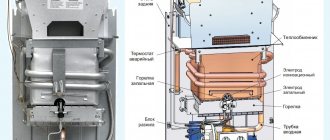

Repair of a gas water heater, in terms of its complexity and the number of possible technical problems, cannot be compared with any other home appliances. More complex and saturated with possible technical nuances can only be the repair of gas boilers at home. If you can still try to repair the water heating device with your own hands, then it is best to entrust the maintenance and repair work of the heating boiler, regardless of the number of built-in automation, the presence of a second circuit and the manufacturer, to a certified specialist.

What can be repaired in a gas water heater with your own hands

Of course, the gas water heater does not always wear out or break down so thoroughly and irrevocably that you cannot do without the help of a specialist. According to the same locksmiths of the gas maintenance service, in 70% of cases, the repair of gas water heaters is reduced to routine maintenance and the elimination of minor defects, usually associated with low quality parts or improper adjustment.

The list of works available for repairing gas water heaters at home can include the following activities:

- Minor repairs and repackaging of pipe couplings and nuts;

- Replacing the elastic membrane in the water-gas column regulator;

- Cleaning and adjusting the operation of the traction sensor;

- Cleaning and flushing the heat exchanger;

- Ignition board repair.

An operation such as repair and soldering of heat exchangers can be distinguished into a separate category.

It is clear that there is a certain category of expensive water heaters saturated with automation and electronics, which simply does not make sense to even try to be repaired at home. For example, repairing Electrolux or Vaillant gas water heaters will be cheaper at a service center due to the high cost of spare parts. The exception is especially critical components, such as a three-way valve or an ignition board, it is better to buy them from an authorized dealer, even if the price is higher. This is the only chance to carry out repairs and not kill an expensive Italian or German column with a substandard spare part.

Conclusions and useful video on the topic

This video shows how to properly clean the ignition tube:

In order to understand the complete step-by-step disassembly, just watch this video:

B osch gas water heaters are widely used to solve an important domestic problem - the lack of hot water. In order for these devices to operate smoothly for longer, they need to be serviced. And malfunctions arising during operation can be eliminated independently, it is enough to know the correct algorithm of actions.

Do you want to tell about your own experience in diagnosing and repairing a Bosch brand gas water heater? Share the intricacies of troubleshooting, add unique photos - the feedback form is located below.

If a flame does not light up in your Bosch gas water heater and you cannot find the cause in any way, and you don’t want to call a specialist, ask our experts and other site visitors for advice.

Why does the wick in the gas column go out, go out? Manufacturers of gas supply equipment strive for perfection, but technology is technology, and various breakdowns still occur.

Ignition failure in equipment ignition systems is a common problem. Sometimes the gas water heater ignites with a clap, does not burn or the wick does not ignite. In our material, we will consider why the wick in the gas column goes out, the reasons and ways to eliminate this.

Repair of the gas water heater Oasis

Chinese water heaters Oasis attracted the attention of the domestic market, first of all, by their low price and simplicity of design, which ensures do-it-yourself repair of a gas water heater in almost any problem situation. The device and format of the main parts are very similar to most domestic systems, so there are no problems with disassembly and repair, even if there is no repair manual or diagram for the Oasis gas water heater.

It is known from practice that the Chinese Oasis gas appliances suffer from three types of defects:

- Fast battery discharge;

- Failure of the spark plugs;

- Leakage of water at the gland of the membrane water pressure sensor.

In the first case, the problem with the batteries appears rather unusual, the indicator board pleases with a blue or green light, but when you try to turn on the gas water heater, nothing happens. Repair of such a defect is carried out by simply replacing conventional salt batteries with alkaline cells with an increased charge capacity. They should be enough for at least a year.

We disassemble the Oasis for repair

If drops of water began to appear under the column, then this most likely means that one of the units of the flowing part of the water heating apparatus will need to be repaired. The Oasis must be dismantled in order to determine the cause of the water leak and carry out repairs. First of all, it is necessary to remove the outer casing of the device. For this, the handles are removed and the self-tapping screws are unscrewed in the lower part of the case.

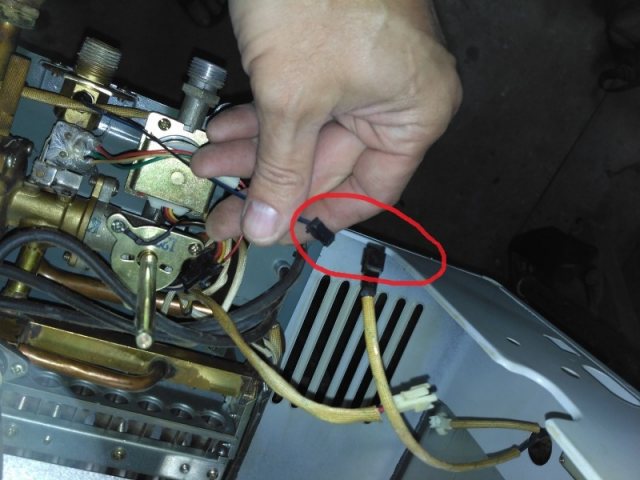

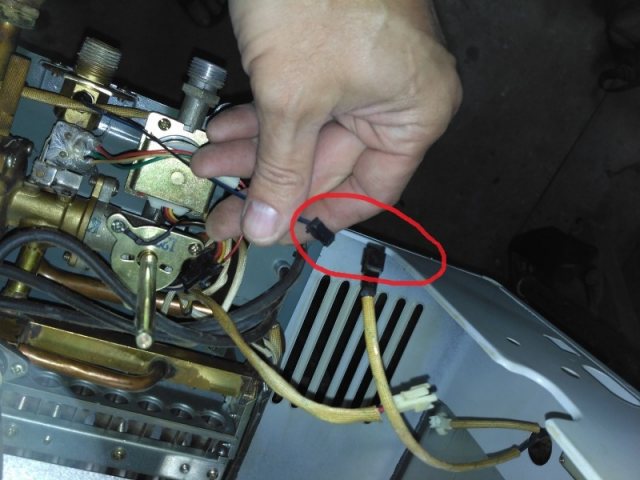

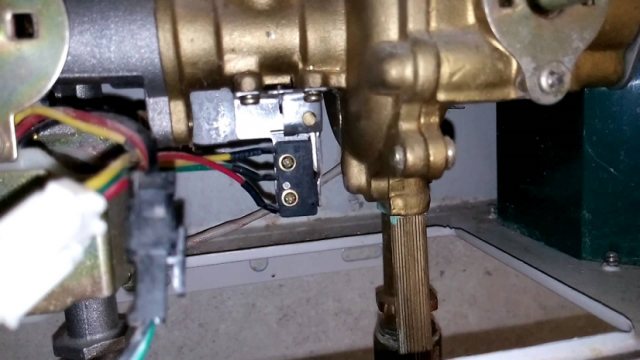

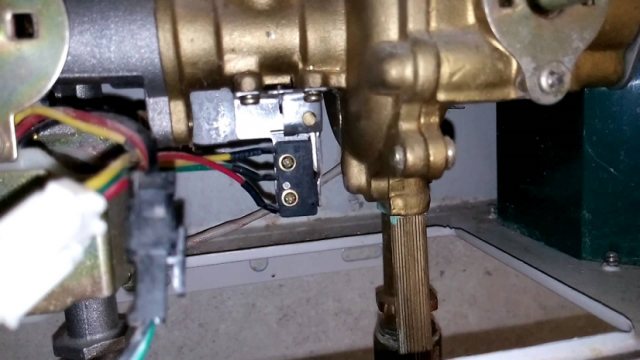

The next step is to disconnect the connectors from the indicator board and microswitch.

We get access to the future place of repair - a membrane water pressure control unit.

We repair the gas water heater block regulator

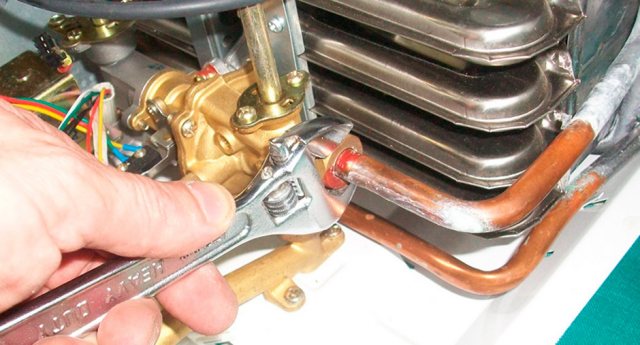

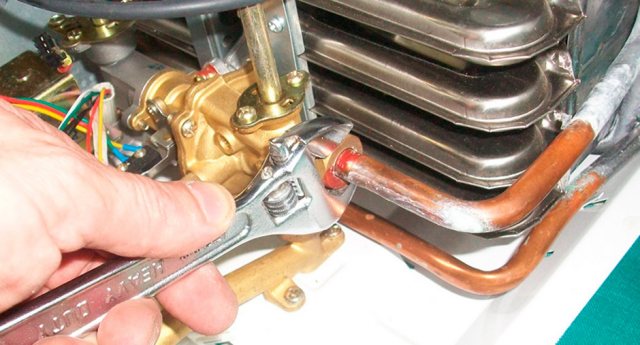

In order to remove the pressure control unit, it is necessary to carefully disconnect the microswitch connector and unscrew the two screws securing the heat exchanger flange to the unit body.

It is clear that before repairing the gas column, the water must be shut off, the water pressure remaining in the system must be relieved by opening the tap.

For repairs, it will be necessary to additionally remove the gas block of the water heater and the burner.

The removed unit can be disassembled for repair by removing the four steel screws. Usually, steel fasteners strongly adhere to brass, therefore, the joint is preliminarily treated with VD-5 or brake fluid.

The pressure control unit works as follows:

- There is a cavity inside the body, which is divided into two parts by a membrane. On one side, water comes up, in the second cavity there is a round float, on which water presses through the membrane;

- The float contains a stem that passes through a rubber gland. When the hot water tap is opened, the flow fills the cavity in the block, squeezes the stem through the gland through the membrane and the float, and squeezes the contact on the microswitch;

- The circuit closes, gas opens, and the ignition device is triggered.

It is clear that the surface of the steel rod, in contact with rubber, intensively corrodes and becomes covered with caverns. Each movement of such a rod leads to a catastrophic depletion of the oil seal, which begins to flow after a year. In addition, for any repair, at the first opportunity it is necessary to change the membrane to a high-quality rubber membrane.

Often there is a situation when, before repairing the oil seal, the gas column begins to boil and spit steam. This suggests that the membrane also needs to be cleaned of dirt and, if possible, replaced.

Repair of the electrode system of the gas column

Chinese manufacturers of gas water heaters Oasis always like to save on the quality of the materials used. As an example, we can cite a situation when a new, fully serviceable gas water heater stops igniting even with a serviceable water and gas control unit and an ignition board.

The reason is the failure of one of the three spark plugs of the burner flame.The design of the burner is such that all three candles must be in good working order to ignite the gas.

Repair of the gas column ignition system begins with the identification of a faulty spark plug. To do this, you need to remove the cladding, turn off the lights and shade the room. When you start the gas column, you can see how on one of the candles an electric discharge hits not into the gas flow, but much lower into the body.

The situation is extremely dangerous and requires urgent repair of the gas-air flow ignition system in the column. It is impossible to postpone repairs, even if the column lights up for the second or third time it starts up. When launched, a large amount of a mixture of gas and air is injected into the fuel chamber and the exhaust device, and if the ignition of the column is triggered with a long delay, an explosion and fire are possible.

For repairs, it is necessary to dismantle all three candles, clean them from carbon deposits, oxidation products. One candle accurately punches the body, the rest is not known in what condition, so all three are put in an insulating heat-shrinkable polymer tube, at least three to four layers. During the repair, it will be necessary to insulate the clamping bar in the same way, with which the candles are fixed on the burner body.

Operation, repair and troubleshooting of Bosch geysers

_________________________________________________________________________________________

There is a Bosch WRD 15-2G speaker at home. If the water supply is interrupted, the main burner does not go out. What is the cause of the problem? The damper in the gas valve is clogged. Check it out. Clean if necessary. The hydraulic valve piston may not move when it is open. Dismantle components, clean, replace if necessary. Check the gas supply pressure. Make adjustments if necessary. Replace the cylinder pressure regulator. What is the reason for the ignition delay and the burner popping? The spark from the pilot burner does not reach the main burner or is weak. Clean the ignition device and nozzle. Then carry out the adjustment. Help me figure out why there is no spark when the WR13-2 p23 device is turned on? Thermocouple wires are disconnected. Fix the wiring correctly. Ignition malfunction. This element should be inspected and replaced. Broken electrode. Change it to a new one. Bosch gas water heater malfunction. I try to turn it on, a spark is present, although the ignition of the igniter does not appear. How can you fix this? Pilot burner nozzle clogged. You have to rinse. The ignition electrode is not in the correct position. Customize it. Air in the gas pipeline. Remove air. Installed gas water heater WR 13-2b (gwh 15). Because of what the ignition device goes out during ignition. What is the problem? Damage to the thermocouple. Replace it. Coil defective. Change it. There is a problem with the WRD 13-2G model. The picture is as follows: the pilot burner ignites, but the main burner cannot. What to do and how to fix it? Insufficient water pressure. Pressurize the system as required. Why you need to turn the adjusting knob to the right until it stops. Diaphragm wear. Change it. About six months ago, I bought myself a Bosch WR 10-2p gas water heater. I installed it myself, and during the work there were no problems, it did not flow anywhere. Now soot has accumulated in it, and it has stopped heating the water. I also decided to carry out the cleaning myself. Share your experience on how to do this. How to remove the copper pipe correctly? To do this, simply lift the bracket and remove the tube? And I also want to remove the heat exchanger in order to completely wash it of any dirt. I also noticed that the flame has changed its color. If earlier it was a uniform blue color, now it is blue-yellow. Why is it so dirty? You have a poor supply of fresh air, so a lot of soot builds up. You need to blow off the dust from the burner and rinse the heat exchanger well. Work for about 2 hours and the instantaneous water heater WR10-2 p23 will be fine.They brought me a Bosch GWH 13-2 gas water heater. I examined her from the outside, everything was in order. We installed a battery in a special compartment and started it up. The instructions say that the green indicator should have turned on, but this did not happen. We decided that it will light up when the device starts working. It turned out that the workers, when connecting it, confused the inlet of the cold water supply and the hot water outlet. It's good that at least the gas was connected correctly. They did not wait for the inspection, and immediately served water. At the beginning, the unit did not react to anything, and then I saw that it was connected incorrectly. They changed everything and installed it as expected. With the help of the power regulator, the combustion began to start. First, the ignition inertia unit worked, clicks were heard. But the device does not light up. Moreover, neither the primary ignition goes on, nor the main burner ignites. All taps are open, water is supplied, gas is also on. He opened and closed the hot water tap several times, but only clicks and no reaction are heard. What could have broken? Is there something in the gas unit? Could an incorrect connection spoil something in it? Your piezo ignition works, which means most likely the Bosch column does not have enough gas. Moreover, you have a new water heater. You are not entitled to repair it yourself, as you may lose the warranty. You will have to contact the service center. In general, the device has a gas supply adjustment. You will find it, it is covered with yellow paint. You need to turn counterclockwise a third of a turn and you should be fine. I have a Bosch WR 13-2p semiautomatic gas water heater installed. It has been working for 5 years already, but now there is a problem. As soon as the cold began, strange things began to happen to her. And the water pressure is very good, the gas is also supplied with sufficient pressure. But the water comes in very cold, therefore, in order for it to heat the water as needed, a higher temperature has to be set in the settings. With this operating mode, the unit turns off after 5-10 minutes of heating. I do not understand its structure at all, but this is what it seems to me. I suspect that the problem is in some kind of sensor responsible for overheating. Perhaps it is very dirty, or broken, and gives the water heater a false signal. Or maybe my chimney is dirty? How do I get my machine repaired? Most likely, your chimney draft is broken, and therefore the Bosch column turns off. The overheating protection is triggered, the traction sensor is responsible for it. Judging by the time after which the device turns off, then this is it. But other options are also possible. For example, if your model has a battery, then it may have run out. You just need to replace it. It is easy to check the operation of the overheating sensor. You need to close the contacts. If the water heater continues to turn off, then this is not due to it. The contacts in the "thermocouple - sensors" circuit may have oxidized or loosened. I decided to install a closed type Bosch therm 4000 S gas water heater. It will work on one point of analysis: in the shower from gas in cylinders. Please tell me which models (open or closed) consume more gas? And another question. Can the copper heat exchanger be cleaned by myself? Or do you have to contact the service department? The closed type provides more stable combustion, their gas-air mixture is constant and does not depend on power. Therefore, their gas consumption is always lower. And if you use a therm 6000 series condensing water heater, the gas consumption will be even lower. But this is already for cottages, not apartments. Heat exchangers can operate for over 10 years without any major repairs. It does not need to be removed for flushing. I also advise you to install special filters. If the closed-type model is installed correctly and operated according to the instructions, little soot is collected in it, therefore, even after 5 years of operation, the heat exchanger does not need to be flushed.But if there is a desire or need, the heat exchanger tubes are washed with a citric acid solution. The display of the water heater will show information that the heat exchanger needs to be flushed. I decided to buy myself a Bosch W10 kb gas water heater. Studied it from all sides. I have a chimney, this is a pipe with a diameter of 12 cm, 2 m of this pipe lies under the false ceiling, and then it also hangs from the ceiling by 1 m. I want to leave a 12 cm pipe running along the ceiling, and replace the rest with a 6 cm diameter pipe. As I understand it, at the junction of the 12 cm and 6 cm pipes, the pressure should drop by 2 times. That is, the flow will slow down. The chimney is even wider, so the pressure must drop even more there. Does this model have a powerful enough fan to avoid problems with neighbors? The Bosch column can be safely connected by implementing air intake from the room. If you look at the instructions, it is written in detail there. Make a transition between pipes 6 cm and 12 cm, then connect your corrugation. All connections must be well insulated, since gas is supplied under pressure there. Your chimney has no effect on your neighbors. Each has its own exit to the roof. You can also install a splitter to make air intake from the street, and the emission of combustion products is already in the chimney. Holes less than 15 cm do not need to be coordinated with anyone. The coaxial pipeline should not be taken out into the street, since it is necessary to maintain the distance to the nearest windows. If you do not live on the top floor, you are unlikely to be able to provide this. I installed a Bosch 10 gas water heater at home. Moreover, it was adapted to work on liquefied gas. To do this, I installed other nozzles, and removed the j6 jumper. But the device won't start and I don't understand why. When I turn it on, the green button lights up for a few seconds, and then the red light blinks, and the fan starts working. No more action takes place. Since the unit reacts to turning on the water by turning on the fan, first of all it is necessary to make sure that the pressure switch is working properly. This is the weakest point of all smoke extraction models. If the fan turns on even when the tap is closed, and is blocked at the same time, you need to look at the sensors and look for a break. It is possible that the contacts of the pressure switch are incorrectly connected or reversed. After you readjusted the water heater, it was necessary to check its operation on normal gas to make sure that the unit is in good working order and there are no breakdowns in it. It could have been damaged upon delivery. And so check according to the scheme. Call the temperature sensors, check the pressure switch. If possible, go to the tuning mode, set the regulator to maximum. To do this, press and hold the torch buttons, and then switch the switch, which must be held until the start of flashing. Also check the fuses located in the control box. I want to buy a WRD 13-2G gas water heater. Studying the options, I did not understand what the digital display is for. What information is displayed on it? Or rather, does it show the real temperature or the desired one? The display shows the set temperature. But if you want, you can see the current one. But this can only be done when the device is working. To do this, you need to go to the service menu. Water began to flow from my Bosch WR 15 gas water heater, and it flows out of its upper part. It has been in operation for 8 years already, and before that it has never broken. Can I fix it? Unlikely. Get ready to buy a new water heater. Please tell me how I can set up my Bosch GWH 10-2 gas water heater, something I can't figure out about it. It's more or less clear with the left knob. It regulates the gas flow. If you set it to a minimum, there is less gas, the temperature is lower. And vice versa. But with the right adjustment knob I am completely incomprehensible. It is written that this is a flow pen.But I don’t understand the expense of what? Perhaps water? Also, I do not understand the principle of energy saving when adjusting this knob. And it is also written that scale pollution is reduced. Can you tell me how these adjusting knobs relate to each other? The left handle is identical to the tap on a gas stove. The more you open it, the more gas will be, the warmer the water will be. And the right handle looks like a regular water tap. The more you turn, the more water will pass through the system, the less it will heat up. In the same way, you can adjust the normal screen installed in the sink, only this adjustment will be coarser. The water heater allows for a softer and more correct adjustment of the water supply temperature. But it is not recommended to touch it. Initially, all adjustments are made with the gas regulator. And only when it is set to the maximum mode, but at the same time the water temperature is not enough, you can already touch the flow regulator. In other cases, this handle should provide maximum water flow. There was a malfunction of the Bosch WR 10-2 p gas water heater. For 4 years she worked without any problems, but a month ago her radiator began to leak. In order to find a leak, I took it off and looked. I found damage to the top. It is impossible to solder there because of the ribs. In order to block the leak, I filled the defeated place with sealant. I also flushed the radiator. The water heater started to work well. But now a new problem has arisen. The device has stopped burning. The pressure is good, but the water comes to the tap cold. If you look through the viewing window, then the gas burns not blue, but yellow flame. Also, the combustion power is much less. What could have broken? The thrust is present, I checked it with a lit newspaper. The gas is supplied with good pressure, tested with a gas stove, which burns without problems. The boiler connected to this gas also works. On an instantaneous gas water heater WR10-2 p23, try to disassemble and flush the heat exchanger and burner. You also need to blow the igniter. This should be done as soon as the flame begins to change color. To solve the problem, try unscrewing the two screws on the side and center, but do not remove them completely. Use a flat screwdriver to grasp the burner and pull it out. Find a rubber ring there. Do not forget to lubricate it with either soap or special silicone grease. Also find the wire with the solenoid valve and disconnect it, without this you will not be able to disconnect the burner from the unit. The heat exchanger will also have to be removed, as it will interfere with the dismantling of the burner. I have a Bosch Therm 6000 gas water heater installed. It runs on liquid gas. No problem. Can you please tell me if I can install any additional devices in order to extend the life of the water heater? First of all, I would advise you to install a 25-50 micron water filter with backwash. It works long enough, and does not require constant replacement of cartridges. You can flush once every six months using a special flush valve. Also, if you have an old electrical network at home, with aluminum wiring, then you should install a surge protector to protect against network problems and possible overvoltage. We install the Bosch 4000 gas water heater. Difficulties arose with connecting cold water. You constantly have to carry a flexible hose with you. I also studied the problem of connecting to the chimney. The instructions state that "The flue gas outlet must be inserted into the flue gas protection manifold connection." I can't understand what the word belonging means. What is it and where can I get it? Can I just take a 135mm corrugation and install it? You need 3/4 and 1/2 corners. Defective gas water heater Bosch WR 10-2p. When starting, clicks are heard, and even sometimes it lights up, but only if the water tap is open to maximum. The water is supplied warm, but not enough.It used to be much hotter. After the device starts, the water supply pressure can already be reduced, and everything will work. If the unit does not want to work at all, I blow cold air on it, and the problem is solved. But you need to clearly find the point to blow. It is located next to the green indicator. During this procedure, the indicator flashes, and after a while the device starts to work. Gas is supplied at normal pressure. What could be? Try to reduce the flow with the right control knob. To do this, it is necessary to turn it in the direction of increasing the temperature to the average value. If you blow air onto a valve or igniter, then you just need to clean the unit from dust. The spark should always appear. Can I supply a new instantaneous gas water heater myself? Or I should only do it with the help of gas service specialists. I have experience in installing a Soviet column. I twisted the eyeliners there. But I have never come across modern models. I suspect that there is a more complex connection diagram. And another question about the equipment. I am thinking of the open model Bosch wr 10. Compared it to the Ariston Fast 14c. But I would like to hear the opinion of professionals about these two models. There is nothing to compare. Bosch mechanical. There is no temperature stabilization in it, and you will fully experience all the inconveniences of membrane control. And Ariston is equipped with electronics. The modulation of the burner is implemented to it, and the outlet temperature is kept stable. Bosch is good in its class, but nothing more. Then pay attention to the Neva 6014, which is similar in functionality. We also advise you to pay attention to the models with a closed camera, they have a faster and more correct adjustment. It is not difficult to change it yourself, but before the warranty remains on it, you still have to contact the service department.

_________________________________________________________________________________________

_________________________________________________________________________________________

- How to troubleshoot and malfunctions on the Juncker boiler

- How to troubleshoot basic problems on boilers Buderus Logano G334

- Errors and malfunctions of Rinnai boilers

- Recommendations for the repair of boilers Buderus Logano G124 / 125

- Possible breakdowns during the operation of the Beretta gas water heater

- How to correctly adjust and repair the Electrolux gas column

- Tips for adjusting and repairing gas water heaters Gorenje

- Values of error codes of boilers Immergaz

- Problems in Junkers gas water heaters - Recommendations for repair and maintenance

- How to identify and eliminate malfunctions in the Ladogaz gas column

- Recommendations for the operation, repair and settings of the Mohr gas column

- We repair the Zota Carbon boiler - Types of faults and options for their elimination

- Repair of the Zota Master boiler - What can be malfunctions and actions to eliminate them

- Celtic boiler error codes decoding

- Repair of the Buderus Logano G221 boiler - Types of malfunctions and methods of their elimination

- Causes of irregularities in the operation of Buderus Logano S131 boilers and how to repair them

- Questions on troubleshooting storage water heaters

- How to troubleshoot the operation of storage boilers

- Electric water heater malfunctions and tips for their elimination

- Electric boiler malfunctions and repair recommendations

- Boiler error codes Hermann Habitat

- Tips for eliminating basic problems in storage water heaters

- Help in troubleshooting storage boilers operation

- Possible malfunctions and breakdowns during the operation of gas water heaters

- How to repair a gas water heater in the event of a malfunction

- Ways to eliminate malfunctions and breakdowns on gas water heaters

- Errors of gas boilers Proterm Cheetah

- Elimination of breakdowns and malfunctions during the operation of gas water heaters

- Causes of malfunctions and repair of gas water heaters

- Repair of gas water heaters in case of malfunctions in operation

- Hermann boilers - Methods for eliminating errors and malfunctions

- Elimination of errors and malfunctions during the operation of Arderia boilers

- Boiler error codes Ariston Egis

Repair of the gas column Neva

Most of the models of Neva gas water heaters have shown themselves to be simple and affordable water heating devices. They are far from the reliability of European models, but their repair costs an order of magnitude cheaper, and almost always you can do it yourself.

Failure and subsequent repair of the spark plug according to the rules is considered an atypical case of breakdown, therefore, after completing the repair work, it will be correct to look for the cause of the defect. Most often, plastic burnout occurs due to condensation flowing through the ventilation system to the gas burner body.

How to repair the heat exchanger flare nut

One of the most common defects of Neva gas columns for almost all models is the low quality of the heat exchanger metal. According to the rules, the heat exchange circuit through which the water flows must not come into contact with aluminum parts, for example, a gas burner or a regulator block. Any such contact can cause electrochemical corrosion of the copper walls, and then the repair will be simply useless.

In addition, the rules for tightening the union nuts, with which the heat exchanger is attached to the regulator and the outlet pipe, are not always respected. With each removal and repair of the heat exchanger, the nuts cut a thin, barely distinguishable track in the copper wall. Ultimately, the flared end and part of the copper pipe simply break off for the tenth time.

In this case, it is necessary to cut and level the breakdown site, install a new nut with an external thread and connect the heat exchanger to the regulator block with an ordinary flexible hose. Any other repair option, as practice shows, turns out to be short-lived.

Repair of a microswitch in the gas column starting system

A situation similar to the Oasis on dead batteries happens with the Neva gas water heater. When you try to start the Neva, the indicator board lights up, but the gas burner does not ignite. Sometimes the column can be turned on 4-5 times.

In this situation, repair of the microswitch is required, due to premature wear of the part or improper adjustment of the unit.

The switch is located next to the water pressure control unit. When the column is started, the membrane on the block squeezes out the stem, which unlocks the switch contact. Unlike Oasis, all parts of the block, including the stem, are made of brass, so there is no corrosion, the microswitch itself must be repaired and replaced.

To carry out repair work, you must disconnect the connector, unscrew the two M3 screws and remove the switch body from the bar, as in the video

Replacing the micrik is easy. You can buy an original part for 400-500 rubles. in a specialized salon or purchase an analogue for 50 rubles. in any radio parts store. There is no difference for repair, in both cases they will sell a part from Chinese consumer goods.

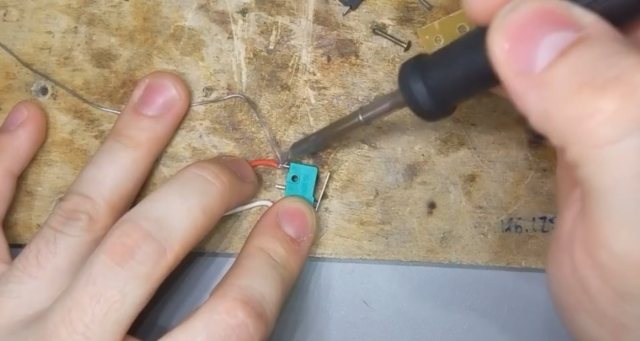

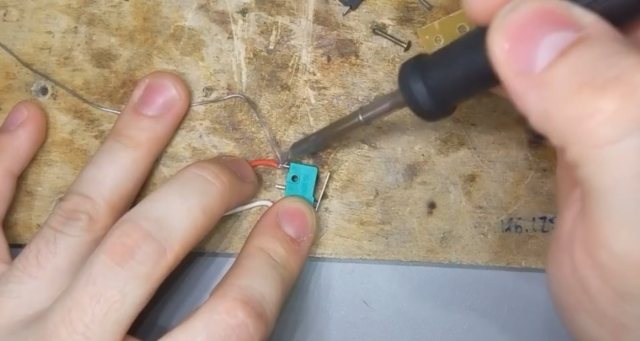

In order to carry out the repair, you will need to unsolder two cores of the wire with a connector from the switch legs, put on a heat shrink tube and solder to the contacts of the new part.

At the final stage of the repair, the switch is fastened with old screws to the mounting plate on the block. Next, you need to adjust the position of the microswitch housing so that the rod completely releases the contact when moving. This is done using mounting screws. One of the screws bends with a radius, respectively, by rotating it, you can move the switch body in the desired direction.

Why does the column not light up or go out?

Periodic malfunctions in the operation of these devices are not associated with technical defects, but with depreciation during operation. Like any technical tool, gas water heaters need to be periodically maintained.

List of major faults:

- it is impossible to start up from the first ignition attempt;

- attenuation of the wick;

- attenuation of the igniter when changing the power of the water supply by the tap on the mixer;

- weak heating of water;

- the igniter goes out periodically;

- weak water pressure through the gas column pipe system.

In the event of these malfunctions, it is not necessary to contact the wizard, because some of them can be solved independently by performing a certain algorithm of work and observing safety rules.

Problem # 1 - the flame won't ignite on the first try

To begin with, it is worth performing the most elementary measures - check the position valves for water and gas supply... If there is no supply of one of them, the work of the column is blocked automatically.

If batteries are used to start the column, then it is necessary to check their performance. And in case of discharge, replace with new batteries.

Provided the problem persists, the next step is to check the chimney. Any ingress of debris and even a volumetric accumulation of soot on the walls of the chimney can lead to a malfunction - lack of draft. Keeping the chimney clean is a necessity that will prevent carbon monoxide from entering the interior.

If there is no thrust sensor that constantly monitors the thrust level during operation, you can check its presence yourself. It is enough to use a burning match, which must be brought to the hole in the column. The absence of flame displacement will indicate clogging of the ventilation system. We turn off the column and clean the chimney.

Another reason could be weak water pressure... This is visually detected when the tap is opened.

If the pressure is of sufficient strength, the problem may be:

- in the contamination of the mesh filter of the water system;

- in the pollution of the water system itself;

- finding a blockage in the mixer filter.

If the first problem can be easily solved by flushing the strainer, then to solve the second and third problems, it will be necessary to unscrew the pipes at the inlet, after turning off the gas and water supply, and flush the system. special cleaning agent.

The next reason is weak gas pressure... This malfunction must never be rectified by yourself. You should definitely contact a specialist.

Incorrectly tuned igniter may be the reason for the malfunction of the column. This happens when the gas pressure in the line does not match the type of igniter. In the case of low pressure, the gas required for ignition goes down. For a more stable operation of the ignition system, it is necessary to mount the electrode that generates a spark to the center of the burner.

Problem # 2 - gas column wick decay

The problem is when the wick goes out when working in a Bosch gas water heater, it may be caused by a weak gas supply. This problem can be caused by dirty ignition tube dust particles and carbon deposits.

To solve it, you need to remove the gas column housing and correctly disconnect the ignition pipe. To clean the inside of the tube, blow out the tube. The edge on which carbon deposits have accumulated is cleaned with emery paper or other abrasive material.

When reinstalling, it is necessary to restore the tightness of the tube by connecting it to the required limit with the gas supply tube.

Problem # 3 - speaker attenuation during operation

There are situations when a Bosch brand geyser suddenly goes out and stops working, it is necessary to identify how long after ignition this happens.

If the shutdown immediately after starting (after 3-5 seconds), then most likely the matter is breakage of the ionization sensor... In this case, it is necessary to check the wiring between the sensor and the control board and, if it works, replace the sensor.

When the column goes out after several minutes of operation, this may be due to:

- weak gas thrust;

- the sensitivity of the alarm relay.

You can check the gas draft in the entire gas system by turning on the gas stove.If the gas supply is visually normal, then the problem is in the gas supply system to the column. To solve it, you need to call a specialist.

Also, the draft problem can be caused by a blockage of the chimney or by the heat exchanger tubes clogged with scale.

Another reason could be broken functionality alarm relay... To do this, you need to open the windows and ventilate the room with high quality. Then try to start the device again. If the column is working again, then the matter is precisely in the sensitivity of the relay. This element needs to be replaced.

Mixing a stream of hot water with cold water can also cause column attenuation. In order to eliminate this problem, it is necessary to perform the adjustment correctly.

Problem # 4 - the igniter of the gas column goes out

One of the important elements of the water heater is the igniter. It is necessary for the smooth functioning of the device, therefore it must work continuously.

To understand why the gas water heater goes out igniter, you need to check the following probable reasons:

- thermocouple malfunction;

- the appearance of external air flows;

- chimney pollution.

To stop the unstable operation of the gas column, an element is used - thermocouple... This is a safety device, the function of which is to timely shut off the gas flow. If the igniter goes out, it shuts off the gas supply.

Thus, when a thermocouple burns out under prolonged exposure to fire, its tip becomes loose, its physical properties are lost, and an involuntary triggering of the protective function occurs. The defective part must be replaced.

Another reason for insufficient heating of the thermocouple is the clogging of the gas nozzle orifice with dust. After completing the cleaning, the operability is restored.

In the event of improper ventilation, the resulting air currents can blow out the pilot burner. It is important here not to confuse this phenomenon with a lack of draft due to fouling. To fix the problem, you need to check that the protective cover of the column is correctly attached and that there are no external sources of air exposure.

It should be remembered that modern devices contain a lot of electronic devices, sensors and modules. A separate malfunctioning of any of them can lead to a failure in the operation of the device. Special equipment is required to detect the problem.

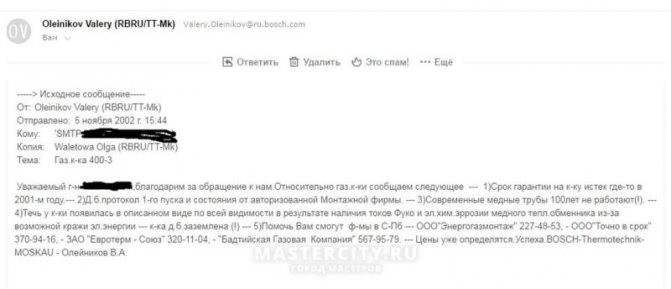

Repair of the Junkers gas column

The advantage of domestic gas water heaters is their high resistance to overloads and low quality of water, and first of all, gas. Experts say that German equipment traditionally shows huge service life without repair, but on one condition - the system must be protected from power surges and equipped with protective filter elements that soften the hardness of the heated water.

But even in such conditions, you have to periodically carry out minor repairs with your own hands of the Junkers gas water heater. The reason is simple, automation, ignition and ignition device are very sensitive to dirt, dust and rust in household gas. On dirty gas fuel, the igniter is the first to fail.

To restore the column, you will need to remove the lid and pull out by hand a thin profiled aluminum tube that provides standby operation. The tube is carefully cleaned with copper wire and rinsed with alcohol. Due to the high content of iron pentacarbonyl in the gas, finely dispersed metal dust precipitates on the walls of the gas pipeline, killing the candles and igniter.

Filters practically do not retain pentacarbonyl, so craftsmen often replace an aluminum tube with a copper tube of a larger diameter. The new gas pipeline is wrapped around the heat exchanger, which ensures the decomposition of the carbonyl in the pipe before entering the ignition zone.

In addition, dirty gas forces you to regularly open and clean the gas burner of the column.

Repair of heat exchangers for gas columns

One of the most severe cases of column damage is burnout, rupture, or through corrosion of a copper heat exchanger. In the first two cases, the repair is carried out only by replacing the part with a new one. In the case of perforating corrosion, thin, 02, -0.5 mm holes are formed on the walls of the heat exchanger through which water flows out of the circuit.

A defect, as a rule, is detected by intense soot formation, water leakage and a drop in pressure in the circuit when the valve is closed.

To repair the heat exchanger, you will need to remove it from the geyser mount. Next, the copper surface is cleaned of soot and scale deposits and subjected to a hydraulic test.

The easiest way is to identify the place of corrosion by pumping air or water under excessive pressure. For example, the outlet of the heat exchanger is muffled with a rubber stopper, and air pressure is supplied to the inlet by a hand pump. The heat exchanger of the gas column is immersed in a container with water and the location of the damage is determined.

You can repair the damage at home by soldering with copper-silver tin solder. The first is used to restore the hottest spots located close to the flame front. To seal with tin, the copper surface is etched with a solution of zinc in hydrochloric acid, heated with a burner and tinned with a massive piece of solder. For normal operation, the thickness of the tin patch should be at least 0.5-0.7 mm.

After the repair, the heat exchanger is checked twice more - using traditional air injection and holding under the working water pressure after installing the unit on the gas column. The pressure in the circuit must not drop for at least 15 minutes.

External signs of a failure in the operation of the gas column

If the junkers gas column does not ignite, the reasons for this may be external factors not related to the condition of the main equipment.

- Incorrect piping. In this case, it is necessary to check the connection of both the inlet and outlet pipes, which will also ensure uninterrupted water supply.

- There is no traction. This is caused, as a rule, by clogging of the chimney with a large amount of dust or foreign objects. Thus, there is no removal of combustion products and the burner goes out. In such a situation, you need to bring your hand to the chimney or a small flame (from a match or lighter). An important condition is the presence of an open window. If the thrust level is sufficient, then the flame will deflect, and air movement will be felt in the palm of your hand.

- There is an unpleasant smell of gas in the room, which can be caused by the installation of an antenna on top of the chimney by neighbors. In this case, the column must be turned off immediately, the room must be ventilated and special gas services must be called.

- The column ignites, but after a while, attenuation occurs. This can be caused by excessive "sensitivity" of the protective relay. In such a situation, it is necessary to cool the room by opening the windows and contact the service department to replace the relay.

- A discharged battery or battery can also cause the device to not work with automatic ignition. This indicates the need to replace them, which you can make yourself.

- A low water pressure may indicate a malfunction of the junkers gas water heater, if the water pressure, for example, in the bathroom and in the kitchen, is different. If they are equally small, then the reason is a weak water supply network.

- The extinguishing of the wick can be caused by an oblique, uneven flame. As a result, poor heating of the thermocouple occurs, which automatically turns off the unit. In this case, it is necessary to clean the dust, which is a mandatory preventive measure when the wick decays.

Bosch gas water heater repair

Hot-water gas appliances manufactured by Bosch are distinguished by their compact size and enormous saturation of automation.The more components and mechanisms in the design, the more likely it is to break.

Bosch WR10 water heating systems are characterized by two types of breakdowns - arbitrary shutdown after a successful start and leakage of oil seals due to high water hardness.

Arbitrary shutdown can occur for three reasons:

- Drop in chimney draft;

- Contamination of the ignition electrode, as a result of which the automation does not recognize a very small ionization current and turns off the gas supply. The repair is reduced to the usual cleaning of the electrodes;

- Heat exchanger overheating sensor triggered.

The last case is the most relevant. The overheating sensor is a bimetallic plate with contacts. When a certain temperature is reached, the plate bends and opens the contacts.

Before recovery, it is necessary to check the operation of the sensor, for example, short-circuit the contacts directly with a paper clip or copper wire. If the gas water heater continues to work in normal mode, then you need to buy and replace the sensor. Severe overheating means that it will be necessary to adjust and check the gas regulator.

How to light a Junkers gas flow column

The overwhelming majority of Junkers water heaters offered to domestic buyers operate in a semi-automatic mode. The ignition of a semi-automatic gas boiler is carried out as follows:

- on the front panel of the water heater there is a valve that opens the gas supply;

- the button is clamped and the wick is ignited with the help of a piezoelectric element;

- the gas valve is left clamped for another 20-30 seconds;

- now the button is released, the flame on the burner should continue to burn.

The pilot burner remains on throughout the day. When you open a hot water tap, the boiler will turn on automatically. The gas column is adjusted on its own, using two regulators-knobs: changing the pressure of gas and water.