Do you need to insulate foam concrete? Which insulation is more suitable? How thick should the mine plate be so as not to freeze in winter? How can you decorate a house from foam blocks? What is the insulation cake for a wet facade? How many layers does a curtain wall have? And if you finish with a stone? Why do you need a waterproofing membrane? How to do without a windscreen? How to install a vapor barrier correctly: inside or outside?

Contrary to the assertions of manufacturers that such blocks of foam and aerated concrete do not need additional insulation, in practice it turned out that in the conditions of the Russian climate, a layer of thermal insulation is not superfluous for them. First, let's figure out how these materials differ.

Foam concrete and aerated concrete: what's the difference?

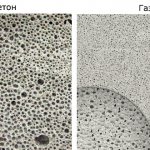

Cellular structure of foam block and aerated block

Both the one and the other material belong to lightweight concrete of the cellular type. The difference lies in the manufacturing method and composition:

- foam concrete is a naturally hardened mixture of sand, water and cement. Cells (bubbles) are formed in it when foaming agents are introduced into the composition;

- aerated concrete has the same composition, but a siliceous binder is additionally included in it. The pores in the blocks are formed after the introduction of aluminum powder into the mixture, which, entering into a chemical reaction with calcium oxide hydrate, promotes the release of hydrogen. Blocks harden at high humidity and temperature.

Aerated concrete is more than 3 times stronger.

Foam concrete and aerated concrete are the same in density, but different in strength. With a density of 500 kg / m³, foam concrete will withstand a load of 9 kg per 1 cm², aerated concrete - 32 kg per 1 cm².

Since the sizes of pores (cells) and their distribution in materials are not the same, the thermal conductivity and moisture permeability of foam and aerated concrete are different:

- under conditions of humidity of 6% D500 foam concrete shows a thermal conductivity coefficient of 0.13-0.16;

- aerated concrete under the same conditions - 0.116;

- pores in foam concrete are unevenly distributed, isolated from each other and unequal in size, therefore they slowly absorb moisture;

- aerated concrete absorbs moisture better, therefore it is not recommended for areas with high humidity.

The advantage of foam concrete is that it absorbs moisture more slowly.

Insulation of walls made of aerated concrete - when it is required and how to do it

Aerated concrete, depending on the density, is divided into heat-insulating (grades D100, D200), heat-insulating and structural (D300, D400, D500), structural (D600, D700). With an increase in density, thermal insulation properties decrease, and strength increases.

If heat-insulating can be used as a heater, which is beneficial, given the long service life of the material, then structural aerated concrete is used for the construction of load-bearing walls up to 3 floors.

In Germany, almost half of private houses are built from aerated concrete. The reason for this is the mild warm climate, the average annual temperature is about +10 degrees, and frosts in winter –10 degrees are a rarity.

Therefore, a wall made of aerated concrete of normal thickness there can be single-layer (without an additional layer of insulation) and at the same time meet the requirements of standards for heat conservation.

Special properties of aerated concrete

Aerated concrete, unlike foam concrete, is produced in an autoclave. Its components are sand, cement, lime, water, aluminum powder (foaming agent). Steam treatment at a temperature of 190 degrees and a pressure of 12 bar forces the components to react with each other, thus forming a new artificial mineral.

Warming - why is it needed?

A common reason for the need to insulate walls made of foam and aerated concrete is a violation of the rules for laying them: to reduce the cost of construction, ordinary cement mortar is used instead of glue. At the same time, the thermal insulation qualities are reduced due to the numerous "cold bridges".

Using cement instead of glue when laying foam blocks.

With the help of "thermal fur coat" they extend the life of the house, otherwise, getting into the pores of cellular concrete, moisture freezes in winter, expands and breaks the material. A layer of insulation helps to exclude the appearance of a "dew point" inside the walls, to keep them in a constant zone of positive temperatures and a minimum of humidity.

The process of insulation from the inside will not be considered in this article, since it is not a technologically correct solution and leads to negative consequences for the structure.

Scope of low density aerated concrete

As you yourself understand, the main task of low-density aerated concrete is external insulation of the facade walls. Such aerated concrete is used on walls with insufficient thermal insulation, and on walls in which mistakes were made during masonry, such as thick mortar joints and cold bridges from reinforced concrete inclusions. Also, aerated concrete with a density of 200 is used to insulate screeds and the floor of a cold attic.

Before considering the installation scheme, it should be noted that low-density aerated concrete is quite fragile, and you need to work with it extremely carefully, especially when loading and unloading.

Before starting installation, you need to prepare the surface for gluing. That is, eliminate the drops on the wall, tear off the influx of glue or concrete, clean and dust the surface.

Choosing a finishing method and insulation

Block house without external finishing.

How to veneer?

With external insulation, they are primarily determined with the type of external decoration. Houses made of foam and aerated concrete blocks are faced with:

- textured vapor-permeable paints and putties;

- thin-layer lightweight plaster designed specifically for aerated concrete (silicone, silicate, lime);

- brick or decorative panels (with mandatory ventilation gaps).

Ordinary cement-sand plasters absorb moisture and do not remove water vapor, and film-forming coloring compositions do not allow air and steam to pass through. They are not suitable for finishing work at home made of foam and aerated concrete.

How to insulate?

It is important to consider the compliance of the insulation with the characteristics of the wall material. It's about again vapor permeability:

For a detailed comparison, see our article "PPP or Mineral Plates?"

- expanded polystyrene - a cheap insulation that does not allow steam and moisture to pass through;

- mineral (stone) wool is an ideal insulation from the point of view of vapor permeability, but more expensive.

Why is this indicator important? Aerated concrete is good precisely for its vapor permeability. During the operation of the house, moisture is constantly formed inside, which the blocks absorb and remove outside. The process is called "wall breathing" and helps eliminate mold and mildew in your home.

If earlier expanded polystyrene was categorically not recommended for insulating gas and foam blocks, today they talk about the validity of its use if the thickness of the walls from D500 blocks is at least half a meter, and good ventilation is established in the house. The dew point is deep within the material, and condensation will not form on the walls.

Mineral plates have a higher vapor permeability than blocks and do not interfere with "breathing".

What is the thickness of the insulation to choose?

Use insulation with a thickness of at least 50 mm.

As for the thickness of the insulation, it makes no sense to use slabs less than 50 mm thick in Russian regions with harsh climatic conditions, strong winds and sudden temperature changes. The best option is 100 mm with a bearing wall thickness of 300-400 mm.

The calculation is approximately as follows: in terms of thermal conductivity, a layer from a block of 300 mm + 50 mm of insulation is approximately equal to a block of 400 mm without insulation. The heat loss of a wall of 400 mm thick + 100 mm of the insulation layer is reduced by 2 times compared to a wall made of blocks of 400 mm, but without insulation, and less than that of a 400 mm block + 50 mm insulation, by 20-25%. Even the increased costs for a layer of insulation of 100 mm will pay off very soon.

Outside insulation technology

Thermal insulation of foam blocks from the outside is more expedient. Here is a list of the benefits:

- The interior space will not be reduced, the area will remain intact.

- Insulation outside will not interfere with the heating of the walls inside the room. If the heat insulator is inside the house made of foam blocks, then they will begin to constantly freeze and thaw. As a result, over time, they will begin to deteriorate.

- If you install the stoves inside, the dew point will shift towards the room. Moisture will begin to accumulate in the center of the wall. This leads to the formation of mold.

If you make thermal insulation of the outer walls, then the dew point is shifted to the outer surface of the walls. It will not collect in the blocks, and thanks to the ventilation gap, it will quickly evaporate.

There are two options for insulating a house from the outside: using the wet facade technology and the ventilated facade method.

Wet facade

The peculiarity of the method is its simplicity. There is no need to build a frame and make ventilation gaps. It is enough to fix the insulation material on the surface and make a decorative finish. For this purpose, it is better to choose foam or EPS.

Sequence of work:

- Good cleaning of foam concrete walls from mortar residues, dust, dirt, grease stains and other debris. Large irregularities are eliminated.

- Further, the facade is primed with an antiseptic agent. Thanks to the primer layer, the adhesion of the foam block with the adhesive solution of the future insulation layer improves. The consumption of glue is also reduced.

- A starting bar is laid along the entire perimeter, on which the first row of insulation will rest. The bar is presented in the form of a metal profile. It is fixed on self-tapping screws or screws with dowels.

- Now the installation of the insulation layer is in progress. A foam or EPS board is laid on the glue from the corner. You need to apply glue around the perimeter, stepping back 2 cm and in the center.

- In order for the plates to stay securely on the foam block, they are reinforced with dowels with an umbrella. Holes are made in the corners and in the center of the slab, into which the dowel is inserted. A screw is screwed into it. It is the dowel screws that are used, not the dowel nails.

- The second row is fixed in a similar way, only with an offset of the seams by 20-30 cm.

- A reinforcement mesh is mounted on top of the finished layer of insulation. It is made of fiberglass, it is needed to prevent the formation of cracks on the surface and for the strength of the insulating cake. A thin layer of adhesive solution is applied to the foam, into which the mesh is recessed. Another thin layer of glue is applied on top.

- Particular attention is paid to corners, door and window openings. It needs extra corners and a double layer of fiberglass mesh.

- When the glue is dry, you can start tiling.

As a cladding, decorative plaster for painting or other types of finishes, such as bark beetle, fur coat, is used.

Ventilated facade technology

In this case, mineral wool can be used as a heater, since there is a ventilation gap here that allows moisture to evaporate and not affect the characteristics of the wool. In addition, a layer of waterproofing film will not allow moisture to penetrate into the structure of the mineral wool.

Sequence of work:

- Preparation of walls from foam blocks. It is carried out in the same way as in the case of a wet facade.

- A vapor barrier film is fixed to the wall. Its peculiarity is in the property not to let moisture through, but to let the air circulating through the walls.

- A vertical or horizontal lathing is installed. Thanks to it, cells are created, 60 cm wide, identical to the width of the insulation. Mineral wool slabs are installed in these cells. The lathing or frame is made of 5x5 cm wooden blocks or galvanized metal profiles. When using wood, it will need to be treated with antiseptics and moisture-proof compounds. The height of the lathing is made according to the height of the insulation layer (for the entire wall). In this case, the distance between the slats is 60 cm (identical to the width of the mineral wool slab). But in order to avoid the formation of cold bridges and to compact the mats, it is recommended to take a step 2-3 cm less.

- When the crate is ready, mineral wool slabs are installed in it. If the width of the mats is 60 cm, and the pitch between the slats is 57–58 cm, then the slabs will fit perfectly without additional fastening. But, so that over time they do not fall off due to structural deformations, it is better to attach them to the foam blocks by means of dowels.

- On top of the created protective layer, a moisture-proof film and a hydro-barrier are mounted.

- The next layer is a counter-lattice, 3-5 cm high. It serves to create a ventilation gap. In addition, siding or other selected decorative material is fixed to it.

It remains only to perform clapboard cladding, siding, imitation of timber.

Installation of thermal insulation and cladding is carried out in dry weather so that the insulation does not lose its properties.

Warming "pies"

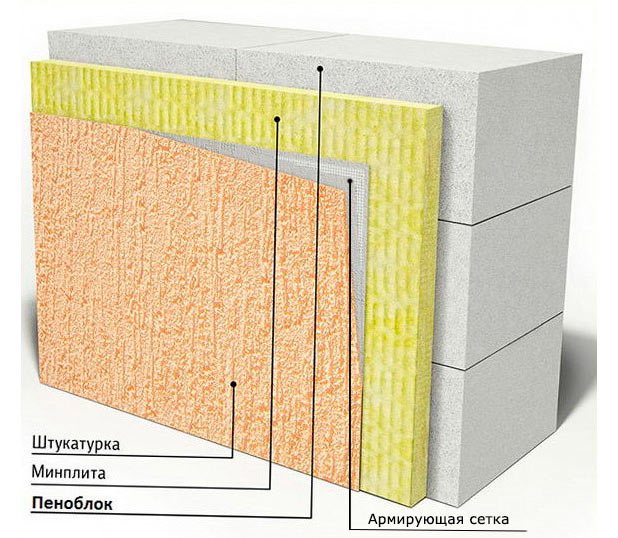

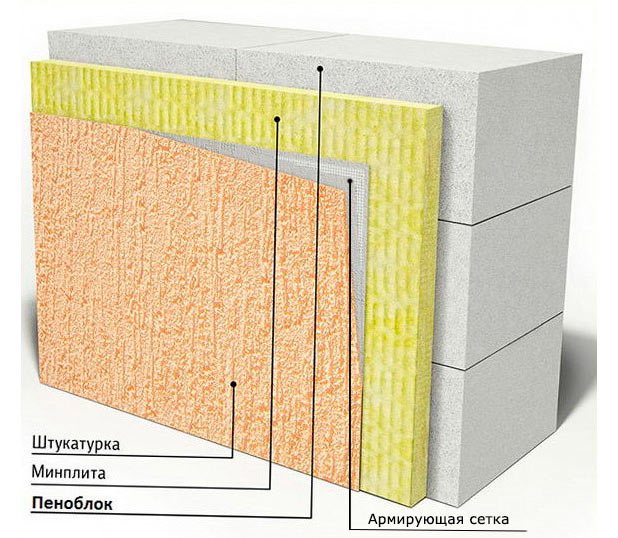

The layers of the insulating structure differ depending on the method of exterior decoration.

- When choosing Wet technology the insulation is fixed to the wall with glue and dowels, then glue is applied to it, into which the reinforcing mesh (plastic or fiberglass) is embedded, then finished with decorative vapor-permeable plaster, which additionally has a waterproof function.

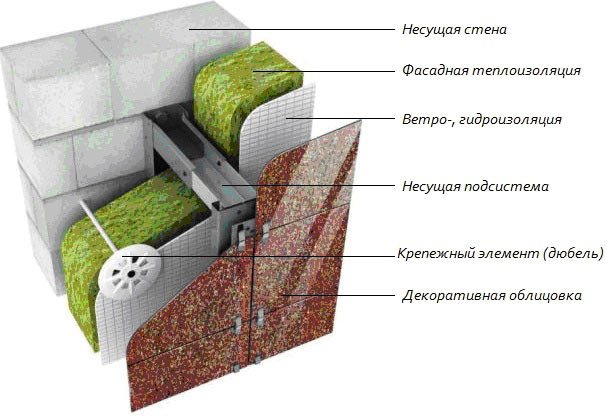

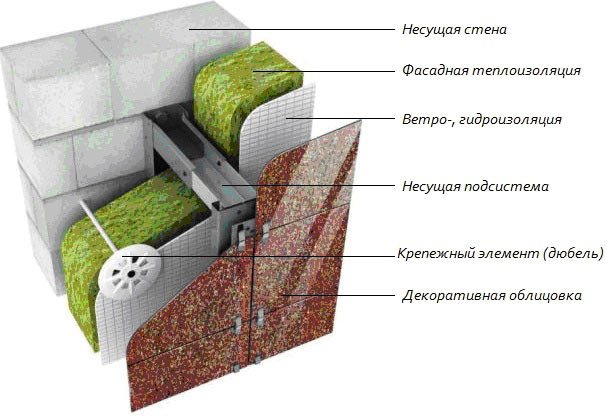

- Warming cake at hinged ventilation facade includes a frame made of wood or metal anchored to the wall; a layer of insulation, fixed with plastic facade dowels; a layer of windproofing - a membrane mounted with an overlap of 15-20 mm at the joints; then the ventilation gap and external decoration - siding or decorative panels, less often - porcelain stoneware slabs.

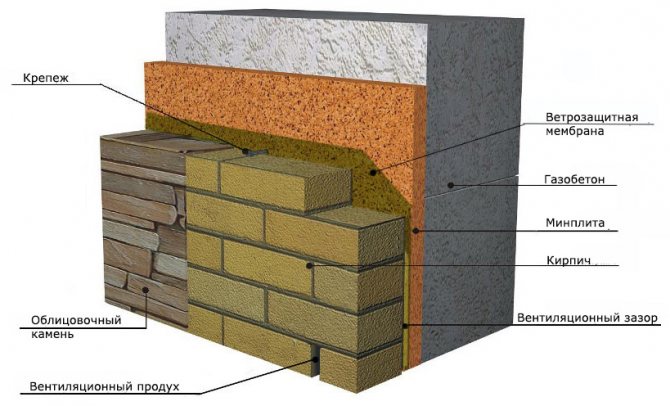

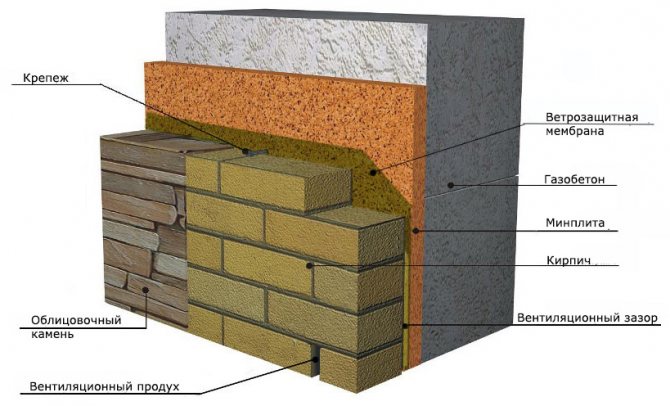

- When facing brick or natural stone the insulation is fixed with dowels to the wall, then a layer of windproof membrane and brickwork (through a ventilation gap of at least 40 mm). This kind of cladding requires additional strengthening of the foundation due to the high load.

Wet facade insulation cake.

Curtain wall insulation scheme

The order of the layers of aerated concrete insulation when facing with brick or stone.

When is the thermal insulation of the gas block justified?

In some cases, when the client does not have enough funds, he may decide to build a house in 2 stages. So, for example, first a house of 25 blocks is built and used, for example, as a country house. And after a while, the client decides to move there for permanent residence, and the question arises about insulation in order to reduce heating costs. In this case, we recommend insulating the aerated block with basalt insulation.

Insulation of a house made of aerated concrete with basalt insulation

The technology of insulating aerated concrete outside with basalt insulation is as follows. We take a basalt slab with a density of 150 kg / m We recommend taking the dowel and nail from a stainless steel, so that in the future, rusty spots do not appear on the facade. Then we align the basalt slabs with an adhesive composition and fill in a special facade mesh there. Then again we go through with glue and, when the composition dries, it remains to prime, cover with decorative plaster and paint the facade.

As a rule, basalt insulation with a thickness of 50 and 100 mm is used. Its cost is in the region of 4500-5000 rubles. for 1 cubic meter m, which is 20-30% more expensive than aerated concrete itself.In addition, it is necessary to additionally pay for the installation of insulation. As a result, a two-layer structure is obtained, which, in terms of service life, is still less than a single-layer one. It turns out that a single-layer wall is more practical and better. Thus, it is economically more profitable to immediately take a block with a width of 350-400 mm, which does not need to be insulated.

Thermal insulation of aerated concrete with foam

Many people wonder whether it is possible to insulate aerated concrete with foam. Of course, if the client really wants to insulate his house in this way, then no one can forbid him.

However, we advise against doing this.

Firstly, mice live very well in polystyrene, so they chew it with pleasure.

Secondly, the foam burns very well and at the same time releases toxic substances. So, for example, if the foam is used inside, then when it burns, two breaths are enough for a person to die.

In addition, foam is a short-lived material. If you plan to revet the facade with decorative plaster, then be ready to start finishing the facade in 7 years, since the service life of the foam is 5-7 years. Thus, your cost item increases.

We come to the conclusion that foam insulation is ineffective, dangerous and unprofitable.

In Soviet times, research was carried out on people living in houses with internal foam insulation, the results of which revealed many negative aspects, for example, women could not give birth. After that, the use of foam in the thickness of the masonry and indoors was banned. Now there is no such prohibition. But apartment buildings have not been allowed to pass for 2 years, even with external foam insulation. We strongly do not recommend insulating houses with polystyrene foam.

In any case, each client decides whether to insulate aerated concrete or leave his house without insulation, depending on his preferences and material condition.

Learn more about aerated concrete and construction from it in the training center "Gazobeton63.ru"

In this article, I tried to reveal the important points that relate to the insulation of a house from aerated concrete. You can find out even more information about working with aerated concrete at free theoretical classes at the Gazobeton63.ru training center. Invite you!

| Vitaly Markov Leading expert on aerated concrete in the Samara region. |

- Not a penny of overpayment, you get aerated concrete at the factory price and the most favorable prices for delivery

- Free consultations from the leading specialist in aerated concrete in the Samara region - Vitaly Markov

- Possibility to pay for the material after its delivery to the object

- Additionally, we check the quality of aerated concrete for our customers. We conduct research in independent laboratories

- We carry the blocks quickly, but carefully. Professional drivers further strengthen and protect your units before transport to the unloading point

- Training center "Gazobeton63.Ru" - learn how to work correctly with aerated concrete and how to check the quality of work of your builders

- We can recommend trusted builders who have undergone special training in working with aerated concrete

By purchasing blocks in winter, you save up to 30 000 rub!

In our Training Center, you can undergo training not only in the construction of aerated concrete, ceramic blocks, but also training in engineering systems UPONOR !

And it's perfect IS FREE!