What are expansion joints

For laying heating or a water supply network, polypropylene pipes are most often taken. They have proven themselves excellently because they have an impressive number of positive characteristics.

But, with such a number of quality indicators, they have a significant drawback - when exposed to heat, they increase and sag.

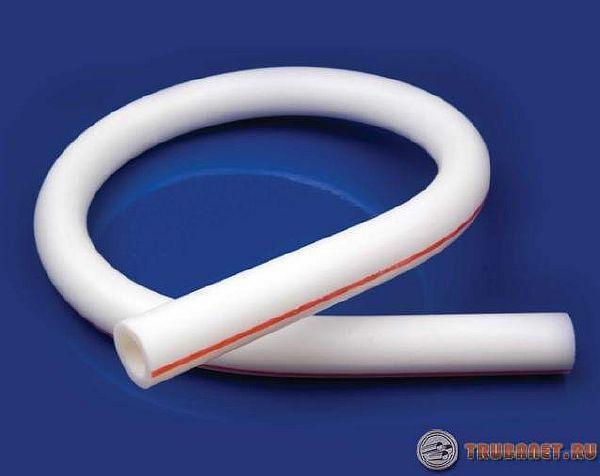

For these reasons, when designing a network with a length of more than 10 meters, flexible expansion joints are installed.

These are simple docking structures that are flexible and visually resemble a loop. But, they play a very important role.

Compensators for laying polypropylene heating networks compensate for the expansion of the pipeline with sharp increases in temperature and pressure.

As a rule, they do not cost much, and the simplicity of the structure makes it possible to easily put the device into the pipeline. This increases the reliability of the network and extends the duration of its use.

What are compensators for?

The operation of heating networks takes place under the influence of temperature differences and changes in pressure inside the system. These conditions are considered hazardous to its functioning. The use of expansion joints solves this problem, smoothing out the influence of negative factors on the activity of pipes. Changes in temperature, pressure cause pipe materials to contract or expand, which leads to deformation and damage to the pipeline. The compensator, as a protection, does not allow the plumbing system to fail.

Possible load volumes should be calculated when developing a design for a heating main and a water supply system. Observing the rules, you can mount elements that can compensate for changes in pipes.

Compensation devices come in different materials, it is necessary to select the appropriate material for this system. The correct decision regarding expansion joints will increase the life of the system without accidents. Compensators, like pipes, come in different materials: steel, plastic.

Attention! Install protective devices in all types of water pipes, laid from any material.

Modern water supply systems are laid mainly of polypropylene material, which is subject to high linear deformation during thermal expansion. Pipes made of this material are always equipped with expansion joints.

Devices mount:

- while laying the plumbing system.

- during the installation of a warm floor.

- in the sewer system.

- in the heating system, in the hot water supply system.

What threatens the expansion of pipes

If you do not take into account the possibility of expansion of pipes during an increase in temperature, then during heating, the elements of the pipeline go to the sides and become not straight, but in the form of waves. This leads to an increase in the level of noise during the flow of liquid.

Deformation of pipes leads to:

- Destruction of the fastening supports.

- In addition, the throughput decreases, because air accumulates in the upper parts of the pipeline.

- To a drop in temperature near heating radiators.

- In areas with bends, cracks appear, which leads to leaks.

Applying the device provides:

- Uninterrupted operation of the system for a long time.

- Maintaining in pipes during its changes.

- Water-shock protection.

- Elimination of deformation during temperature changes.

How big is the need for these devices

Consider the question: "Do I need a compensator for polypropylene pipes" should be from such an angle that experts recommend putting them on a mandatory basis.

And they motivate it with the following reasons:

- Normalized operating pressure in the line throughout the entire period of use.

- Maintaining straightness along the entire length of the network.

- Convenient planning and laying of the pipeline.

- Small size.

IMPORTANT! Experts unanimously say that these adapters are very important. Otherwise, the laid heating pipeline made of PP blanks will not last a long time. Heat deformation will damage it.

Compensator classification

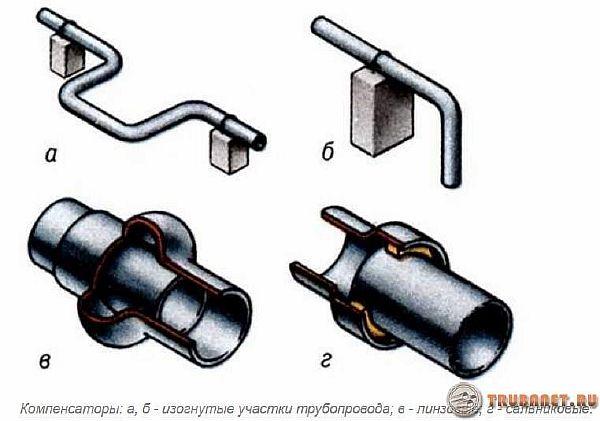

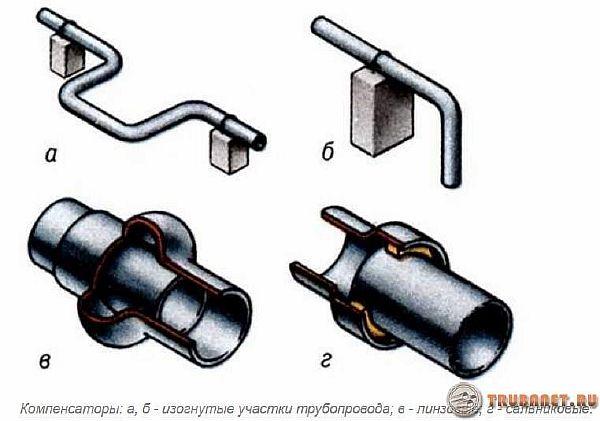

There are several types of expansion joints, let's briefly consider each of them.

- Loop expansion joint for polypropylene pipes

- Snake type compensator

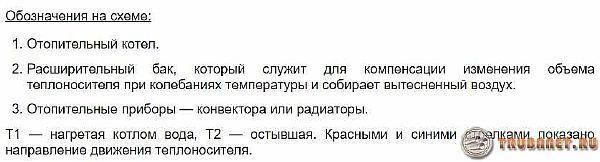

- Axial bellows device (it is marked with the abbreviations arrester or KSO). The first elements are much easier to install, since they are equipped with special guide assemblies. They are a kind of fixed supports, which greatly facilitates installation.

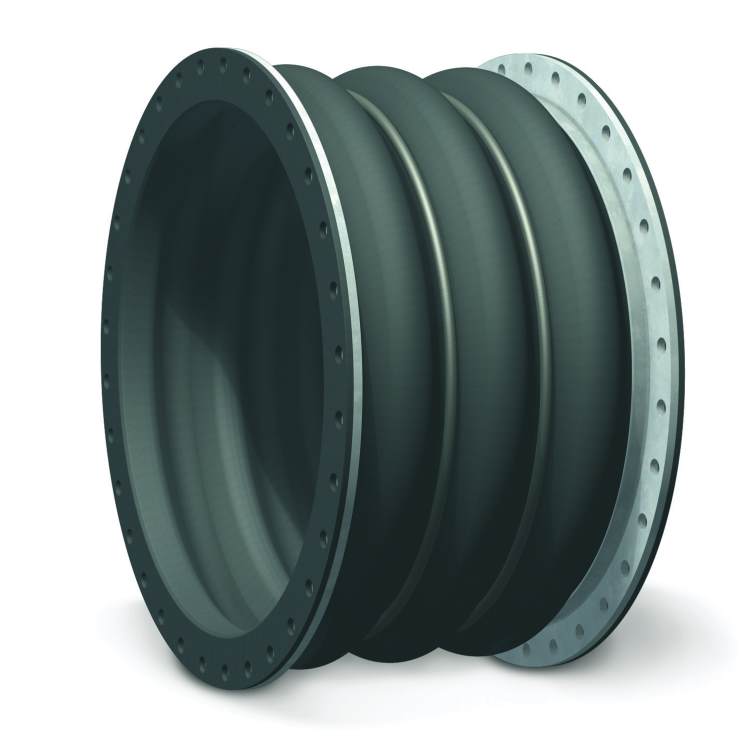

- Flanged bellowsmade of rubber. They are used to dampen the shock wave caused by a sudden increase in pressure in the network and compensate for inaccuracies in the pipeline axis.

- Shear... They differ in that they compensate for movement in 2 areas at once in relation to the main axis. They consist of one or two corrugations made of stainless steel, which are interconnected by means of fastening fittings.

- Universal... As the name suggests, such expansion joints work in all degrees of travel at once - angular, axial and transverse. They are mainly used in small pipelines or where the use of bellows devices is limited for one reason or another.

- Swivel... With the help of these devices, expansion is eliminated where the pipeline turns, and the required angle is fixed. Scope of use - highways in which the direction changes by 90?.

How to choose a device correctly

To find out which compensating element is best installed on polypropylene, you need to understand in detail the device of these devices.

Polypropylene (PP) piping is installed very often. With its help, they equip the supply of hot water, where the temperature rises to almost a hundred degrees. During use, polypropylene has shown a number of characteristics, thanks to which it is ideal for plumbing systems and heating. It is not afraid of the influence of aggressive chemical environment, has a low weight and is quite durable.

But, despite all the advantages, polypropylene also has a significant drawback. As the temperature rises, the linear expansion capacity of polypropylene increases markedly. The system then begins to sag.

For this reason, it is recommended to install flexible expansion joints in areas with a length of more than ten meters. They make it possible to reduce thermal expansion.

To select and install it correctly, you must take into account the diameter. It must match the diameter of the pipeline itself. Most often, the diameter that the expansion element has is from 20 to 40 mm. For a house and apartment, a 20 millimeter device will be enough.

As for the manufacturer, it is better to give preference to well-known world brands. They represent high quality goods for polypropylene nets, which are successfully used in many areas.

Distinctive features of the installation of polypropylene pipes

Polypropylene pipes have a lot of operational advantages, including:

- resistance to aggressive chemical environments;

- insignificant weight;

- excellent strength;

- long service life (according to the manufacturers, the pipes can last half a century without repair work and replacement).

It is also worth noting that the pipes do not bend during installation - special connecting fittings are used to turn the line. Only in this way is a change in the direction of water movement achieved.

To create welds, special welding is used for polypropylene pipes, but, alternatively, the same fittings can be used. The latter, by the way, are sometimes equipped with built-in metal threads, which allows the pipeline to be connected to metal elements.

Note! PP pipes also have a significant minus - thermal expansion (increase in volume / length at high temperatures).

Due to this drawback, pipes can sag. But the situation is corrected with flexible expansion joints (if the length of the line exceeds 10 meters). You can learn about the features of the installation of the described pipes from the video material below.

Video - How the installation of polypropylene pipes is carried out

Thermal expansion can be compensated for by means of special expansion joints. They are an ordinary connecting structure, but they are flexible and visually resemble a wrapped loop. These devices are very important, since when the pressure or temperature in the line rises, they compensate for the thermal expansion.

Such expansion joints are not too expensive (about 300-500 rubles), and thanks to their extremely simple design, they can be easily installed in a water supply system. As a result, the reliability of the system is increased, and its service life is increased.

Video - Expansion joints for polypropylene pipes

Varieties

In practice, the following varieties have shown themselves best:

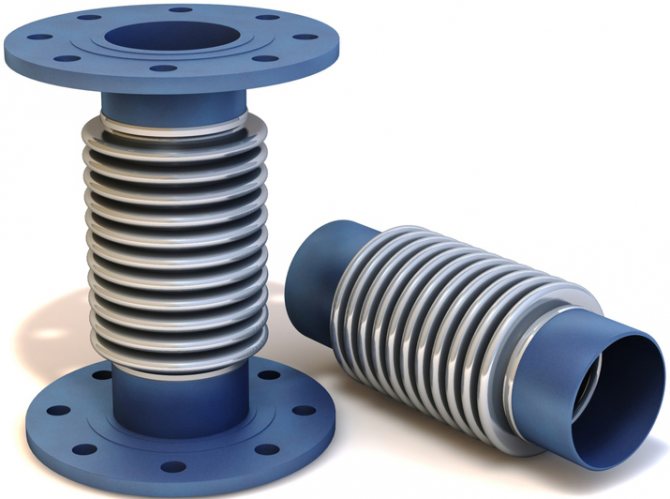

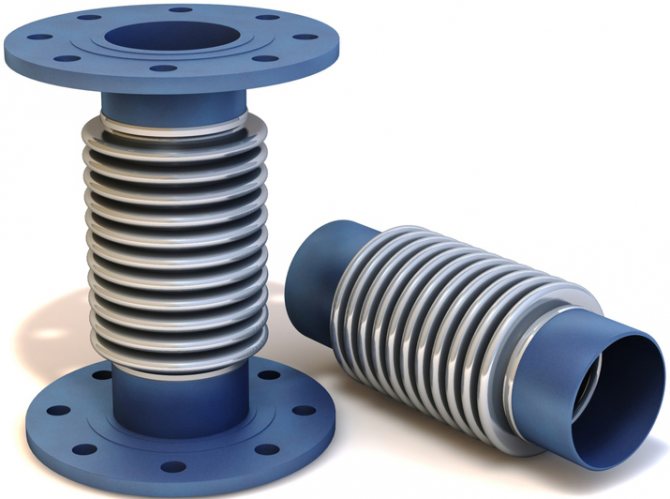

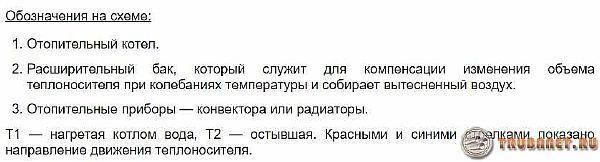

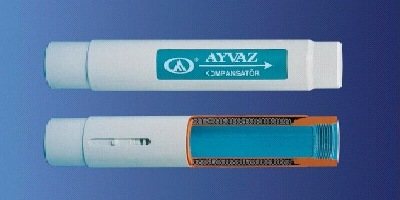

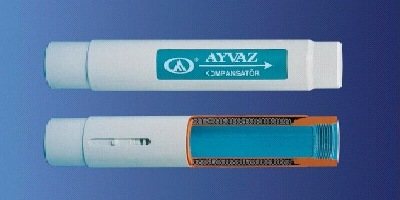

- Bellows expansion joints for polypropylene (PPR). They are used when installing a heating and water supply network made of PPR materials. The conventional diameter of the bellows types is from 1.5 to 5 cm. The type of connection of bellows varieties is a sleeve, and the casing is made of aluminum. The inner screen is made of stainless steel. Working medium temperature up to one hundred and fifteen degrees, pressure up to 16 bar. The working medium for the bellows version is drinking water, air, steam.

- Shear. They are designed to compensate for movement in two directions. Design features in this situation are one or two bellows corrugations. It is made of stainless steel and fastened with fittings-connectors.

- Swivel They are used to level the linear increase in the area of turn of the highway and are used to fix the turn. Most often they are taken to change the direction of the system by ninety degrees.

- Universal. They are endowed with three options for working strokes. They are placed where it is necessary to lay a short network, or in a place limited for installing a bellows type.

- Flanged. These rubber parts are installed in such a place where there is a need to dampen the shock wave from a sharp increase in the average working pressure. They also smooth out the axial inaccuracies of the pipeline.

- Loop-shaped device.

- Serpentines

- Axial bellows mechanisms

- Flanged devices made of soft material

- Bellows

- Versatile, effective for axial, angular and lateral displacement. They are recommended for installation on a small branch of a highway that has branches.

Manufacturers offer a variety of devices that are of excellent quality. But, the self-made compensation loop in the heating system also copes with the functions assigned to it.

It is not difficult to make such a device with your own hands. The compensation loop can be made in a short time.This important detail, fastened correctly, becomes a guarantee of the flawless operation of heating or hot water supply.

Simple self-made equipping with a compensation loop will increase the working resource of communication networks up to half a century.

Varieties of expansion joints

Products are available in different diameters and lengths

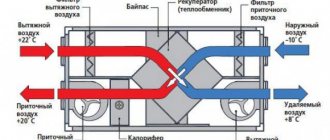

The constructive solution of the compensator determines the purpose of the product and its displacement during operation. Devices without thermal and waterproofing are produced, or preliminary protection is provided on the body, depending on the type of heating main (air or underground).

The manufacturer manufactures types of expansion joints:

- axial;

- flanged;

- angular;

- cardan;

- shear;

- starting.

Unloaded expansion joints are used in heating mains to prevent thrust loads, seismic types are used in areas of suspected earthquakes. External pressure devices are installed in the lines when there is a high pressure of liquid or gas in the environment or a lack of it is felt.

Structures differ in length and diameter, number of bellows and type of steel, size and grade of metal of branch pipes. Products work in rotation, stretching, bending, compression, and are available with or without connecting flanges.

Axial

Axial expansion joint designed for installation in a straight pipe section

KSO expansion joints for pipelines reduce the axial displacement of the pipeline, reduce vibration and prevent destruction from expansion when heated. The efficiency depends on the number of bellows and rings. The difference from other types lies in the threaded connection with the line branch pipes.

Axial expansion joints differ in characteristics:

- through passage size 15 - 100 mm;

- withstands a pressure of 16 bar;

- lengthwise size - 260 mm;

- permits movement along the axis for compression up to 30 mm, for expansion - 20 mm;

- axial stiffness parameter - 30 - 89 kg / mm.

The movement limiter and the branch pipe are made of galvanized metal, the bellows and the inner screen are made of stainless steel. For the protective case, steel is used, the device is produced in one section and is designed for the temperature of the energy carrier up to + 90 ° C.

Flanged

Flanged rubber expansion joint

The bellows of this type is made of rubber or rubber, for the flanges the raw material is heat-resistant metal, and the cord is made of durable fabric. Flange mounting greatly simplifies the installation of products. Compensators are used in a chemically active environment, they are used in heat supply and air conditioning, they are installed during the reconstruction and repair of boiler equipment.

Flanged structures reduce vibration, reduce temperature shifts along the length, compensate for the deviation from the central axis of the pipeline.

Main settings:

- nominal diameter - 32 - 800 mm;

- withstand the temperature of the energy carrier -10 - + 135 ° С;

- work with a pressure of 16 bar.

Flanges are free and solid in structure; they are attached to pipe elements with pins, bolts using washers and nuts. Paronite gaskets are used, sometimes steel ones, made of thermally expanding granite or fluoroplastic, are used.

Angular

Corner expansion joint

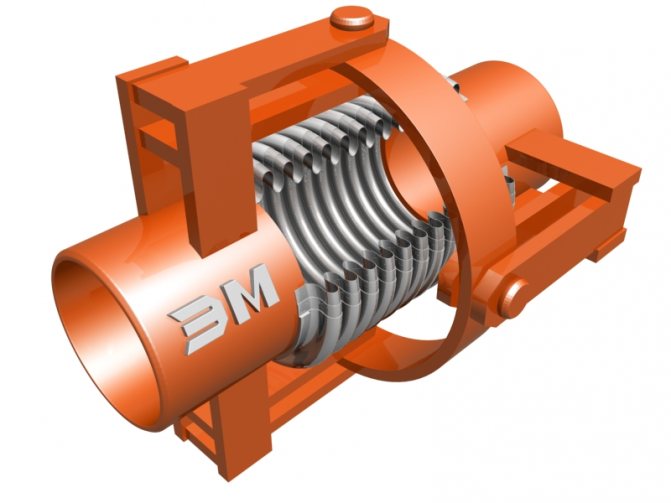

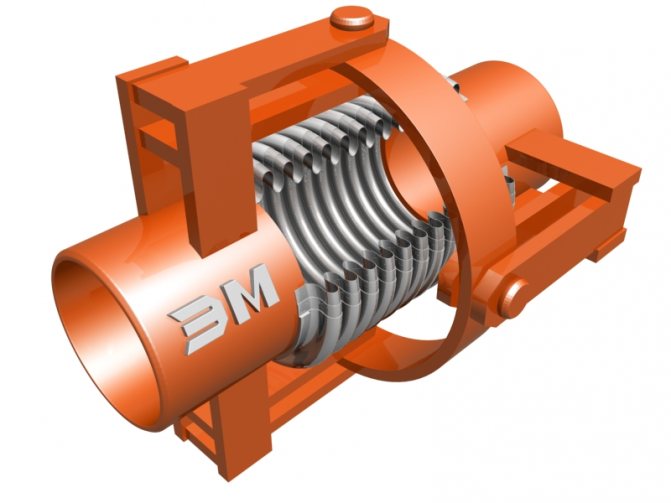

The KSP (rotary) is placed in the case of limited space, when it is possible to compensate only for the shift along the axis and rotation of the contour without changing the plane. Contains a bellows, a guide element and fasteners. The device provides for the shift of the pipe along the selected angle, for this there are hinged or gimbal stops.

Characteristics of rotary (angle) expansion joints:

- nominal through diameter - 15 - 1600 mm;

- maximum head - 1.6 - 4 MPa;

- movement along the axis - 24 - 200 mm;

- shield and protective box made of steel;

- bellows material - stainless steel;

- available with one or two sections;

- works with an energy carrier heated to +85 - + 150 ° С.

Corner structures are used as part of a heating main and for pumping oil, gas, and are used in the chemical industry.

Gimbal

Cardan expansion joint

Bellows expansion joints of pipelines balance the movement of the contour in different planes, thanks to the hinge elements, they are bent in the direction of the central axis. The displacement of the line is compensated for along the X, Y, Z axes and in terms of rotation due to shrinkage, vibration. Flexible design allows for deformation in rigid contours.

Specifications:

- designed, calculated and manufactured in accordance with the EJMA standard;

- contain in the structure 2 bellows with cardan-type hinges;

- sideways displaced by a multiple of 100 mm (100, 200, 300, 400), other displacement sizes must be ordered separately;

- nominal through diameter - 25 - 1000 mm;

- works with energy carrier temperatures -190 - + 850 ° С.

The bellows is made of stainless steel, connectors, pipes are made of chrome-plated steel. It is placed in the design position by welding or using a swivel flange. Used in any piping system.

Shear

Shear expansion joints

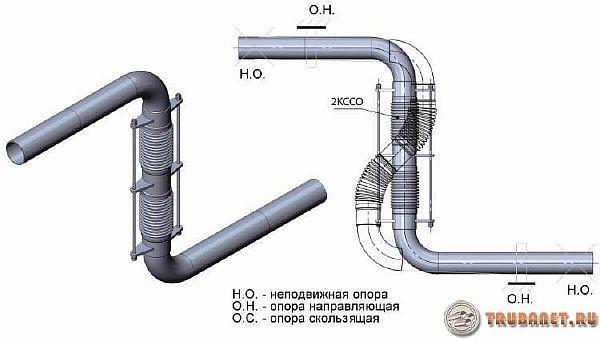

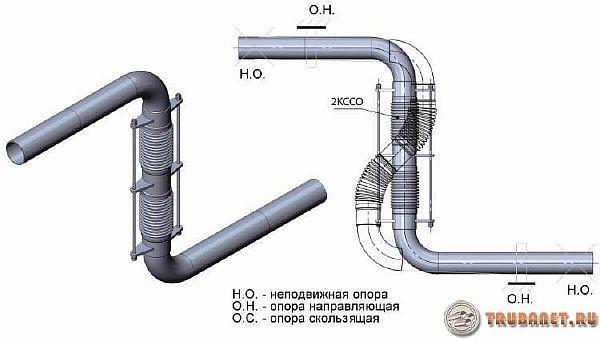

KSSO compensators balance the shift due to longitudinal compression or lengthening of the contour under the influence of temperature, eliminate the consequences of misalignment. The design includes a corrugated capsule, a guide piece and fasteners. Longitudinal displacement is coordinated by means of guide pins.

Parameters of shear compensating devices:

- nominal diameter of the passage - 32 - 500 mm;

- maximum head 0.6 - 4 MPa;

- bellows, ties and branch pipe are made of stainless steel;

- the material of the protective screen is chosen by the customer;

- withstands the temperature of the energy carrier up to + 850 ° С.

Sliding devices are made in one and two sections, they are used to compensate for the stress in pipelines of oil, water, steam, gas. They are used in various industrial sectors and in energy complexes.

Starting

The start expansion joint is applied once when starting the hot water system

The SCK compensator is used temporarily as a disposable device when starting the heating main or hot water pipeline.

Technical specifications:

- nominal diameter DN nominal - 50 - 100 mm;

- shift along the central axis - 80 - 175 mm;

- device rigidity at the level of 430 - 2300 N / mm;

- transports water with temperatures up to + 150 ° С, steam - 250 ° С;

- allows the speed of water flow up to 5 m / s, steam - 65 m / s;

- the normalized pressure when starting the line should not exceed 1.5 MPa.

The starting expansion joint is used when laying the contour using the channelless method. The material of the body, pipes and bellows is selected by the customer.

Which option is better to install on polypropylene

When tested in practice, all of the listed devices give the expected result. T-shaped devices, bellows, and others show high efficiency. This manifests itself in the same way in all water supply and heating systems.

Technical analysis confirms that expansion joints on polypropylene heating pipes work flawlessly, only they are recommended for use in flexible polypropylene structures.

Before installing the expansion joint on a polypropylene pipe, the following calculation must be made. It is necessary to calculate the load, pressure and compare the diagrams of each wiring and heating risers.

At the same time, it will be clear where it is necessary to put additional nodes - compensating devices. When calculating expansion joints for PP mains, it is necessary to take into account many indicators, including the cross-section of the pipe assortment, the diameter inside and outside, the types of bends, heating risers, and the type of installed and already standing mechanisms.

Purpose of compensators

The simplest expansion joint can be represented by a flexible polyethylene pipe that can form a loop.

Such a compensator is able not only to protect the pipe from destruction during thermal expansion, but to evenly distribute the load when the internal pressure rises. Hence follows the main purpose of expansion joints, which is to increase the service life of the materials of the main lines, as well as in the effective functioning of the entire system.

Many people mistakenly believe that it is necessary to use compensators only when installing communication networks for a private house. In fact, they are widely used in apartment buildings, manufacturing plants, and also in public places. In all these cases, their purpose is represented by five main tasks to be solved:

- increasing the operational life of the line;

- vortex flow prevention;

- ensuring the integrity and tightness of the system;

- distribution of internal pressure;

- suppression of the consequences of thermal expansion of materials.

Mounting features

The main methods of fastening in this case are:

- welded;

- flanged.

In order to correctly mount the compensation device, you need to know that most types of these devices require rigid fixation using welding.

Before installing an expansion joint for polypropylene heating pipes, it is necessary to check the coincidence of the diameter of the pipe product and the element to be installed. This is the only way to make a heating structure with high tightness.

It is better to assign the installation of a flange joint to professional craftsmen. For such a joint, the installation of a counter flange will be required. This allows you to create a split joint, which is very convenient when carrying out repair work on the heating or water supply pipeline.

The bellows mechanism is placed on a linear short section of the line, and works great for a room where temperature drops of the coolant often occur.

Important! Before starting installation work, it is recommended to check the installed part for damage. If any are found, this device cannot be installed.

What is a compensator for?

The compensator is a polypropylene element for connecting pipes. This is a piece of pipe bent in several ways, which allows the assembly of pipelines of any configuration. L- and U-shaped parts, compensators in the form of a loop and a snake are produced. Fittings for installation are sometimes included in the kit. Manufactured from static polypropylene by injection molding.

It is needed so that the pipes in the communications are not deformed, and serves to compensate for expansion during temperature extremes.

Polypropylene tends to expand when exposed to high temperatures or pressures. The task of the expansion joint is to prevent expansion and sagging of the pipes. It takes on the deformation load, prevents pipes from sagging and breaking the tightness of the networks. This is due to its design and the cushioning properties of the material.

How the calculation is performed

The calculation of expansion joints for polypropylene pipes is not difficult to perform, but in such a situation you will need to understand the principle of their operation and know their varieties.

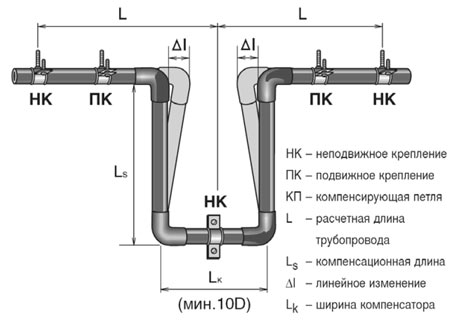

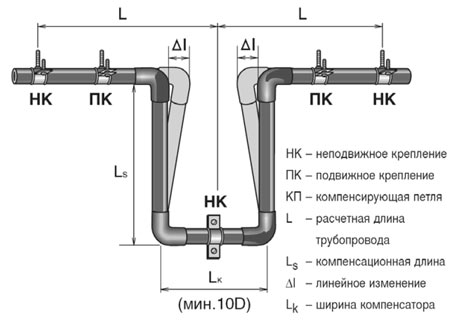

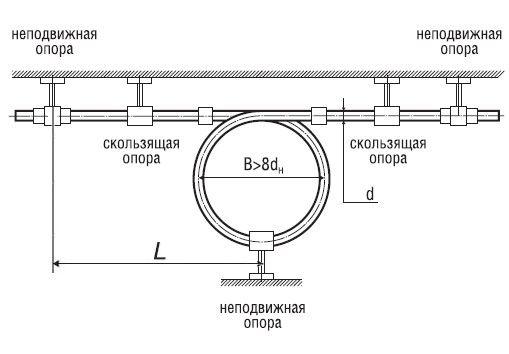

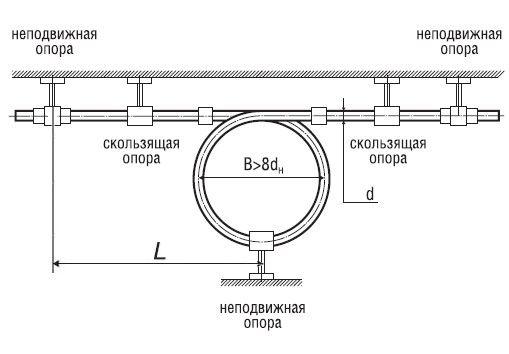

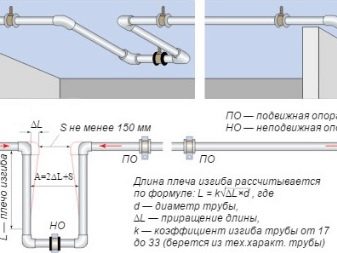

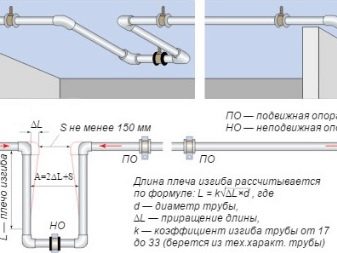

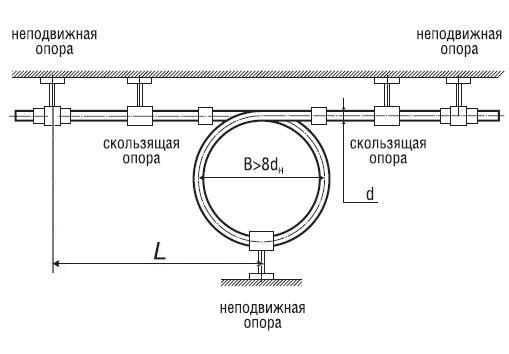

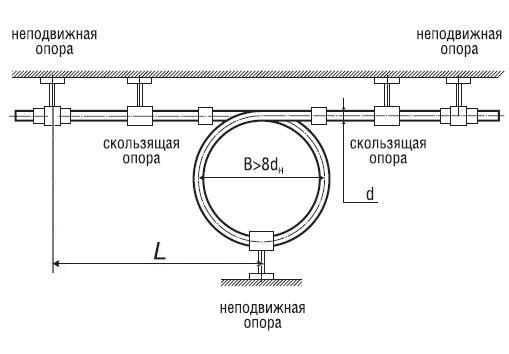

There are certain norms according to which the calculation of sliding, fixed mountings is carried out. In any area between the fixed supports, one such mechanism (at least) must be inserted.

To determine their exact number, it is recommended to draw an exact plan of the pipeline and mark all fixed fixtures. It is so easy to calculate the required amount for each section of the highway.

When calculating, use the following formula: Q = L / ΔLk.In it, the first indicator is the required number of compensating elements, L is the length of the section. ΔLk is the value of the compensating possibilities, it is expressed in millimeters.

Detailed information for the calculation can be obtained from the manufacturers of pipe-rolling assortment.

Installation: calculations and requirements

Before installing the expansion joint into the system, draw a line diagram. Indicate all bends, pipe diameter and length, wall thickness, presence of previously installed expansion joints, places of bends and branches, connected devices. It is necessary to put on the diagram the values of the distances between pipes of different types (for example, flexible and rigid), supports.

Mark the locations of the fixed mountings. If the support will be located next to the expansion joint, then you need to fix it well. The distance between two expansion joints of different types should not be less than 3 meters.

It is mounted on a straight section, with the exception of rotary expansion joints designed to maintain the angle of rotation of the line.

Important! Only one bellows expansion joint can be installed between two fixed mountings.

There is a formula for calculating the number of expansion joints: Q = L / ΔLk. According to the formula, Q is the number of expansion joints, L is the length of the segment, ΔLk - denotes the compensating capabilities of the part and is calculated in millimeters.

Data on the value of the latter indicator can be obtained by purchasing a compensator.

When determining which expansion joints to choose for PP pipes, take into account information about the coolant and its temperature, pressure inside the system, and the direction of movement of the coolant or water.

Find out if the trunk is exposed to external loads, what is the nature of the connection of the trunk elements. Before installation, make sure it is intact and free from defects.

How to calculate the right size

The dimensions of the expansion joint for polypropylene pipes can be calculated based on an example. For example, a blank is taken, which has a size of 90 mm.

It will expand by 4.2 cm and contract by 2.1 cm. Accounting is carried out for the largest increase, ΔL / 2 = 21 mm.

It is necessary to draw a horizontal line from the vertical section to the intersection with the gradient line of 9 cm of the workpiece. Then it is necessary to lower the perpendicular from the intersection to a horizontally placed scale.

The resulting value will show the knee free size for the loop mechanism. Based on this, the compensator 12 cm long and 6 cm wide will allow free movement with an amplitude of 2.1 cm. Therefore, the product will be able to freely contract and expand.

It is recommended to calculate the distance between expansion joints during the laying of polypropylene pipes with a margin.

At the same time, it is necessary to calculate that this distance must be selected based on the fact that the reinforced product expands by 1 mm for each running meter, and not reinforced by 3 mm.

The exact elongation values for each product depend on temperature changes, volume and grade, as well as the manufacturer. They must be checked on the manufacturers' websites.

П - shaped elements

High-parameter steam lines are designed in such a way that thermal deformation is leveled out due to the natural configuration of the pipeline.

In places where this cannot be achieved, U-shaped elements are placed. They come in three options, which are distinguished by the ratio of the shoulder length and straight inserts.

A U-shaped compensator for polypropylene pipes, just like analogues of another type, needs to calculate the dimensions necessary to compensate for the thermal change in the line.

For precise definitions, you can use the proposed online forms. It is very convenient to perform all calculations on them.

The calculation of the u-shaped compensator for polypropylene pipes is made taking into account the following recommendations:

- I advise you to take the highest stress level in the backs in the range from 80 to 110 MPa.

- The optimal ratio of the overhang of the element to the outer volume of the workpiece should be taken as follows - Н / Dн = (10-40). With this calculation, an element overhang of 10 DN corresponds to a pipe line DN 350. And an overhang of 40 DN corresponds to a line of DN 15.

- The optimal indicator of the width of the p-shaped joint for its overhang is advised to be taken within L / H = (1-1.5).

- If a very large version is required for installation, then it can be replaced with two smaller structures.

- When calculating the thermal increase in the line, the temperature of the heat carrier is taken into account the highest, and the environment - the lowest.

When performing calculations of the u-shaped form, it is necessary to take into account the following parameters:

- The pipe is filled with liquid or vapor.

- What material is the pipe made of (metal, plastic).

- The highest ambient temperature is not more than 200 degrees Celsius.

- The network pressure must not exceed 16 bar.

- The structure stands on a horizontal highway.

- The joint is symmetrical and the shoulders are the same size.

- Immovable supports must be very rigid.

- The line is not exposed to wind and other load influences.

- Friction resistance of movable supports during deformation is not taken into account.

- The bends are smooth.

It is recommended to put U-shaped mechanisms on straight extended zones.

Watch the video

The absence of U-shaped devices on a rigidly reinforced line with different temperatures of the medium leads to stresses that lead to deformation and destroy the pipeline.

Kozlov mechanism

Kozlov's compensator for polypropylene pipes is an excellent option for heating and plumbing.

Watch the video

This mechanism is intended for leveling the thermal increase of reinforced and non-reinforced PP pipe-rolling materials in the hot water supply and heating system.

Kozlov's design works exactly like other similar devices. But, at the same time, it has some design differences.

The Kozlov connection takes up little space and has a presentable appearance. It fits harmoniously into the system.

Some technical indicators of this mechanism:

- The ability to compensate for the compression of a polypropylene article of 2 cm for a volume of 2.5 cm and 2.5 cm for a volume of 3.2.

- Working pressure level - 16 atm.

- The highest operating temperature is 100 degrees.

Installation on risers

Before installing these parts on plastic risers, and straight sections of the highway, you need to process the technical units with asbestos cloth. So the structure will be protected from metal splashes.

Only one technical unit is allowed to be placed between two fixed fasteners.

Putting this device on a riser or a straight section, you need to check the coincidence of the fastened elements. The threaded version of the device on polypropylene systems does not guarantee high strength, therefore, welding is recommended.

Also in great demand is such a device as the "American". This detachable fitting has a metal thread on one side and a polypropylene base on the other.

How such structures are installed

Video

Installation and installation of expansion joints on polypropylene pipes must be carried out in accordance with the main requirements and standards:

- Before the start of the welding activities, the craftsmen wrap the technical units with asbestos cloth. This is done to prevent splashes of metal.

- Installation may only be carried out in a direct network area.

- Between two immovable fasteners, only one technical unit is allowed.

- Before carrying out work, it is necessary to check whether the technical parameters of the element match the data of the pipe network.

- And most importantly, this connection must be inspected for defects and damage before installation. In the event of any defect found, such a product cannot be taken into work.

Installation will depend on the type of product you choose. The threaded method in operations with polypropylene products does not provide the required high strength.

To achieve this strength, welding works are used. They are considered to be the most efficient and reliable fastener. A welding machine is used for them.

Watch the video

IMPORTANT! Such type as "American" is very popular during installation. The essence of this method is to use a detachable fitting. It has a metal thread from one entrance, and from the return entrance it was equipped with a PPR base.

If the installation is carried out in a combined way, then the joint is performed using welding on one side, and on the other - a threaded type of joint.

The installation of expansion joints on polypropylene pipes has some peculiarities. Professional craftsmen will highlight several types of fastening.

- Welded.

- Flanged.

During welding operations, the structure is fixed “tightly”. During installation, the end of the workpiece is soldered with a compensation. For high tightness, the seams during operation must completely match.

In the case of flanged fasteners, the part is fixed not on the pipe, but on the counter flange. Thanks to this, a split joint is obtained, which makes it easy to change the required technical unit in the event of a leak.

Video

Such installation can only be performed by highly qualified specialists, because it is rather difficult to work with.

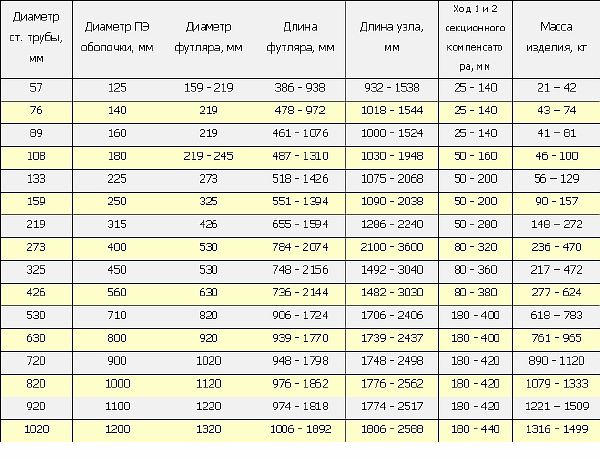

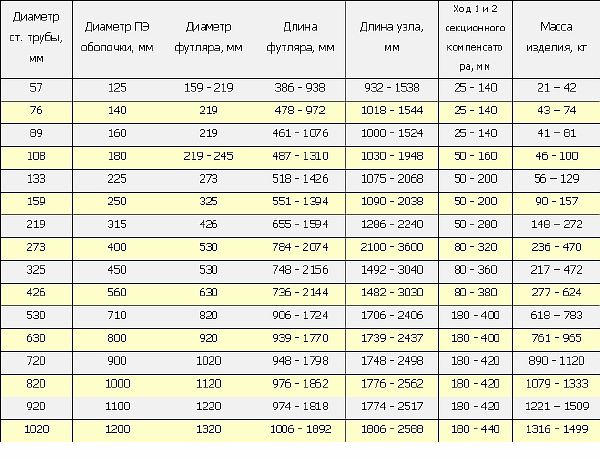

Tables used for compensating devices

The table for installing compensating mechanisms on polypropylene pipes for each type of device is different. For example, for a loop-shaped device, it is like this:

And then you can see the table that is used for bellows devices.

The calculated length of compensation is taken as a distance at which there are no suspensions and supports that impede compensatory movement. The spacing between the supports is set in accordance with the ambient temperature and the pipe diameter.

If difficulties arise in the calculation, and an inexperienced master will have them most quickly, then it is better to ask for help from professionals. An experienced craftsman can provide assistance not only in choosing the right one for a particular situation, but can also quickly install the device. The finances spent on his services will guarantee the reliable operation of the heating system in the house.

Their purpose

The role of compensating devices in polypropylene heating pipes is enormous. Many people mistakenly believe that this detail is not so important. But, this opinion is fundamentally wrong. If the line constantly shrinks or lengthens freely, then additional stress arises in its walls.

Consequently, thermal expansion poses a serious threat to the integrity of the entire structure. As a result of its action, the service life of the polypropylene (PP) pipeline is significantly reduced. If you do not provide for any measures to smooth out the ramp, then the line will quickly fail. What an economical owner will never allow.

Self-compensation and compensation through the use of an elastic element can be distinguished from the methods of combating the effect of change from temperature influence. Additional countermeasures include installing the required number of supports to eliminate sagging.

Polypropylene, due to its flexibility, allows for protective compensation. The most effective is the compensation option, when the bend of the highways is performed perpendicular to the direction of the route. In this direction, a free compensation length is left, which prevents additional stress and pressure build-up.

Separately, it is necessary to dwell on the importance of deformation smoothing. This method is based on the use of the cushioning capabilities of the material itself, this includes all types of polypropylene: PP, PPRC and others. Deformation smoothing by means of compensating parts has become widespread due to its low cost.

These parts take on the mechanical load, and at the same time the section of the line and the fasteners are unloaded. After the influencing factors cease to act, due to the elasticity of the compensating mechanism, the network returns to its original state.

Summing up, we can conclude that which of the options to choose: simple in the form of a loop, Kozlov's device, or bellows, everyone will make a decision independently. But, one thing is clear for sure, you cannot do without this device.

Any economical owner who cares about the comfort of his home will make his choice in favor of the presence of these mechanisms. This simple and inexpensive device will save a lot of money in the future, which will have to be spent on replacing a broken line.

Types of expansion joints for polyethylene pipes

Practice shows that several types of expansion joints can most effectively secure a polyethylene system. They are also top-ranked in the building materials and equipment market. As a general information, we note that in addition to the above loop, there are also expansion joints - coils, bellows axial expansion joints, pipe and flange-type devices, shear and rotary products.

All of them differ in the principle of the internal structure and in the method of installation. Even by the name, it is easy to determine in which specific cases you need to use this or that device. If swivel expansion joints are installed on line nodes, then the bellows axial expansion joint is mounted in a straight section.

Installation technology

Expansion joints can be installed using flanged and welded connections. When using welding, the elements are fixed in such a way that it is not possible to break the connection without using cutting. The advantage of this method is an absolutely tight seam, and the disadvantages include the impossibility of quickly removing the part in case of accidents or repairs. To make a welded connection, use a special soldering iron designed for polypropylene pipes.

Before starting the installation, that part of the compensator that will enter the polypropylene pipe must be thoroughly cleaned of burrs. The thermostat of the soldering iron should be set to 260 degrees, and after the heating indicator goes out, you can start welding. The connection process is as follows: the end of the pipe and the end part of the compensator are heated with a soldering iron until the polypropylene begins to melt, after which the parts are tightly connected and held in this position for some time.

During the setting and solidification of polypropylene, it is forbidden to adjust and rotate the connected elements. Rigid fixation and ensuring the immobility of the joint until the moment of complete solidification of the material is of decisive importance.

The flanged method is more common. It forms detachable joints and differs in the method of attaching the expansion joint to the pipeline. When using this technology, not the pipe surface itself is used as an attachment, but the end of the counter flange. This provides a stronger and more rigid connection and minimizes the chance of leaks. The advantage of this type of fastening is the ability to quickly open the pipeline system in the event of an emergency. The disadvantages include the complexity of installation and the need to contact specialists.

Before installing the expansion joints, you need to make sure that the connector and the pipe are compatible, and also check the parts for mechanical damage and marriage. Cover assemblies with asbestos cloth before performing work. This will prevent hot splashes from entering the outer part of the pipeline and the compensator and retain their original appearance. When carrying out installation work, remember that only one connector should be placed between two adjacent fixed supports.

The installation of corner models deserves special attention. When installing them, the pipeline must be well secured. To secure the structure, it is recommended to use a sliding and fixed type of supports. Moreover, the support located directly next to the expansion joint must be securely fixed with a clamp and rubber gaskets. The installation of angle expansion joints requires a calculation of the possible expansion of both the main pipe and its perpendicular branches.

After carrying out the calculations, the results of the calculations are applied to the drawing. When drawing up a diagram, it is necessary to take into account the differences in cross-sections not only of the pipes to be connected, but also of all elements of the pipeline. Based on the results of the calculations, you should determine the power of the models and choose the method of their installation.

Polypropylene expansion joints are important elements of heating and hot water systems. They help to form a stable and not prone to deformation of the pipeline and significantly increase the service life of trunk networks.

In the next video, you will find an overview of the Kozlov expansion joint for polypropylene pipes.

Advantages and disadvantages

Feasibility of using polypropylene expansion joints due to a number of indisputable advantages of these elements.

- Consumer availability and low cost allow for little money to form a technically flawless pipeline system that will fully comply with all building codes and regulations.

- Equalization of pressure and isolation of vortex flows within the system help to evenly distribute the load on the inner surface of the pipes and ensure structural integrity.

- Due to their simple design and high quality materials, the expansion joints are characterized by overall reliability and long service life. With proper installation and observance of the operating conditions, the expansion joints can last 50 years or more.

- Full compatibility of expansion joints with all types of polypropylene pipes guarantees absolute tightness and correct functioning of the system.

The disadvantage of expansion joints is their compatibility only with polypropylene pipes. This type of connection is not suitable for installation on metal pipelines.

Device and scope

Polypropylene lines have a number of significant advantages: they are quite resistant to the effects of chemical components, are lightweight and have high strength. With the help of plastic pipes, it is possible to create a system of any configuration, giving the pipeline a vertical or horizontal direction at any angle. The only drawback of the system is the tendency to linear expansion of pipes with an increase in the temperature of the coolant. As a result of prolonged exposure to the hot coolant, the pipes elongate and sag. To prevent this from happening, a special connecting device, called a polypropylene expansion joint, was used on long sections of the pipeline.

The compensator is represented by a loop-shaped design that takes on physical activityarising from the increase in pressure and temperature in the pipes. Expansion joints are made using the injection crimping method, and polypropylene is used as the material.Despite the simplicity of design and budgetary cost, the U-shaped expansion joint is considered an important part of the pipeline: it significantly extends the service life of the pipeline and increases the reliability of the system as a whole.

The element is capable of withstanding a pressure of 10-18 atmospheres and can be installed on any section of a polypropylene pipe, the length of which exceeds 10 meters. The only limitation for using the compensator is the water temperature exceeding 90, and in some models even 100 degrees.

In addition to reducing the consequences of linear expansion, expansion joints guarantee complete tightness of the system. in case of hydraulic shock, they stabilize the working pressure indicators, dampen vortex currents and significantly increase the service life of pipes. The scope of application of expansion joints is quite wide. The connector can be installed in communications that provide water supply to all types of buildings, as well as in heating communications and sewerage systems of premises for any purpose. Installation of the element can be performed on vertical and horizontal pipes, including both flat sections of the main line, and corner joints and branches.

Expansion joint mounting options

Expansion joint made of polypropylene - fastening

Experts distinguish two types of fastening:

- Welded.

- Flanged.

The welded version fixes the described technical element “tightly”. The end of the pipe and the end of the expansion joint are brazed by welding. In order for the seam to be airtight, it is necessary to match the diameters of the two elements, the thickness of their walls, as well as the inner section. Using all these parameters, it is easy to carry out the correct calculation and select the appropriate bellows expansion joint.

The flange method does not fix the expansion joint to the pipe, but to the counter flange. With this method, a detachable connection is provided. In the event of an emergency, this allows the replacement of the described technical units.

Note! It is rather difficult to make such a connection on your own, therefore flange mounting is available only to specialists.

How to choose a compensator?

The performance of the entire system depends on the correct choice of such a device. Therefore, you should heed the following tips:

- Buying a ready-made unit assumes that its design matches the specifics of the pipeline section.

- It is required to measure the diameter of the pipe in order to select an expansion joint that fully meets the specified parameters. The most popular flexible pipes in everyday life are in the range of 20 - 40 mm.

- A flanged expansion joint for polypropylene pipes assumes a hermetic detachable connection, and in case of an emergency breakthrough of the pipeline, the expansion joint can be replaced quite quickly.

- Installation is carried out on a straight section of the heating pipeline, using the type of compensator that is most appropriate. Before installation, check once again whether the diameter of the pipe and the built-in technical unit corresponds.

- The gap between expansion joints of various configurations varies within 3 m.When a welded type joint is used, a loop or bellows assembly is most often used.

The cost of expansion joints of any type is within 500 rubles. Due to the simplicity of design and installation, they are installed independently.