With the development of technologies, the requirements for the comfort of housing are increasing, which depends on many factors, including the state of the environment inside the home. Indoor temperature, air humidity, noise level, illumination - all these are components that characterize living conditions. Comfortable values of these parameters are achieved by using materials with appropriate characteristics in construction and decoration. At the same time, multifunctional materials provide not only the comfort of living, but also the efficiency of using other means of special finishing.

Let's consider the importance of performing vapor barrier in a room, modern vapor barrier material "Izospan", and how to lay Izospan on the ceiling - the base, more than other structures in contact with steam.

What is Isospan

In rooms with high humidity or enclosing structures insulated with soft heat-insulating materials, a vapor barrier is required.

The simplest vapor protection of the foundations is provided by a roofing material or polyethylene shell, which also serves as a waterproofing. But such a primitive double-sided barrier does not allow moisture to escape from the base material and insulation. In addition, drops of condensation formed on the film run down or fall down, without having time to evaporate, forming puddles on the floor and streaks on the walls.

Modern vapor barrier materials are much more functional, their varieties are made for a specific task and therefore, while ensuring vapor protection, they are devoid of the listed disadvantages.

By protecting the base from contact with condensate, the vapor barrier performs the following functions:

- protects the base from contact with condensation, preventing the formation of fungus;

- insulates the base insulation from external moisture, while maintaining its thermal insulation properties;

- allows the water originally contained in the materials of the supporting structure and thermal insulation to evaporate;

- retains condensate on itself, preventing it from draining and ensuring gradual evaporation.

An example of a modern vapor barrier material is the products that have been produced by the domestic LLC Hexa - Nonwovens for 12 years under the Izospan trademark.

Izospan are diffusion films or membranes made of modern polymers, produced using special technologies that allow to endow the varieties of this vapor protection with certain characteristics, which, in the context of a wide selection of insulating materials, facilitates the selection of a product with the desired functionality. The format and strength of Isospan are made in such a way that the installation of the vapor barrier can be carried out with optimal performance and quality.

Why do you need a vapor barrier insulation

Vapor barrier in the case of using moisture-absorbing heaters is always necessary. The fact is that the characteristics of mineral wool are such that the material installed on the inside of the wall is in contact with warm air, which contains water vapor. In the absence of a hydro-barrier, moisture penetrates the thermal insulation layer on the floor, where it condenses, turning into water.

As a result of humidification, the thermal insulation properties of the mineral wool material are reduced, in addition, mold and mildew may appear in a humid environment. If the vapor barrier under the insulation on the wall is correctly laid, then it becomes an obstacle to moisture. Therefore, the thermal insulation device requires the installation of a vapor barrier between the warm air of the room and the insulation.

Types, characteristics and fields of application of isospan

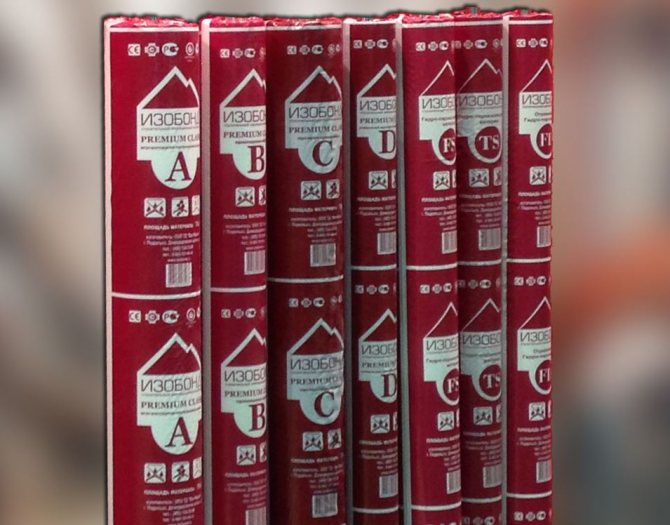

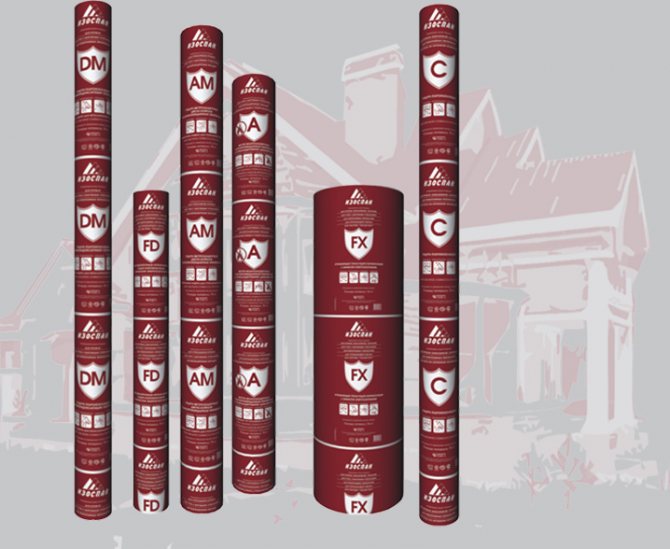

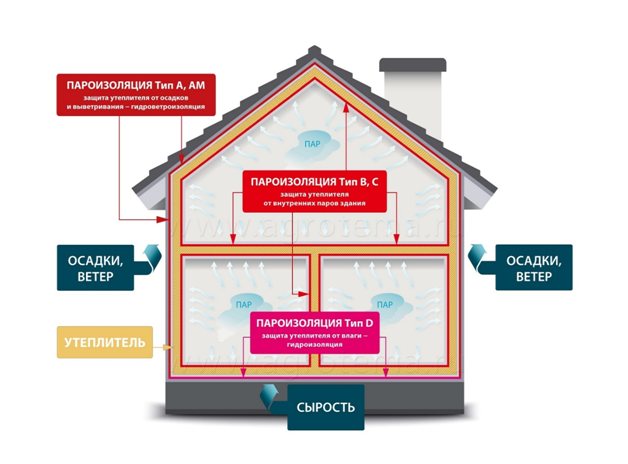

All types of produced isospan are made of polypropylene and are divided into 4 capacious lines, differing in characteristics and functionality:

- vapor-permeable, but waterproof and windproof membranes (5 classes - A, A with OZD - fire retardant additives, AQ proff, AM, AS;

- films with vapor and waterproofing properties (6 classes - RS, B, C, RM, D, DM);

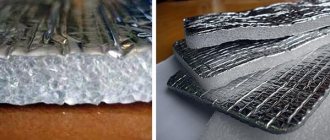

- energy-saving heat-vapor-waterproofing materials with a reflective coating (4 classes - FB, FS, FD, FX);

- adhesive tape (7 types - KL, KL +, SL, FL, FL Termo, ML proff, SUL - self-adhesive sealing tape).

Materials of all varieties have the following general merits:

- the required degree of paronization;

- a sufficient degree of tensile strength and bursting shear;

- environmental friendliness and safety - no harmful emissions;

- the presence in each group of fire-fighting varieties that have the property of self-extinguishing;

- manufacturability due to elasticity, ease of cutting and optimal format for installation.

To simplify the overview of the above varieties, we will consider 4 types of isospan that are most widely used for vapor barrier - marked on the packaging with markings A, B, C and D. But this does not mean that the other modifications of isospan are not suitable for vapor protection - on the contrary, they either higher performance, or designed for specific operating conditions. You just need to know how to choose and correctly lay these types of isospan on the ceiling.

Izospan type A

Izospan A is produced in two types - wall and roof.

Isospan-A roofing is a wind- and moisture-insulating, but vapor-permeable membrane, laid between the roof insulation and its flooring (metal tile, cement-bonded particle board, ondulin). Such a shell is designed to prevent the formation of under-roof condensation, as well as to protect the insulation and structures of inclined roofs of buildings from it with an angle of inclination of more than 35 degrees.

The outer side of the group "A" isospan is smooth, has water-repellent properties and is UV-resistant. The structure of the inner surface of the membrane is voluminous, preventing the formation of condensate and allowing water vapor from the insulation to erode outward.

A more advanced version with a slightly lower vapor permeability value (at least 850 g / m2 / day), but lighter and having three times more water resistance, is the Izospan AM vapor barrier.

Izospan type B

Izospan V is a universal two-layer protection of insulation and building structures from the steam of the internal environment, which also has waterproofing properties. The material is laid on the inside of the insulating layer of attic, basement and interfloor ceilings, as well as a soft roof. "Izospan-V" is placed with the smooth side to the thermal insulation layer, and the rough outer surface with this arrangement helps to keep condensate on it, followed by evaporation into the air environment of the room.

Izospan type C

"Izospan-S" is also a two-layer material for the device of double-sided steam and water protection of insulated coatings and ceilings, but its high strength allows the material to be used as a waterproofing layer on concrete, earth and other floors with insulation.

Izospan species D

This type of vapor-waterproofing isospan has increased strength, since it is made on the basis of a fabric woven from polypropylene. The high tensile strength characteristics of Isospan-D make it possible to use this material to isolate building structures from the effects of atmospheric moisture outside, while the effect of even a static snow load on the insulating coating is permissible.

Like Izospan-S, the D-type of vapor barrier can be used as a waterproofing shell on concrete and earthen floors, while the general application is hydro and vapor barrier in two directions, protection from snow and wind of cold and insulated pitched roofs, wooden structures , as well as roofing from condensation from the inside.

Structure and parameters

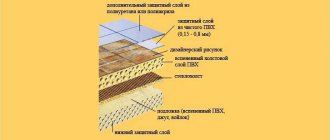

Structurally, Izospan B is a polypropylene film with one smooth side and the other covered with a thin rough layer of fibers of the same material.

The smooth sealed surface of the film creates an impermeable barrier to steam and water, and the fibrous coating is an excellent collector of condensate that will remain on the film and will not get into the insulation of walls and ceilings.

The effectiveness of this protective coating depends on which side of the film will adjoin building structures or insulation.

Izospan B has excellent performance characteristics:

- vapor permeability not less than 7 mg / (m • h • Pa);

- water resistance not less than 1000 mm. aq. pillar;

- tensile strength not less than 25 N / cm;

- operating temperature range from -60 ° С to +80 ° С.

The film does not lose its properties from exposure to direct solar ultraviolet radiation for 4 months. Izospan B is produced in rolls, strips 1.4 and 1.6 meters wide and with a total area of 35 m2 and 70 m2. What width and area to choose the material depends on the geometric dimensions of the protected surfaces.

Common technologies for vapor barrier ceilings with isospan

The vapor barrier of the ceiling base is performed using one or a combination of several types of this vapor barrier, and you can install any isospan on the ceiling yourself. The individual characteristics of the varieties of this vapor barrier material are indicated on the packaging, which makes it easier to choose the protection of the desired class. When choosing the right brand of isospan, it is necessary to take into account the functionality of the floor (basement, interfloor or attic), the material of its execution, the type of insulation and the operating conditions of the room. The location of the vapor barrier in relation to the base and insulation is also of great importance, since a correctly performed vapor barrier is also based on the orientation of the material used.

How to put Izospan on a concrete ceiling

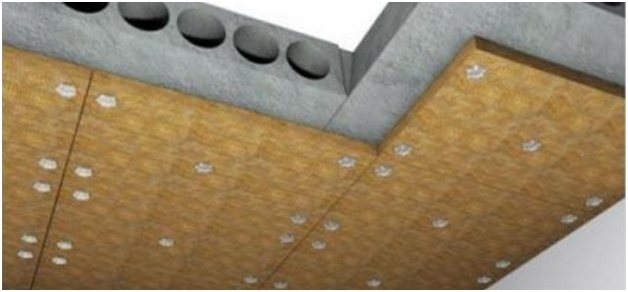

When repairing a ceiling, an intermediate operation performed after leveling with cement mixtures and before insulating the base from the inside is waterproofing - in case of a leak from above, if there are highways or plumbing fixtures on the floor above. A layer of waterproofing applied to the ceiling from the side of the room with a coating method (deep penetration composition or on a bituminous basis) will simultaneously perform the function of vapor protection, which is mandatory when using soft insulation. The easy-to-use coating method of waterproofing eliminates the need to lay a layer of isospan-A on the ceiling, the waterproofing properties of which, moreover, are lower.

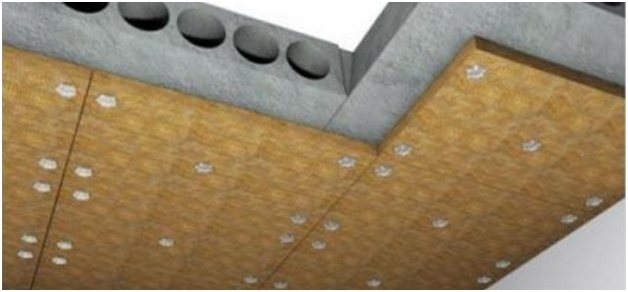

When installing heat protection from a rigid insulation (polyurethane foam, polystyrene foam) over the waterproofing, there is no need to install a vapor barrier. But if mineral wool is used for insulation, especially if it is laid in a frameless way (with plastic fungi), then a vapor barrier is necessary - this insulation is hygroscopic and, in addition to reducing its thermal insulation qualities, it will also "please" with a decrease in thermal insulation qualities.

A soft insulation is mounted on the waterproofed ceiling with the help of plastic mushrooms in such a way that the fastener caps press the thermal insulation layer together with the isospan-B vapor barrier to the concrete base. Izospan is laid in strips with an overlap of 15 cm on top of each other, and on the ceiling - 5-10 cm down, with the smooth side towards the insulation.The edges of the gaps are glued longitudinally with Izospan self-adhesive tape, brands FL or SL.

On the ceiling, markings of the arrangement of sheets of insulation with fungi are preliminarily carried out so that the longitudinal rows of fasteners are arranged in even parallel rows with the same pitch. Wooden slats treated with a hydrophobic compound are installed along the longitudinal rows of fungi, attaching them to plastic caps with self-tapping screws. Decorative plastic panels or siding can be laid across the longitudinally mounted slats.

Material properties

Polymer-type membranes have earned positive reviews due to the properties of the protection of premises:

- The ability to conduct heat.

- High density due to the structure of the membrane type.

- Waterproof.

- Strength, resistance to external influences, breakthroughs.

- UV protection ability.

- Modern technologies make it possible to produce building materials with a high degree of environmental safety - this applies to all types of isospan.

Prices for plastic films depend on the type to which it belongs and the manufacturer that presents it on the market. Izospan is sold in rolls with a waterproofing side inside, the area of one roll is 70 sq.m.

The price for one roll of types A and B, which are suitable for use on the ceiling, can range from 1000 to 2000 rubles.

There is Izospan self-adhesive tape on sale, which is used in various capacities. It costs about 500 rubles. per piece, it has about 30 m.

Often unscrupulous manufacturers want to pass off their products as isospan, so when buying, you should ask about the availability of a quality certificate and compliance with production standards. To calculate the amount of a product, there are special online calculators on the websites of special construction companies or intermediary stores.

By the way, you can buy a good lining on the website of the company RealWood.ru. Good quality and reasonable prices.

Isospan installation in the interfloor overlap

If both floors are residential, that is, heated, vapor barrier can be performed using only one type of material - isospan-V, but it will be laid on both sides of a soft insulation

When installing the interfloor overlap on the supporting beams, the boards of the draft ceiling are sewn to them from below. Then, on the rough ceiling from the side of the upper floor, a soft insulation is placed between the beams, the thickness of which should be 3-5 cm less than the height of the rafter section.This difference in size is necessary so that after laying the vapor barrier film on top, a ventilation gap forms between the isospan and the thermal insulation, necessary for weathering moisture from mineral wool.

Isospan-V is laid on top of the heat-insulating layer - the smooth side towards the insulation. The vapor barrier film is attached to the beams with staples using a stapler, avoiding strong tension or sagging, with overlap of the strips 10-15 cm on top of each other, with gluing the joints between themselves and the walls with Izospan-SL or -FL connecting tape.

Over the rafters along their entire length, counter-rails are nailed - wooden blocks with a section of 4x4 or 5x5 cm, across which the boards of the final floor are laid.

Important! After finishing laying the finished floor, it is necessary to check and, if necessary, knock out the boards of the rough ceiling from below, the fastening of which can weaken from knocking on the rafters from above.

Then they proceed to the installation of the vapor barrier on the rough ceiling, which is carried out according to the same rules: using a stapler with staples across the ceiling boards, with the volume side of Isospan-B towards the room, with a vapor barrier of 10-15 cm inlet.

At the end of the vapor barrier, the base is finished with siding.

We recommend visiting the website of the wholesale and retail sale of the company's sawn timber https://www.realwood.ru/. Larch, pine, spruce. Quality products.

General principles of application

The film is laid from bottom to top with the overlap of the strips one on top of the other 10-15 cm. The joints of the strips are glued with Izospan KL, KL + tapes. Izospan B is always mounted with the smooth side to the insulation. The contact points of the sheets and battens of the crate, the counter battens of the air gap are sealed with a special sealing tape. The tape is pressed with the self-adhesive side simultaneously against Izospan B and the abutment surfaces.

Docking areas with windows, niches and openings for utilities (ventilation, sewerage, water supply) are sealed with Izospan ML proff tape. The same tape is used to finish joints with concrete and wooden structural elements.

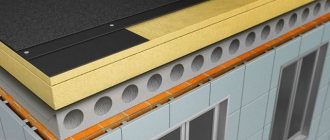

Installation of isospan when installing a covering under the roof

This situation differs from the previous one in that the external environment with all accompanying factors - wind, rain, snow, etc. is located above the cover. In addition, when choosing the type of isospan in this case, one should also take into account the roof structure, which can be flat or with a slope.

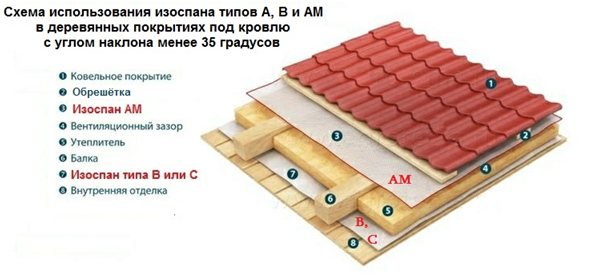

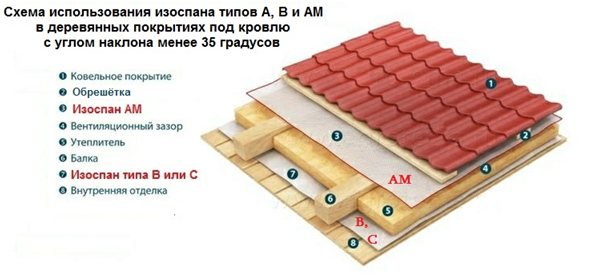

Steam protection of a wooden ceiling for a roof with a slope

Across the roof rafters, wooden slats with a cross section of approximately 3x6 cm with a step of 0.5 m are stuffed from below, on which a soft insulation is laid on top. On top of the insulation, an additional crate of slats is arranged in order to lay a vapor barrier made of Isospan-A on it. Izospan A-class is designed to protect insulation and roof structures from wind, snow and rain, but its smooth surface is not laminated, as it is intended for use on roofs with a slope of more than 35 degrees, in which water droplets roll down. Additional lathing is performed to ensure this slope angle, so that such a film does not sag over time and does not let water through it into the insulation.

Isospan-A is laid on the crate and is attached to it according to the method described above. Further along the rafters, counter-rails are sewn, on top of which the lathing for the outer roofing is mounted.

On the inner side of the coating, the Isospan-V vapor barrier is spread on the cross-sectional slats of 3x6 cm and fastened with a stapler, on top of which the internal siding trim is mounted in a direction perpendicular to the location of the bars.

Thus, the soft insulation turns out to be insulated on both sides by different types of isospan with the implementation of a double-sided ventilation gap:

- Izospan-A protects insulation and structures from wind, under-roof condensation, rain and snow, without preventing moisture from escaping from the insulation and construction materials in the opposite direction;

- Izospan-V insulates soft thermal insulation from moisture contained in the room air.

Steam protection of a wooden ceiling for a flat roof

The design of the vapor barrier on the ceilings of such a roof structure is somewhat different from the vapor barrier of the previous type of coating. Since the smooth surface of isospan-AM has lamination, its strength and waterproofing characteristics are much higher than the vapor barrier of type A, therefore, the AM vapor barrier can be used with a roof slope of less than 35 degrees and even on flat substrates. At the same time, there is no need for an additional lathing device over the insulation - the strength of Isospan-AM itself is sufficient, but for this it must be properly laid, fastened and docked.

The choice of materials for creating a vapor barrier layer

The main property of a vapor barrier material that you should pay attention to when choosing is the ability to pass a minimum of steam. This criterion is calculated by the amount of steam that passes through 1 m 2 per day. Some materials have an index of 3-5 g / m 2, but most of them are characterized by a vapor permeability of less than one.To know how to choose a vapor barrier for the ceiling in your case, you need to study the possible options.

The first vapor barrier material was glassine, its vapor permeability was 80 g / m 2. However, modern insulation in some cases has an indicator of about 0.02 g / m 2. The appearance of the materials used as surface insulation from steam and atmospheric moisture is practically the same. Therefore, it is very important when choosing to carefully study the information indicated by the manufacturer. Otherwise, you can purchase not a vapor barrier, but a waterproofing material, the use of which will lead to damage and the mandatory replacement of the thermal insulation layer.

To protect the ceiling, it is recommended to use the following types of vapor barrier for the ceiling:

- A vapor barrier polymer membrane refers to roll materials, one side of which is completely smooth, the other is rough. The roughened side should be directed downward during stacking so that a minimum amount of fumes can penetrate the cake. The presence of roughness prevents the accumulation of condensation on the surface.

- Film polypropylene and polyethylene materials can be reinforced and unreinforced. This type of insulation requires the mandatory creation of a ventilation gap between the vapor barrier and insulation. Ceiling vapor barrier foil is used for limited construction budgets and can be installed on both sides.

- The foil-coated membrane on the ceiling is recommended for use to create a barrier to the path of moist warm air, as well as to reflect heat rays and their return to the room. In both cases, the installation is performed with foil towards the steam and the flow of warm air.

In most cases, vapor barrier materials have accompanying documentation, which, along with technical and operational characteristics, describes which side to fasten the vapor barrier to the ceiling, and the fastening technology itself. To avoid unpleasant moments during operation, when choosing a material, you should pay attention to the possibility of direct contact between the vapor barrier and insulation.

Formation of rolls of vapor barrier polymer film is performed in accordance with how the material will be rolled to create a vapor barrier layer. There is a recommended overlap mark along the long edge of the strip so that the insulating carpet on building structures is solid.

The direction of the strips of insulating material does not play a special role, the roll can be rolled out along or across the ceiling. The main condition is the creation of an overlap and strong fastening of the strips into a solid canvas using adhesive tape.

Particular attention must be paid to the exit points of chimneys and various communication risers. When deciding how to fix the vapor barrier to the ceiling, it is important to ensure the complete tightness of the vapor barrier layer. To do this, the material is cut, and the edges are glued to the structural elements with adhesive tape and additionally fixed with a rail.

It is recommended to choose the gluing materials and vapor barrier from the same manufacturer. Otherwise, complete tightness cannot be guaranteed at the bonding points. Due to the characteristics that each manufacturer endows its products with, material deformation and even its destruction can occur.

Among the large number of manufacturers of rolled roofing materials, the TechnoNikol company should be distinguished. It produces building materials for use in the CIS countries, including polymer vapor barrier membranes, polyethylene and polypropylene films.

Vapor barrier membranes are available in several innovative self-adhesive options, as well as materials that are installed using bitumen mastic or by fusion with a gas burner.

The products of the company are no less popular. Its range of materials ranges from standard vapor barrier films to foil insulation with a layer of insulation and a self-adhesive coating on the back.

although not a monopolist in the building materials market, it occupies the entire niche of vapor barrier films and membranes. Their products are a windproof, vapor-permeable, waterproofing membrane under the Izospan trademark. Series A, B, C, D, E, F, K, etc. are available depending on structure, density and application. Basically, these are two-layer nonwovens, where one side is smooth, the other is fleecy and / or rough.

Using the Izospan B film as an example, we will tell you which side to lay to the insulation, how to lay it correctly and what they are intended for in general.

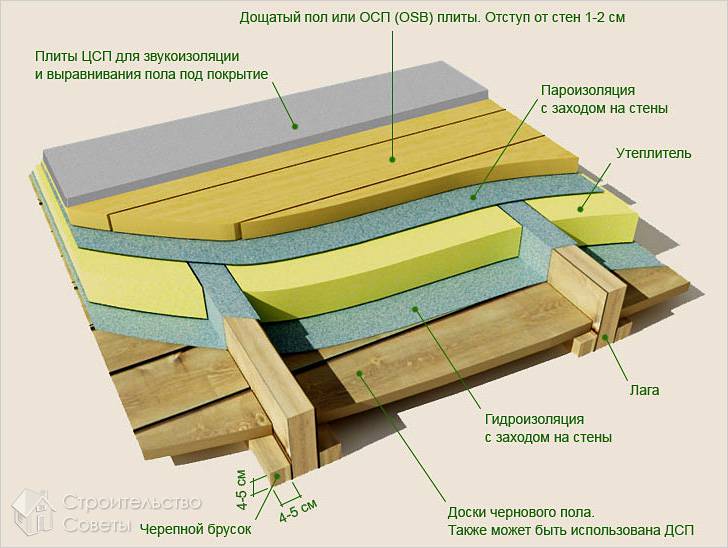

Laying material on the floor

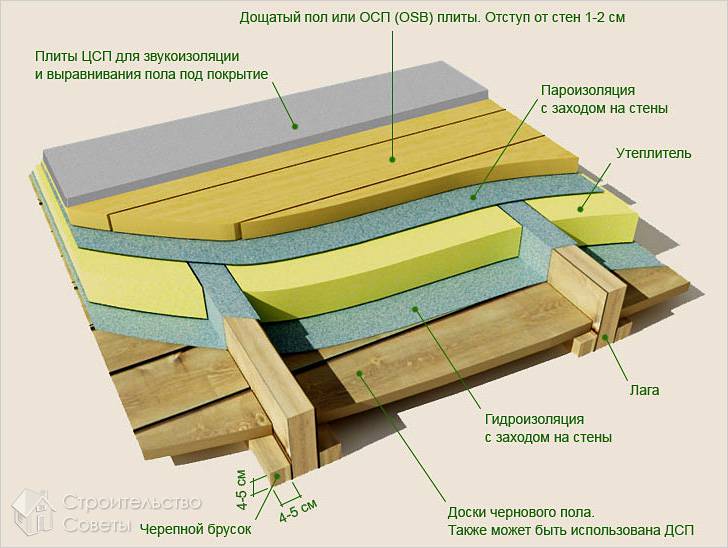

By performing a vapor barrier in the house, you can avoid the accumulation of condensation underground, preventing the growth of mold and mildew on the wooden floor. To understand how to do the job correctly, you must follow the step-by-step instructions.

Preparing the subfloor

Before laying the vapor barrier, it is important to treat wooden blocks and other parts with a special antiseptic material that will protect the floor from rotting and insect infestation. If the vapor barrier is made on a floor that has already served a lot, all materials are removed and debris is removed. Wooden parts are also treated with hot linseed oil or primer and put into place.

Vapor barrier installation process

The initial laying of the material serves as a vapor and waterproofing layer that prevents moisture and vapor from entering the ground. The roll should be spread on a horizontal surface and laid on the floor. The strips of material must be overlapped by 15 cm. The film is fastened to each other using mounting tape; double-sided tape is also suitable. This connection prevents gaps through which moisture can enter. Fastening to the logs is performed with a stapler or nails.

Installation of insulation

Between the lags, insulation can be attached to the vapor barrier layer. Moreover, its thickness should be at least 50 mm. Mineral wool, polystyrene foam or expanded polystyrene mats are the best options. During the installation process, it is important that no gaps form, and the material fits perfectly to the joists.

Laying the second vapor barrier layer

The second layer serves as a barrier for steam that comes out of the room, preventing it from getting to the insulating layer. The material must be laid so that a gap is formed between the vapor barrier layer and the finished floor.

Floor installation (finishing)

Floor boards are laid on the logs. Subsequently, they are covered with a finishing floor covering. It can be laminate, parquet.