Every person who has ever encountered the construction of buildings or structures with his own hands knows that one of the most difficult elements is the ceiling.

You can do without a foundation when building a house, a bath, a gazebo can be without impenetrable walls, but the ceiling device must always be of high quality.

The ceiling is divided into three types - slabs, monolithic and wood. Each of them has its own advantages and disadvantages, and the installation process is completely different.

There are three types of ceiling slabs - slabs, monoliths and wood. Each has its own advantages and disadvantages, and the installation process is completely different. There are a number of other features that should be taken into account before installing the ceiling, since not everyone can be suitable for this or that case.

Requirements

Beam types of floors

Overlapping the ceiling, regardless of what material went into their manufacture, must meet the accepted standards:

- The overlap is obliged to withstand the operational loads calculated by you in advance. The design load includes the weight of the floor beams and the ceiling finish material you choose;

- The rigidity of the structure must withstand all expected loads, while it must not deform;

- It is also necessary to provide the ceiling with sufficient sound and heat insulation characteristics.

- One of the main characteristics of a ceiling slab should be its fire resistance.

There are two types of ceiling slabs: slab and beamed.

Construction requirements

The overlap is a structure designed to separate adjacent rooms by height. In other words, the ceiling forms the floors and helps to separate the rooms from the basement or attic.

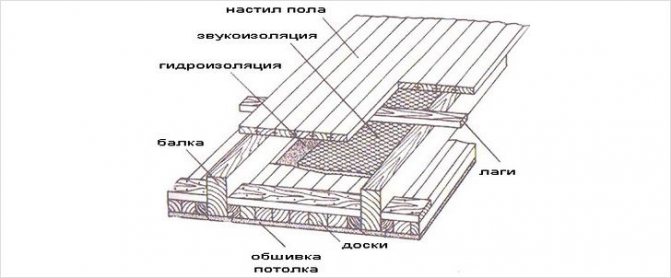

Ceiling device diagram.

The ceiling design must meet certain requirements. So, without fail, it must be durable, because the load will be placed on it in the form of furniture and people. There are certain limits of the payload: for the attic floor, it should not exceed 105 kg / m2, the interfloor and basement must withstand a load of up to 210 kg / m2.

Among other things, one of the essential qualities of the overlap is rigidity; during the action of loads, the slightest deflections should not occur.

During the installation work on the installation of the floor with your own hands, you need to take care of its sound insulation in accordance with the norms. The level of noise absorption can be increased by sealing all possible cracks at the joints of the material.

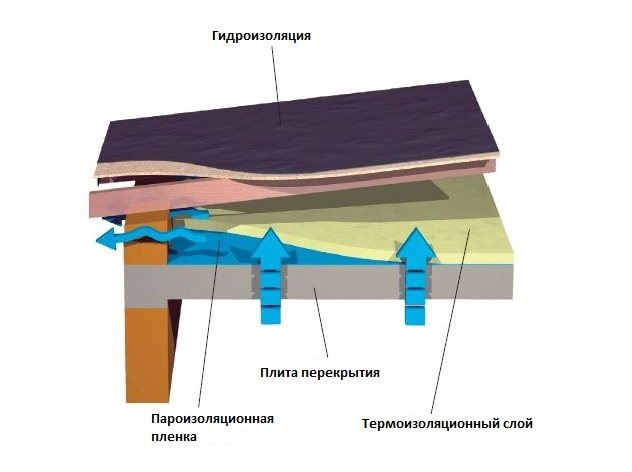

Ceilings designed to separate rooms with different temperatures (basement and room, room and attic) require an additional layer of thermal insulation.

Beam floor

Beam processing

This type of flooring is very popular for individual construction. When building your home, become familiar with the method of constructing timber joists.

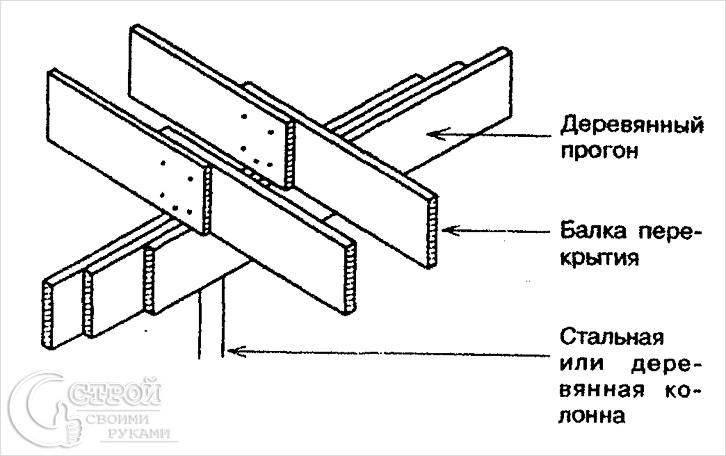

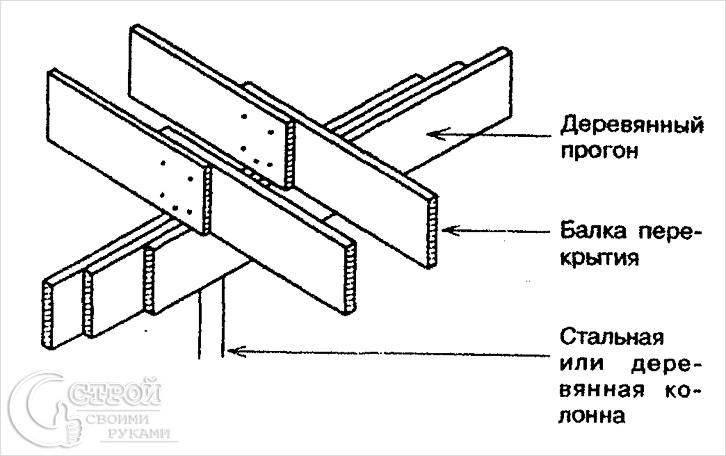

Wooden beams, supported by the load-bearing walls of the building, form the basis of the beam floor. Calculate their cross section depending on the length of the step between them and the distance between the load-bearing walls, overlapped by the beams and, of course, on the expected load on the ceiling.

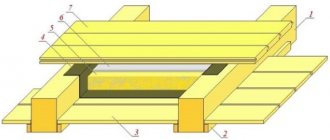

Leaning beams on a wooden purlin

Take your timber choice seriously. When constructing a ceiling, remember that beams can be made from different types of trees.The main thing is that they are well dried for 100 days. This largely determines their quality. Check the beams before starting the construction of the floor. Check for rot, cracks or other wood disturbances. Do not use rejected beams in construction.

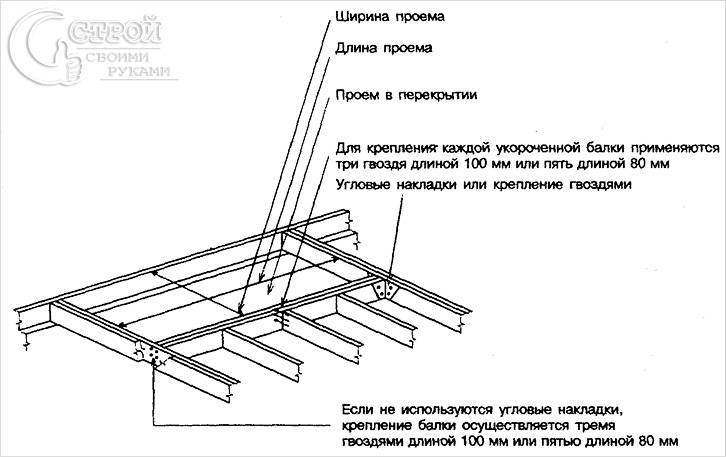

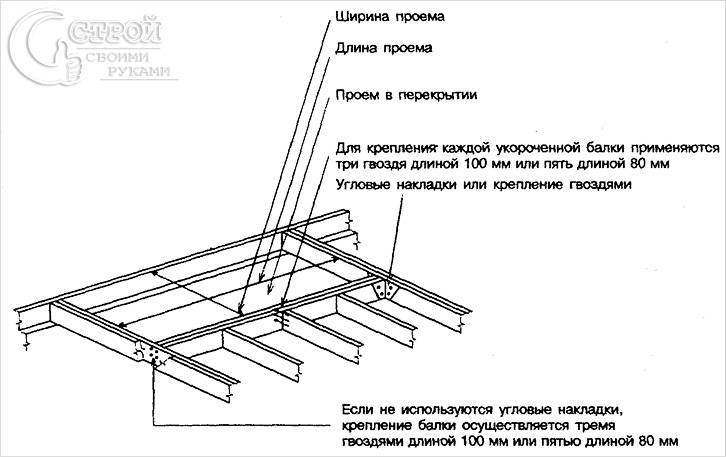

Floor opening scheme

- Place the beams on the walls and level them flat. Do this with tar board liners of varying thicknesses. Never use wedges made from untreated wood for this job.

- To reinforce the joints of the beams on the inner walls, secure them with metal brackets and clamps. Instead, you can use wooden strips made from planks at least 40 mm thick.

- According to fire safety rules, floor beams must not be placed closer than 400 mm to the chimney.

- Be sure to treat the ends of the beams that are embedded in the load-bearing walls with an antiseptic, tar and wrap with roofing material. These measures will protect the timber beams from the occurrence and development of rot.

- To stiffen the floor, fasten each second beam to a metal fastener embedded in the masonry.

- To make a rough ceiling, prepare the skull bars, then attach them to the side edges of the beams. Attach the material of your choice to the bars, which forms the rough ceiling.

Ceiling finishing materials

Each owner of his own real estate, before making a ceiling in the house, decides the issues related to the choice of finishing materials. When doing the work yourself, using drywall or PVC wall panels is a good option. In both cases, it is advisable to fasten the ceiling along the beams to the lathing installed strictly horizontally, since deviations from the horizontal and other surface defects will be very noticeable. At the same time, drywall and panels can be mounted between the beams without lathing and careful alignment (about

Slab ceilings

Laying floor slabs

Basically, slabs are used in the construction of apartment buildings.

When building your own houses, this type of flooring is less in demand. Plates are characterized by a large dead weight, which means that during their installation, the use of special equipment will be required, and this is associated with an increase in cash costs.

Note!

Slabs have an undeniable advantage. They do not burn, are characterized by high strength and durability.

If you have installed a slab floor according to the existing rules, you will end up with a flat ceiling surface that does not require additional leveling and grinding.

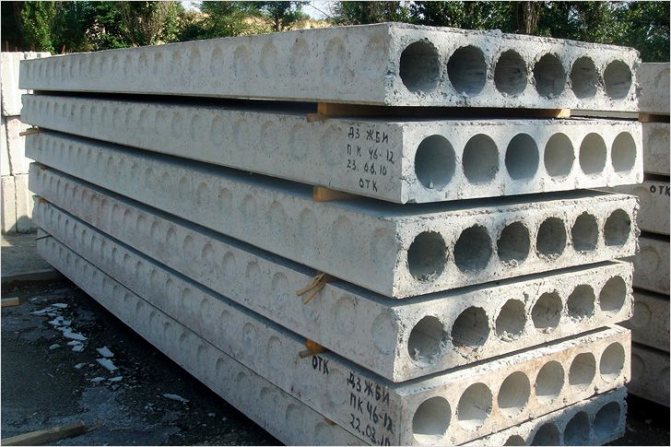

For the manufacture of slabs, heavy and lightweight concrete is used; they can be solid or hollow inside.

Note!

When building a private house, it is better to use hollow core slabs. They are characterized by excellent heat and sound insulation parameters. In addition, their weight is much less.

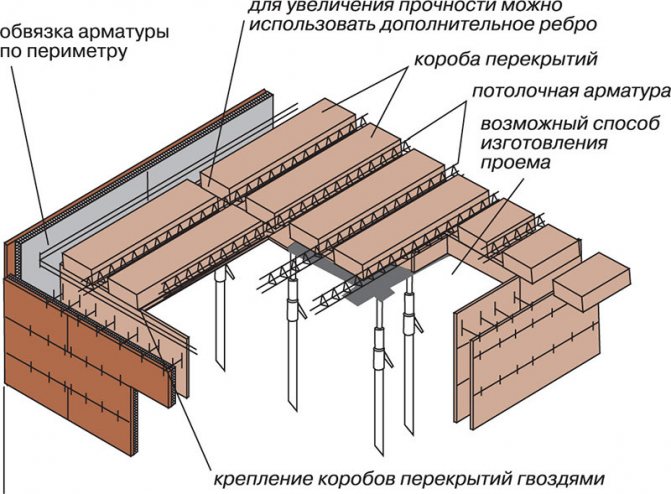

Ribbed overlap

There are two types of slab slabs: monolithic and prefabricated.

When installing slabs, they are laid on the load-bearing walls of the building, for greater reliability of the structure, erected with a thickness of at least 150 mm. Bearing walls should be 3 m apart. If it exceeds this value, then you will have to install a crossbeam, this will make your construction more expensive.

Prefabricated monolithic

When starting the construction of a private house, you must determine exactly which ceiling ceiling - slab or beam - is most suitable in your particular case.Remember that the final result is greatly influenced by the quality of the materials used and the observance of all technological requirements for the installation of floors. If you do everything right, you will end up with the expected result.

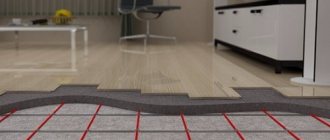

A few words about ceiling insulation

Mold at the joints of the ceiling and walls indicates that there is a heat leak in the house in this place.

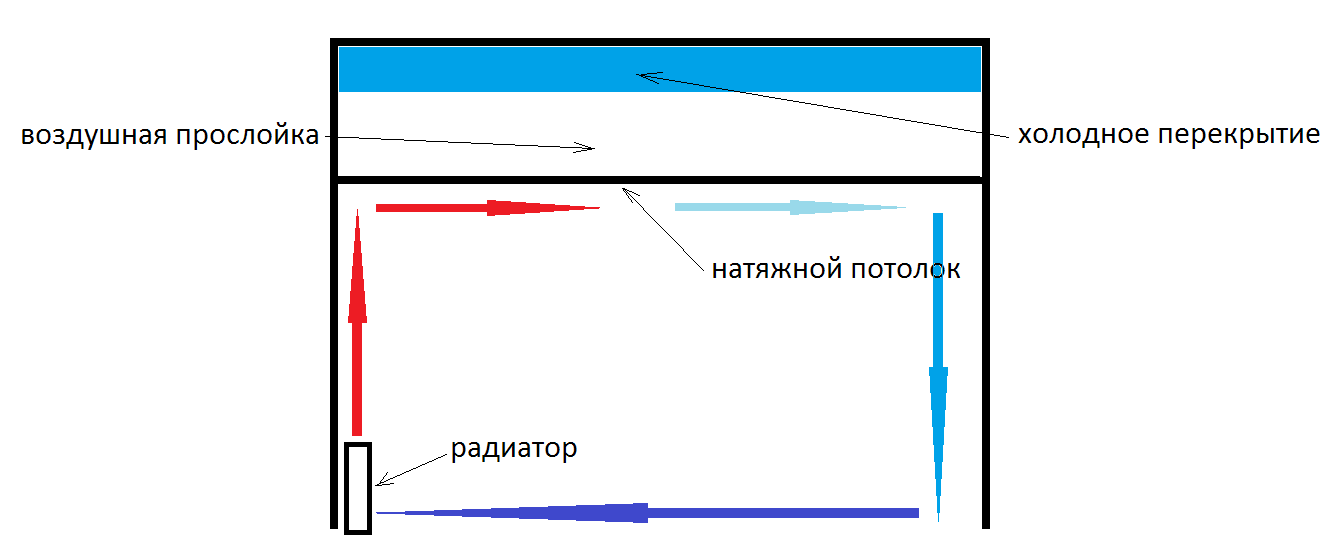

Why insulate ceilings? In the cold season, in the process of convection, warm air from the batteries rises upward. If the ceiling is cold, warm air settles on it, and dampness appears due to the temperature difference.

This is especially noticeable in the corners, where the joints of the ceiling and walls freeze. By the way, mold appears in the same place. High-quality insulation will solve the problem of dampness, and there will be no more mold.

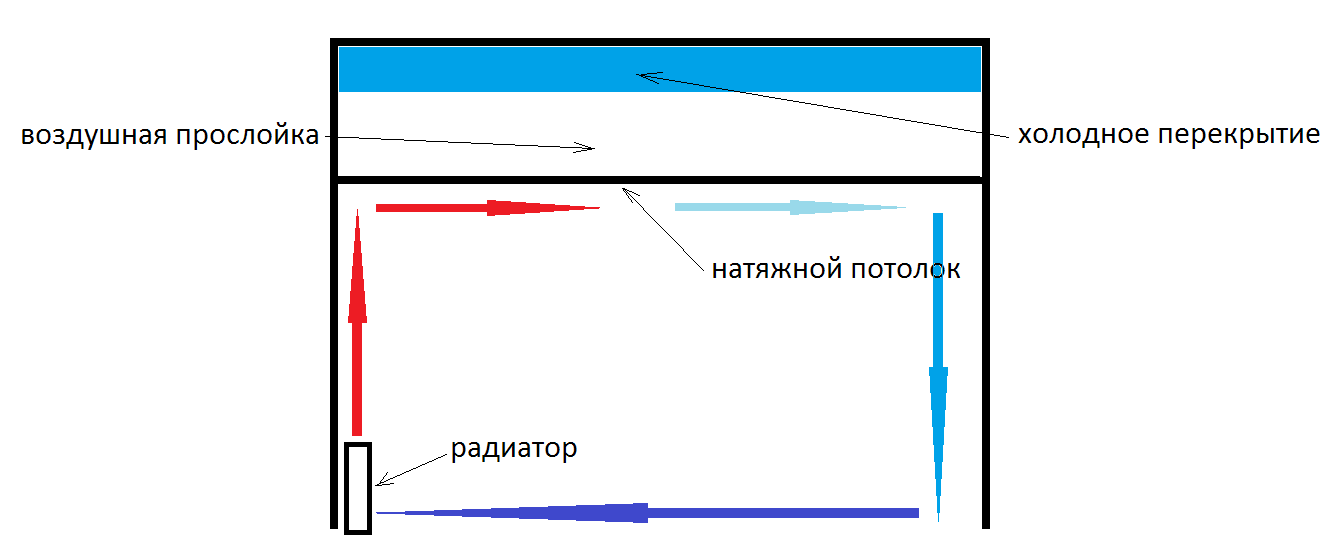

The easiest way to insulate the interior is to install a stretch ceiling, due to which a heat-insulating air gap appears

If the roof is cold, you can insulate the ceiling in a private house with your own hands in two ways:

In this photo, low-density mineral wool is laid between the beams of the hardwood floor under the cold roof.

- From inside the dwelling... Thermal insulation is attached to the floor from below, and decorative finishing is performed on top of the insulation;

- From the attic... Insulation is lined, laid out or sprayed over the floor.

Plaster does not fit on most heaters, so insulating the ceiling in a private house from the inside is not a good idea. In addition, a layer of thermal insulation will make the ceiling lower.

It is much easier to install insulation materials from the attic side. Indeed, in the attic, there are no requirements for the beauty of the floor.

The insulated suspended ceiling is good because it can be sewn up with different materials, from drywall to clapboard

An exception to the rule is the thermal insulation of ceilings in frame houses, where the ceiling from the side of the rooms is hemmed with plywood or oriented strand board (OSB). In frame houses, we insulate the ceiling with our own hands, laying insulation either from the attic or from the room.

How to make stretch ceilings in a wooden house

For stretch ceiling structures, a sheet of polyvinyl chloride or polymer fabric is used, which is fixed on a frame made of an aluminum or plastic profile.

This type of finish is suitable for newly built log houses, where floor shrinkage will occur for several years, and this circumstance makes plastering or painting impossible. The disadvantage of stretch ceilings is that they significantly lower the height of the premises.

Varieties of the ceiling

Before proceeding to the study of a step-by-step guide on how to make a ceiling in a bath with your own hands, it is useful to decide what specific type of floor is planned to be built.

There are several types of ceiling:

- hemming;

- grazing;

- panel.

Each type of ceiling has its own installation features. To make a choice, you need to familiarize yourself with all the nuances, as well as pay attention to the specifics of the purpose of each floor.

The false ceiling can be used in both small and spacious saunas. It is characterized by:

- increased strength;

- excellent thermal insulation;

- long service life.

When choosing a false ceiling, additional installation of floor beams is required. They are laid on the crown of a log house. Then wood is hemmed to the installed beams. The inner space is filled with insulation.

A plinth ceiling is ideal for constructing a ceiling without an attic. The advantages of this ceiling option are:

- no need to lay a layer of insulation;

- quick erection of the ceiling base;

- a budget option.

The panel version of the ceiling is most often rejected by those who decided to build the ceiling on their own. It involves the execution of more complex technical tasks. It is also difficult to do some of the work on your own, without asking for help from friends, relatives, who can act as an additional labor force.

Despite the complexity of installation, many persistently prefer just such a design. This is no coincidence, since such a ceiling is characterized by:

- versatility;

- increased strength;

- sufficient rigidity.