Natural resources are not unlimited: sooner or later they will run out. Therefore, humanity is increasingly using renewable resources for its needs. And it doesn't matter if it is energy, construction or other areas of industrial production.

Natural linen insulation also fully belongs to the category of renewable building materials. At the same time, its use began so long ago that even in fairy tales for children, foam plastic and basalt wool, which are currently popular, were not even allegorically mentioned.

The editorial staff of the StroyGuru portal decided to figure out how relevant linen insulation is in the XXI century, where are the advertising moves of manufacturers, and where are the real advantages of thermal insulation material.

Features of linen insulation

Flax belongs to annual bast crops with thin fibers (20-50 pieces per stem). In turn, the fibers consist of porous, up to 150 cm long, separate "hairs" (10-40), enclosed in a flexible sheath. Thus, a flax stem can be fluffed into 200-2000 simple cellular structures that perfectly keep heat and absorb sound waves propagated by the air.

In its pure form, flax cannot be used for insulation - it quickly cakes, due to the presence of a solid trunk and is subject to decay. Therefore, primary processing is needed in the form of crushing and scutching to free the fibers from the fire.

However, even in this form, the fibers are quickly caked. Therefore, synthetic substances (synthetic winterizer) are added to them, which are responsible for the elasticity of the canvas and its volume. To combat putrefactive microflora, the method of heat treatment is used, as a result of which all microorganisms die - the material becomes biologically pure. But this does not mean that over time, flax will not begin to deteriorate. This is facilitated by two factors:

- starch (an excellent base for the development of pathogenic microorganisms) - added to mats for gluing fibers;

- constant dampness in a room with a linen insulation.

In addition, one should not forget about the high degree of flammability of flax fiber, which requires the treatment of belts, cloths and mats with fire retardants. These points need to be considered when buying linen insulation.

Is it really as environmentally friendly as they say

The cost of linen insulation is very high. Therefore, to promote a product on the market, chips are needed that should stimulate sales growth. Among them is the absolute ecological purity of the product.

This advertising ploy is confirmed by the quality mark awarded by the EU Commission to environmental building materials. In this regard, we note that for the most part, all construction products from flax of Western firms have this sign. How is it in Russia? After all, we buy mainly a domestic product.

Let's try to find out if linen insulation is really eco-friendly. For the analysis, you need to know the composition of the insulation. And here questions arise. If boron salt was used as fire retardants, and starch is a binder, then there is no doubt about the ecological purity of linen insulation.

But to improve consumer characteristics, chemical binders are increasingly used instead of starch (in some brands, up to 30% of them). In this case, it is not necessary to say that the products are natural, although manufacturers claim the opposite.

Advantages of linen insulation

Linen insulation is made from the plant of the same name - flax. It has a pleasant smell and will allow you to insulate your home without harming your health.

Linen insulation is a new generation of insulation. It does not need additional quality checks, as it is made from environmentally friendly ingredients.

Most modern heaters affect your health in one way or another. For example, seemingly safe glass wool spreads fine and sharp particles. They enter the lungs and can cause asthma attacks. It's not even worth talking about foam at all, this material releases toxins, which, according to unverified data, can lead to oncology.

Flax is devoid of all these drawbacks. But it has a number of advantages.

Advantages of linen insulation:

- Flax has antiseptic properties. Therefore, on the walls that are insulated with this material, fungus and mold will never appear.

- Insulation made from such material does not cause allergies, which is especially important if small children live in the house.

- The thermal insulation qualities of flax will not go anywhere if it gets wet.

- Linen material does not have the peculiarity of electrifying.

- The heat capacity of flax is high. In the summer, it does not allow the heat to enter the house, but in the winter, on the contrary, it retains heat.

- The soundproofing properties of the linen material are at a high level.

- Mice and rats cannot get into linen stoves. This is especially important for private homes.

- You can easily attach linen insulation to the walls. At the same time, it will not crumble and emit dust.

- Natural linen insulation prevents condensation from forming. This quality is especially important in the winter season.

- Linen insulation is made on a natural basis. Therefore, it does not emit substances hazardous to health and can be used to insulate interior walls.

- It has a very long service life. Manufacturers assure that it can be used for 75 years.

Ecolin is an excellent insulation material for insulating the interior walls of a house. Such insulation will not make you worry about the health of your loved ones.

Characteristics

Information on the technical and operational characteristics of linen fiber insulation is still controversial. There are a number of objective reasons for this. Therefore, we will not refer to different sources to explain our choice, but we will give the lower and upper boundaries of each indicator:

- thermal conductivity coefficient - 0.03-0.04 W / (m * K);

- density - 15-38 kg / m3;

- sound absorption coefficient - 0.98;

- operating temperature - from -70oС to + 169oС;

- service life - more than 50 years;

- flammability class - G1;

- vapor permeability - MU1 (yes, equal to 0.4 mg / m * h * Pa);

- sizes of mats: length - 100-120 cm; width - up to 60 cm; thickness - 5 and 10 cm.

Rolls can be up to 160 cm wide and cuts from 20 to 400 mm.

Pros and cons

All building materials have their own advantages and disadvantages. Linen is no exception. According to reviews on the forums to pluses this type of insulation includes:

- high thermal insulation properties - the thermal conductivity coefficient is only 0.03-0.040 W / (m * K), which is only slightly inferior to polyurethane foam, is on the same level with foam and surpasses mineral wool;

- durability, confirmed by practice - the service life is 50-100 years (manufacturers indicate the number 50, but in practice, when dismantling wooden buildings, linen insulation was in working order for 75-100 years);

- vapor permeability, allowing the walls to "breathe", removing excess moisture from the room to the street;

- increased hygroscopicity, which on the one hand is a negative property - it quickly gets wet, on the other hand, linen-based insulation, like wood, regulates the humidity regime in the room: with an excess, it absorbs vapor molecules, with a deficiency, it gives off, and dries very quickly. A big plus in this property is that no vapor barrier is required. Consumers do not need to be afraid of frequent, but short-term wetting of flax, becauseafter drying, all characteristics are restored in full. The only thing that can happen is darkening of the fibers;

- Possibility of installing a raspor, without the use of glue and dowels. Such installation became possible after manufacturers began to make mats in width and length slightly larger (by 2.5 cm) than the standard dimensions of the lathing cells or the distance between the lags (beams);

- environmental safety, while not only in relation to homeowners (not an allergen, does not emit harmful and toxic substances when heated and burning), but in general, flax absorbs CO2 when grown, completely decomposes, can be reused, belongs to renewable resources;

- good sound insulation performance, but only airborne sound waves are absorbed. Flax is practically useless against structure and impact noise;

- simple and safe installation - all work can be done with your own hands without the use of overalls. The problem arises only if the mats need to be adjusted to the size - the flax fiber is poorly cut.

Among the many advantages of a heat insulator, one should not forget about disadvantages... And they are critical in many ways. Among the cons:

- high price. The material is available at a cost only to wealthy property owners;

- increased flammability. It is not for nothing that the powder contains flax components. Therefore, processing with fire retardants is required. And not just sprinkle with boron salts, but add up to 13% of this substance to the mat. After processing, the flammability class decreases from G3 to G1 (does not support combustion);

Attention: studies by Finnish scientists have shown that with a mass fraction of flame retardants of less than 12%, flaxseed products burn well. And the lower the percentage of boron salts, the more difficult it is to extinguish the flame.

- susceptibility to complete decomposition, whatever the manufacturers' brochures say. However, there is one thing: putrefactive microflora reproduces only in an environment with constant humidity or the presence of a base in the form of starch. This must be taken into account during construction and repair;

- damaged by rodents, which is again in conflict with advertising, albeit with a proviso. Mice and rats do not digest flax fiber, so advertising seems to be right - the product is not included in the rodent food chain. But the fact that this natural insulation is the favorite habitat of these pests is modestly silent;

- loss of operational properties (heat and sound insulation), under mechanical stress (squeezing);

- needs to be treated with moisture-proof compounds when used in rooms with high humidity, which further increases the cost of thermal insulation.

Linen insulation: a modern solution for sustainable renovation

At the present stage of development of interior design and renovation work, more and more attention is paid to the quality of the materials used. Last but not least, it is assessed how this or that material is safe for humans, as well as nature during its disposal. This niche was rightfully occupied by linen insulation.

At the dawn of its development, human civilization grew and actively used flax for various purposes: the manufacture of oils, garments. And even seemingly unnecessary leftovers from production - coarse tow - were used to insulate houses, clogging up the cracks of the huts with it. It is this property that the manufacturers of modern insulation drew attention to, proposing a new type of material - linen insulation in slabs.

Features of the

In its pure form, flax has a negative quality of fast caking for construction and finishing works, therefore, the plates used for installation will not have such a long service life. To correct this natural disadvantage in the production of linen insulation, in addition to the main component, a small part of polyester fibers is also used, which provide the material with volume, make it elastic,significantly increase the wear life.

In the production of this type of insulation, the fibers are heat treated in order to destroy harmful bacteria that could potentially be found in natural flax. As a result, the possibility of a pathogenic source of microorganisms in the linen insulation is excluded - it is biologically pure.

Benefits of linen insulation

Despite the fact that linen insulation is similar in function to its counterparts made from mineral wool or glass wool, expanded polystyrene, it has a number of advantages:

- Safe. Due to the use in the production of mainly environmentally friendly, natural ingredients, it does not contain, does not emit harmful substances, gases during operation, and due to processing at high temperatures prevents the appearance of dust and any odors, as a result, does not cause allergies or irritation upon contact.

- Fire resistant. Heaters made of plant fiber are fire-resistant, especially after processing with special substances that prevent fire - fire retardants. For example, a species such as Izolna contains borax as an element for fire protection. The flammability class with the appropriate impregnation is set to G1, and without it - G3.

- Non-toxic. In case of a possible fire, it does not emit toxic substances, since it consists of natural ingredients.

- Biostable. Flax is a natural antiseptic. Specially heated and purified, it does not allow the development of fungi and various microorganisms.

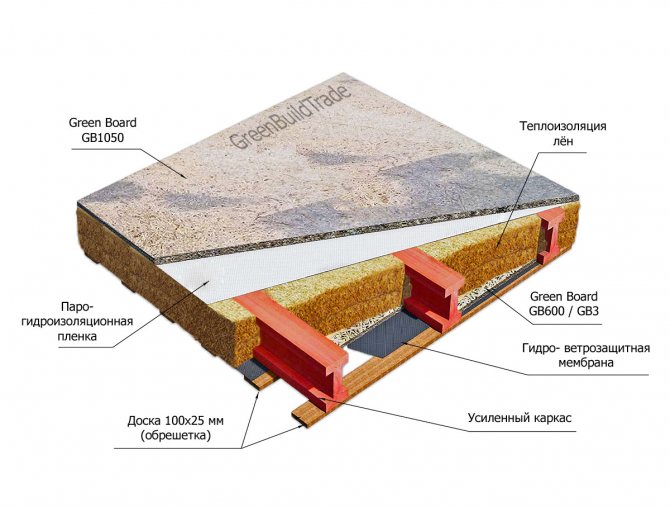

- Moisture resistant. Heaters made of flax allow not to produce additional vapor barrier of walls, since they do not accumulate excess moisture, steam, condensate in their composition. In this case, there is no violation of the basic functions of the insulation. However, for bathrooms and other rooms with very high air humidity, it is recommended to use foil insulation, especially if starch was used in their production.

- Easily recoverable. When wet, wet or external pressure, linen insulation can deform, but after that, it restores its original shape as soon as possible.

- Non-electrostatic. Linen insulation is not electrified, and also does not conduct electricity, which is important when used, for example, in country houses.

- High heat capacity. Insulation made of flax in slabs is less conductive to heat, its thermal conductivity is 0.03 - 0.04 W / (mK). Thanks to this, in the winter the house will be warm, and in the summer the heat will not penetrate into the room.

- Soundproof. The material also inhibits sound more than analogs: the sound absorption coefficient can reach 0.95.

- Long lasting. It has a long service life - from 50 to 100 years.

Disadvantages of linen insulation

Like any building or finishing material, this type of insulation is not without a number of disadvantages. However, their list is not as impressive as the number par excellence:

- High price. Even the most expensive mineral analogue will cost half the price of linen insulation due to the production of the latter from natural components, which significantly increases the cost.

- Limitations in the scope. Despite good performance when wet or mechanical stress in rooms with high humidity, this type of insulation requires additional protection from moisture, as well as from constant direct physical impact that deforms the plate.

- The need to find a balance between the ability of insulation to prevent fire, durability and naturalness: to increase the fire resistance, the material is treated with fire retardants, which lowers the environmental friendliness of the material, to increase the service life of flax fibers, polyester fibers.

Application area

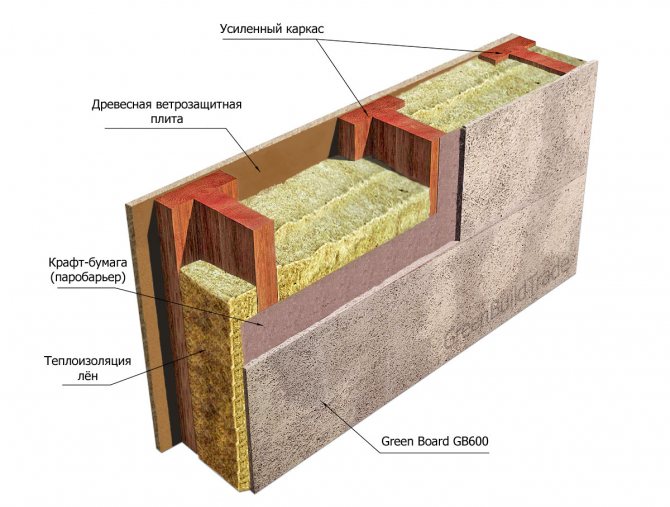

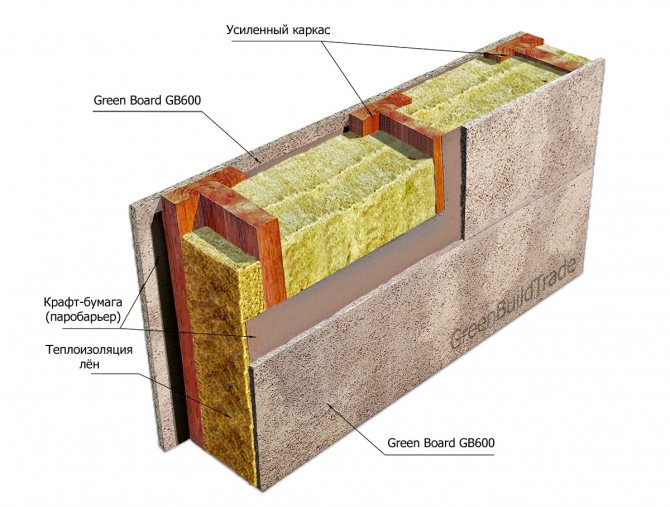

In terms of sales volume of 0.5% in physical terms (in m3), linen insulation in slabs (together with tapes for warming between joints) occupies a modest last place in the market of thermal insulation materials. There are two reasons: the high price and a special niche in thermal insulation tied to wooden houses. It is rarely used in buildings made of other types of building materials, although flax can be used for thermal insulation:

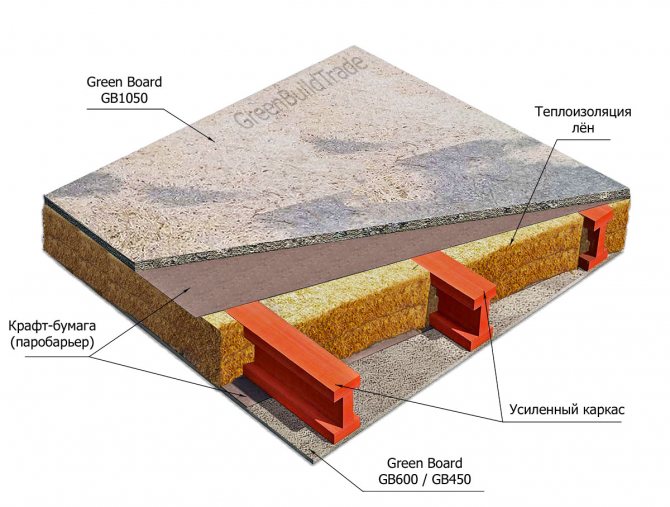

- floor, but only along the logs (not used under the screed due to the loss of performance under pressure);

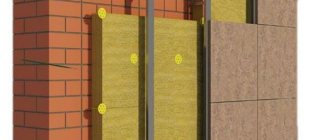

- walls, both inside and outside. But there are also limitations here: you cannot use the “wet method” of insulation;

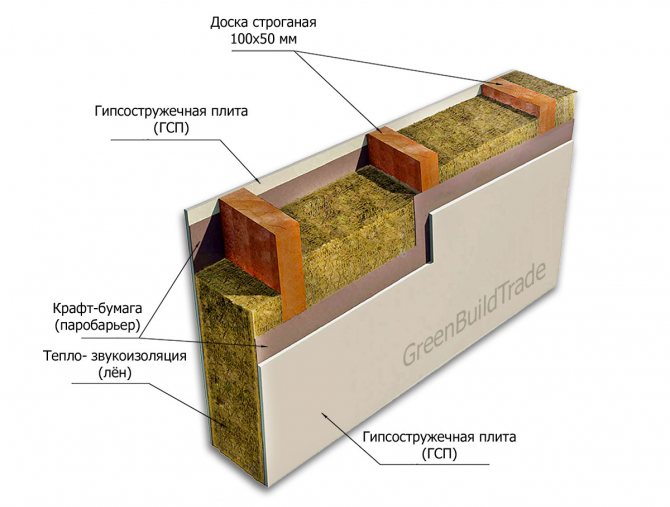

- interior partitions, but mainly as a sound-absorbing material;

- ceiling, but outside. For internal insulation, the height of an apartment or house decreases too sharply (to the thickness of the mat of 10 cm, you also need to add a cladding or a suspended (suspended) ceiling);

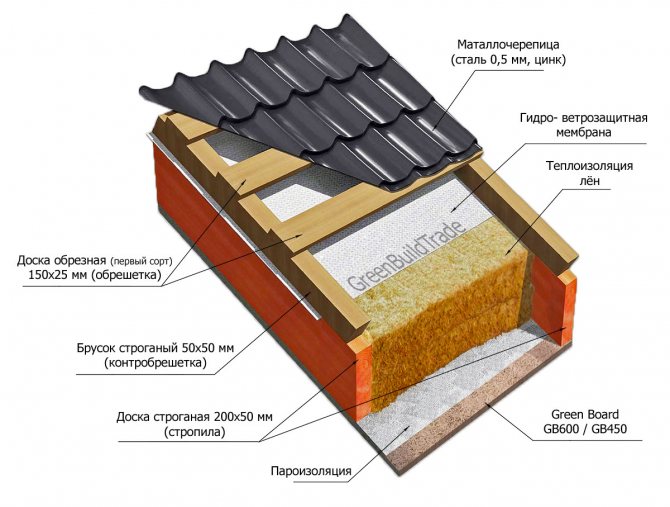

- roofs, but only pitched;

- door and window blocks - serves as a seal.

In addition, fiber tapes are used to insulate the interconnection of log cabins, and tow is used to seal various cracks and gaps. If we consider in the context of the types of buildings, then flax can be effectively used in frame and wooden houses, apartments.

Frame house. Difficult climatic conditions in Russia did not allow finding the best insulation option for frame houses. Negative nuances always appear. With the advent of linen mats for insulation, it turned out that they are almost ideal for this type of building: they perfectly protect against noise, heat loss in winter and overheating of house rooms in summer. The ability of the insulation to regulate the indoor microclimate all year round turns flax into the main type of heat insulator for frame buildings.

Wooden house. Initially, linen and wooden houses were inseparable. Their collaboration goes back several millennia. Therefore, with the advent of new qualities in linen insulation, the use of flax fiber thermal insulation materials for the insulation of various structural elements of a wooden house is most organically seen.

Flat. Linen mats do their job well in an apartment when insulating the floor and walls. Limitations exist for the bathroom and kitchen due to the high hygroscopicity of the fibers.

Applications

Linen insulation is used in a very wide range of construction work. Due to its unique qualities, this material is famous for its high noise and heat insulation:

- various types of roofs, attics;

- walls (external, internal, as well as interior partitions);

- floors, ceilings and floors.

An unexpected area of application can be found for linen mats not treated with various substances. If necessary and desired, they can be used not only as mattresses, but even as blankets.

The use of this material for insulation is quite extensive. Due to the ease of installation, it can be used on a wide variety of construction sites:

- Frame houses. The project for the construction of similar dwellings that came to us from other countries needs to be adapted to Russian weather conditions. That is why linen heaters, which have high heat resistance and sound insulation performance, are optimal for frame houses. Moreover, the ability of this material to pass moisture and control the microclimate in the house, giving the structure an important feature of log houses. Thanks to this, the owners do not have to worry too much about the need for increased heating in winter and cooling the air in hot summer.

- Wooden houses. The use of flax for warming huts goes back many centuries, during which the positive properties of this material have been tested and confirmed by many generations. Modern industry even more allows the use of linen insulation, but already in the form of mats and slabs.An important feature of these insulators is their natural ability to cope with excess moisture, which eliminates the need for additional vapor barrier of walls with films and significantly increases the service life of wooden structures.

- Apartments. Linen mats or slabs are convenient to use in the process of insulating premises in apartment buildings. Firstly, it is one of the best soundproofing that humanity has at the moment. Secondly, the ease of use and changing the size of the material (only scissors and a sharp knife are needed) allows you to make repairs using linen insulation even in small spaces. And, thirdly, Ekolen insulation is completely safe for health, which is especially important in a populous city.

Thus, a universal linen insulation is useful both in an apartment and in a country house. Regardless of the manufacturer or the form of release of the material, consumers who turn their attention to this insulator, tested over the years, become the owner of a modern home, perfectly isolated from noise and temperature drops, harmless to the people living in it and the environment.

Insulation types

The construction industry offers consumers several types of linen insulation:

- tow;

- felt (linen);

- batting (linen);

- mats (plates).

Tow. Tow is waste from the processing of flax and other bast crops (hemp, jute, etc.), arising in the process of scutching. Consists of coarse, short, tangled fibers heavily contaminated with fire. It has been used in construction since the beginning of the cultivation of flax for the production of textiles.

It is mainly used for insulating log cabins. But it can be found in the openings of doors and windows (instead of polyurethane foam), as well as in the joints of the plates of the main insulation, for example, foam.

Felt. The definition of "felt" has nothing to do with linen insulation, because the word originated to define a dense nonwoven fabric made of wool. But manufacturers of a similar material made from flax fibers could not come up with an independent name for dense nonwoven ribbons. So they began to call their products linen felt.

A product is made from long fibers using needle-punched technology - this is when special needles with barbs form a canvas, fastening it with their own fibers. It is used as an inter-crown linen insulation.

Batting. Batting is another type of nonwoven fabric. It differs from felt in that nylon or cotton thread is used to fasten the flax fiber layer. It is used in the same way as felt, but with one difference: it fits in two layers. This requirement is explained by the production technology - the insulation tape has a low density. Only about 500 g / m2.

Mats. Flax fiber insulation mats are produced using starch, which serves as a binder between the fibers. In many industries, mats are additionally stitched with silk or cotton threads. Thermal insulation material is produced in the form of rolls and plates with a thickness of 5 and 10 cm. It is used for thermal insulation of various building structures.

Attention: in materials about linen insulation, another type is called: flax-jute. However, the use of the term "flax-jute" to define insulation as an independent type, consisting of a combination of linen and jute fibers, is incorrect. It would be more correct to say that other types of bast crops can be added to flax fibers. After all, the so-called “linen-jute” insulation is produced in the form of felt, batting and mats. Therefore, it is impossible to say that this is an independent type of heat insulator.

Description and features of the production of linen insulation

For hundreds of years, plant fibers have been used as insulating materials. Nowadays, natural heat insulators do not lose their relevance.One of the most popular plants used for the production of insulation is flax. Tow is made of long fibers, and mats and rolls of various thicknesses and densities are made from short fibers. High-quality linen insulation, as a rule, eliminates the need for additional caulking of log cabins.

This material is made using needle-punched technology. The fibers are fed to the carding machine, where the fire is separated from the pure raw materials. Further, the future insulation is sent to a special needle-punching machine, which, by means of needles with notches, pierces the fibers and forms a solid canvas.

Linen heat insulators, like any other natural materials that contain cellulose and polysaccharides, are not particularly fire resistant. Therefore, during the production of fibers, they undergo a special treatment with fire retardants. The minimum content of boron compounds for imparting fire resistance to linen insulation reaches 13 percent.

A linen heat insulator can be produced according to two “recipes”. As a result, you can get a 100% pure material, the fibers of which are glued together with starch-containing components, as well as a mixture of flax fiber (85%) and lavsan (15%).

Due to its technical characteristics, in particular the ability to dry quickly after getting wet, linen-based insulation is indispensable for use in conditions where condensation is expected. This is the best heat insulator for baths, attics, roofs.

Popular brands and prices

In the Russian trade network, linen insulation can be found under many brands: Thermo-Hanf, Val-Flax, TermoLen, Flaxan, Ecoteplin, Ecoterm, Ekolen, etc., as Russian production and manufacturers from Europe.

"TermoLen". Products under the TermoLen brand are manufactured by the Novosibirsk Flax-Jute Company. She was the first in Russia to master the latest AirLay and thermal bonding technologies for the production of environmentally friendly natural insulation materials from flax.

The use of modern equipment in the processing line made it possible to abandon starch as a binder (a bicomponent synthetic winterizer fiber is used), which provided the mat with additional elasticity, durability and volume recovery after removing mechanical loads. All this together allows you to install the insulation in the cells of the lathing raspor, without additional fastening.

You can buy insulation at a price of 5,760 rubles / m3 and above (depending on the density).

Ecoteplin. One of the leaders in the production of various types of flax products is the Russian concern "Khors". It includes not only processing enterprises, but also agricultural production. Therefore, the TermoDom enterprise, which specializes in the production of heaters from bast crops, uses its own raw materials.

A feature of the product is the complete absence of synthetic materials. Starch is used as an adhesive. This is both an advantage and a disadvantage. The plus is that the product is categorized as absolutely environmentally friendly. Therefore, it can be used without restrictions in living quarters with children or allergy sufferers.

Minus in fast caking and a service life of 40-50 years (starch is to blame - it serves as a base for the reproduction of putrefactive bacteria), which is almost half the size of analogues with synthetics in the composition.

The cost of 1 m3 starts from 5500 rubles.

Ecoterm. Insulation "Ecoterm" gets into the trade networks of Russia from Belarus (CJSC "Politeks"). It is produced in the form of mats with a thickness of 5 and 10 cm. It is used for sound and heat insulation of private houses and apartments.

Mounted by a polyester fiber binder. It has high density and elasticity, resistance to deformation and shrinkage (does not cake for a long time).However, such properties still do not allow the use of insulation under the screed.

In addition, the lack of impregnation from fire retardants should be attributed to a serious drawback, which really affects the price - it is lower: insulation can be bought from 5,000 rubles / m3.

Val-Flax. Products with an unusual name "Val-Flax" are manufactured by LLC "Artemida" (Novgorod). Newcomer to the construction market. However, the high quality of the product that meets all EU requirements and the price (from 5400 rubles / m3) paint its prospects in a rainbow color.

EcoLen. Smolenskaya specializes in the production of linen felt using needle-punched technology. Dense tapes "EcoLen" are used for sealing connecting joints between the crowns of a log house and in the form of seals when installing window and door blocks.

On the recommendation of the manufacturer, this material can also be used to insulate the walls of wooden houses from the inside of the room, which raises a number of questions: why is it necessary at all and what fastening technology to use for a thin canvas. The downside is the lack of fire protection.

The company's products cost from 4900 rubles / m3.

Installation features

Having studied the main types of environmentally friendly insulation, you need to disassemble the methods of their installation. Plates, roll materials and mats are fixed like ordinary mineral wool. In any case, you need to choose the most environmentally friendly insulation for buildings and install it in stages.

Stage 1. Preparation

The first step is to prepare the work surface. To do this, remove the old casing and thermal insulation from it. In this case, chips and other defects must be plastered.

You also need to clean the coating from dirt and dust. Then they take up the main work.

Stage 2. Lathing

For maximum thermal insulation of the building on its outer walls, you need to make a frame from wooden slats or iron profiles. In thickness, it is equal to the thickness of the insulation. The distance between the frame elements is made along the width of the thermal insulation boards.

Stage 3. Installation

The installation is carried out differently depending on the type of insulating material used.

Laying eco-friendly insulation

Mats and slabs made of natural material are placed tightly between vertical profiles (from bottom to top). A cladding is installed on top of the material. If the attic is being insulated, then an environmentally friendly insulation is inserted between the rafters.

Installation of cellulose insulation

There are 2 ways to install cellulose insulation:

- Dry.

- Wet.

It is necessary to insulate inclined surfaces using the first method. A hole is made in the closed cavities and the ecowool is blown into the structure with a compressor. It is also allowed to manually fill the cavities with material.

The second method of ecowool installation is optimal for frame structures. I moisten the material with water, after which it is blown to the surface. This allows it to adhere well to any surface. Due to this, the required thermal insulation layer is created on the surface, the excess of which is cut off.

With such simple methods, it is possible to quickly insulate housing with environmentally friendly materials, which will create a healthy climate and comfort in the house.

By choosing the most environmentally friendly insulation for finishing the house, as well as properly installing it, you can make the house very warm, cozy and economical in terms of heating costs.

Selection features

When choosing linen insulation, you need to pay attention to the following parameters:

- the material should not have foreign impurities in the form of a fire, which not only impairs the appearance, but also reduces the technical and operational characteristics;

- the density of the tape or web must be uniform. Otherwise, cold bridges form over time;

- when choosing between tow, batting, felt and mats, you need to focus on the place of use. Here the role is played by the width and thickness of the insulation, its density and purpose. So, for profiled beams, felt up to 3 mm thick and up to 300 g / m2 density is suitable.The joints of rounded wood crowns should be sealed with felt 5 mm thick and 500 g / m2 density or 15 mm thick batting (it will settle when the log is laid). Between the timber you need a linen felt 10 mm wide and 8 kg / m2;

- the binder must still be polyester fibers. There will be no harm to the health of family members, and the service life is almost doubled.

Brief instructions for installing linen insulation

Working with natural insulation is very simple. From the tools you will need scissors, a knife, staples for fastening.

We carry out installation according to the following scheme:

- We carry out measurements if tile or roll material is used. If you plan to lay on a horizontal surface, then you do not need to use fasteners.

- If you need to cut the insulation, we take a regular knife or scissors. In this case, it is not even necessary to first get it out of the package.

- If you are insulating a wooden building during construction, then we cut the material into strips of the required length and width and put it between the logs. We join the tapes and fasten them with staples.

- If you are insulating the joints of an already built building, then you should use a chisel to push the tow or tape deep into the space between the crowns.

- Plates and sheets of linen heat insulator are perfectly fixed even without fasteners. To do this, we set them up between the rafters or logs.

- If the surface has a slope, then we additionally equip the crate to allow moisture to erode outward.

- If the building will be exposed to moisture, it is recommended to protect the insulation with a vapor-permeable membrane. We place it with an overlap of 10 centimeters and glue the joints with tape.

Watch the video review of linen insulation: Linen insulation is great for insulating so-called "green" or "eco" houses built of wood. They are environmentally friendly, have good technical characteristics and are durable. Also, flax-based tile material is used to insulate ordinary brick, concrete buildings.

Insulation technology

A feature of the technology of insulation with linen mats is that the insulation cannot be fixed with glue or dowels. Only set by surprise. Therefore, using the example of wall insulation inside a house with linen insulation, we will consider all the nuances of thermal insulation work. They are executed in the following sequence:

- the wall is cleared of everything unnecessary: switches, sockets, fixtures, etc.;

- an audit of the condition of the wall surface is carried out. Repair work is carried out if necessary;

- the crate is stuffed with cells 1-2 cm smaller in width and height so that the mats become a surprise;

- the rolled insulation is cut to size, while you should not forget about an overlap of 1-2 cm;

- mats are installed in cells;

- counter-lattice is stuffed;

- the insulation layer is closed with a finishing material, for example, PVC panels or clapboard or sheets of drywall for painting or wallpaper.

Important: vapor barrier works under flax are not carried out.

Types of linen material

Flax has been used since ancient times for the manufacture of fabrics and clothing. Previously, shirts, dresses, bags and other wardrobe items were sewn from it. Such clothes did not have a bad effect on the body and looked beautiful.

Taking advantage of the experience of our ancestors, modern people also began to sew linen clothes. And noticing the unique properties of this fabric, they began to think about using it in construction. It turned out that linen not only retains heat, but also prevents heat from entering the house. Few materials can boast of such properties. Therefore, they began to make insulation from flax.

It may seem to you that the property of flax not to let the heat through is an advertising campaign of manufacturers of linen insulation.To make sure that this is not the case, in the hottest weather, you can wear a linen dress or a long-sleeved shirt (linen should be tight enough), after walking for several hours, you will notice that in a regular T-shirt you are hotter than in such clothes with a long sleeve.

Linen insulation is produced in different variations. We are talking not only about the shape of the insulation, but also about its texture. Let's take a look at what products are used to insulate homes.

Types of linen insulation:

- First of all, it is worth talking about linen wall insulation. They can be sold in the form of mats, tape, rolls or slabs. Each of the options is quite convenient, and here the choice depends more on your preferences. Many people choose mats.

- There are also linen insulation for filling gaps. These are linen tow and sanitary flax. The tow is quite narrow, but it rolls out perfectly and is hammered into the walls; it is used to insulate houses from ordinary timber. Plumbing flax has different sizes and is used for buildings from a profile bar and calibrated logs.

Linen insulation is of different types. It is definitely impossible to say which of them is better. It all depends on the size of the room and your preferences.