with oil or enamel paints will allow it to radiate a lot of heat. The darker the color of the paint, the more heat the surface of the brick oven can give off. Moreover, it is known that shiny smooth surfaces have the worst heat transfer. When choosing how to paint a brick oven, you should not paint it with aluminum paints and the like. If the thickness of the walls of the hearth of the furnace meets certain standards, its outer side can reach a temperature of 80 ° C. Such heating is able to withstand synthetic compounds such as nitro paints, pentaphthalic paints and many others. Oil paints made on the basis of drying oil, if painted with them on the surface of the stove, can darken at this temperature.

Today, building stores sell paints for a brick oven or fireplace, which have high heat resistance rates. However, their color range is rather scarce. If the desired shade was still not found, the brick oven can be treated with a special primer and painted with latex paint.

Before purchasing the paint required for a brick oven, make sure it is heat resistant. For this purpose, the best option is to use an organic silicon enamel. After all, it is able to maintain its performance at temperatures up to 600 ° C. Either turpentine or solvent 646 is used as a solvent for this type of enamel. To obtain a good result, a brick oven should be painted with a thin layer without drips in 2-3 approaches.

Varieties of paints

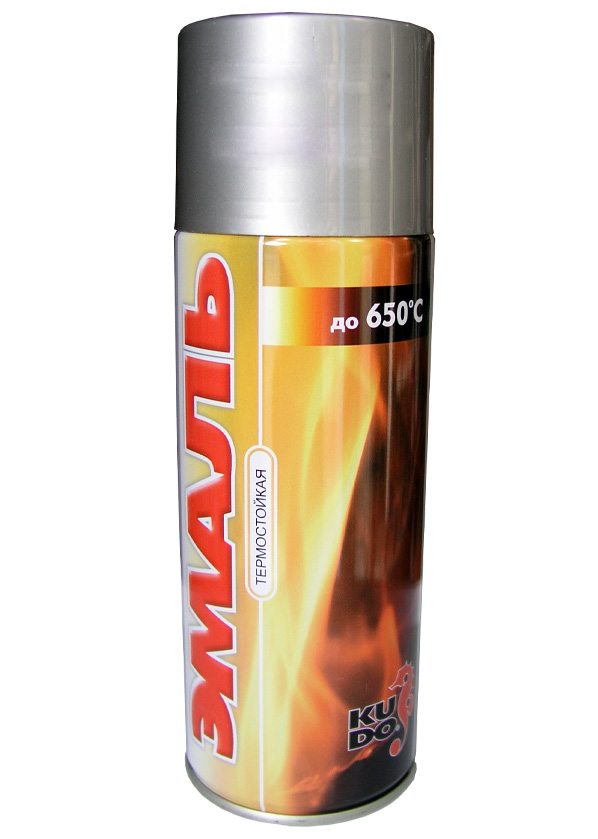

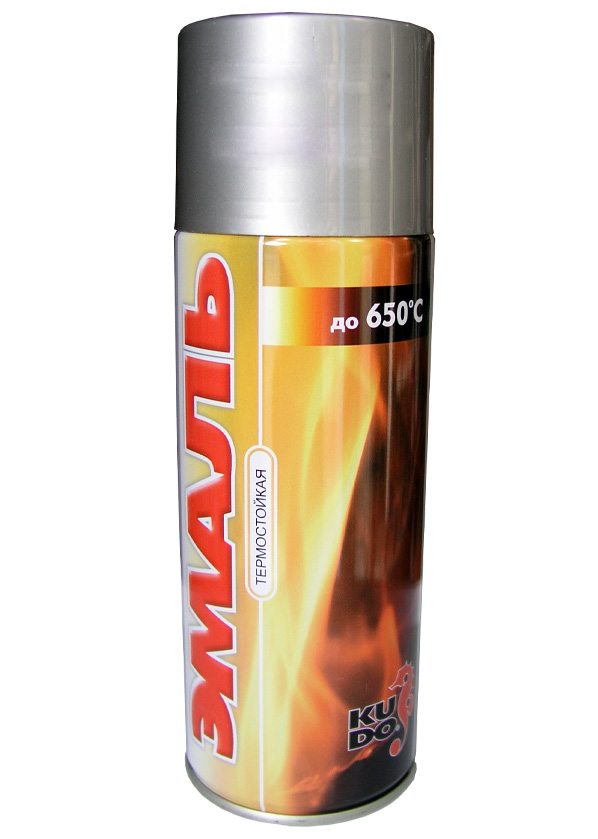

Packing of enamels.

- In order for the masonry to retain its attractiveness as long as possible and to be less destroyed by drops and under the influence of high temperatures, it must be covered with a protective compound. Just because your fireplace looks respectable doesn't mean it shouldn't be painted. In order for it to further delight you with its beauty, the structure must be coated with a colorless heat-resistant varnish.

- Enamels and varnishes on a silicon-organic basis are now widely used; they are usually labeled with the abbreviation "KO". They reliably protect the surface not only from cracks and dust, but also protect it from exposure to a humid environment, which is important for barbecues or barbecue ovens located outside.

- Some formulations may contain silicone to give the surface a glossy sheen. Typically, most formulations are available in suspension and are filled in cans or aerosol cans. Once on the surface, they penetrate the pores of the brick and form a strong, heat-resistant film.

- Any stone structure of this purpose always has metal structural elements, which should also look decent. To prevent valves, doors or cast iron from rusting, special heat-resistant varnishes and enamels are used. Best of all, formulations packaged in aerosol cans are suitable for these purposes.

- Their price is slightly higher, but such paint lays down evenly and has a beautiful, glossy sheen. Plus, there are relatively few metal elements in the structure and 1 spray can will be enough for you for a long time. The cans are also convenient in terms of the speed of painting, it is enough to paste over the metal perimeter with masking tape and the composition can be applied. Drying time does not exceed 3 - 4 hours.

Transparent varnish for bricks.

Important: when buying heat-resistant paint for metal in aerosol cans, pay attention not only to the temperature characteristics, but also for which metal it is intended.

Aerosol can with heat-resistant enamel.

- Most of the paints for brick ovens are designed for temperatures up to 500 ° C, which is usually enough, but there are some paints that can withstand up to 700 ° C, they are used more for metal braziers or surfaces directly next to the fire.

- Taking into account the fact that the burning temperature of coal is about 850 ° C, the inside of the masonry heats up to a maximum of 600 - 700 ° C, hence the outer facing will not heat up above 300 - 400 ° C. Temperature values for charcoal are somewhat lower.

- Enamel of the KO-8101 brand can be called almost universal, it perfectly protects not only stone surfaces, but also behaves well on metal. The temperature range for which it is designed is from -50 to + 650º C. It can be used to paint indoor structures, outdoor grills, barbecue ovens, sauna stoves, chimneys and metal fittings.

Heat-resistant enamel KO-8101.

- It can cover not only brick and metal, but also concrete or asbestos-cement slabs. Another advantage of this composition is the widest range of colors among heat-resistant paints. Almost all the primary colors of the rainbow are represented here, from black or red to yellow and blue.

- Enamel KO-8101 is good, but its price is quite high. If you are interested in paint for a brick oven in a more affordable price category, then we can recommend such brands as KO-811, KO-168, KO-174, KO-835A, KO-1112, KO-85. Most of them also stand up well to the external environment and are suitable for outdoor use, but they are rated for temperatures up to + 450 ° C. Plus, they are only available in black, red and green.

Varnish KO-85.

- A special place is occupied by KO-813 enamel. This paint is available only in silver color and contains aluminum powder. It is designed for both brick and metal surfaces.But you need to use it carefully, because the excessive presence of gold and silver in the interior looks rude.

Important: in pure form, with the exception of aerosol cans, all these compositions are practically not used due to their thick consistency. Dilute them with solvent No. 646 or turpentine.

The video in this article shows one of the types of heat-resistant paint.

Brick oven in a modern interior

A brick oven can easily fit into the most modern interior design and even become its "highlight".

Today, among homeowners, interiors made in the style of chalet, country, and shabby chic are very popular. Their distinctive feature is the naturalization of various details and decorative elements. As well as possible, a brick Russian stove or fireplace will fit into such interiors, as a bright and stylish addition. These items can be a real highlight. To do this, they can simply be painted with transparent paint. However, before painting the surface, it must be properly prepared. If there are any visible defects on it, they must be eliminated by filling with putty. The latter is prepared by mixing latex paint and brick flour.

How to make DIY brick paint

You can achieve a beautiful shade of a brick oven yourself by making your own paint. First, red brick flour is rubbed. Whipped egg whites and milk are added to it until a thick consistency. The mixture is thoroughly mixed. You need to paint the stove with a new brush, applying paint to the surface of the stove preheated to a warm state. In this case, the brick surface acquires an even red color. This coating is heat-resistant and has increased abrasion resistance. At the end, the stove must be painted with linseed oil, which will make the dark red surface matte. If desired, you can get shine by applying a special synthetic varnish.

This type of painting a brick oven is approved by experts. After all, the resulting dense rough surface contributes to the greatest return of heat to the room and, having excellent elasticity, prevents the formation of cracks and various defects.

When faced with a choice of how to paint a brick oven, you can apply another method of preparing paint for a brick oven. All that is required for this is turpentine and PF-283 varnish. Both components are mixed in equal proportions. The result is a transparent, slightly matte blend. In order to give it the desired shade, you can proceed as follows: gouache of a certain color is well dried and ground into a fine powder, which is added to the prepared mixture. The paint is ready to use.

What is used today

Heat resistant paints help prevent deterioration of various materials. They are used for painting household heating devices and in industry. Heat-resistant enamels and paints are painted:

- stoves and fireplaces from any material;

- heating batteries;

- chimneys;

- dampers and doors for ovens;

- braziers;

- brake calipers;

- electric motors;

- steam pipelines;

- transformers;

- heating parts of industrial machine tools.

When choosing paint, pay attention to the following important parameters:

- Maximum temperature. Standard paint can withstand up to 450 ° C. Please note that it is impossible to do with one paint for the stove; for the metal parts of the stove it is better to choose enamels that can withstand 600 ° C and above.

- Anti-corrosion. For painting stoves and boilers in baths and saunas (high humidity conditions), anti-corrosion paints are needed, they protect the painted surface from rust. Such paint is also suitable for outdoor barbecues.

- The foundation. Choose water-based or non-toxic solvent based paints to avoid being poisoned by the emitted toxins.Refractory non-combustible components in the composition will retain the properties of the coating under strong heating.

- Fillers. Heat-resistant paints that can withstand temperatures above 500˚C should include zinc or aluminum powder.

There is also a universal thermal paint on sale for all types of surfaces. When applied, it forms a thin film, under which moisture and air do not penetrate. In order not to be mistaken when choosing a paint, study the description, information on the purpose and reviews on the forums, as well as consult with the seller, specify for use in what temperature conditions and for what surfaces it is designed - dry heat, fire, steam - metal, brick or concrete. Marking can tell a lot.

We suggest that you familiarize yourself with: Thermal insulation of walls from the oven

Modern paints and varnishes, which are exposed to thermal effects, can withstand heating up to 350… 400 ºС. The flame temperature in the firebox, where the wood is burning, reaches 450 ºС. When coal is used as fuel, it rises to 1000 ° C.

The outer stove surface does not heat up in the same way as the firebox. However, to cover it, you should choose a heat-resistant paint or varnish that can withstand heating up to 400 ... 550 ºС. Heat-resistant paints and varnishes are made for different purposes and different surfaces. Manufacturers indicate on the packaging the temperature resistance of the coating, as well as the type of surface for which it is intended: brick or metal.

The range of refractory compounds includes coatings in various shades. Colorless varnishes keep the natural look of stone or brick for a long time.

Natural drying oil

Coating with natural linseed oil does not change the natural shade of the brick, but makes it darker. The peculiarity of drying oil is that a heating device covered with this composition can be heated only for a limited time. Therefore, it is not suitable for stoves in residential premises, and is used to cover heaters installed in a bath.

The basis for the production of silicone coatings for stoves or fireplaces are organic resins. These paints and varnishes have good adhesion to surfaces of various textures. They form a durable moisture-resistant coating that can withstand up to 250 heating-cooling cycles. The disadvantage of organosilicon compositions is the poverty of color solutions, which is due to the chemical properties of these coatings.

Natural drying oil for ovens.

Alkyd paints and varnishes can be used for brick surfaces that do not heat above 100 ° C. Manufacturers of formulations introduce marble or granite dust, components with antifungal and fire-fighting properties into them. The disadvantage of alkyd compounds is their low elasticity.

Heat resistant paint

Painting of brick or plaster stoves, chimneys and fireplaces is carried out with heat-resistant paint, capable of withstanding heating up to 200 ... 400 ºС. High-temperature-resistant varnishes should also be included in this category. Their working temperature is 250… 450 ºС.

Heat-resistant compounds not only withstand prolonged exposure to high temperatures - they are safe for humans, since they do not emit hazardous substances when heated. Heat-resistant coatings do not affect the heat exchange between the heater and the room air, they are resistant to detergents, and are elastic. To provide the oven surface with a uniform, uniform coating, 2-3 coats of paint should be applied.

Furnace before and after painting.

Advantages and disadvantages of heat-resistant paint

The heat-resistant paint used for painting a brick oven has a number of advantages. The surface treated with it acquires certain properties: wear resistance, heat resistance, electrical insulation. It protects the brickwork from oxidation, contributes to its strength and endurance. It is quite easy to paint the stove, and no pre-application of primer is required.The paint retains its performance for ten years.

The disadvantages of heat-resistant paints include an aggressive chemical composition and an unpleasant odor. They have a long drying time. When working with such paints, precautions should be taken due to the presence of toxic substances in their composition.

Briefly about the main thing

Heat-resistant paints for metal for ovens or for bricks are compositions that not only withstand high temperatures, but also have high mechanical strength and moisture resistance.

The classification of paints of this type divides them into three types: refractory, heat-resistant and heat-resistant. It all depends on the temperature that they can withstand.

In addition to paints, manufacturers offer a heat-resistant colorless varnish for painting bricks.

The application method is exactly the same as for conventional paints and varnishes.

Ratings 0