It is possible or impossible to repair a gas boiler without a specialist

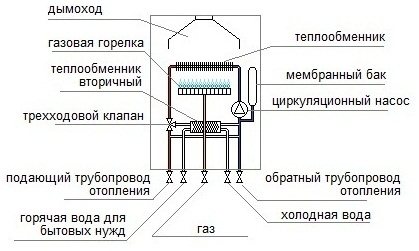

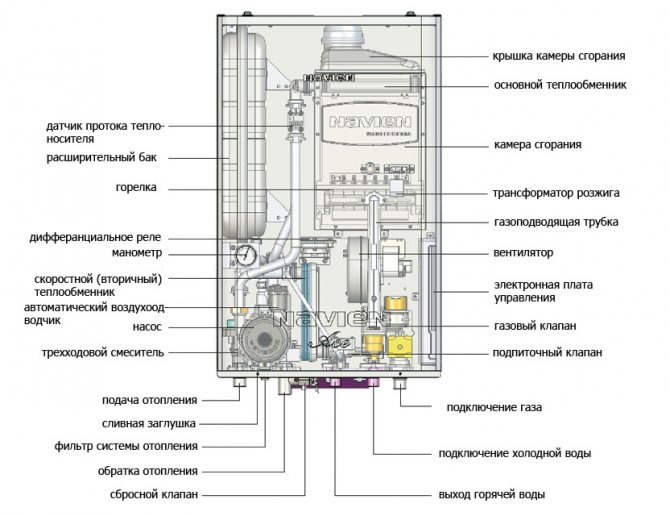

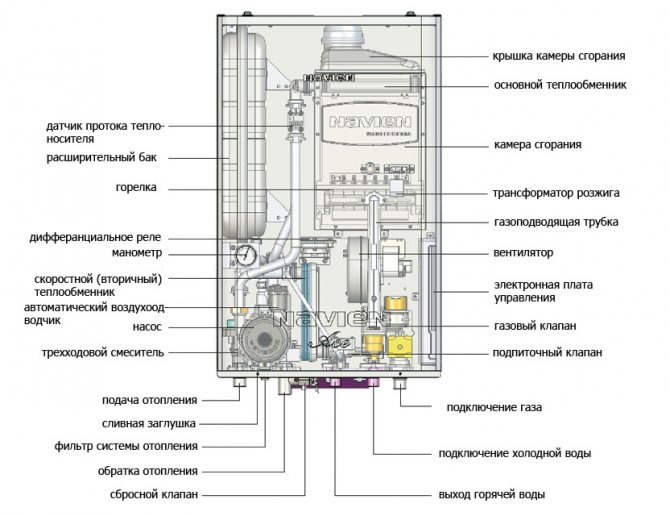

A typical gas boiler consists of many elements, which can basically be grouped into 3 groups:

- Burner.

- Blocks providing safety.

- A heat exchange unit equipped with several additional devices, which include a fan, a circulation pump and many others.

The structure of this mechanism can be simplified as follows.

If you detail the picture, you can find about 2 dozen different elements in the device.

The main danger during repairs is a possible gas leak. This can happen due to improper repair, dismantling or installation of equipment that is associated with the fuel supply.

Therefore, it is better to entrust the repair of these parts of the structure to a specialist. Also, do not troubleshoot the electronic equipment of gas boilers on your own. Automation is a specific device, therefore, without appropriate qualifications, it is almost impossible to correctly carry out restoration work and repair such equipment yourself.

What can be repaired by hand

All other elements can be repaired by yourself, for example:

- Flushing the heat exchanger performed manually (for this, the unit is dismantled, after which it must be correctly put in place). It is possible to carry out these works without dismantling - using pumps.

- Chimney cleaning will be needed in cases where there is a problem with traction (mechanical or chemical removal of blockages is performed).

- Fan repair pressurization by lubricating its bearings with technical oil.

In fact, it is possible to repair a gas boiler on your own only in those cases when it comes to mechanical damage or blockages that can be easily identified visually (or by smell).

The rest of the breakdowns are considered more serious, therefore they are eliminated with the help of a specialist, and not with your own hands.

What does the automatic equipment for gas heating boilers AOGV consist of?

A standard automatic system should have several basic elements.

Ignition elements. In modern systems, there is no burning torch. The pilot burner is ignited using a piezoelectric element that produces electrical energy as a result of mechanical pressure on the crystal. There are systems in which you need to open the gas supply valve with one hand, and press the piezo ignition button with the other. In the most modern boilers, one button is responsible for the operation of both processes. Further, the gas valve is controlled in one of two ways:

- Due to the voltage that occurs when the thermocouple is heated.

- By heating an additional thermal generator (more often used in imported boilers).

Automation of gas boilers AOGV most often works due to the energy of a thermocouple.

In both cases, the generated energy creates a voltage that acts on the gas valve coil. It remains open to supply gas as long as the gas burner is lit.

Thermoregulation system. These elements control the temperature of the water. They consist of a temperature sensor and a valve system that shut off the gas supply when the set temperature is reached. In the most modern models of boilers, a room thermostat has been added to the control circuit, which, depending on the temperature in the room, gives a signal and the need to close or open the gas supply valve.

Control elements for effective and safe removal of combustion products. This is a draft sensor that is installed in the chimney.Wires connect the draft sensor to the gas valve. If there is no optimal draft, a signal is sent to the valve, it closes and stops the gas supply.

Automation for gas heating boilers does not allow you to turn on the gas supply, if the performance indicators of the equipment go astray, the slightest breakdown or depressurization of pipes occurs.

Additional elements and capabilities of automation

In some models, the automatic equipment for gas boilers AOGV is equipped with a thermostat, which regulates the gas flow. The reason for a decrease in the intensity of work may be an increase in the temperature outside or a signal from a thermostat in one of the rooms about exceeding the maximum permissible temperature.

Models that are mounted in the "Smart Home" system assume the possibility of remote control of heating modes.

A modern, correctly installed and adjusted automatic system on heating equipment helps to reduce heating costs by 40%.

The main causes of a gas boiler breakdown

Before figuring out how to repair a gas boiler with your own hands, it is useful to understand exactly why malfunctions occur. Correct understanding of the reasons will help to avoid the problem in the future. Practice shows that 4 harmful factors are most often affected:

- Electricity drops - this problem is especially relevant in remote settlements and villages. Modern equipment is necessarily equipped with stabilizers, as well as energy storage devices, which ensure the operation of the device for a short time even after the source is turned off. Therefore, if there are no such devices, you should purchase them in advance.

- Poor quality water - this problem arises in cases where the equipment is used not only for heating, but also for obtaining hot water for domestic purposes (double-circuit gas boiler). The equipment is not damaged by the water itself, but by the presence of salts in it, which increase the hardness. If the concentration of these insoluble substances is high enough, it can lead to equipment wear in as little as 1-2 seasons. Therefore, it is necessary to take care of the installation of filters that purify water.

- Installation errors can lead to rather serious consequences, including fatal breakdowns, failure of all equipment. Therefore, this work can only be entrusted to qualified specialists.

- Finally, a role can also be played by frosty winters... Usually, during such a period, the neighbors turn on the equipment at full capacity, and in this mode it works for a long time. As a result, the pressure in the gas pipeline system drops significantly, and the boilers begin to work largely in vain. At this point, you can use equipment that runs on a different fuel (for example, diesel). It makes sense to purchase it if the region has long, harsh winters.

Is it worth repairing the boiler yourself?

A modern gas boiler is a complex and potentially hazardous system. The main danger of such units is the risk of gas explosion in the event of improper handling of the equipment or untimely elimination of various malfunctions.

Various kinds of automation are responsible for maintaining the operation of the gas boiler at an optimal level. An inexperienced user is often unable to understand its device. Therefore, it is better to immediately invite specialists to troubleshoot serious problems.

On your own, you can try to eliminate only visible damage and various contaminants that have led to the failure of the pipe, chimney and other parts of the boiler.

Common breakdowns table

The most common breakdowns of a gas boiler are described in the table.

| problem | possible reasons | what to do |

| small burner flame | air entering the gas line or clogged nozzles | call the master |

| the burner goes out quickly | malfunction of the ionization electrode | |

| the flame comes off, the nozzle makes an abnormal noise | the draft is too strong (the flue pipe is high) or the pressure in the system is not adjusted | reduce cravings |

| the boiler does not turn on | different | you can turn the plug to change the contacts, and turn it on again |

| malfunction of automation and electronic equipment | different: it is difficult to eliminate on your own | call the master |

| incorrect operation, voltage drop | power drops | put the stabilizer |

| scale clogging | hard water | clean and put on the filter |

| overheat | clogging of the heat exchanger with soot | clean the mechanism by hand |

A video overview of possible combustion problems and their causes can be seen here.

How to repair a boiler with your own hands: step by step instructions

After a specific breakdown has been accurately diagnosed, you can begin to eliminate it. Of course, in the event that there is confidence that this is a feasible task that does not require special skills and equipment.

Preparatory stage

- First of all, it is necessary to disconnect the device from the power supply, and also tightly shut off the gas valve. Even if the repair is not associated with elements directly in contact with fuel, this condition is mandatory.

- If it is difficult to estimate the time of restoration work, and they can theoretically take several hours, you should completely drain the water from the heating system or pour an antifreeze solution there (if it is not there). The fact is that during the repair, the air temperature in the room can drop to negative values, and the water will freeze.

- Safety precautions: along with shutting off the gas valve and de-energizing the system, it should be remembered that the working surface must cool down to an acceptable level before repairing. Otherwise, touching it may cause burns.

Cleaning the heat exchanger

If the boiler overheats, this may indicate 2 reasons:

- The automation that controls the operation of the device is faulty.

- The heat exchanger is clogged (soot deposits).

Automation is repaired only with the help of special equipment, which in most cases is not in the house. But it is quite possible to clean the heat exchanger yourself.

The sequence of actions is as follows:

- Turn off the boiler, let it cool down.

- Shut off the taps.

- Remove the front cover.

- The remaining water is discarded (open a hot water tap or a valve inside the mechanism to drain water from the heating system).

- Remove the heat exchanger.

- The heat exchanger is cleaned first mechanically, then - in a solution of vinegar and citric acid, taken in equal quantities (you can use a tablespoon per liter of water). Instead of a solution, you can also use special formulations purchased in the store.

- The heat exchanger is kept in such a mixture for 1-2 hours until it is completely cleaned.

- Then washed with running water and wiped dry.

- They put the heat exchanger back, close the lid, fasten all the parts.

Chimney cleaning

A decrease in draft and overheating of a gas boiler can certainly be associated with a clogged chimney. It is in this part of the system that the greatest amount of soot accumulates. However, the accumulation of dirt is quite rare, since the gas does not provide an abundant amount of waste.

Hermann boilers - Methods for eliminating errors and malfunctions

_________________________________________________________________________________________

Gas wall-mounted boiler Hermann Micra-2. The burner does not light up. How to determine the cause? There are no error codes on the panel or in the manual. If the unit is to be replaced due to its malfunction, then the heating system must be drained when replacing it? There can be many reasons for poor ignition of the burner: It is necessary to check all parameters according to the instructions.In particular - the water pressure (not the flow), the 3-way valve - reaches the microswitch and is there a click? If not, adjust, if the valve is faulty or the mikrik itself, replace. If you turn off the hot water supply - does the burner not light up either? If it lights up, then there may be a problem with the NTC DHW sensor. If none of the above helps to identify the source of the problem, then it is easier to invite a specialist and resolve the issue on the spot. When replacing the device, it is absolutely not necessary to drain the heating system if the design of the system provides for the isolation of the boiler from the system. There should simply be taps, closing which, you can dismantle the unit and the coolant will not flow out of the system. If those were not found, then you will have to merge. Recently, a problem was discovered on the Herman boiler. There was a sudden failure of the device with further interruption of work and error E02. How to fix? Error code E02: Boiler overheating detected. The temperature of the safety thermostat is more than 104 C. If there are no messages for ignition in real time, then the error will not be recorded. The gas burner is extinguished due to the increased temperature of the heating circuit, although the heat exchanger continues to heat up. For heating phase 92C, for DHW phase 96C. The boiler will be blocked by the automation system if, within 15 seconds, the temperature of the safety thermostat turns out to be more than 104 C. When the thermostat detects a temperature above 104 C in heating or anti-icing mode, the boiler automation will delay on average 30 seconds. If during this period of time the temperature of the thermostat sensor and the temperature sensor does not drop to one hundred degrees, the boiler automation will display an error. Blockage of the unit occurs when a signal is received to ignite the burner unit. If at the moment of ignition the protection thermostat has a temperature of more than 104 degrees, the boiler will go into standby mode for 10 seconds, and only after that it will show a malfunction. The temperature sensor for heating or the thermostat for overheating has worked, blocking the functions of the device. The protection thermostat will trip after the temperature rises above 104 C. Wait for the device to cool down and reset it using the reset key. Inoperability or incorrect operation of the emergency thermostat. We recommend that you change it. Lack of liquid circulation in the heating circuit. Check the pressure for the heating system. Its values in the cooled system are equal to 1.2 bar. There is air in the heating main. Remove excess air from the system through the automatic air vent. The circulation has disappeared. The shut-off valves must be fully open, which impede the necessary circulation of the liquid. Failure of the functions of the circulating water pump. The pump cannot reach the required speed. Diagnose the voltage and characteristics of the electrical network. If a voltage outage is detected in the electrical network, it is connected to the electrical network by means of a stabilizer transformer. Check the resistance in the stator winding of the pump electric motor for damage or short circuit. The pump is operating normally, but the head is poor. The impeller appears to be worn out. If damage is determined, the pump must be replaced. Rotation of the pump does not occur, although the inflow to it is intense. We are testing the pump, there may be a jam. Remove the plug, then turn the rotor shaft of the motor. There is no power supply to the circulation pump. The electronic board is broken. the boiler will need to be rebooted. If the problem persists, change the electronic board. Overheating of the combustion products thermostat. it is necessary to wait until the thermostat sensor has cooled down, then a reboot is performed. Hermann Habitat 2. A new heat exchanger was installed, and water from the heating enters the shower. Why is that? It seems to me that the boiler heat exchanger is leaking, or does not hold the make-up tap.You can still check this way. We remove the boiler, it shouldn't be hard, and check it out. Pour water into the tubes of the heat exchanger and see if water comes out of the DHW tube. If the boiler is many years old, anything could happen to our water. Alternatively, you can replace the check valve or install one if it has not been installed before. Explain to me exactly how to lower the pressure at the Herman boiler? And is it allowed to reduce the gas pressure? Does the unit have a regulator with which the pressure of the gas mixture is equalized or is it not recommended for them to make this correction? The regulator must adjust the pressure of the fuel entering the boiler. When it is extremely small, the burner will not start to ignite, when it is enlarged, the torch comes off the wick, and the burner will go out immediately after ignition. Further procedures for regulation. Heat the machine well. Open the entire chimney. Turn on the main burner to the maximum mark, at this moment the fire will turn blue-yellow. Turn off the gas cock to remove the yellow tint of the fire. Next, check the operation of the unit in all modes. Why, when the Herman boiler turns on and runs for about one minute, then the error E02 pops up. How can you fix it? Error E02 - Enabling safety sensors. Red light is on constantly - type of alarm: RESET. Reason: the smoke was removed incorrectly (even temporarily, in exceptional cases it can be triggered by a strong gust of wind). Press the RESET button to turn on the device. If the blockage is repeated: Check the operating condition of the chimney. On E models, check that the vent is not blocked. The vent must be of the same size as required by law and must be fully open. Some types of vents have a built-in mosquito net that can be clogged with dust or cobwebs. If the room where the appliance is installed has fireplaces, stoves, wall fans or cooker hoods equipped with an exhaust pipe to the outside, have a professional technician check that the ventilation hole is correct, otherwise the unit may malfunction. For SE models, check that the air intake and exhaust ducts are clean and in good working order. During installation, the instructions, slopes and dimensions given in the passport must be observed. Another reason: the unit has overheated and the safety thermostat has tripped. Wait 20-30 minutes for the boiler to cool down, press the RESET button. If the blocking persists, call the service. The red light on the Habitat 2 boiler is flashing, apparently a sensor error. How to identify and fix the error? Try simply flipping the plug in the outlet first. The device is sensitive to phasing. Disconnect all sensors from the board and leave power. Turn on the voltage for a couple of minutes, and then turn off and reconnect all sensors. If this does not help, then a new board is needed. There is a Habitat 23 boiler at home. Water has to be topped up several times a week (the pressure in the system drops, although there are no leaks). There is a suspicion that the three-way valve is not working properly. Why is the pressure decreasing? There are several reasons for the pressure drop in the heating system: There is a latent leak in the heating system. There are cases when a latent leak was detected a year after the commissioning of boiler equipment. The make-up valve is not completely closed. Despite the fact that a check valve is provided on the make-up tap in the boiler, the coolant is poured into the hot water supply system. There are “air pockets” in the heating system after the start-up. Periodically, air leaves them and the pressure drops. Then it's a matter of time. The pressure in the heating system can stabilize within 2-3 months. This is normal. In the future, replenishment once every six months is the norm. Heat exchanger is leaking.It is checked visually or by pressing. To do this, it is necessary to involve qualified specialists or act by replacing suspicious parts and assemblies. There was a pumping of the heating system, the next day we had a release of water from the boiler onto the kitchen floor, how to avoid flooding the apartment? The device has a 3 atm relief valve for the heating system. This is the maximum pressure of the heating circuit. The maximum pressure of the hot water supply circuit is 6 Atm. At the same time, there are no safety valves for the DHW circuit. All these parameters are specified in the technical specifications. When working in winter, the Herman boiler is constantly turned on and off after about a minute, and the piezo ignition is constantly triggered. Shouldn't it just turn off the gas and burn at low after reaching 80C? There may be several reasons: the device is not set to the minimum power; clogged primary heat exchanger; chimney problems. The Hermann Thesi gas boiler crashed with an E02 error. What about this error? Overheating of the boiler triggers the safety thermostat and blocks the start. The E02 error code can be cleared by the user by pressing the reset button. But first you need to let the device cool down for 30 minutes. During the operation, the circulation pump and the DHW sensor were changed. During the last week in heating mode, the burner ignites, heats up for about 5 seconds and turns off without causing an alarm. The cyclicity is uneven: it can turn on immediately, maybe after 30-40 seconds. Looked through block 537 ABC. There is no visible damage, no missing. Checked C9: (mica-ceramic 0.47X400 V) - normal (0.46 mF). It is doubtful that the burner almost immediately reaches the maximum mode - the flame modulation is not visible. A 3-minute switch-on delay is set (jumper JP2 removed). What do you advise: look further on the block or check the gas valve? Check the heating NTC sensor - whether it is working and whether the wires have come off. It often happens with these models that due to poor contact on the NTC sensor, spontaneous shutdowns begin and no error is displayed. The Herman boiler shows an E03 error, then it stops. If it starts up, it starts to work irregularly. Another time it will start and can work for half an hour, an hour, or no more than five minutes, but basically it does not want to start at all, resetting the parameters does not save much. How to fix this problem? Error E03: Insufficient traction. For the correct and safe operation of the gas boiler, it is necessary to provide traction for the removal of exhaust gases so that they do not enter the living quarters. This is monitored by the automation, and if any problems appear, the thrust sensor is triggered, and the device is blocked. Possible reasons for the lack of thrust: narrowed diameter of the outlet duct, inaccuracy during installation, pollution, ice on the walls. Limiting the diameter of the flue duct results in poor draft. The length of the flue pipe is exceeded. We advise you to carefully study the instructions for use of the boiler and comply with the relevant requirements Too long horizontal section of the smoke exhaust pipe can cause a lack of necessary draft. The thrust pressure switch is damaged - When a vacuum develops in the inlet tube, a faint click will be noticeable. There is no contact of the control board with the draft sensor, there is condensation, as well as incorrect connection of the tubes to the pneumatic relay. There is a problem with the fan - There is a blockage in the fan impeller. There is not enough lubricant on the fan shaft, which is why it has a low speed. Poor contact between electronic board and fan. How to turn on the pump on the Hermann Thesi boiler for permanent operation? It is necessary to turn off the external thermostat, if any, and regulate the temperature with the circuit temperature, then the pump will work constantly, but this is not an economic mode.For what reasons, the display constantly gives an error code E03, what should I do? Error E03 denotes the actuation of safety devices that are responsible for removing flue gases. Clean your chimney. They pumped water into the heating, the device drove it through the pipes and water came from below. What could be the problem? The pressure in the system may not be adjusted, therefore the safety valve is activated. Tell me why error E06 began to appear very often? How do I fix the problem? Error 06 - malfunction of the temperature sensor. Call the wizard to fix the problem. After a recent thunderstorm, when trying to ignite, the Micra 2 boiler gives an E35 error. This happens both when you try to heat the water, and when the unit is installed in the winter mode of heating the house. The input voltage comes from the stabilizer, and fluctuates around 216-217 volts. Can you help with solving the problem? Error E35 (inappropriate flame) can be corrected by yourself. A special device blocks the device if it detects a flame when it should not be. You need to press the reset button. Why on the Herman Habitat boiler do not have time to warm up the batteries and the temperature sensor is triggered? How do I fix the problem? Most likely you need to adjust the flow through the coolant batteries. This is done with a special hex wrench - at the bottom of the radiators, often on the left, there is a plug, turning which you will see a tap under the hexagon. It is regulated as follows: the first battery from the boiler is opened a little, the next a little more, the next even more, and so on. The latter is possible to the fullest. The point is that immediately after the device, the speed of the coolant is high and you can pass a little through the first battery - and so the radiator will heat up. But the next ones already require a larger volume of hot liquid, they are opened more strongly. Then all the battery will heat up, but you will have to pick it up empirically, nothing can be done, it's worth tinkering. And of course, it will not be superfluous to make sure that the temperature is set correctly and the sensor is working properly. Check if the pump is pumping water. Maybe it is faulty, and therefore the heat simply does not go to the batteries. Periodically, you need to bleed air from the radiators, it also prevents them from heating up normally. When heating the heating, the Herman boiler very often turns on and off, how to increase the interval? Install a room programmable thermostat, and the unit will operate more rarely and more economically. What kind of malfunction occurs if the display shows error code E39? What should be done in this case? Error code E39 means that water is supplied below 0 degrees, and the boiler does not turn on the burner, but turns on the circulation pump, forcing the water to circulate in the hydraulic system. This phase lasts 15 minutes. If, in the meantime, the temperatures of the sensors have increased by more than 1C, the unit will prepare for normal operation. Otherwise, the error will become permanent and it should be assumed that water freezes in one or more sections of the hydraulic circuit. There is a problem with hot water, the unit turns on and off, it does not write errors on the screen. What does all of this mean? Check the temperature sensor of the running water, replace if necessary. If everything is in order with the sensor, then the control board will be repaired. The boiler works, but the heating system does not heat up, and the return circuit heats up. At a set temperature of 65 degrees, it can turn off at 75 and turn on at 14 degrees. What could be the problem? It looks like an airy system. It is recommended to vent the air.

_________________________________________________________________________________________

_________________________________________________________________________________________

- How to troubleshoot and malfunctions on the Juncker boiler

- How to troubleshoot basic problems on boilers Buderus Logano G334

- Errors and malfunctions of Rinnai boilers

- Recommendations for the repair of boilers Buderus Logano G124 / 125

- Possible breakdowns during the operation of the Beretta gas water heater

- How to correctly adjust and repair the Electrolux gas column

- Tips for adjusting and repairing gas water heaters Gorenje

- Values of error codes for boilers Immergaz

- Problems in Junkers gas water heaters - Recommendations for repair and maintenance

- How to identify and eliminate malfunctions in the Ladogaz gas column

- Recommendations for the operation, repair and settings of the Mohr gas column

- We repair the Zota Carbon boiler - Types of faults and options for their elimination

- Repair of the Zota Master boiler - What can be malfunctions and actions to eliminate them

- Celtic boiler error codes decoding

- Repair of the Buderus Logano G221 boiler - Types of malfunctions and methods of their elimination

- Causes of irregularities in the operation of Buderus Logano S131 boilers and how to repair them

- Questions on troubleshooting storage water heaters

- How to troubleshoot the operation of storage boilers

- Electric water heater malfunctions and tips for their elimination

- Electric boiler malfunctions and repair recommendations

- Boiler error codes Hermann Habitat

- Tips for eliminating basic problems in storage water heaters

- Help in troubleshooting storage boilers operation

- Possible malfunctions and breakdowns during the operation of gas water heaters

- How to repair a gas water heater in the event of a malfunction

- Ways to eliminate malfunctions and breakdowns on gas water heaters

- Errors of gas boilers Proterm Cheetah

- Elimination of breakdowns and malfunctions during the operation of gas water heaters

- Causes of malfunctions and repair of gas water heaters

- Repair of gas water heaters in case of malfunctions in operation

- Hermann boilers - Methods for eliminating errors and malfunctions

- Elimination of errors and malfunctions during the operation of Arderia boilers

- Boiler error codes Ariston Egis

DIY repair of double-circuit boilers

Especially often it is necessary to repair double-circuit boilers, since they work in an enhanced mode, heating the premises and storing hot water for domestic needs.

NOTE

During the repair of gas boilers, the dismantling of structures is almost always necessary. It must be carried out carefully, remembering the connection sequence, in order to then correctly assemble all the elements of the system.

Repair of a wall-mounted gas boiler (cleaning and flushing the heat exchanger with special means) is clearly shown here:

Gas boiler malfunctions: prevention

Obviously, a preventive measure is always better than repairing an already existing breakdown. Therefore, it is important to know about those methods of preventing gas boilers from malfunctioning, which will help to avoid trouble and practically guarantee that the problem will not be caught by surprise.

First of all, you should refer to the instructions from the manufacturer, where the rules for operating the mechanism are detailed. As a rule, they are practically the same for different models.

Cleaning the heat exchanger

This is the most vulnerable point in the boiler, since a large amount of soot periodically accumulates in it. In most cases, the heat exchanger is made of stainless steel, less often of copper. It must be cleaned at least once every 3-4 years.

This is done with a wire brush. And if the mechanism is made of copper - a metal sponge, which is used for washing dishes. It is advisable to annually monitor its condition for contamination, especially after a cold winter, when fuel consumption increases significantly.

Pressure test

It is carried out periodically, several times a year. The optimum range for each model may vary slightly, but is usually between 1.0 and 2.0 bar (if the mechanism is cold). If the indicator drops regularly, it is preferable to immediately contact the service company.

Checking the water level

This is a very important requirement. After all, if the amount of moisture is less than the standard one, this can lead to a rather rapid wear of the mechanisms.The level is checked annually, especially often after repairs have been carried out, when moisture can evaporate faster than usual.

At the same time, every summer, before the start of the next heating season, all the liquid should be removed, and the parts and assemblies should be carefully examined for scale, dirt, damage and other malfunctions.

Proper care of the boiler

Includes the usual security measures:

- Do not direct water jets at the equipment, i.e. it can only be washed with a rag (by hand).

- It is not allowed to enter jets of air, steam, especially hot. Therefore, it is best not to place equipment in the kitchen.

- Also, do not place any objects on the surface of the unit.

- Shocks, mechanical influences, radiation, etc. are not allowed.

- If there is a long period of downtime (1 or several seasons), the equipment is prepared for it in advance. For example, you need to take care of frost protection, which is described in detail in the instructions for the gas boiler.

Thus, in some cases, there is indeed an opportunity to repair a gas boiler with your own hands.

But if the breakdowns are quite serious, or the malfunctions of gas boilers are not fully understood, there is only one way out - to invite a specialist from a service company.

Possible malfunctions and repair methods

To eliminate complex breakdowns or malfunctions of gas equipment, it is necessary to involve certified specialists or organizations. In some cases, it is quite possible to carry out minor repairs to a gas boiler with your own hands.

gas smell

Most often, gas begins to smell when it seeps out of the leaks in the thread of the inlet pipe. If a characteristic odor is detected, immediately turn off the heater and ventilate the room. The following materials and tools are required to repair:

- a thick solution of soap in water,

- gas or adjustable wrench,

- thread sealant - plumbing thread or FUM tape.

You can fix the problem in this way:

- lubricate all connections with a solution, soap bubbles will appear and burst in the place of gas seepage,

- turn off the gas supply,

- unscrew the eyeliner,

- wind the sealant on the thread, carefully tighten the connection until it stops, but do not overtighten,

- open the gas supply,

- re-lubricate the connection with soapy water, make sure there are no bubbles.

If they continue to appear, immediately shut off the flow and contact the gas workers.

the fan does not work

If the usual tonality of the fan's operation changes, the appearance of extraneous sounds or in the complete absence of such sounds, it is safe to assume that the fan is out of order.

To fix the problem, you will need:

- crosshead screwdriver,

- replacement bearing,

- rags,

- CIATIM type grease.

Repairs are carried out in the following sequence:

- disconnect the device from the mains, disconnect the gas supply,

- remove the fan,

- remove dirt from the blades with a rag,

- if parts of the fan, such as the coil or contact groups, are darkened or melted, the fan will have to be replaced,

- remove the fan casing, inspect the bearing.

If it is out of order, replace it with a new one, not forgetting to lubricate it.

Another reason for fan malfunctions can be the instability of the power supply parameters. In this case, you should purchase a voltage stabilizer of appropriate power and connect the boiler through it.

If the interruptions in the operation of the fan are caused by a malfunction of the control system, it is necessary to involve professionals to repair the gas boiler board.

high temperatures

Excessive temperature is most often caused by contamination of heat exchangers and a decrease in their ability to remove heat energy from the furnace.

To correct the situation, you will need:

- hydrochloric acid solution

- hard wire brush,

- gas or open-end wrench,

- thread sealant.

The heat exchanger is cleaned in the following sequence:

- turn off the gas and electricity supply to the unit,

- close the valves at the connection to the heating system pipelines

- carefully unscrew the heat exchanger with a wrench,

- remove carbon deposits and other contamination with a wire brush,

- gradually pour hydrochloric acid into the radiator through the nozzle, the appearance of foam indicates a strong contamination of the pipes with scale,

- let the acid drain, repeat the operation,

- flush the heat exchanger with plenty of water.

Now you can mount it back, not forgetting to wrap the threaded connections with a seal.

When working with an acid solution, care must be taken and be sure to use personal protective equipment: acid-resistant gloves and goggles, or a transparent face shield.

If a leakage of coolant from the tubes is detected, to repair the heat exchanger of a gas boiler, you must contact a workshop.

sensor malfunction

A common fault is erroneous operation of the burner flame sensor. A characteristic symptom of such a malfunction is the attenuation of the torch a few seconds after ignition. On devices with the self-diagnosis option, the corresponding error code is shown on the display.

To fix the problem, shut off the gas and electricity supply. This is followed by a thin skin of the electrodes contacts, without removing the sensor from the boiler. If cleaning does not work, the part will have to be replaced.

The draft sensor should be removed from the device, rinsed with an alcohol solution and blown out with compressed air to dry completely. If this does not help, you should contact the professionals.

settings failure

Sometimes a malfunction of the control system can be tried to be corrected by resetting the settings to the factory values. For the combination and duration of pressing the control buttons for this operation, refer to the user manual. If after the reset the unit does not work, you should call specialists.

chimney clogged

Chimney clogging is found in floor-standing gas boilers with an open combustion chamber. The quality of traction is checked as follows:

- turn off the gas supply,

- open revision,

- in a metal dish, bring a piece of paper to the revision and set it on fire,

- if the leaf is not sucked into the chimney, and the smoke went into the room, the draft is insufficient and the chimney is clogged.

It is better to call a professional chimney sweep to clean the chimney.