Seeing that water is flowing from a gas boiler, do not postpone the solution to this problem on the back burner. After all, you do not want to change the entire boiler because of a small crack in the heat exchanger, do you? Let's say right away that coolant leaks occur for other reasons and in other places. How to detect and eliminate them is the topic of our article.

We will tell you how you can quickly identify a leak. We will show you which structural components are most susceptible to loss of tightness. Our recommendations will help you quickly identify the cause in order to eliminate it without waiting for irreparable breakdowns.

Places of water leakage

Leaks can occur along the entire water path. If a double-circuit gas boiler is flowing, the problem may be in the following nodes:

- heat exchanger;

- pipes;

- expansion tank;

- places of detachable connections.

The level of complexity of the upcoming repair largely depends on the location of the water leak.

The easiest way is to eliminate leaks at the points of detachable connections. It is more difficult to repair a leaking pipeline inside the equipment. The most time consuming process is the repair or replacement of the heat exchanger.

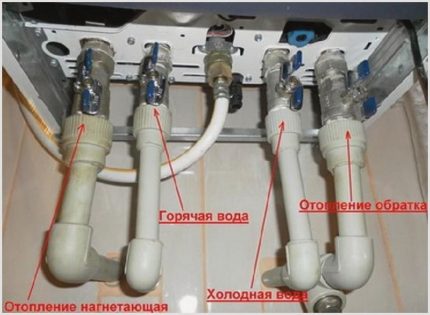

The double-circuit boiler is equipped with connections for connecting 4-pipes through which water is transported. In case of insufficient sealing of their joints, a leak of coolant, cold or hot water occurs

Repair leaks as soon as possible after they occur. Loss of heating medium can lead to automatic shutdown of the boiler.

An attempt to compensate for the loss of the coolant by periodically adding a new portion is fraught with accelerated wear of the boiler. The water is saturated with oxygen, which accelerates the corrosion of metal components, which shortens the life of the heating equipment.

How can you tell if a boiler is leaking?

Leaking heating medium reduces the hydraulic pressure in the heating system. Let's say right away that pressure can also change for other reasons, for example, due to a change in the density of water. But if the arrow of the pressure gauge stubbornly falls down or the display shows a notification about the lack of water in the system, you must definitely check for leaks.

Inspection of problem areas is carried out: first of all, detachable connections, including taps. But it is not always possible to determine the place of the leak visually, because the coolant will not necessarily flow in a continuous stream, flooding the floor. More often than not, it just drips. Drops evaporate on hot surfaces.

Therefore, you need to pay attention not only to damp places, but also to traces of drips, rust spots. It is better to look for leaks with a flashlight; inspect hard-to-reach areas with a mirror. Place wipes under the possible leaks. Their wetting will serve as confirmation that there is a coolant leak here.

A mandatory element of the heating system is a pressure gauge that measures hydraulic pressure, a pressure drop may indicate a coolant leak

If only a drop in pressure indicates a leak, it may not be in the boiler, but in other elements of the heating system, including radiators, which also need to be checked.

It can be done as follows: water is drained from the circuit and air is pumped in with the help of a compressor. It will come out of the leak with a characteristic noise. If pipes are laid under tiles or in concrete floors, you will need to use a phonendoscope to hear the sound of the air coming out. Also in this case, leak detection can be performed using a thermal imager.

What to do if a gas boiler drips

If, in spite of prevention and other measures, a leak still occurs, the first step is to make sure that the tightness of the boiler is broken, and not the pipes in the immediate vicinity. Remember that boiler repair in most cases requires the use of welding equipment and a special permit, therefore we strongly do not recommend that you carry out the work yourself.

The second thing to do is drain the water from the system. A pipe containing water cannot be welded. After completing these steps, you can call the emergency team. Who should I call? Of course, in!

What to do with condensation?

A puddle of water under a boiler is not necessarily a sign of a leak. Perhaps this is condensation, that is, water formed during the condensation of steam.

When the boiler is started, air containing moisture enters its combustion chamber. When a gas-air mixture is burned, this moisture turns into hot steam much faster than the heat carrier heats up. The vapors come into contact with the still cold surface of the heat exchanger and settle on it in the form of condensate.

When condensation occurs, the vapor settles on cold surfaces as water droplets containing a small percentage of acids that corrode metal surfaces

After heating the coolant to 60-70 degrees, the condensate evaporates. To speed up this process, when starting the boiler, you can set the adjustment knob to the appropriate division, and then, if necessary, reduce the heating to 40-50 degrees.

The formation of condensation when the boiler is operating for a long time with a coolant temperature above 60 degrees may indicate an improper organization of the heating system. It is worth checking again whether mistakes were made in the design and installation of the piping.

The problem of condensation cannot be underestimated, since prolonged exposure to an acidic environment on metal surfaces leads to their corrosion. Wet surfaces attract soot, which leads to a deterioration in thermal conductivity and a decrease in boiler efficiency.

Condensation also settles on the inner surfaces of non-insulated chimneys, which leads to accelerated pollution and wear. Chimney insulation helps to solve the problem.

The heating boiler is leaking. What to do?

Setting up a heating system for a private home requires a lot of effort and cash. You need to worry about purchasing good equipment for heating, pipes, heating appliances. New, not so long ago equipped systems, under the conditions of correct installation work, rarely interrupt. But if the heating system operates the house for a very long time, breakdowns may appear.

One of the most stressful issues is a leak in the heating system. It can appear due to various reasons. The problematic place can be located anywhere. The heating boiler itself, the heating device or the pipeline can leak. If you do not pay your own attention to this problem in a timely manner and do not do something, there is a risk of coming into contact with unpleasant results.

Violation of the mechanism of gas water heating

Heating equipment has its own warranty period, during which the devices must work without failures. But boilers are used for a much longer time than envisaged, thanks to this it is quite reasonable that problems may appear in their operation. You can learn about them by very characteristic features. So, for example, the pressure drop in the heating system is due to the fact that the heating boiler is flowing. What to do in this case? Replace the broken equipment with a new boiler, or try to get rid of the problem with other options.

Why does the gas boiler flow

If you suspect that a leak has appeared in the heating system or in the room heating device itself, the first step is to establish the reason why it could appear. There are not so many of them.

For the production of heating boilers, cast iron or steel is used, and these metals, as everyone knows, are prone to corrosion. Taking into account the fact that water flows regularly in the boiler, weak points can be damaged by corrosion.

Corrosion of heating systems, as a consequence of leakage

You need to pay attention! In the process of manufacturing heating boilers, anticorrosive compounds are not used for surface coating, but in the manufacture of electric water heaters they are used. But, as practice says, radiators usually last a very long time, and hot water heaters break when their service life ends.

The resistance of radiators to corrosion can be explained by the fact that their body has thick walls, specifically 1.5 mm. The thickness of the walls of the firebox is even larger - 2 mm. That is why heating boilers are able to correctly perform their own work throughout the entire period of operation, and if malfunctions do occur, for example, a heating boiler leaks, what to do is easy to decide. Either purchase a new device or clean up the leak, if it is realistic and makes sense.

"Dead water"

Most owners may not give significance to this moment, but it also affects the working capacity of the heating system. Perfectly, the system should circulate "dead water", That is, one where there are no additional compounds and no oxygen. Microorganisms cannot breed in it, naturally, and the effect on the inner walls of the heating system components should be small. This water does not help the appearance of corrosion, rust or other problems.

Sometimes the injection of the heat carrier is required. This should be done very infrequently. The water that enters the boiler from the tap is saturated with oxygen and other substances, due to this it affects the metal, sediment falls from it and scale appears. It is believed that it is possible to pump the heat carrier once a year at the beginning of the heating season. However, if there is a way to avoid this, you should take advantage of it.

Poor welding quality and boiler leakage

The weakest points of the boiler are the welded seams. Poor quality of their implementation can become the reason that the heating boiler is leaking. What to do in this situation? Purchase new heating equipment. If the seams are created efficiently and professionally, there will be no difficulties with them. However, if any flaws are found in the seam, they may not even affect the operation of the boiler immediately, but after a couple of years, when the warranty period for the heating equipment has already expired. Even if the problem is that the device with a factory defect was approved for sale, after a while it will not be easy to bring it.

You need to pay attention! In factories for the manufacture of heating equipment abroad, automation is mainly used for welding seams. But we still use X-rays for stitching seams with might and main, thanks to this, technologists must rather carefully monitor the quality of the seam, if, of course, the owners do not want the name of the company to suffer.

Another reason why the heating boiler leaked is considered to be burnout of the furnace. Steel and cast iron have the property of burning out if they are under the influence of an open flame for a long time. If the boiler is in operation under normal conditions, burnout occurs very infrequently. The following factors can provoke problems:

Gas boiler burned out and flows

- work in the highest heating mode for a long time;

- the use of a boiler with a low power parameter for heating an insufficiently insulated or very large room;

- high flame;

- incorrectly adjusted burner power;

- poorly made burner.

To prevent the formation of leaks in the heating boiler, when purchasing equipment for heating, preference should be given to models from leading manufacturers. You should also regularly monitor the operation of the boiler, avoid overloading, as this may turn out that you will need to purchase a new boiler.

Excess pressure

The main reasons for the formation of leaks in the boiler are the excess of the possible pressure. And the thing is that the equipment for heating, no matter how powerful it is, is designed for a certain pressure. When the heat carrier overheats, it expands, due to which the boiler expands and a leak occurs.

Pressure drop in the water supply system and heat supply leakage

You need to pay attention! Excess pressure in the heating system can be dangerous for the inhabitants of the house. The expansion of the heat carrier can turn not only with a leak, but even with an explosion of a heating boiler.

You can prevent a situation when a gas boiler is flowing. What can be done for this? First of all, it is necessary to monitor the state of the valve and the device to determine the pressure value, to remove breakdowns in time. And you should constantly (at least once a year) check the serviceability of the diaphragm valve.

If you find that the boiler or heating pipes are wet, but the pressure remains normal, the fastest thing is not a leak, but the appearance of condensation. When the boiler has warmed up enough, the condensate will evaporate.

If you are faced with the flow of Dani's cauldron, what to do is a key worrying question. With a certain period, even the highest quality models can break down in operation. You should not undertake the removal of leaks on your own, especially if you do not have the necessary experience and knowledge. It is better to entrust this matter to specialists in order to avoid trouble. If the problem cannot be corrected, it will be necessary to purchase new equipment for heating.

Does it flow through threaded connections?

The boiler heating circuit is closed. The heated coolant flows from the heat exchanger tube to the supply line and then to the radiators. The coolant returns through the return pipeline, entering the heat exchanger again and then continuing to circulate in a circle.

The heating circuit pipes are connected to the supply and return pipelines by means of threaded (detachable) connections using connecting parts - squeegees with union nuts, or otherwise American.

With the help of American women with union nuts, expansion tanks, shut-off valves and other elements of the heating system are connected to the highways

Threaded connections are sealed with elastic heat-resistant seals in the form of rings. If they are worn out or if installed incorrectly, water leakage occurs. Poorly tightened nuts lead to the same consequences.

If you see water dripping at the threaded connection, you should first try to tighten the nut. Excessive zeal is useless here, since if the nut is tightened too tightly, it can break. If, after tightening the nut, water continues to leak, the seal must be replaced.

Turn off the gas and water supply in advance, drain the water from the heat exchanger. Unscrew the union nut, replace the seals and reinstall the nut.

Manufacturers of heating boilers seal detachable joints with gaskets made of rubber, silicone, paronite or other elastic materials. They are easy to use, durable and always commercially available. Often come complete with clamps. When choosing gaskets, take into account the size of the thread.

You can also use sanitary flax as a sealant. Regardless of the presence of leaks, the seals are changed every time the water lines are disassembled.

The heating boiler is leaking, what should I do?

Heating boilers are often used to heat a private house. It happens that in this device the pressure decreases and a leak occurs. Should I call the foreman at home when the heating boiler is leaking? What to do with the remaining fluid in the system? Drain it completely, or remove the leak with your own hands without stopping the system? To answer these questions, you need to find out the reasons for the dangerous situation.

Causes of boiler leakage

The pressure drop in the boiler is caused by a leak, which occurs both in the closed circuit of the heating system and in the heating apparatus itself. This issue can occur due to the following reason:

- Hidden leaks. They can occur in closed wiring and in the internal pipes of the boiler. They occur due to the reason: corrosion, poor-quality installation process of pipes, weakening of the connection or penetration of the heating main during repair work. Basically, most hidden leaks occur at pipe joints.

- Violation of the integrity of the membrane tissue in the heating boiler. Quite a rare reason, but at the same time delivering a lot of worries.

- Crack or fistula in the boiler heat exchanger. Occurs due to long-term use of the heating device or when its warning is fulfilled.

- An incompletely closed valve for dumping the liquid of the heat carrier into the drainage system.

Removing the leak with your own hands

Before sealing a leak in a boiler or in a heating pipe system, it is worth preparing a certain tool. It can be an inverter device or a thermal imager. To eliminate the leak, use the following guidelines:

- Latent leakage is best "illuminated" with a thermal imager. Such a diagnosis will make it possible to very accurately determine the place of breakdown and prevent small fistulas that can become difficult. Removal of the problem area is carried out by replacing the emergency section of the heating main or by tightening the docking element.

- If the integrity of the membrane tissue in the expansion tank is broken, repairs are not performed. In this case, you need to purchase a new product in the store.

- A crack in a heat exchanger is one of the most difficult problems to diagnose. If you have experience in welding, you can try to weld a fistula on your own. However, it is better to seek the help of a professional master or hand over the heating equipment to a warranty center.

- A tap not closed to the end is the most innocuous reason, which is sometimes forgotten to check. Eliminated by a complete audit of all locking valves. They are stretched and placed on the desired value.

Of course, you can remove the boiler leak without welding. In this case, you need to act depending on the location of the breakdown. The first thing to do is turn off the entire system and let the heat carrier cool down. After that, it is necessary to drain all the liquid from the system. If a leak is detected in an open section of the heating main, a plumbing clamp with a rubber gasket is applied. The leak on the heat exchanger can be closed with liquid welding.

Expansion tank problem

The volume of water in the heating circuit varies depending on the heating level. As the temperature rises, the volume of water increases, which entails a change in the hydraulic pressure inside the closed heating system.

At this moment, the elements of the heating circuit would undergo an increased load, fraught with their breakdown. But this does not happen, since the design of the boiler is complemented by a safety system, which includes an expansion tank that receives the resulting excess water.

The device and principle of operation of the expansion tank, divided by a membrane into two chambers, the location of the air valve and the branch pipe for connection to the water main

For installation on heating pipelines, open and closed expansion tanks are used. Open tanks are installed outside boiler rooms, for example, in attics, and are supplied with a whole system of pipes for connecting expansion, circulation, signal, overflow pipes.

All models of wall-mounted, both double- and single-circuit boilers are equipped with built-in expansion vessels. They are of a closed type, have only one branch pipe and two internal cavities, separated by a membrane. To ensure the standard pressure in the expansion tank, there is air or an inert gas, for example, argon, in its upper cavity, and there is an air valve with a nipple.

Excess coolant flows through the pipe into the lower cavity. The membrane bends, the air is compressed in the upper cavity, and the coolant takes up part of the internal space of the expansion tank.

The excess coolant generated during heating is discharged by the safety valve of the boiler itself or the heating system. If necessary, the liquid is replenished through the boiler make-up valve.

In open and closed expansion tanks, leaks occur at the threaded joints of the pipes with pipes. To eliminate them, tighten the union nuts or replace the gaskets, as mentioned above.

The metal bodies of the expansion vessels are subject to corrosion due to the presence of oxygen bubbles in the water mass. Corrosion leads to the formation of fistulas (holes), which become the place of leakage of the coolant.

The more often you have to pump a new portion of water into the system, the higher the risk of damage to the expansion tank housing and other metal components. If there are fistulas, the tank is changed to a new one.

What is the danger of condensate in the chimney?

You need to take action immediately if condensate flows from the chimney, we figured out why this happens, but you should also pay attention to the possible consequences. Moisture itself is very destructive. If we talk about brick passages, then the condensate easily penetrates into microcracks and crevices. With temperature drops, it expands and is able to destroy brick. If the cause is not eliminated in time, the probability of the need for major repairs is high. In addition, the condensate flowing down can destroy the stove or fireplace.

Owners of stainless steel pipes shouldn't relax either. Since the products of combustion contain acidic compounds, condensate is corrosive and can destroy even corrosion-resistant metal.

Also, moisture in the chimney leads to a deterioration in draft. Because of this, combustion products are not completely removed and partially enter the room. Such a phenomenon can cause carbon monoxide poisoning, so you should not ignore the smell of smoke in the room, as well as water flowing down the pipes.

Take action if water flows from the chimney, why you should not ignore the problem, we figured it out. A simple and effective solution can be the use of FuranFlex technology, but if the system has an incorrect design, then you will have to resort to more radical measures.

Similar articles:

You have questions? We can call you absolutely free!

We will contact you and answer any questions you may have!

Safety valve leaks

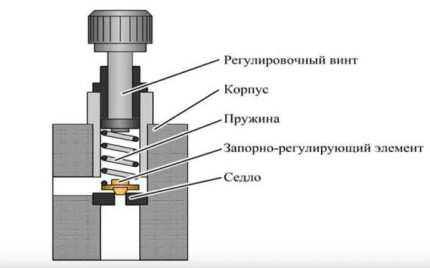

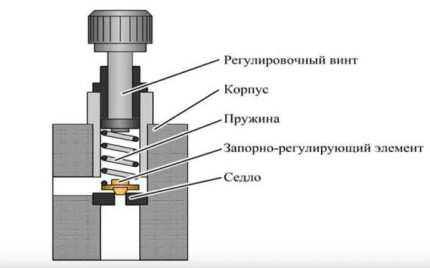

An important element of the safety system is a safety valve, which is necessary to "back up" a closed expansion tank. In boilers for individual heating systems, spring-loaded safety valves are usually installed.

Spring Type Valve Diagram showing major functional parts including down spring, poppet, seat

There is a metal spring in the body of such a valve, which presses on the stem, and this, in turn, holds the support plate in a position when it is tightly pressed against the seat.

If, when the pressure in the heating system rises, the expansion tank for one reason or another does not cope with its functions, the coolant increases the pressure on the plate. The spring at this moment is compressed and lifts the plate over the seat. Through the resulting hole, the excess coolant rushes into the drain pipe and further into the sewer.

If the expansion tank is selected incorrectly and its volume is insufficient to accommodate all the incoming water, the membrane may rupture and water will fill the entire upper cavity. With a further increase in pressure, the safety valve is triggered, through which the formed excess coolant is removed.

The safety valve is also triggered if the diaphragm is torn due to wear, when air leaks through a faulty nipple, or if the control automation malfunctions

If the connection of the valve branch pipe to the drain pipe is not tight enough, the coolant will not be in the sewer, but on the floor. To prevent this from happening, during a technical inspection, they pay attention to this area and, in the presence of the slightest leaks, they are sealed.

The safety valve, installed outside the heating boiler, has a similar design and can also leak, requiring urgent repair

Be sure to determine the cause of the valve operation. If necessary, a new expansion tank is installed taking into account the volume of the coolant in the system, a worn membrane, a faulty nipple or a tank assembly are changed, and problems with settings and control are solved.

An emergency situation for a heating boiler is standard for the safety valve itself, because it is needed precisely in order to reduce the damage from the consequences of an accident. But the valve can fail itself, causing the coolant to leak.

Most often, a breakdown is associated with a spring, which is constantly under stress and eventually loses its elasticity, which leads to leaks even during normal operation of the system. The defective valve is replaced with a new one.

When choosing a valve, its technical parameters are taken into account:

- nominal diameter of the nozzle bore (DN);

- size of the threaded connection;

- response pressure.

Requirements for safety valves for heating systems are regulated by GOST 12.2.085-2002.

The traditional material for sealing threaded connections is sanitary flax (tow); to increase the reliability and durability of sealing, flax is impregnated with a special compound

But what if the gas boiler is leaking due to the breakage of a recently installed valve? This happens when a grain of debris, such as rust from an expansion tank, gets between the plate and the saddle. In this case, the valve is removed, rinsed under running water and installed in place.

The valve is installed so that the spring is vertical. An arrow is shown on the body indicating the direction of flow of the coolant. Heat-resistant elastic gaskets or sanitary flax are used to seal threaded connections.

Steps to eliminate leakage with liquid sealant

The procedure for using liquid sealants to repair a home heating system can seem daunting. In some cases, clots of sealing liquid cause partial blockages and impede the movement of the coolant. Therefore, in order not to harm the heating equipment due to your inexperience, it is better to invite a specialist. In any case, you need to study the instructions for using a specific type of sealant for heating batteries and strictly follow it.

Once you decide to use a liquid sealant to fix a problem in your heating system, you need to make sure that:

- the reason for the drop in pressure is precisely the leakage of the coolant, and is not associated with a malfunction of the expansion tank;

- the selected type of sealant for heating systems corresponds to the type of heat carrier in this system;

- the sealant is suitable for the given heating boiler.

Damage to the heat exchanger and pipes

If the heat exchanger of a gas boiler is leaking, the wall may have burnt out, a crack or fistula may have formed. According to the material of manufacture, heat exchangers are divided into copper, steel, cast iron.

Metal cracks are formed by thermal stress and hydraulic pressure. Corrosion processes lead to the formation of fistulas. Repair is carried out by soldering.

The main stages of the process:

- dismantling the heat exchanger;

- cleaning and degreasing the area around the leak;

- soldering using flux and solder;

- test;

- installation.

In the event of a leak in an easily accessible place, complete dismantling of the heat exchanger for repair is not necessary. It is enough to remove the casing, shut off the gas and water, turn off the electrical wires, drain the rest of the water.

For soldering, a solder is selected that corresponds to the material of manufacture, for example, copper-phosphorus solder containing silver is suitable for copper heat exchangers, the temperature regime must be observed at the soldering point

The soldering point is cleaned and degreased with a solvent. Soldering is carried out using a soldering iron or a gas torch. The heat exchanger is installed in place and communications are connected to it.

The tests are carried out by pressing. The circuit is filled with water, the pressure is increased to the test value and checked with two pressure gauges for at least 5 minutes. If no pressure drop is recorded, no leaks are noticed during visual inspection, the repair can be considered complete.

In case of severe damage, the repair of the heat exchanger is impractical. They just change it to a new one. It is also impossible to solder many Chinese-made heat exchangers, since they are made of thin sheet alloys that cannot withstand soldering.

how and what is the best way to repair a crack in a wood-fired boiler?

Little technical difficulties. In the near future we will be online and the site will be a little better.

I have 3 types of home heating: wood, gas, electric. I use gas and electric. Wood-burning is included in the same system, is regularly under water, but I have not used it for seven years. A month ago, he ran - gave a crack somewhere along the seam. Than I just did not close it up: cold welding, electric welding - it's useless, it still leaks. It was possible with argon, but a master with equipment is needed - it is both expensive and expensive for a small crack. Tell me how and what is the best way to close up the crack in everyday life, and most importantly quickly.

Yuri the Macedonian pupil

- Activity: 161

- Reputation: 8

- Gender: Male

Yuri the Macedonian pupil