Home / Boiler automation

Back to

Published: 24.05.2019

Reading time: 3 minutes

0

851

Modern scientists, together with engineers, are looking for an increase in the efficiency of heating systems in order to reduce the negative consequences of the environment affecting us. One of the ways to solve this problem is weather-dependent automation capable of controlling heating systems.

This group of devices is able to control fuel consumption in a running unit, taking into account the current weather changes. At the same time, it is possible to predict excessive cooling or excess temperature in the heated room in order to immediately compensate for possible deviations.

It is important to understand that the work carried out by weather-dependent automation is aimed at maintaining the optimal balance between a comfortable microclimate and an economical heating mode.

- 1 Weather-dependent automation device

- 2 How it works

- 3 Advantages and disadvantages

- 4 When weather-compensated automation comes in handy

The device and principle of operation of weather-dependent automation

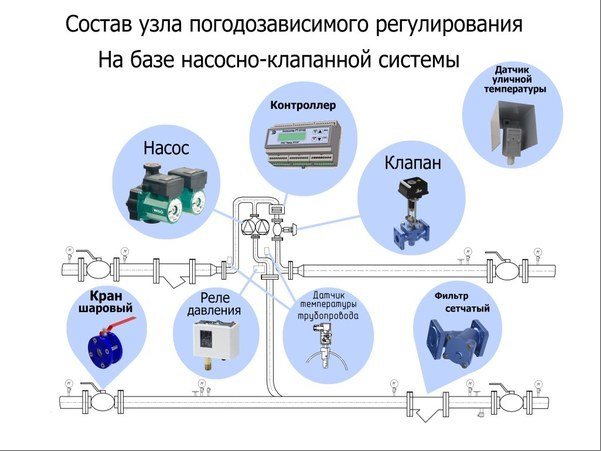

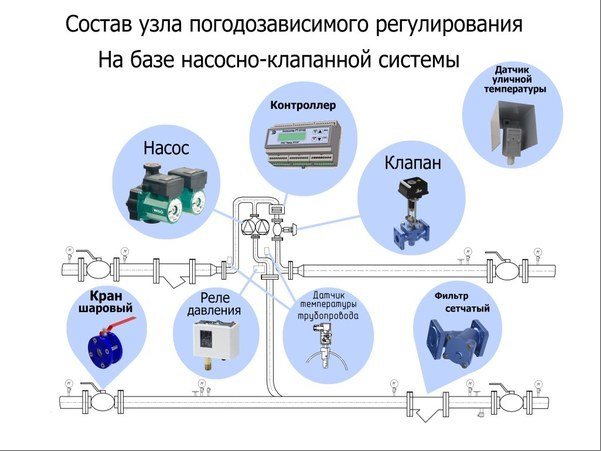

The mechanical part of the heating automation is a pump with a control valve. The equipment is controlled by a computer based on data from 4 temperature sensors that respond to the temperature outside and in the room. The program for intelligent regulation of weather-dependent boiler control is embedded in the controller. The circuit is adjusted according to the operating conditions and the type of room.

Existing regulatory schemes are based on three principles:

- The hydraulic elevator uses return water, mixing with the water heated in the boiler. The device is controlled by a weather-dependent heating regulator, giving a command to move the cone gate according to the readings of the sensors.

- A circuit with a circulation pump and a three-position valve restricts the heated flow and returns the waste heat carrier to the system. The three-way valve is controlled by the processor according to a given program.

- The shut-off valve on the return line is closed by a valve. The device is controlled by the weather-dependent heating system controller according to the temperature sensors.

Weather-dependent automatic sensors for heating systems of an apartment building (MKD) are installed in a living room.

The individual heating station (ITP) is located in the basement, where it is easier to maintain the equipment.

Types of control devices

To ensure control over the temperature regime of the heat generator or consumer, the same device equipped with a temperature sensor is used.

These devices are divided into three categories, which can work either singly or in conjunction:

- Thermostat

... This device is the simplest control device in the heating system. Located in a building, it monitors changes in air temperature. When the required temperature is reached, the thermostat sends a signal to the boiler or the radiator valve, as a result of which the heating of the coolant stops or the supply of liquid to the radiator is blocked. Self-installation of the thermostat is not particularly difficult: just look at the photo, which shows a diagram of its connection and operation, to make sure that this design is simple. - Heating agent temperature regulator

... Such a device can work independently or together with a thermostat. The design works by means of temperature sensors that are installed inside the heating circuit. They constantly monitor changes in temperature in the system and transmit this data to the control module, which controls the mixing valve of the circuit.If an increase in temperature is required, the regulator can perform this task using a valve. - Weather-dependent automation of heating systems

... This type of device can be classified as the most complex, since such a system has to work not only with the heating circuit, but also with the environment, due to which the most accurate and rational temperature control is provided.

The basic design of the weather-dependent automation includes an outdoor thermometer, a thermal circuit regulator and a thermostat located in the room. Despite the high cost, such a system is considered the most in demand, since it is able to provide the maximum comfort that can only be squeezed out of heating. Weather-dependent automation of heating systems uses sophisticated software systems that allow you to ensure maximum efficiency and economy.

Weather-dependent automation can be controlled both from its own remote control and remotely by installing the necessary software on a smartphone or tablet (more details: “

How to choose a remote heating control - characteristics, possibilities

"). In this case, you can regulate the temperature in the house from a distance from it.

Conclusion

Automation for heating boilers is expensive, but immediately after installation, these devices will begin to save fuel, which will affect the economic situation after a while. In addition, it is the automatic temperature control system that ensures maximum comfort in the house.

Types of automatic control systems

When using individual heating, apartment owners often have a problem with temperature control. The manual adjustment method is inaccurate and consumes excessive fuel. The use of automatic weather-compensated regulation of the heating system saves resources and frees up personal time.

Types of automation:

- a thermostat wired to a dependent mechanism;

- wireless control of the heat preservation system depending on the weather.

Functions of control devices:

- keeping the room temperature by the thermostat at a given level;

- programmed setting of the heating level by time of day for up to one week.

Types of devices:

- mechanical thermostat - turns on the electrical network when the ambient temperature changes;

- electronic device - precisely controls heating according to sensor signals;

- electromechanical device - a temperature relay controls the valve drive.

Heating control thermostats can be connected to a pump, boiler or mechanical shut-off actuator.

Operating principle

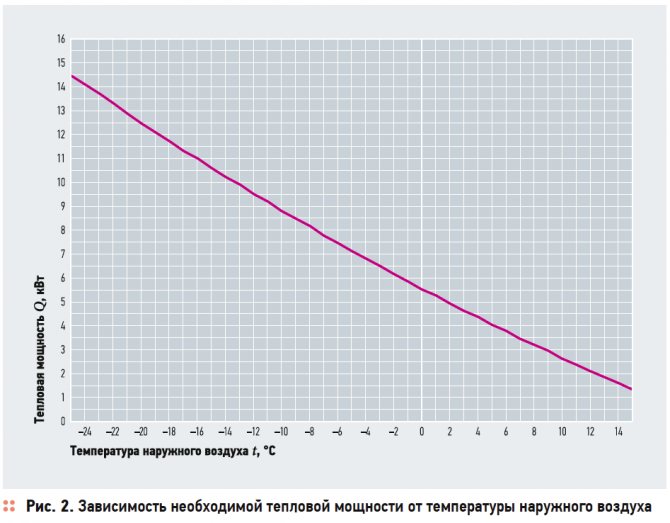

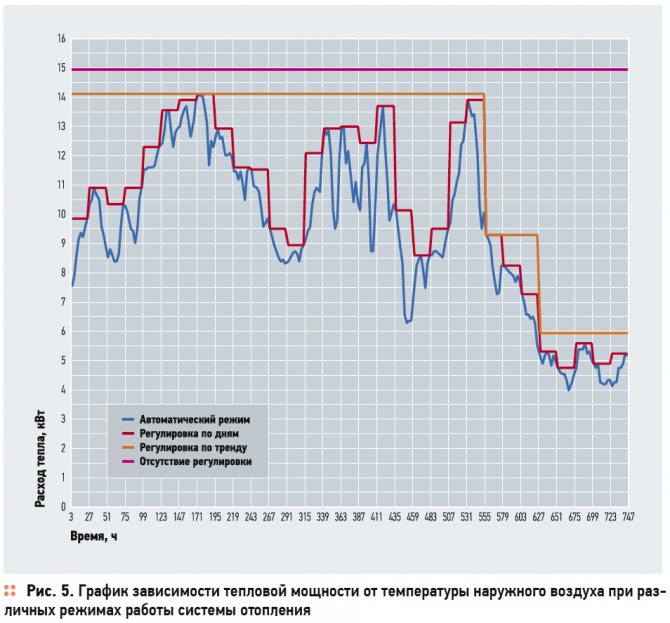

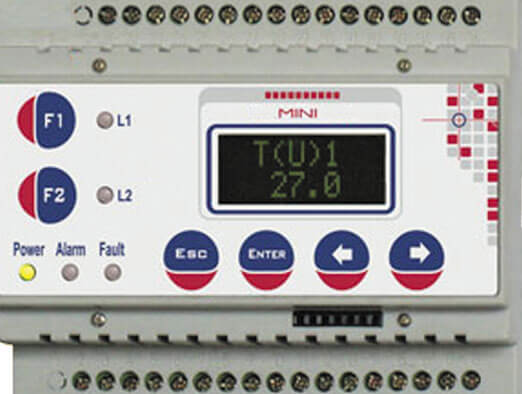

When configuring the controller a "curve" is set... With its help, the program calculates the need for heating the room. Starting position curve - the point at which the temperatures of the coolant and the environment are equal. As a rule, it is 20 degrees Celsius. After calibration, the device independently monitors the need for temperature changes.

Manufacturers set several curves in the user interface so that tuning does not take too much time. Having chosen the program, the specialist starts the system. Further, she functions independently.

For better synchronization, two sensors are required - one outside, the second inside.

By checking the readings, the system will not produce additional heating at a comfortable room temperature.

For this reason you need to choose the right roomin which the sensor will be installed.

Heating or cooling the coolant takes time, so the heating cannot sharply adjust to the temperature difference.

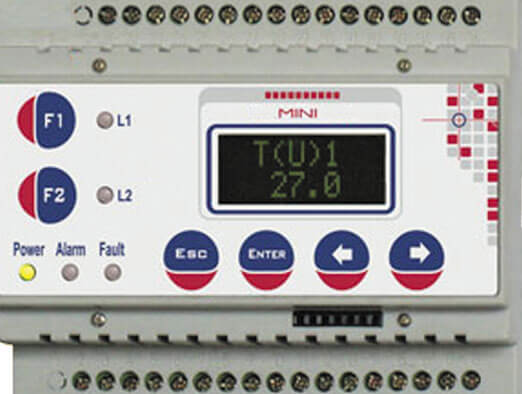

Controller

The controller is the heart of the hardware device. It monitors sensor readings and sets the room temperature. The factory functions of the device are responsible for heating, and also inform the owner about problems. The custom settings are designed to maintain the most comfortable conditions possible.

Rules for the operation of weather-dependent heating

Heating control systems have a self-diagnosis function. Error messages are sent to the display, and the owner is left with the choice of how to resolve them.

If the temperature controller does not work, you need to check the electricity first.

Frequent problems:

- crackling during operation - poor contact with the power supply;

- weak heating of the room at a high set level - an extraneous thermal effect on the sensor is possible;

- the device connected according to the rules does not turn on - the reason is in the design, replacement will be required;

- blinking of the LED - the temperature sensor has broken;

- the thermostat does not provide the set mode - the device is faulty.

For continuous operation without failures, it is sufficient to comply with the operating requirements established by the manufacturer. Installation and configuration of the system is carried out according to the instructions.

External factors affecting the heating control system

An assessment of all factors influencing the operation of the equipment will help to consider in detail the advantages of weather-dependent heating control systems for a private house. The classic control unit with indoor temperature dependence has disadvantages that cannot be corrected even with the most modern electronics.

Heating system inertia

This is due to the thermal inertia of the building. Thick walls and massive thermal insulation do not make it possible to quickly influence the temperature inside the room; a certain time interval must pass before the room will feel a decrease in the comfortable temperature. The same is the case during a warming or thaw, when the temperature rises outside, and inside the thermostat it will require maintaining the set upper threshold for heating the air for several more hours. It is with the inertia of the heating system that one of the main factors that negatively affect the operation of devices is associated.

The specifics of building a heating system

The second point lies in the specifics of the construction of the heating system itself. Weather-dependent sensors in the simplest heating system of a private house record and transmit data on changes in room temperature to the control module. After processing the received data, the automation of the control unit adjusts the operating mode of the heating boiler - increasing or decreasing the temperature of heating the coolant. This is not the most effective way to maintain the optimal temperature in the house, the sensors often work late, and the control unit suffers from significant delays in the delivery of commands. But even if we discard the errors of automation and assume that it works just perfectly, the adjustment is carried out by adjusting the operation of the gas burner, gradually increasing the risk of damage to the boiler itself.

Single set of equipment

It's another matter if the entire system is built as a single set of equipment, originally designed as a weather-dependent heating system. In this case, we can talk about a really economical consumption of energy resources and taking into account external factors affecting the operation of the system.

Among the factors taken into account in the operation of automation include:

- Daily change in air temperature inside and outside the building;

- Air humidity accounting;

- Wind speed, its direction, the nature of air movement;

- In addition, the influence of sunlight can be taken into account, and how much the sun heats the walls of the building;

The most modern systems, in addition, take into account the results of weather changes not only in the place where the building is located, but also receive information from the network and adjust work depending on medium and short-term weather forecasts for 1, 3 and 6 days.

Using automatic heating control

Heating control systems differ in function and price. Simple models are controlled by a remote control or touch screen. Complex systems have their own software with remote control access. Weather-dependent automation is available in different types of heating boilers:

- wall-mounted, located in one of the rooms;

- floor-standing, installed in the boiler room;

- electric boiler.

In the controller program setting, the initial value is set when the inside and outside temperatures are the same. Then the calibration is carried out, the parameters of the coolant are selected for each type of weather. The manufacturer programs his own options by default, one of which can be selected for work.

To set up the system, you need to install temperature sensors outside and in the room so that the data is transmitted without distortion.

The advantages of management are the availability of autonomous operation, saving resources. Disadvantages of weather-controlled automation - maintenance and repairs can be expensive due to the replacement of faulty electronics.

Situations in which weather-dependent automation cannot be dispensed with

The first situation is when the customer likes to turn the knobs, adjust something, that is, he likes to "play". Because of his love, he requires the installation of weather-dependent automation.

The second situation is when there is a need to equip a boiler room, which provides many different objects. For example, the main house, a security house, a separate garage, a bathhouse, a swimming pool, ventilation, and so on. Here, except for weather-dependent automation, the problem cannot be solved. This case is not typical, since usually houses up to 500 square meters do not require any weather-dependent automation.

The third case is production. For example, the ceiling height is 12 meters, the area is 5 thousand squares, 60 thousand cubic meters needed to be heated. There were no other sources of energy other than diesel fuel. The expense was huge, we had to install weather-dependent automation. Consumption has been cut by three times, it is vital there.

In an ordinary house, automation is not really needed, if you are not too lazy to go into the boiler room and turn the temperature knob. A very simple operation.

Weather-dependent automation Vaillant

Vaillant's Multimatic VRC 700 controls underfloor heating and up to 10 mixed heating circuits.

Vaillant VRC 700 Multimatic specifications:

- setting of parameters with a rotary knob;

- work with solar heating of the coolant and forced ventilation;

- preset heating curves Vaillant - night, guest, day and ventilation;

- recording of an individual control program;

- remote diagnostics of the system by service.

VRC 700 weather-compensated automation control schemes:

- One direct heating circuit and recirculation pump with additional module.

- Two mixing lines, expansion VR 70, boiler pump.

- Direct heat carrier flow control.

- Circuits - straight and mixed, with two VR 70 modules, recirculation pump.

- Control of two heating medium mixing lines with expansion VR 70, module VR 91 regulates the process.

- Regulation of two mixing circuits by means of a VR 70 expansion and a boiler via a condensing boiler board.

- Three mixing lines with VR 71 module and a recirculation pump.

- Controls more than 3 contours, one of which is straight. The scheme includes extensions VR 60, VR 32, VR 90.

The version of the Vaillant VRC 700/6 weather-dependent automation can connect several boilers to work, and with the VR 900 unit, control the cascade remotely in a special application.

Baxi weather-controlled boilers

Gas boilers consume fuel even in normal mode, since the burner continues to work when there are no people in the house. With good insulation of the house, turning off the heating reduces the temperature by 2 ° C in 6 hours, and turning on heating gives an increase of 2 ° C in one hour.Boilers of the Baksi Luna 3 Comfort model are remotely controlled via a mobile application. A script for automatic heating control can be linked to a calendar.

Boilers of the Baxi Slim series have the following functions:

- remote inquiry of temperature in the apartment and on the street;

- remote control of water temperature in the direct and return circuits;

- reading of gas meter readings;

- control of pressure in the system;

- notification of errors and emergency stop of the boiler;

- remote activation of the boiler.

Advantages of wall-hung boilers:

- separate heating and water heating circuit;

- constant temperature of the coolant;

- silent work;

- electronic modulation of the flame;

- boiler operation at reduced gas pressure in the system;

- the ability to connect underfloor heating.

The Italian manufacturer Baxi boilers are unpretentious.

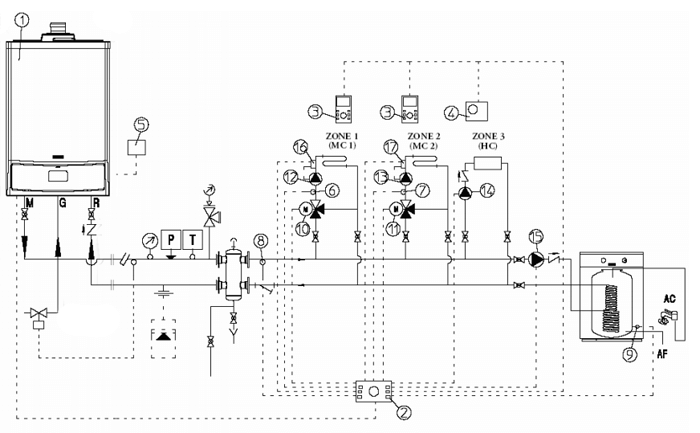

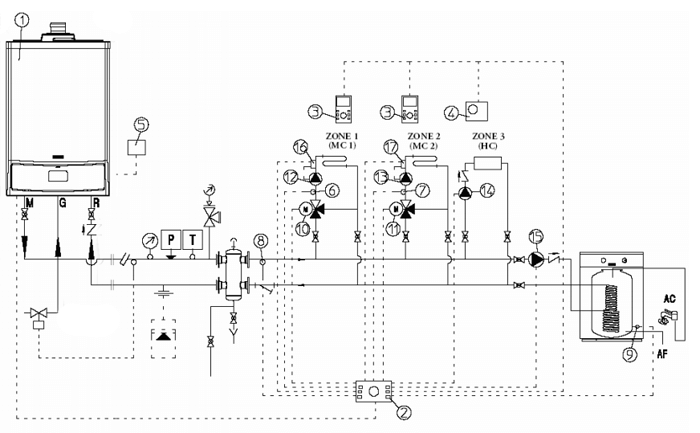

Boiler room piping schemes and circuit control principles

In order to organize the operation of one or several heating circuits in the hydraulic system, they must be connected to a heat generator-boiler. This problem can be solved in different ways, experts call them piping schemes for boiler rooms. Consider the most common of them, as well as the principles of organizing the appropriate management process with all their advantages and disadvantages.

Heating circuits are divided into direct and mixing circuits according to the method of reaching the temperature in them. The water temperature in the direct circuit is reached only by the burner and depends on the duration of its operation.

In the mixing circuit, the coolant temperature is determined both by the operation of the burner and by the position of the damper of the actuator - a three-way mixing valve with a servo drive. Having resorted to the first option, you can easily connect a low-temperature boiler with one radiator heating circuit and provide its automated control depending on the outside temperature. This business is quite simple and relatively inexpensive. If it is required to organize, in addition to heating, and hot water supply, and without resorting to mixing units, two types of schemes are used. The first is with a three-way valve, the second is with two pumps.

The simplest is the circuit with a three-way changeover valve equipped with a servo drive. The water from the boiler is directed to the tap, which, in turn, directs it either to the heating circuit or to the boiler heating circuit. The changeover can be carried out by the command of the boiler control panel. The control of the water temperature in the boiler is carried out by automatic equipment using a temperature sensor installed in it. As soon as the water cools down below the required level, a command is given to switch the three-way valve. It should be taken into account that with such a piping and control scheme, during the heating of water in the boiler, the heating is turned off (that is, it is impossible to organize hot water supply control with mixed priority).

The collector circuit, as the name suggests, involves the use of collectors for piping the boiler room, which are pipes with outlets for the required number of circuits. Such a scheme, being quite simple, has become widespread due to the appearance of the so-called fast assembly components. They include pumping and mixing groups. These devices make it possible to assemble a system with several heating circuits rather quickly (piping a boiler room takes a few days). However, it should be noted that such modules are used mainly for small boiler houses - up to 85 kW.

Nevertheless, they are extremely convenient during installation and significantly reduce the risk of error due to the notorious human factor, since they are assembled and tested for operability and tightness in the factory.

There is an interesting option for piping boiler rooms using a hydraulic separator (hydraulic arrow). This refers to the scheme of the primary and secondary rings, the principle of which is as follows: boiler water constantly circulates along a small circuit (primary ring), from which, with the help of circulation pumps, other heat consumers (different circuits) are taken away. The advantage of this scheme is the ability to connect a large number of secondary circuits while ensuring the nominal flow rate through the boiler and the relative simplicity of the design.

DE DIETRICH (France) recommends using a thermohydraulic distributor (abbreviated as TGR) for piping its boilers. When using it, a constant flow rate of the coolant through the heating device is achieved - regardless of the value of the water flow rate in the heating circuits, where this indicator may be different. As a result, it is possible to achieve optimal balanced operation of the boiler and heating circuits.

It is important to note that the automation of many manufacturers allows you to control the boiler and circuits in a variety of boiler room piping schemes. However, it is better to entrust the search for the most suitable option and the selection of automation to a specialist.

Automatic control of boilers Protherm

Boilers without regulation turn on heating depending on the parameters of the heat carrier. Protherm weather-dependent equipment controls heating based on data from outdoor and indoor sensors. Thermostats save up to 30% of fuel, reducing the frequency of the boiler switching on.

Room regulators that are used with the electric boiler Proterm Skat:

- Instat Plus with wired connection, maintains temperatures from 5 to 30 ° C, there is a night mode to reduce heating.

- Termolink B - room regulator for air heating in the range from 8 to 30 ° C, programmable operating mode for 24 hours, frost protection function.

Electric heating is a safe and emission-free source of heat in your home. No ventilation system required for installation. The equipment of an electric Protherm boiler is simpler than a gas one.

With the floor-standing cast iron boilers Protherm Bear, thermostats on the eBus are used:

- Termolink P - there is a modulation mode, regulation of air and hot water heating, heating control curve depending on temperature sensors.

- Termolink S - can change the boiler operating mode by time of day, programmable for a week. Vacation mode and frost protection are preset.

Medved series boilers change the water temperature with an injection burner. The heating element is made of cast iron. The display on the panel informs about the parameters of the coolant.

Heat exchanger TEPLOCOM CLOUD

Heat exchanger TEPLOCOM CLOUD

able to implement new technologies to control the heating system. Its functions go far beyond the usual maintenance of a given temperature in the house. On the basis of "cloud technology", it implements a mechanism for transferring information from connected equipment and its remote control via a smartphone.

Features of the TEPLOCOM CLOUD heat exchanger:

- Informing about accidents and the state of the heating system. Boiler control via smartphone from anywhere in the world.

- Constant monitoring of the state of the gas boiler, the temperature on the street and in the house, the temperature of the coolant, the occurrence of a leak, the presence of a 220V network. It is possible to connect contact sensors for additional notification.

- Temperature control is carried out depending on the outside temperature using WeatControl technology, which minimizes temperature fluctuations in the house during the day.

- Individual schedule of comfortable temperatures for the whole week.

- Possibility of placing up to 10 wireless temperature sensors within a radius of 300 meters.

- Reducing gas consumption by up to 30% and combating harmful emissions into the atmosphere due to the reduction of the generated carbon dioxide.

- Free apps to work with TEPLOCOM CLOUD

on Android and iOS. - The delivery set includes: heat exchanger, wireless radio temperature sensor, leakage sensor, outdoor temperature sensor, coolant temperature sensor, GSM SIM card, built-in Li-ion battery.

Weather-dependent automation Meibes

The HZR-M Meibes weather-compensated thermostat controls the heating medium mixing circuit independently, complete with other controllers. Characteristics of the Maybes device:

- interface with icons;

- built-in heating programs;

- integration with other regulators on the eBUS bus;

- autonomous power supply with batteries;

- display backlight;

- connector for connecting a computer.

Weather-dependent automation for heating systems of a private house - devices with remote access Meibes LE HZ of German production.

The thermostat controls two circuits or a cascade of 2 boilers, recirculation pumps. Meibes LE HZ features:

- connecting controllers remotely;

- expansion of control by 8 loops via eBUS;

- symbolic menu;

Advantages - easy installation on the wall.

Characteristics of automatic heating control systems

At the moment, a wide range of heating automatics is presented on the market. Despite the differences in design, functionality and parameters, the same requirements are imposed on all automation, the fulfillment of which is mandatory.

The first and most important requirement is reliable and effective feedback, which is achieved through the presence of highly sensitive temperature sensors. During the operation of the automation, minimal temperature drops will still appear, and the task of the sensors is to prevent a noticeable drop.

Automation for heating systems should also ensure energy savings, in which the temperature sensors are also directly involved: the better they are adjusted, the less often the heat generator will start - and this is already a direct saving.

In addition, an important parameter when choosing automation for heating is a clear and pleasant interface that will allow you to make adjustments without any effort and knowledge (for more details: "Adjusting the heating system - details from practice"). This simplicity comes at a price, since even the simplest control panel hides a complex controller for the heating system underneath. The reliability of these devices is very high, but the cost corresponds to the high quality.

All devices must be safe and reliable - this is a prerequisite. The installation of such systems is usually carried out by qualified specialists, but there are also models that you can install yourself.

ZONT thermostat

The ZONT H-1 weather-compensated heating controller is an intelligent system that is remotely controlled via the GSM or Internet protocol. The device is connected via a mobile application, a personal account on the manufacturer's website or by SMS commands. Thermostat features:

- 2G SIM card management;

- transmission of readings of temperature sensors and boiler operation mode;

- selection of the heating control curve;

- room heating programming for a week;

- notification of errors and emergency cases;

- a message about a power outage in the house;

- history of operations for 3 months;

- software update via the Internet.

The thermostat is connected in 2 ways - via the terminals on the boiler or via an adapter to the digital bus. Heating control can be performed in relay mode, with periodic switching on of the gas burner. Digital control via adapter is possible - electronic flame modulation.

Specifications ZONT H-1:

- operating voltage 10-28 V;

- analog and digital inputs;

- connection of 10 wired and radio channel sensors;

- operating range from –30 to + 55 ° C;

- exit to the mode - 50 seconds;

- plastic housing, universal surface mount.

Boiler operation with underfloor heating

For comfort, a warm floor system is used in the house, where the heat carrier is water or liquid with a low freezing point. The circulation pump is regulated by weather-dependent automation.

Composition of the underfloor heating scheme:

- weather-compensated controller;

- outdoor temperature sensor installed in the shade;

- mixing unit servo drive;

- circulating water temperature sensor;

- underfloor heating pipeline;

- thermostat in a heated room.

The Russian-made TRTs-03 controller maintains the temperature along the heating control curve.

Warm floors are used with other types of room heating. There are four types of weather controllers designed to work together:

- Main - controls 8 types of hydraulic circuits, 6 of which include a boiler.

- Expansion for 2 hydraulic systems in addition to the main regulator.

- Independent mixing circuit control, can independently regulate one system.

- Heating control unit with buffer tank and timer.

Warm floors have significant inertia, so the room thermostat reacts more accurately to the weather.

Weather-dependent automation for greenhouses

Growing agricultural products year-round in northern climates is a difficult task. To ensure the vegetation of plants, weather-dependent heating is used. The best option is a piped soil heating system that stimulates root development and reduces energy consumption.

The temperature in the greenhouse is different at night and during the day, and the soil should be warmer by 2-3 ° C. Aries TRM-32 automation or Aries PLC 100 controllers, combined into a system with a control center, will cope with such a task.

Characteristics of the control system Aries TRM-32:

- control of heating of the coolant based on the signal of four external sensors;

- connection to a computer via an adapter;

- control range from –50 to + 200 ° C;

- wire communication length - 1200 m;

- the temperature in the greenhouse is from +1 to + 50 ° C;

- push-button control, information display;

- programming the heating schedule at a given temperature value;

- switching from day to night operation.

Remote control of the greenhouse microclimate is carried out by airing and changing the speed of the pumps.

Regulation of the heating system using the operation of pumps

Among the known schemes for heating systems with control from a weather-dependent automation unit, the optimal option for controlling the temperature of warming up rooms is a scheme using circulation pumps. This scheme is more used for heat supply of district heating buildings, when additional pumps are installed at heat points to pump the coolant from the mainline to a specific consumer. In such a scheme, in addition to the pumps themselves, other equally important elements are used, for example, a heat accumulator and a hydraulic separator - a hydraulic arrow.

The essence of this method is to quickly increase the flow rate of the coolant to the radiators by switching the pump operation. After receiving information from external and internal sensors, the control unit, according to the program, tears out the operating mode of the circulation pump. By increasing or decreasing the flow rate of the coolant, the automation regulates the flow injected into the radiators. To achieve the desired temperature, the automation opens, or vice versa, closes the three-way mixing valve and the liquid heated to the desired temperature, under the action of the pump, enters the battery circuit.

This option for controlling the heating system using pumps allows you to bring the room temperature to the desired value in a very short time without adjusting the boiler burner. It is simple and reliable, while heating boilers do not need to be constantly adjusted, setting the temperature to 40-45 degrees.

DIY automatic regulation

Weather-dependent regulation is used to maintain comfort and economy. They install weather-dependent heating with their own hands in small private houses and in summer cottages. Factory-assembled devices are suitable for stable operation of the system. Self-made devices will not work stably, they are unsafe.

A universal boiler Ochag, which runs on solid fuel, is suitable for a country house. The control circuit has three temperature sensors - the coolant in the boiler, waste gases and water in the boiler. Actuators - air flow damper and damper on the pipeline. Automatic control is organized using the Arduino Nano controller.

Weather-compensated heating control

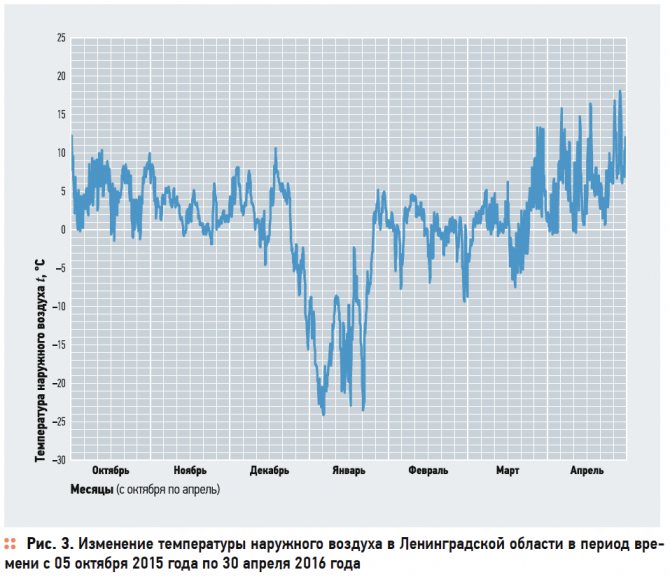

At first glance, everything is logical, but I had a question about the advisability of a constant adjustment of the temperature of the coolant in the heating system. It is believed that a one-time adjustment of the heating system for a period of time is sufficient in the event of a sharp change in the outside air temperature. In this case, the adjustment can be made manually using various remote control systems, while avoiding unnecessary "bells and whistles" in engineering systems and thereby simplifying their operation. In order to understand this, let's consider the second function for which weather-dependent heating control is needed - saving energy resources. I am sure that you do not need to be an academician to answer the question of which type of regulation of the coolant supply will be the most energy efficient. Naturally, automatic. But the question immediately arises, how much the cost of generating heat energy is reduced if you use weather-dependent heating control, and how much the cost for it is reasonable.

(no votes yet)

How necessary is a weather-compensated heating system

Heat management automation is not always necessary. Regulation takes place with a deviation of 2 ° C from the norm in a room with a sensor, in other rooms the spread is greater. The cost of installing separately installed automation reaches 2 thousand euros.

If the equipment is supplied with a heating boiler, the use of weather-dependent automation is justified. In other cases, the costs will not cover the possible savings.

Thermostatic radiator heads are enough to regulate the heating.

Benefits of automatic heating control

Due to its high cost, weather-dependent regulation is more often used in apartment buildings and industrial buildings, where it is economically justified. Automation advantages:

- constant temperature;

- reduction in fuel consumption with temperature drops;

- automatic control of the environment by sensors;

- maintaining a low temperature;

- lack of a human factor.

Boilers of new models are equipped with automatic regulation. The functions of these systems are sufficient for comfort in the house without extra investment.