Insulation of windows using Swedish technology

The problem of keeping warm in the house is now more acute than ever - in the light of the high cost of heat carriers. One of the most effective methods is to insulate windows using the Swedish Euro-Strip technology for the winter, and, once and for all, there will be no need to do it again and again before each new season. Such insulation of wooden and plastic windows has a service life of up to 15-20 years. Our company carries out custom-made repairs and insulation of windows using Swedish technology in Moscow and with a visit to Moscow region.

Order service

Milling grooves, installing sealant and applying sealant

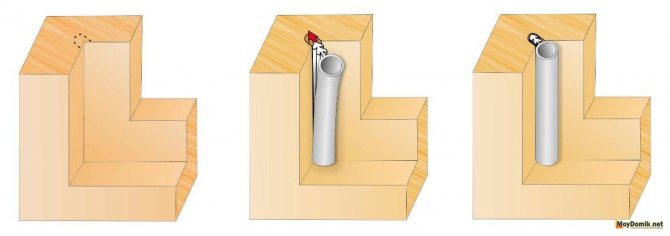

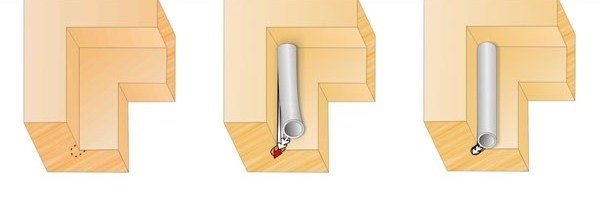

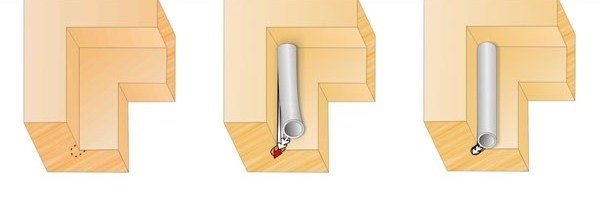

To carry out further work on insulation in the Swedish way, it will be necessary to mill the grooves for laying the heat-insulating seal.

Milling is performed with a straight grinder or a drill with a special cutter attachment. For this, a sample is made around the perimeter of both flaps, with a depth equal to the “legs” of the seal and a width of 3-3.5 mm.

The seal is laid in pre-prepared grooves

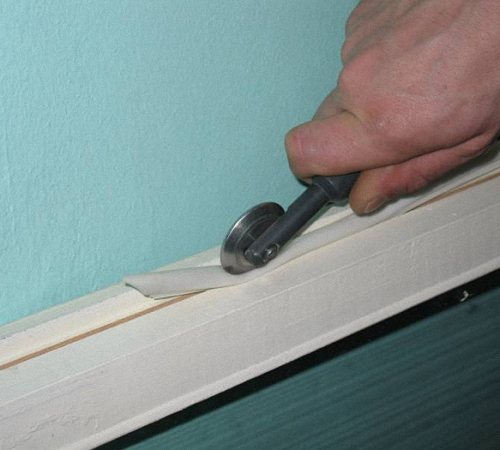

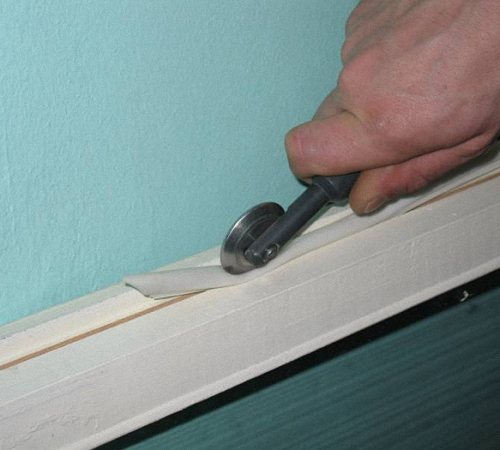

After that, in the resulting groove, using a seaming roller, the type of material we need is laid. To create additional thermal insulation, a rubber seal is glued into the interframe space.

For the installation of heat-insulating material, it is better to use a special seaming roller.

Having carried out the installation around the perimeter of the entire window structure, they begin to seal the seams and glass. To do this, from the inside and outside of the window, the joints are coated with sealant. This will prevent cold air from entering and blowing through the joints.

To seal the glass, remove the glazing beads and dismantle the glass. The assembly seams are cleaned of contamination, sealed with silicone sealant and reassembled.

After completing the sealing work, the sashes are mounted back, and the final adjustment is made, for more convenient opening and closing.

Sealing joints with silicone sealant

On this, the Swedish technology insulation can be considered complete. To check the quality of thermal insulation, a burning candle is carried along the perimeter of the structure. If the fire does not tighten and the flame behaves calmly, then the sealing is done at the proper level.

Benefits of the Euro-Strip Method

- The advantages of this method are impressive, because the Scandinavians, where winters are even harsher than ours, understand how best to save heat.

- Firstly, this method can be used to insulate old and new, only installed windows.

- Secondly, window insulation using Swedish technology can be performed on any materials. Our specialists will perform Swedish insulation of wooden, plastic PVC, aluminum windows of various shapes and types with the same effect. Including, it is possible to carry out insulation of a roof window of any design, as well as the slopes of plastic windows.

- Using this technology, you can not only insulate windows in an apartment, but also a balcony, loggia and door windows - entrance, balcony, vents, etc.

- To make this heat-retaining procedure, among other things, is very profitable - the price for Swedish insulation of old wooden windows is ten times less than buying and installing new ones.

- The effectiveness of this method is very high - it makes it possible to completely eliminate drafts, exclude the ingress of dust, moisture (no leaks, even in a downpour!), Noise from the street. That is, the repair and insulation of old wooden windows using the Euro-Strip technology gives the effect of a double-glazed unit in reinforced-plastic windows of the highest quality.There is forever no need to seal with tape even in the most severe frosts, and in the summer, windows can be opened and closed as needed - this does not affect the quality of the seal.

What is the advantage

Swedish technology for insulating wooden windows allows you to repair windows without significant investments, and an environmentally friendly material - wooden frames will remain, but will become more airtight for many years.

Insulation of windows will allow you to get rid of street noise, as well as almost completely remove the penetration of dust and debris between the window sashes.

After the restoration of the windows you will receive:

- protection from drafts;

- your room will become much warmer. This means that you will save heat, because, on average, after the windows are insulated, the temperature in the room will rise by as much as three to five degrees, and you need to pay less for heating;

- you will save yourself from unnecessary street noise;

- the dust in the room will be much less and you will not have to do wet cleaning every day;

- you will forget about the "fascinating" process of gluing the windows with paper or adhesive tape with the onset of cold weather, and with the arrival of spring - removing the wrinkled and dirty "insulation";

- the appearance of the windows after insulation will remain unchanged, because even when the folds are closed, it is almost impossible to see the insulation.

Material features

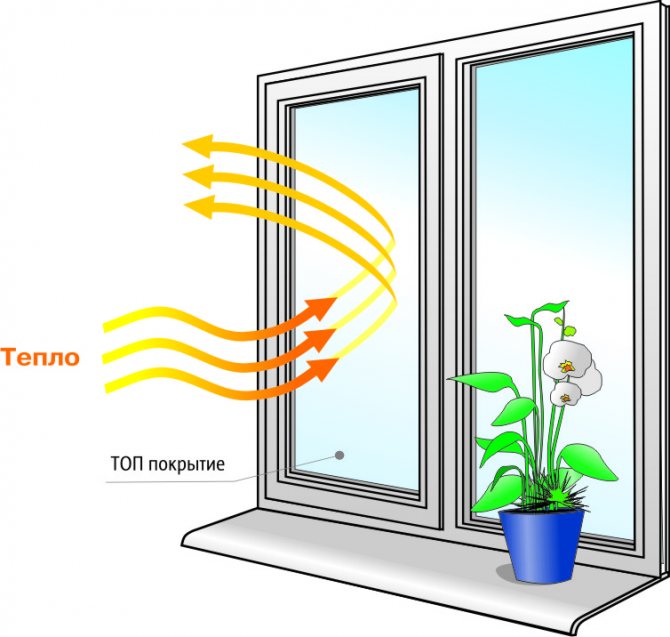

Tubular Euro-Strip is a certified, environmentally friendly material that retains its qualities at temperatures from -80 to +200 degrees. In addition, the manufacturer notes the property to trap radiation. The original material is branded every 75 cm. This composite material is made on the basis of silicone rubber with the addition of propylene, a copolymer of ethylene and diene monomer.

Materials (edit)

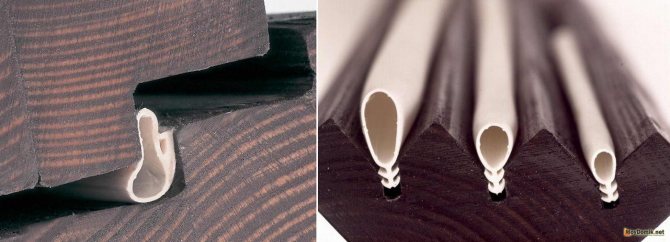

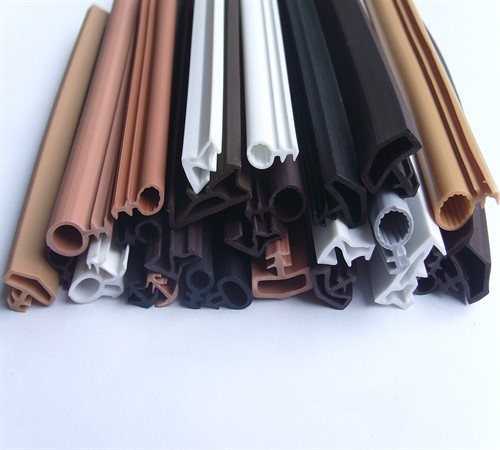

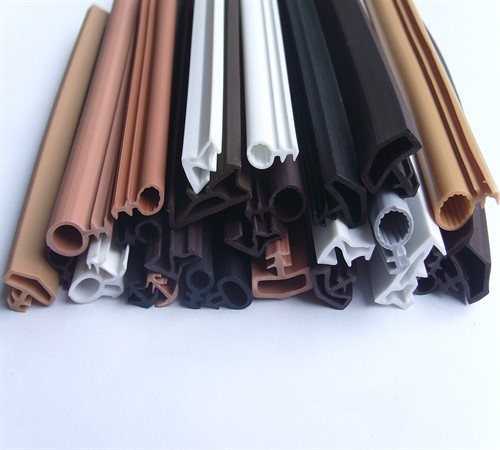

Today, there are several options for Eurostrip insulation on the building materials market:

- Silicone seal. This material is soft and resilient and can be shrunk to almost nothing. In addition, the material is resistant to acrylic and alkyd paints, which will allow you to paint windows without removing the insulation. This material is suitable for use on crevices of various depths and configurations.

- EPDM (rubber). The main disadvantage of such a heater is its rigidity and roughness, which makes it suitable only for the same uniform slots. Also, the product is afraid of the effects of paints, so the seal can be used on rarely painted windows. The cost of this material is slightly less than that of a silicone seal.

- TEP (thermoplastic elastomer). The seal is low cost. Its main disadvantage is the fear of temperature changes.

If you still want to install a seal that is afraid of painting, and at the same time plan to paint the window in the future, then this material can be used provided that the painting is done very carefully without paint on the product.

Window insulation according to the Swedish Euro-Strip technology, in Moscow and the Moscow region!

When insulating windows using the Swedish Euro-Strip technology, a 3-stage installation of seals is used. The leaves are removed from the hinges and prepared for the correct installation of the seals.

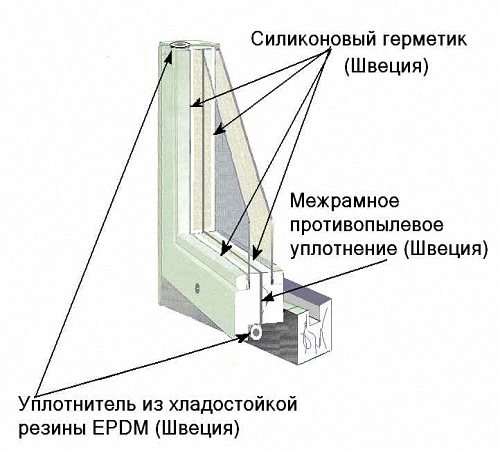

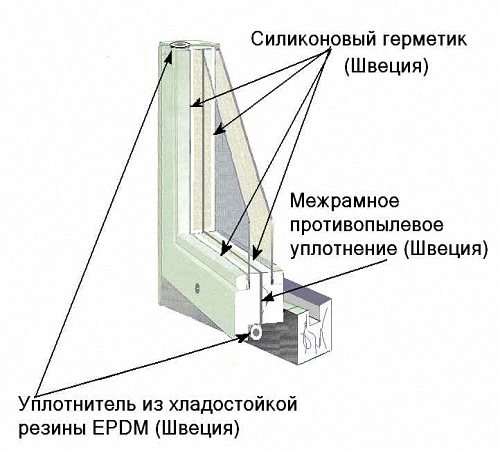

Stage 1 A Swedish Euro-Strip silicone seal is installed in the end parts of the sash (This is the main seal eliminating 95% of all drafts and blows!)

Stage 2 In the space between the frames (between the sashes), the Swedish EPDM seal is installed. (This is dust and sound insulation) Sashes and frames are adjusted (restoration of the window geometry). This helps the seals eliminate all drafts and blowing, and makes it more comfortable to open and close the window!

Stage 3 At the final stage of window insulation, glass is sealed (these are dust insulation, noise insulation and moisture insulation).

Windows can be insulated with a Swedish tubular sealant in any weather, our specialists do the job quickly and efficiently. At the same time, our masters can perform repairs, restoration of windows, replacement of glass, installation of new fittings.

Window

45 votes

+

Voice for!

—

Against!

In order to save money on the replacement and purchase of a new window, Swedish insulation technology is becoming more and more popular. There is a statement that after this procedure, old wooden windows are able to function for several more years. Moreover, the cost of all materials is available to almost everyone. We will try to figure out whether this is true further.

Table of contents:

- Features of Swedish window insulation

- Window insulation using Swedish technology: features and benefits

- Swedish technology for insulating wooden windows: general recommendations

- Do-it-yourself window insulation technology, characteristics of the seal

- Varieties of windows that can be insulated using Swedish technology

- How to quickly insulate windows using Swedish technology

Features of Swedish window insulation

Swedish window insulation technology got its name from the materials used in the process of its implementation. Rubber seals are made in Sweden and are of high quality and durability. At the request of manufacturers, this material is capable of performing its functions for more than ten years.

The process of performing insulation according to Swedish technology is quite complicated, for high-quality work, you will need to have skills in working with a certain tool. Since, for example, in order for the seal to be well fixed on the surface of the window, it will be necessary to build a groove section, and for this it is necessary to work with a cutter.

If you turn to the services of professionals, you will have to shell out a lot of money to carry out this process. Insulating a standard window will cost about $ 20. At the same time, the list of work includes:

- removal of flaps;

- preparation of grooves for installing a seal;

- installation of a seal;

- fitting sashes;

- sealing glass areas.

If you need to replace old hardware or repair a window frame, you need to spend extra money.

Tip: To save money when hiring a professional, when insulating a window with two frames, it is recommended to insulate only one of them - the inner one.

But, it is extremely unprofitable to hire specialists to repair and insulate a window using Swedish technology, since the amount of repair will be equal to the cost of an ordinary plastic glass unit. In this case, you do not need to spend time and effort on restoration. If you want to save money, all work must be done manually, and if you study all the recommendations well, then it is quite possible to do this.

The owner of the windows faces a difficult choice between buying a new window or insulating an old one. The first option will provide an opportunity to choose a new window, more modern and improved, and in the second option, it will receive an old, but well-repaired window. The choice is of course for the owner.

If all the details of the window are intact and not damaged by rot or fungus, then it is preferable to choose the Swedish insulation technology, which differs only in positive reviews. If there is damage to the wood on the window, then it is better to give preference to buying a new glass unit.

Insulation of windows using Swedish technology: features and benefits

This technology was developed by the Swedes in order to save energy for heating the premises in the winter season. After its development, it really paid off, and became quite popular all over the world.

If we compare this technology with ordinary window gluing, then its advantages are obvious. Since it allows you to freely ventilate the room even in winter.

To carry out the warming procedure, you will need:

- rubber seal;

- silicone sealant.

To begin with, the window is removed and its sashes are dismantled. Next, using a pencil and a ruler, you need to outline the place where the niche for the sealant will be located. It is installed around the entire perimeter of the frame.

A router will be an excellent assistant for cutting a niche. After that, a seal is inserted into it. But the work does not end there, you should check the evenness of the window, the correspondence of all corners, tighten the hinges and replace, if necessary, the fittings. A silicone sealant is used to seal the joints between the glass and the window frame. If it gets on the glass surface, do not remove it immediately, but wait until it is completely dry and use a razor blade to remove the cured mixture.

Please note that Swedish seals are available in different sizes. The selection of material is carried out in accordance with the size of the gap to be sealed. The dimensions of the seal are from five to twelve millimeters.

After installing the window frame, all joints are completely sealed. In addition, it is possible to paint the window.

Advantages of window insulation using Swedish technology:

- significant reduction in heat loss, which will have a positive effect on heating costs;

- environmental friendliness and harmlessness of the materials used does not cause allergic reactions;

- the speed of the process, which lasts about 180 minutes;

- no need for constant gluing of frames in the winter season;

- no dust and dirt during operation;

- after restoration, the window will serve for several more years;

- the appearance of condensate masses between two glass panes of a wooden window is excluded;

- the absence of drafts will improve the comfort in the room and help to avoid illness;

- insulation of windows using Swedish technology allows you to increase the temperature in the room by 3-5 degrees;

- the soundproofing properties of windows are improved - street noise and the sounds of cars are not heard;

- the overall appearance of the window remains unchanged, the insulation is practically invisible.

Swedish technology for insulating wooden windows: general recommendations

1. Thoroughly wash the windows before starting any work.

2. Check all window accessories for correct operation. Inspect the locking mechanisms and doors.

3. Remove the sashes from the hinges, so as not to spread dirt in the apartment or in the house, it is better to take them out into the street.

4. Adjust the sashes, remove excess paint from them.

5. Start sawing the groove for the seal.

6. Install the seal, make sure it fits tightly to the window.

7. Carry out a series of insulation works on the inside and outside of the window sashes.

8. Reinstall the shutters.

9. Start replacing the fittings.

10. Check the system for drafts. To do this, bring a sheet of paper or a lighted match to the window.

Do-it-yourself window insulation technology, characteristics of the seal

A tubular material called EuroStrip is used as a seal when insulating windows using Swedish technology. It is based on silicone rubber made in Sweden. It is this material that has the following advantages:

- resistance to temperature extremes;

- resistance to exposure to chemical and paint materials;

- the duration of operation is more than 15 years.

We suggest that you familiarize yourself with the main types of EuroStrip insulation used in the process:

1. Silicone based sealant - soft and elastic texture, good shrinkage.Resistant to alkyd or acrylic paints. Used to seal the largest gaps.

2. Rubber-based seal - hard and rough to the touch. Seals well only slots of the same width. It is unstable against paints and varnishes, it has a lower cost compared to a silicone seal.

3. A sealant in the form of thermoelatoplastic - unstable against temperature extremes, but the cheapest.

To carry out work on self-insulation of windows using Swedish technology, you will need:

- large construction stapler;

- milling cutter;

- silicone based sealant;

- staple staples;

- a roller with a handle to help install the seal;

- screwdrivers;

- pliers;

- vacuum cleaner;

- stationery knife.

Clean the sashes from mold, paint residues or old gaskets. Replace fittings. Replace glasses if necessary. Remove the sashes from the hinges. When carrying out work in the winter, take care of installing a protective screen to prevent heat loss in the room.

Using a router, cut a groove no more than half a centimeter deep and up to three millimeters wide. When you get close to the areas where the hinges are located, leave a gap of one and a half centimeters between them and the groove.

Install the seal using a special roller, pumping it with this tool. When rolling, it is recommended to make a return movement, which will prevent strong stretching of the material and its deterioration.

Refit the sash and paint it if necessary. Use hot glue to seal the cracks in the wooden areas of the window.

Varieties of windows that can be insulated using Swedish technology

1. Windows of the pre-revolutionary period are distinguished by their splendor, large size, beautiful carving and high cost. The presence of such windows in the house ennobles it, but almost all types of these windows need repair. In most cases, such windows have upper sections made in the form of an arch or a stationary fragment. Their insulation implies the installation of a seal along the perimeter of the fragment, if there are glasses on the putty, they are removed and installed using silicone sealant. If the fittings in the form of beautiful forged parts are inoperable, they have to be replaced with ordinary metal locks. Of course, with a complete restoration of windows, it is possible to manufacture fittings to order, but this procedure will be very expensive. Sashes on such sashes do not have a rebate, so the seal is installed directly around the perimeter of the box. If necessary, use polyurethane foam to seal the joints between the wall and the window.

2. Insulation of windows of the Stalinist period requires caution and care. This type of windows is particularly durable and of high quality. The best quality timber was used in their manufacture. As the locking mechanisms of such a window, a latch is used, which is distinguished by its reliable locking. They are being replaced by alternative locks. For fixing with a stack, a putty made from natural drying oil and metal-containing powders was used. It is recommended to replace these glasses with more modern ones. The seal is installed around the perimeter of the box.

3. Restoration of the windows of the double-glazed windows of the Khrushchev era implies a collapsible structure, consisting of several parts, similar to modern double-glazed windows. The seal is installed along the perimeter of the sashes, which are removed one by one from the window.

How to quickly insulate windows using Swedish technology

There is another less expensive option for window insulation, which involves gluing a silicone seal to the sash surface.

Before you get acquainted with this method, we propose to consider the advantages of silicone seals over their counterparts:

- resistant to mechanical stress;

- low abrasion;

- good insulating qualities;

- waterproofness;

- resistance to exposure to ultraviolet radiation;

- softness and elasticity;

- duration of operation;

- mold and mildew do not form on its surface;

- use at temperatures from -70 to +150 is possible.

If there are no skills in working with a cutter or for some reason it is impossible to make a niche for a sealant, there is an easier way to insulate windows. There are two variations of it:

- installation of the seal with a stapler;

- fixing the seal on the surface of the door frame with special glue;

- use of a self-adhesive sealant.

All these methods are less expensive than the previous ones and help to achieve the effect of warming only for a certain time, from one to two heating seasons.

Therefore, before choosing a method of insulating windows using Swedish technology, you should weigh all the options and think whether it is worth doing, or it is cheaper and more practical to buy a new window.

After insulating care tips

To preserve the integrity of the structure after insulation, it is recommended to observe the following maintenance rules:

- it is advisable to wipe the sealant with a damp cotton cloth two or three times a year;

- not recommended, it paints the seal after installation. For some types of material, paints and varnishes can damage the surface and reduce performance. Although the Swedish insulation technology provides for these works, we strongly recommend refraining from this type of finishing;

- periodically inspect the structure for integrity and damage. It is highly undesirable for the thermal insulation to come into contact with foreign objects.