Scope of application of vapor-moisture insulating membranes ↑

The basis of the film is polypropylene, which provides the coating with strength, tear and pressure resistance. The use of roll insulation extends the service life of multi-layer building structures and helps to achieve an optimal ratio of humidity and temperature in the house.

The use of Izospan modifications is the best solution in the following situations:

- protection of heat-insulating materials and internal parts of the structure from steam and moisture penetration;

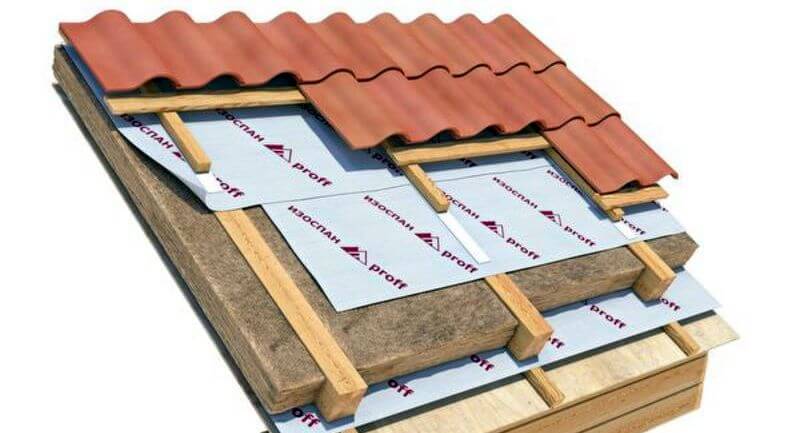

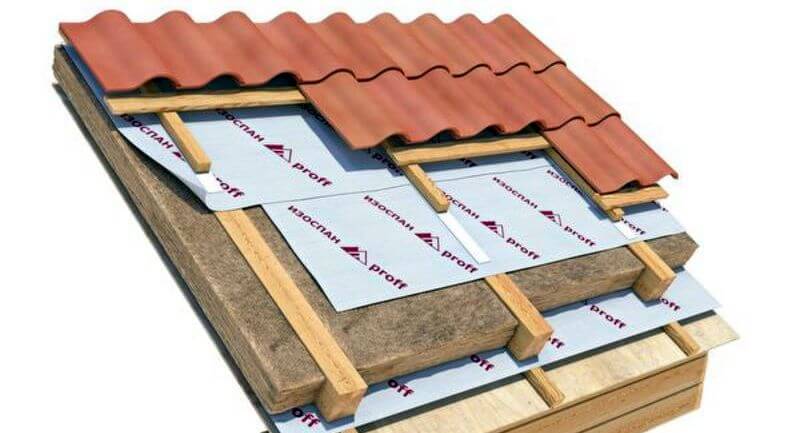

- arrangement of a "roofing pie";

- ensuring the vapor tightness of the attic, attic and interfloor floors;

- insulation of the structure from atmospheric precipitation, UV radiation in areas of insufficient joining of roof elements;

- additional waterproofing of different types of foundations;

- increasing the efficiency of the heat-insulating material.

High performance and affordable cost have become the main factors in the increased demand for materials.

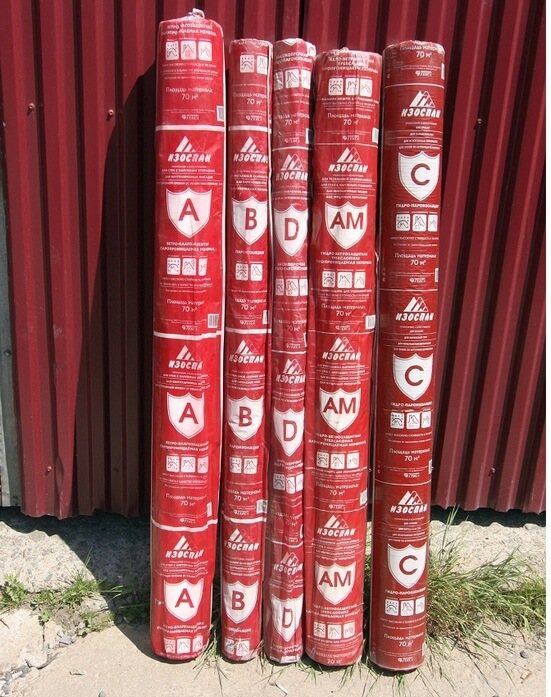

Classification and characteristics of roll insulation ↑

The manufacturer has developed a whole line of waterproofing materials. Some types of Izospan and their use are quite versatile. Other modifications of the product, on the contrary, are highly specialized and maximally reveal the protective qualities under certain installation conditions.

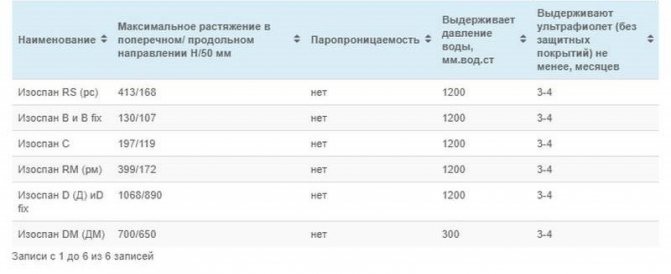

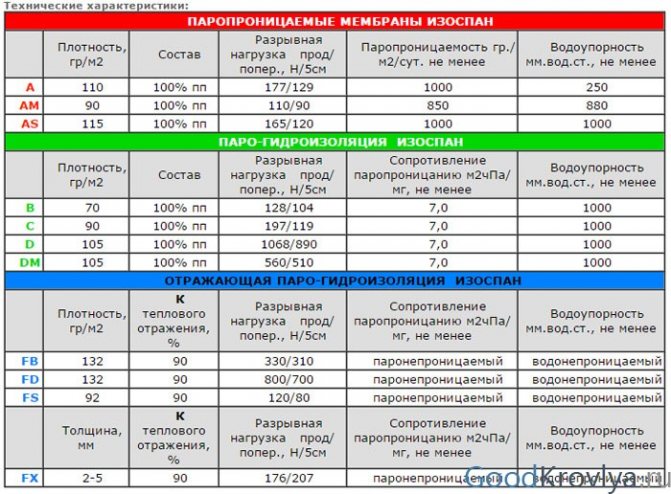

Types and characteristics of Izospan

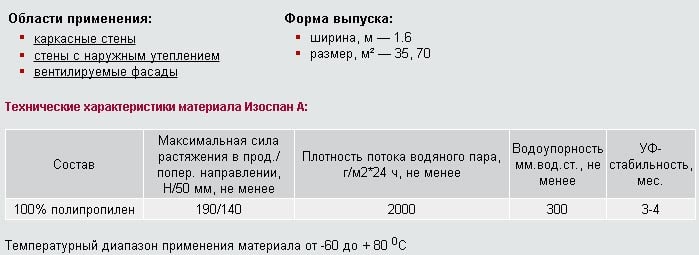

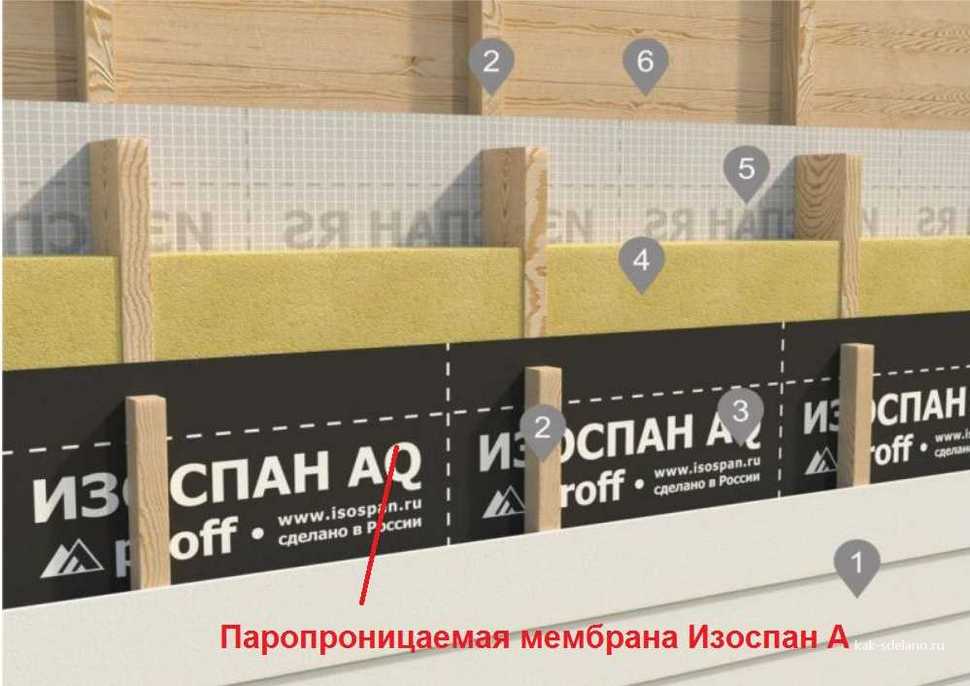

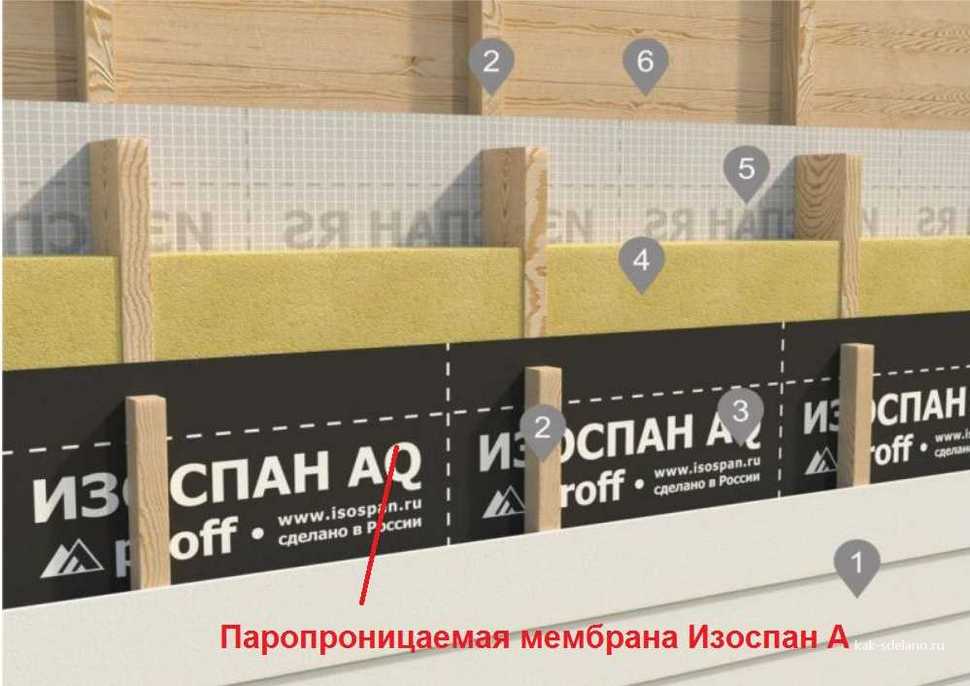

Windproof membrane category A ↑

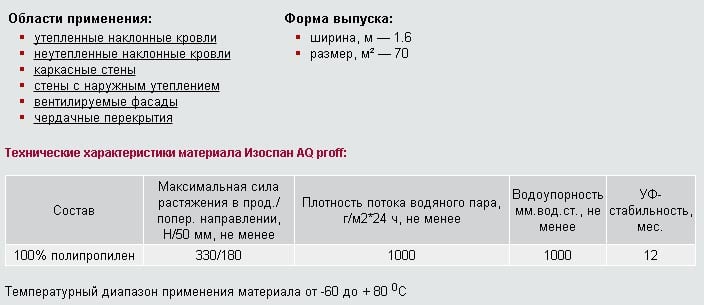

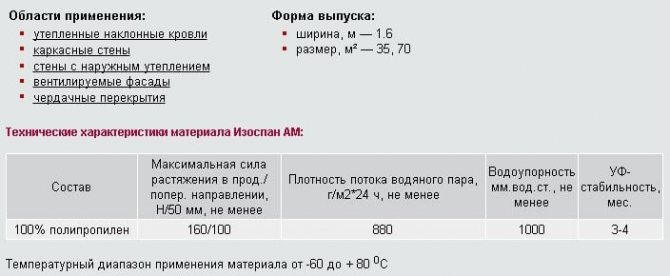

Category A contains vapor-permeable polymer membranes designed to protect internal elements. The material facilitates the release of steam into the atmosphere Insulation is used when arranging insulated roofs, frame walls and ventilated facades.

Izospan A has a smooth water-repellent outer surface and a porous base on the inner side. Due to this structure, moisture from the insulation is quickly absorbed into the membrane and removed to the outside. When laying insulating material of category A, two rules must be followed:

- Suitable for use on roofs with an angle of inclination of 35 ° and higher.

- Installation work is carried out in calm and dry weather.

- For high-quality steam extraction, an air gap must be provided. For this purpose, a control rail is stuffed onto the rafters.

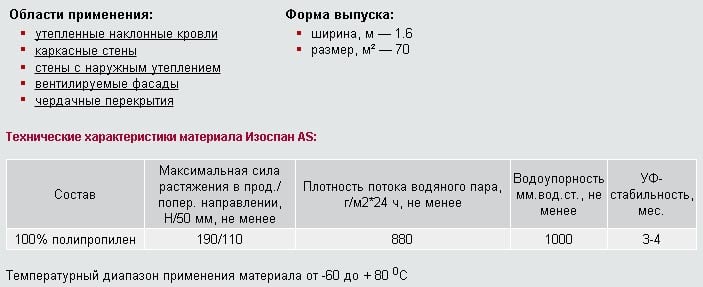

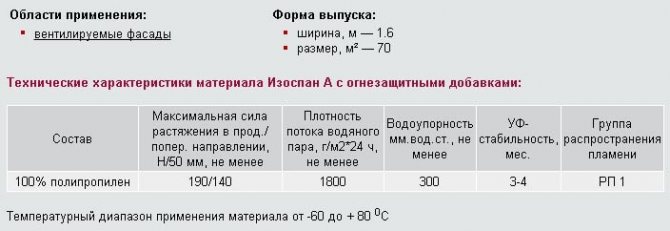

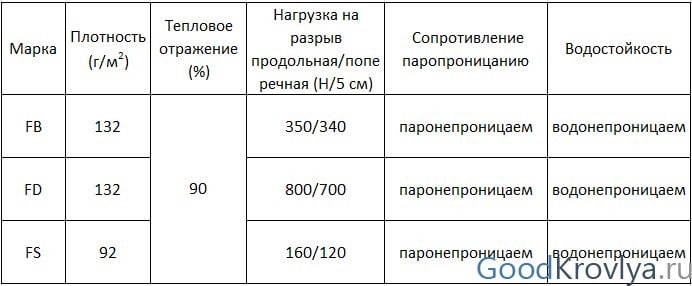

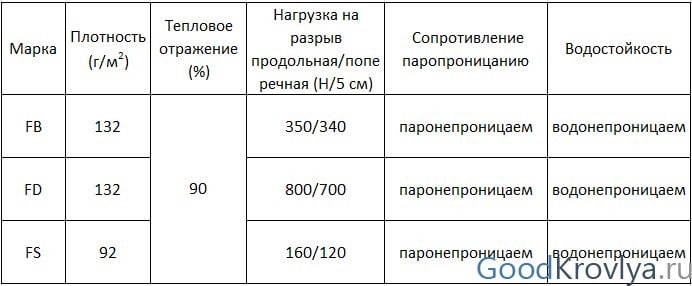

Specifications Izospan A, AM, AS

Izospan AM and AS modifications are three-layer diffuse membranes. They differ from their counterpart in reduced vapor permeability and the possibility of laying without crate.

Waterproofing films of grades B and C ↑

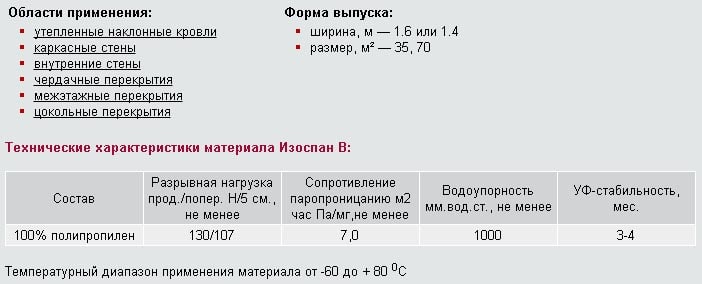

Film insulation of category B has a design similar to materials of group A. The main difference is increased water resistance (at least 1000 mm of water column). The vapor barrier does an excellent job with the task - it protects wooden and metal elements from the effects of condensation and moisture from inside the structure.

Izospan B is considered universal and is suitable for insulation of walls, roofs and internal ceilings. Possesses the following technical characteristics:

- breaking longitudinal and transverse load - 130/107 N / 5 cm;

- density - 72 g / m2;

- temperature range of application - from -60 ° С to + 80 ° С.

Group B vapor-waterproofing films are installed with an air gap of 5 cm above the fleecy side of the vapor barrier. It is the rough side that prevents condensation from flowing to the finish. Improved vapor barrier properties explain the demand for this material when laying laminate and parquet flooring.

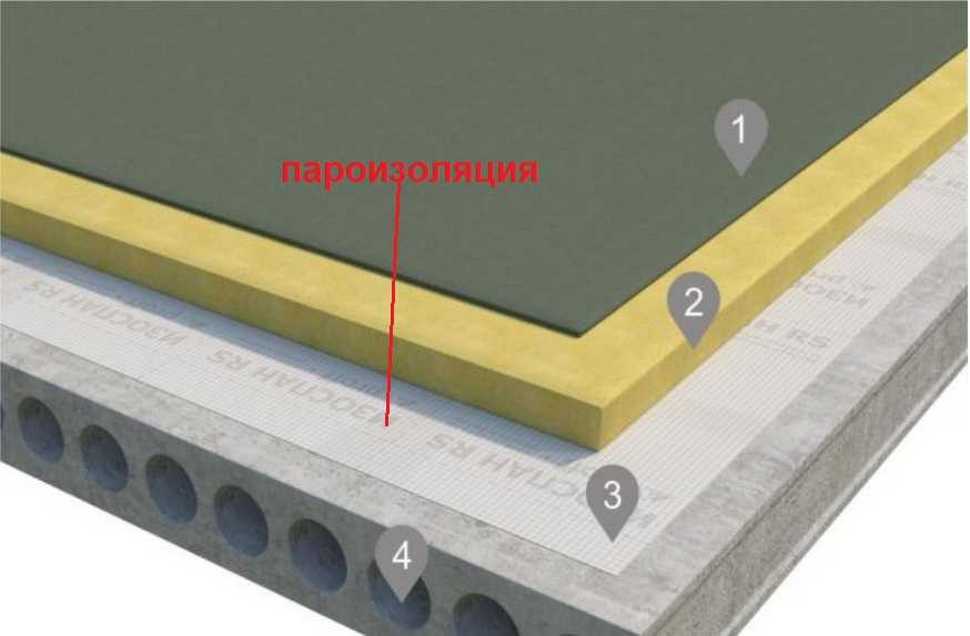

Vapor barrier under a wooden floor - scheme

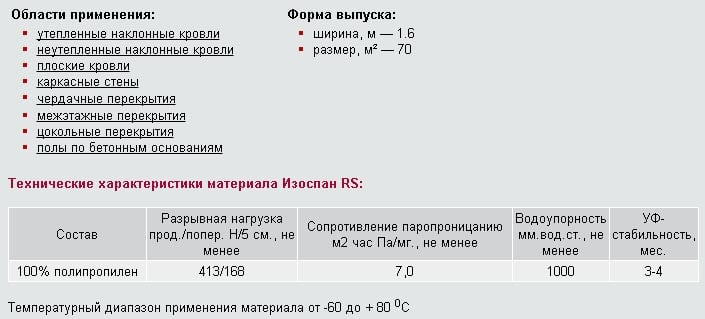

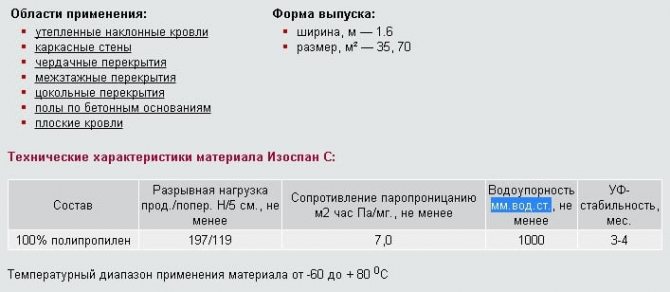

Izospan S.A distinctive feature of insulation is a large margin of safety and, as a result, high reliability and durability. The breaking load is 197/119 N / 5 cm and the density is 90 g / sq. m. The cost of a type C waterproofer exceeds the analogs of group B.

Izospan category C completely isolates the structure from capillary moisture and condensation.

Main functions:

- protection of "cold" and insulated roofs;

- steam and water insulation of a flat roof;

- moisture protection of wooden horizontal floors and concrete floors.

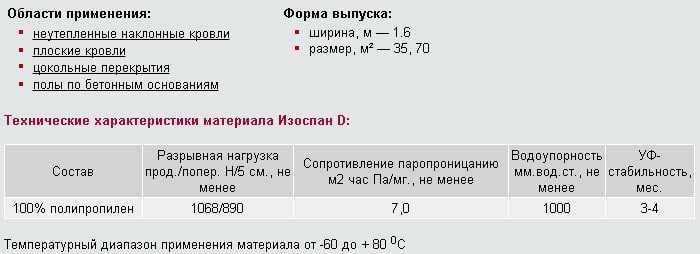

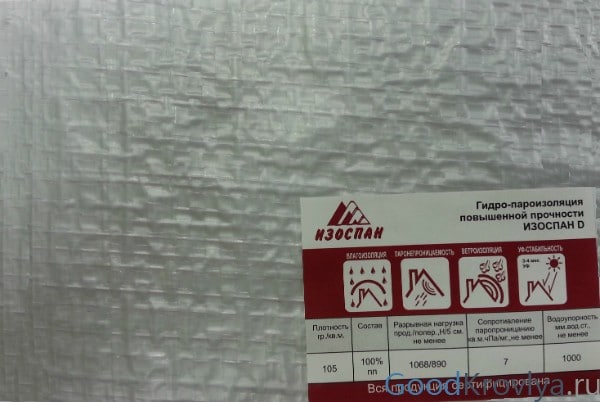

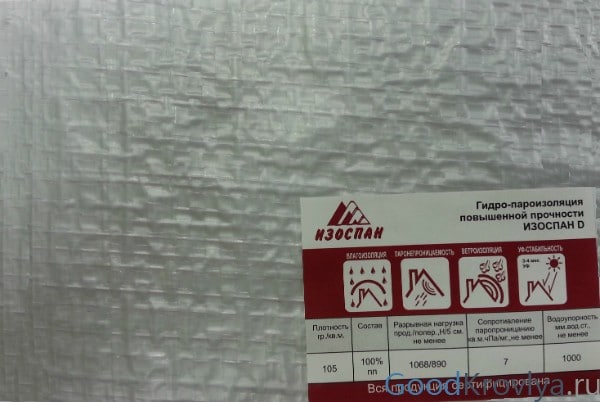

Heavy-duty canvases of category D ↑

Vapor barrier Izospan D is a two-layer woven fabric made of high-tech polypropylene. The multifunctional film is resistant to solar radiation and can withstand significant mechanical stress and snow load. Hydro and vapor barrier of the serial type D or DM is distinguished by its extra strength - a strip of fabric 5 cm wide does not deform under a weight of up to 106 kg.

Waterproofing category D

High technical and operational characteristics explain the versatility of category D film insulation. The material will adequately replace any of the above-described analogs and cope with more complex tasks:

- waterproofing floors on earth and concrete base;

- insulation of basement floors in rooms with high humidity;

- arrangement of a temporary roof and protection of the structure from precipitation.

New developments - energy-saving materials ↑

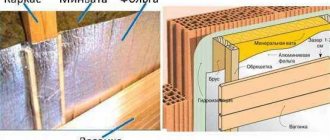

Izospan vapor barrier films of the FB, FD, FS and FX brands are modern high-tech waterproofing materials capable of reflecting 90% of infrared radiation. Progressive insulation acts as a reliable barrier against condensation, wind, moisture, and at the same time - increases energy savings.

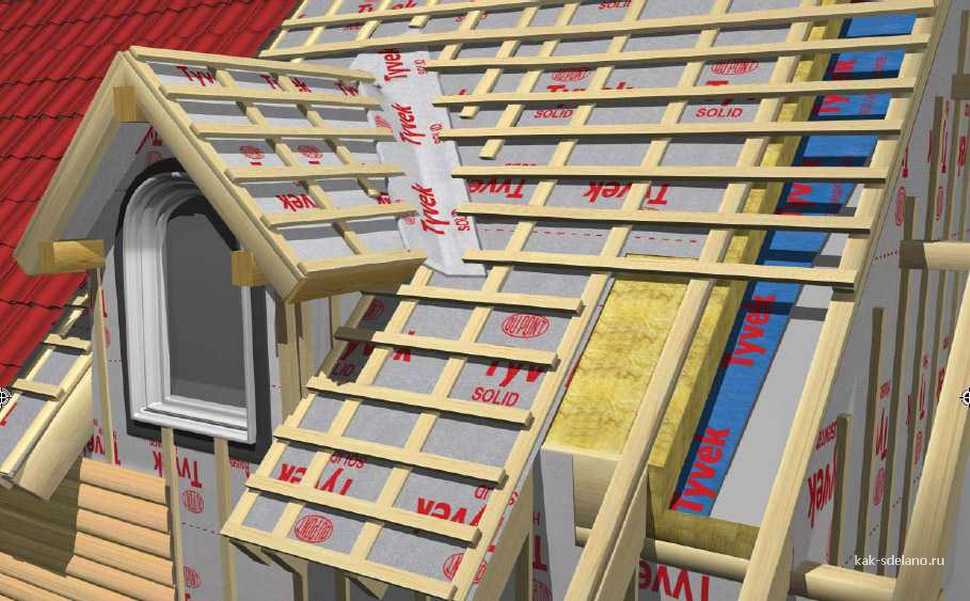

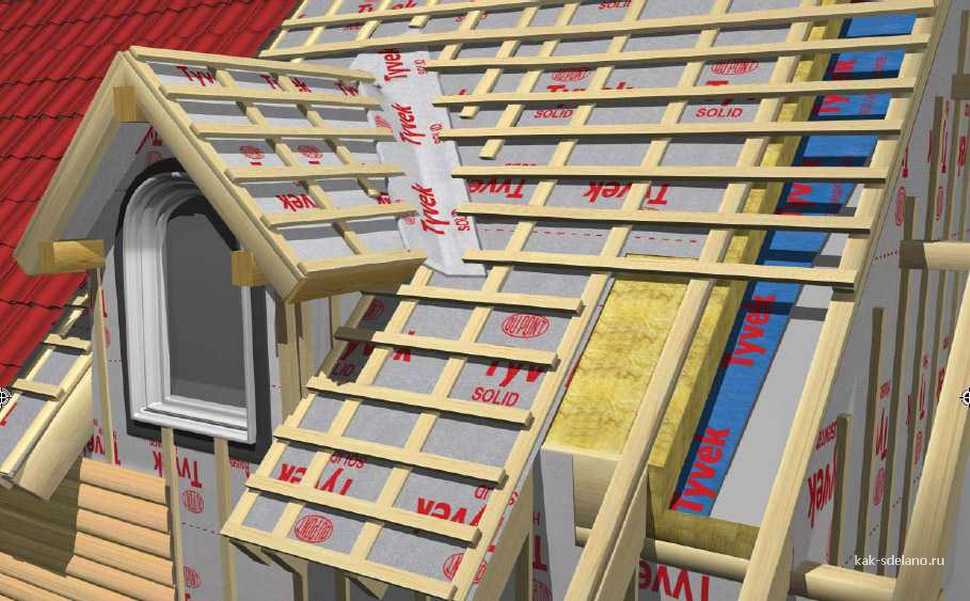

Attic vapor barrier

Thermal reflective insulation of FD and FS categories is made of two-layer polypropylene film. Izospan FX is based on foamed polyethylene of various thicknesses, and FB grades are made from kraft paper. Regardless of the type of insulation, one side is metallized. The reflectivity of materials is massively used in the arrangement of a "warm home", namely:

- as a backing layer for insulated floors;

- wall cladding behind heating radiators;

- thermal insulation of basement, attic and interfloor floors;

- construction of baths and saunas.

Energy-saving insulation characteristics

Important! Energy-saving films are completely impermeable to water vapor. Due to this feature, their use is possible only in buildings where a forced ventilation system is provided.

Izospan A: instructions for use

The Izospan A group of materials is a vapor-conducting windproof membrane that does not conduct water in a liquid state. The exception is Izospan A base. This membrane is only a windbreak. It does not impede the passage of steam and water. It is used in the ceiling over the ventilated façade, it is stuffed from the side of the subfloor. Protects mineral wool from blowing, does not interfere with the removal of moisture from the insulation.

To understand where and how best to use Izospan A, look at the characteristics. Once again: the film is not blown through (retains heat), removes steam, does not allow water to pass through. These properties are needed in the following constructs.

Rules for laying and installation of windproof vapor-permeable membranes

Vapor barrier materials are laid on vertical, inclined and horizontal surfaces. Despite the fact that the designs are different, the installation rules do not differ. Here's what to remember:

The basic rule of installation is to make overlaps and carefully glue them

- On pitched roofs and walls, work begins from the bottom. On horizontal roofs - from one of the walls.

- The second layer of material is laid with an overlap. That is, one panel overlaps another for at least:

- 10 cm on the walls;

- 15 cm on roofs;

- 15-20 cm in ceilings.

- Vertical joints (if any) are the same dimensions.

- All joints of the sheets are glued with double-sided adhesive tapes.

- Adjacent to the walls, the rafter system is also glued. It is recommended to use Izospan self-adhesive sealing tape for adjoining the rafter system. For joints - KL, for joining the KL + structure.

The task of vapor-permeable waterproofing and windproofing is to let steam through, but not to allow moisture in the liquid state. Therefore, the strength of the joints is important.

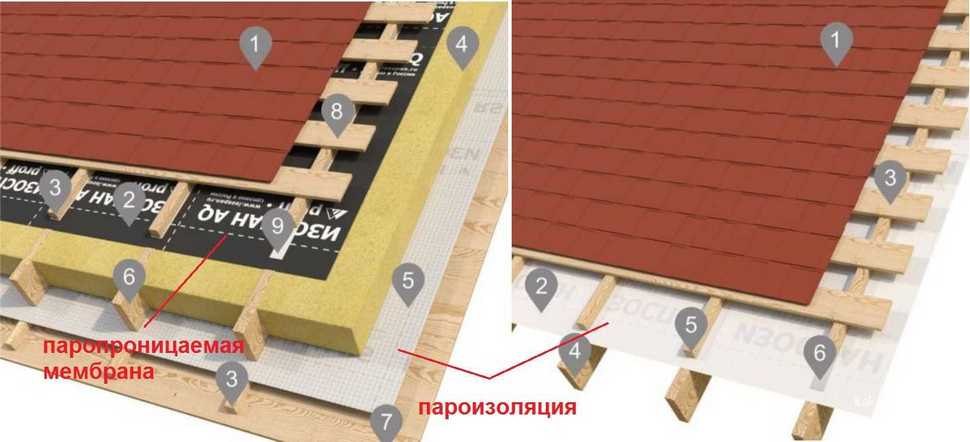

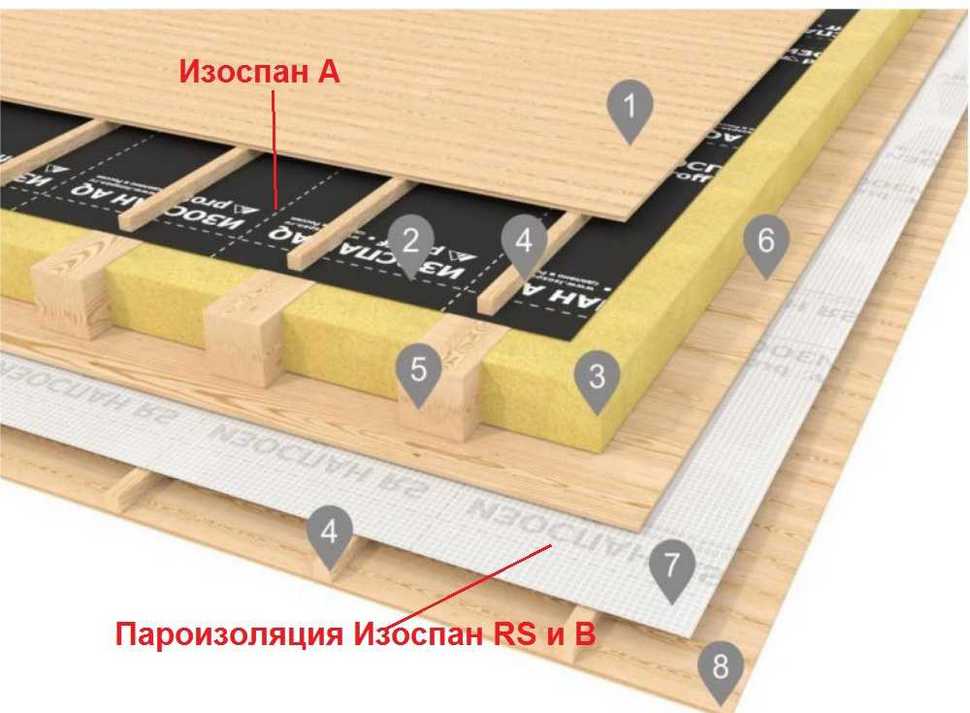

On a pitched roof, over insulation

The vapor barrier is laid on top of the mineral wool, and the top is covered with any roofing material. Let's see how everything works. Here it is necessary that the steam that has got into the insulation from the attic is removed. At the same time, condensation and possible leaks did not get into the insulation. So you need to remove steam and not let water through. This is exactly what Izospan A.

Application of Izospan A in a pie of insulated pitched roof

The membranes are unfolded with the "towards themselves" logo. It is better to lay it not in tightness, but with sagging. In this case, condensate, from which there is no escape on the roof, will drain to the center, and then into the gutter of the drainage system. So it will dry out faster even in a damp time, moisture will linger less, and it is less likely to get into the insulation.

On top of the vapor barrier, slats are stuffed along the rafters, and then across the crate for the installation of roofing material. With such a device and the presence of ventilation holes in the roof, the vapor barrier will be blown and dry.

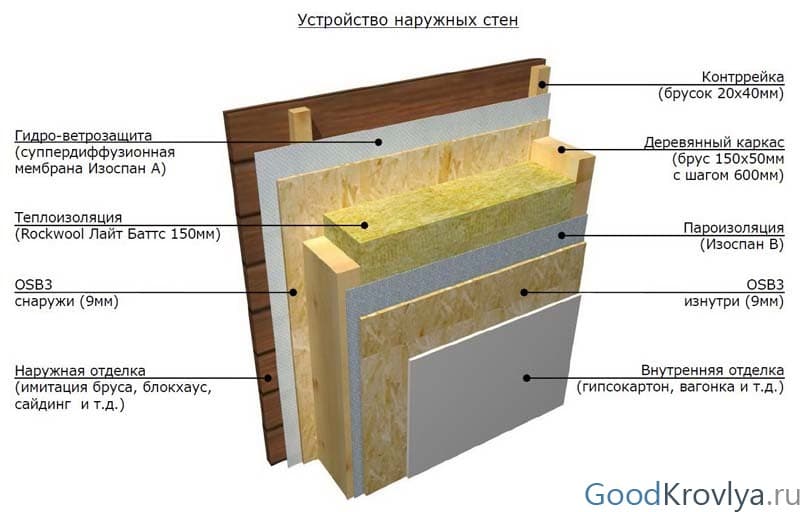

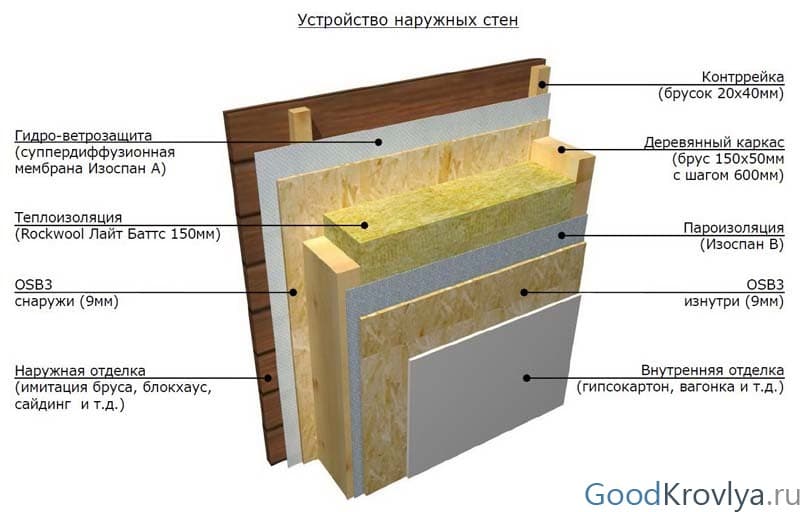

In the frame walls from the street side

Usually indoor humidity is higher than outside. And no matter how we protect the walls, steam seeps into them. These are the laws of physics. And since he hit the wall, he must be taken out. So here is the same task - to remove steam. This can only be done from the street side. So Izospan A is also placed in the frame walls from the side of the street. All types of Izospan A can be used here, except for the "base".

Izospan A - instructions for use in a frame wall

When using Izospan A "in its pure form", it does not matter which side to lay it on. All other modifications - AS, AQ, AM - unfold so that the logo is outward.

For wall insulation with mineral wool and for ventilated facades

With external wall insulation, in ventilated facades, the situation is almost the same as with the frame. Some kind of moisture seeps into the wall from the room. Then it penetrates into the insulation. Since wet mineral wool is a poor insulation material, care must be taken to ensure that this steam is quickly discharged. In this case, it is necessary to protect the cotton wool from getting wet and keep warm to the maximum. That is, the problem is solved by all the same vapor-permeable membranes of the Izospan A.

Application of Izospan A for external wall insulation and in the system of ventilated facades

Any vapor barrier for use in the case of external wall insulation, except for Izospan A with OZD, AF + and a base. The styling rule is the same - we unfold the logo towards ourselves. Izospan AF + is recommended for use in ventilated facades. If a metal structure is used, its strength will ensure that the vapor barrier will not break. If the ventilated facade is cladding on wooden beams, Izospan AM, AS and AQ in any of the options may well be suitable.

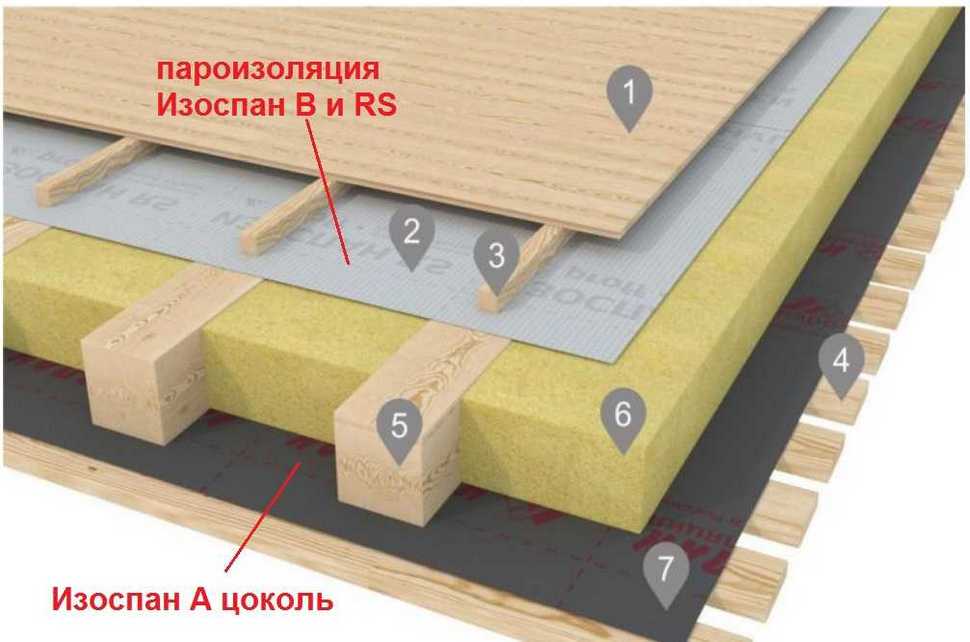

Overlap over ventilated subfloor

The ceiling over the ventilated plinth insulated with mineral wool has its own characteristics. First and foremost, for the circuit to work, the subfloor must be ventilated. This means that there must be air vents in the foundation. And they must be open even in winter, otherwise you will have wet insulation and cold in the house.

How does such a cake work? From the side of the house, moisture and steam seep into the insulation. If you just knock out the insulation with a net or slats, the wind walking in the underground will do an excellent job of removing moisture.But at the same time, it will carry away the heat and gradually carry out the particles of mineral wool, reducing its thickness. To get rid of the blowing out of heat and insulation, use Izospan A vapor barrier A base. It allows steam and moisture to pass freely in both directions, but does not let the wind through.

Izospan A: instructions for use in the ceiling over the ventilated subfloor

Such an objection may arise. Moisture from the soil will evaporate and enter the insulation. Under certain conditions, it condenses on the membrane, which makes the insulation wet. Is it better to use a vapor barrier with waterproofing properties? Not. It won't work. If the membrane does not conduct moisture, then the one that condenses or gets into the insulation will remain there. Because it won't get hot enough to evaporate and be discharged as steam. In a couple of years, you will have bags of water hanging from the ceiling and completely wet and unusable insulation.

And in order to reduce the evaporation of moisture from the soil, a dense film is placed in the subfield, a layer of sand (any, but without clay and dust) is poured with a layer of 5-10 cm on it. The film retains most of the moisture, and the sand works as an adsorbent, absorbing the fallen condensate. It (sand) is also dried by a walking wind.

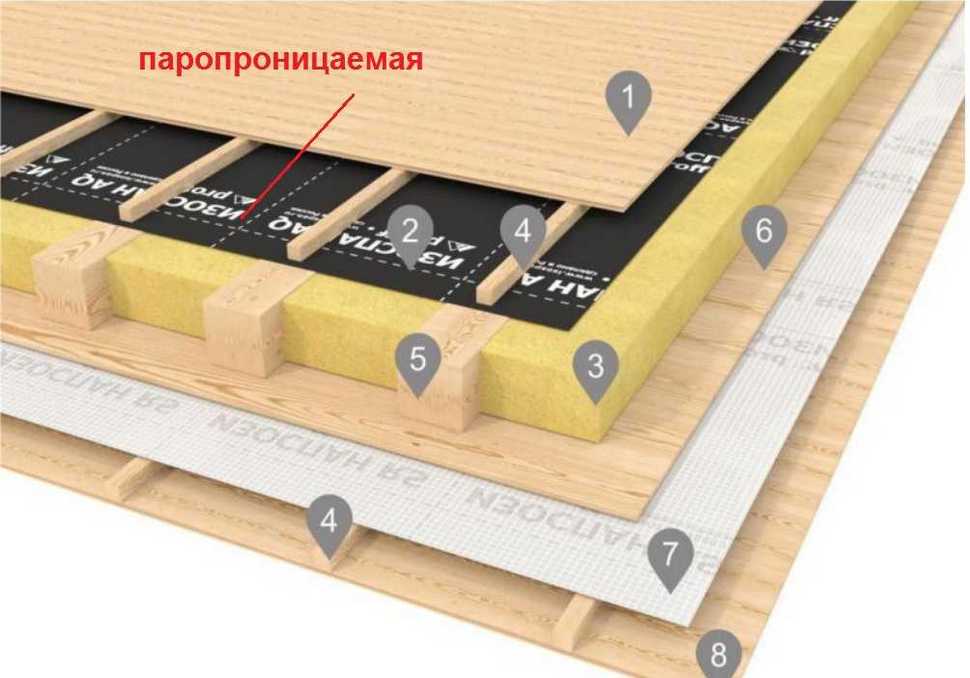

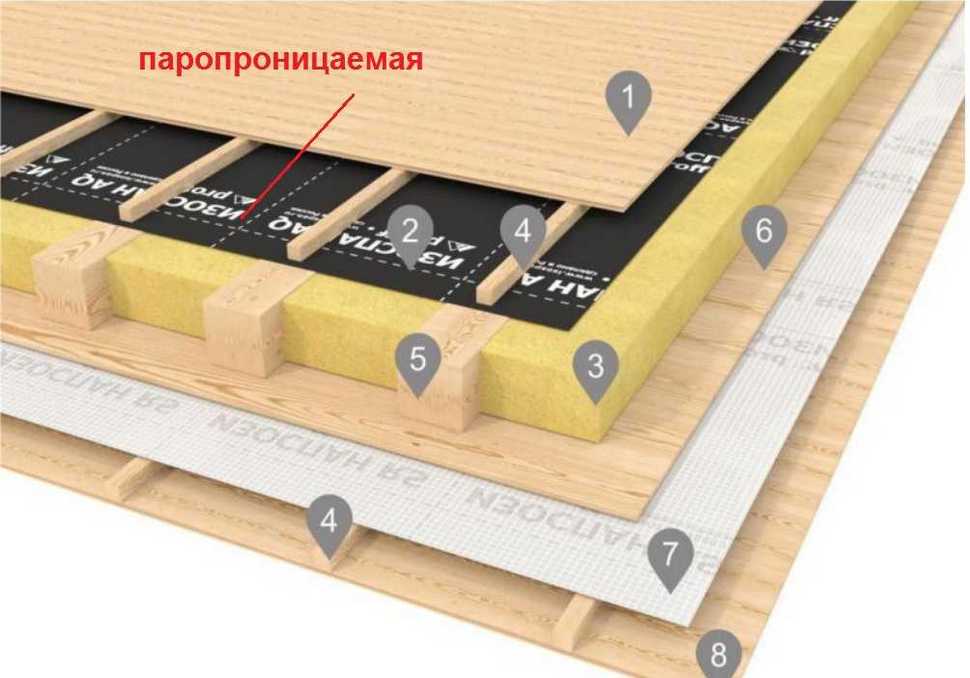

Interfloor and attic overlap

In the ceilings, steam enters from below, and should be discharged from above. Therefore, a vapor barrier to protect against moisture is placed on the bottom, and a vapor-permeable wind barrier - on top. In this cake, it additionally protects against the penetration of mineral wool particles into the room. Putting Izospan all the same - the logo should be facing you.

Izospan A for the floor - in the interfloor and attic overlap

In the interfloor overlap, to reduce the cost, vapor-permeable Izospan can be replaced with non-woven material (any type of geotextile). Its main function here is to protect against the penetration of small particles of mineral wool into the air. But you can do this only if the flooring is a sheet material in two layers, and in a gap between the seams. Otherwise, moisture can seep out and then just a non-woven material will not protect the insulation from getting wet.

In the attic floor, such a replacement is not considered at all - here it also needs to be protected from heat weathering. So wind protection is essential here.

Also note that the vapor barrier is attached to the beams with counter-rails. And on them the flooring is already laid. Counter battens are needed to create a ventilation gap, which is a prerequisite for moisture evaporation. It is important.

Qualitative analogues or a brand: the nuances of choice ↑

In Russia, goods produced under the Izospan trademark are in great demand. However, there are also its lesser-known counterparts on the market:

- Megaspan specializes in the production of construction membranes and insulating films. The model range repeats the Izospan vapor barrier line for roofs, walls, ceilings, facades, etc. Megaspan materials are more affordable and are not inferior in quality to their main competitors from.

- "Keramospan" produces film insulation, the declared characteristics of which are similar to the original.

- Axton is a foreign manufacturer of building materials, including hydro-vapor barrier. The company pays special attention to the sanitary and environmental safety of its products.

For your information. Companies use uniform product labeling. For example, the properties of Megaspan B correspond to the technical characteristics of Izospan V.

Characteristics of Izospan class B

The difference in price between branded insulation and analogs is sometimes very noticeable. However, the reasons for the cheapness may be understated quality. Unscrupulous manufacturers use the following tricks:

- Reducing the density of the material. This is invisible to the naked eye, but water resistance and strength deteriorate.

- Lack of UV stabilizer - the film becomes vulnerable to sunlight.

- The use of recycled raw materials in production reduces the service life of the coating.

- Replacing polypropylene with polyethylene or adding chalk to the raw material leads to a "weakening" of the structure and a reduction in the life of the film.

What technical characteristics are important for evaluating the properties of building membranes and films

In order to understand the differences between Izospan materials, and also to be able to compare them with the products of other companies, it is advisable to know which indicators are most significant for assessing the properties of building films. An ordinary consumer does not need to go into details, measurement methods and calculation formulas, but the characteristics that are important for Izospan should be named:

- Vapor permeability - the ability of a membrane to pass water vapor, provided that the atmospheric pressure on both sides of the membrane is the same, and the partial vapor pressure is different. Characteristic - vapor permeability coefficient, unit of measurement - mg / (m · h · Pa).

- Resistance to vapor permeation - the ability of the film to retain water vapor, measured in m2 · h · Pa / mg.

Both vapor permeability and resistance to vapor permeability depend on the properties of the material and its thickness. The methods for determining and calculating the values are given in SP 50.13330.2012.

- Water resistance - the water pressure that the web can withstand until the moment of leakage, is measured in millimeters of water column.

- Breaking load characterizes the strength of the web. This is the maximum load that a film or membrane can withstand without breaking. Measured in centi-newtons (H x cm).

- UV stability is the time (months) during which a material can be exposed to ultraviolet radiation outdoors without deterioration.

In the photo Izospan A, the marking of the canvas reflects the purpose of the material, its technical characteristics

The technology of laying roofing hydro-vapor barrier ↑

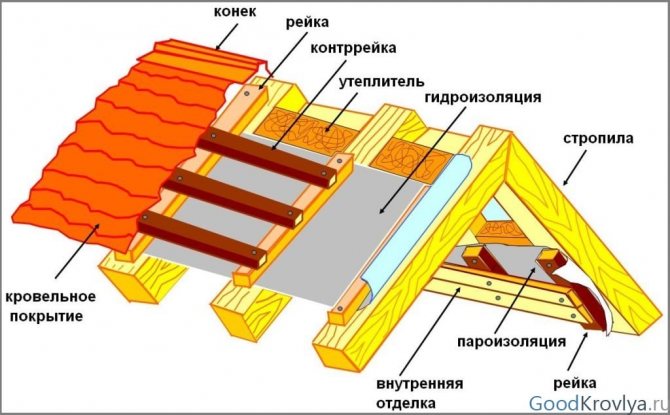

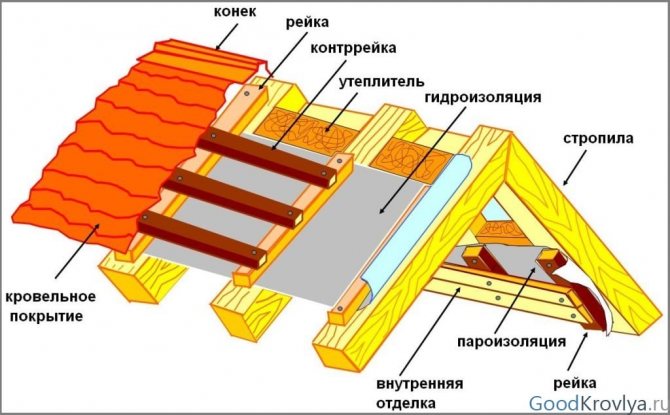

Installation technologies for various types of film insulation are similar to each other. The sequence of work depends on the finishing of specific structures. Below is a step-by-step instruction on the use of Izospan B vapor barrier when creating a "roofing pie".

Installation instructions ↑

Before proceeding with the installation, it is necessary to have an idea about the structure of the roof and the sequence of placing the layers of the "roofing cake". Insulation from above must be waterproofed, and a vapor barrier must be mounted from below. Both films are fixed to the roof rafter legs.

Important! The Izospan B vapor barrier is mounted in the direction from bottom to top. As a rule, one strip of roll is not enough to cover the roof slope. Therefore, first the film is rolled at the bottom of the roof, and then at the top.

Installation of Izospan film

Algorithm of actions:

- Open the roll and fix the free edge of the film sheet to the outer rafter. Fixation with fasteners with a wide head. To speed up the work, you can use a construction stapler with staples.

- Expand the Izospan roll for the roof and stretch the canvas parallel to the floor to the opposite edge of the rafters. It is necessary to check that the vapor barrier film sags slightly. Under the influence of low temperatures, the material shrinks slightly and shrinks.

- Cut the foil with a slight gap and attach the edge to the rafter system.

- Additionally fix the vapor barrier on the intermediate rafters.

- Proceed with the installation of the second canvas. Izospan B is overlapped with a width of more than 10 cm.

- Fasten the strip to the truss structure.

- Glue the joints between the canvases with Izospan SL connecting tape or ML proff single-sided tape.

Important! Before using Izospan and finally fixing it to the rafters, you need to make sure that the film is laid with the smooth side to the insulation, and the rough side to the inside of the building.

Roof vapor barrier: expert advice ↑

Roof vapor barrier is a crucial stage in the construction of a house. Builders' mistakes are costly for households. After taking a bath and cooking, vapors rise upward, penetrate the insulation and reduce its thermal insulation properties. Over time, this leads to wetting of the rafters, the formation of mold, freezing of the roof in winter and damage to the interior decoration.

The structure of the "roofing pie"

To prevent negative consequences when installing a vapor barrier, it is important to take into account some of the nuances:

- Before starting installation work, you should carefully study the instructions for using Izospan for roofing. Izospan category A, B, C is fixed only indoors.

- When laying and attaching the protective film, it is necessary to avoid tension on the material, the appearance of holes and other defects.

- Steam and waterproofing on the roof of the attic room is fixed with counter-rails. In the future, the installation of interior decoration is performed on this crate. In addition, the slats ensure the tightness of the joints between the rafter legs and the foil insulation.

- The allowances on the sides of each canvas must be at least 15 cm. This is enough to bring the vapor barrier onto the gables or adjacent slopes.

- It does not matter which side to lay Izospan AM on. The main condition is the installation of the membrane film directly on the insulation.

Types of vapor barrier Izospan

All modern vapor barriers are universal for use on various surfaces. They differ only in their properties: strength, water resistance, UV resistance, vapor permeability.

There are such types of Izospan from:

Vapor-permeable membranes for protection from wind and moisture Izospan:

- BUT;

- AM;

- AS;

- АQ proff;

Density from 110 g / m2 to 120 g / m2.

This type is used for outdoor work (when insulating roofs and walls). It prevents moisture from accumulating under the roof, allowing condensation to evaporate freely. The structure of the material on the one hand has an effect that repels water, and on the other hand it has a rough surface. This feature can extend the service life of the insulation layer and the structure itself for many years. The diffusion membrane Izospan is made of polypropylene, which does not have a negative effect on humans. Also, the product is not susceptible to the appearance of mold and any fungi.

Membranes are used in such cases:

- insulation of attics and roofs;

- siding walls of low houses;

- construction of frame structures;

- as ventilation of outdoor insulation in high-rise buildings.

It is recommended to lay membranes on the roof at an angle of at least 35 degrees.

Izospan waterproofing and vapor barrier films:

- IN;

- FROM;

- D;

- DM;

- Rs

- RM;

Weights from 72 g / m2 to 100 g / m2.

A two-layer material is used to protect both wooden and metal structures from the negative effects of water and moisture. Izospan film is treated with a special water-repellent agent, which makes it possible to use it as an additional layer when filling the floor with cement. Izospan spreads on the floor with the soft side over the insulation.

Tapes (RM and RS have an additional third layer, which allows them to be used as water vapor barrier in ceilings between floors).

The purpose of the vapor barrier films is as follows:

- arrangement of interior walls;

- protection of the floor from high humidity;

- insulation of roof insulation inside the premises;

- installation of floor coverings.

Steam-waterproofing and heat-insulating materials with energy saving effect: isospan fd, isospan fs, isospan fb and fх with a density from 90 g / m2 to 175 g / m2.

The canvases have high vapor barrier properties, which makes it possible to quickly warm up the room and save on heating it in winter.

Izospan fb and fd are made of craft material and lavsan, as a result of which they have increased strength and can save their characteristics at temperatures up to +140 degrees.

Foil-clad isospan has reflective properties that reduce heat loss.The main thing to remember is how to properly lay the material on the roof: the metalized side should face the inside of the house. Films by the size of a roll are attached to the ceiling end-to-end and glued with special tape.

Vapor barrier of various structures: location schemes ↑

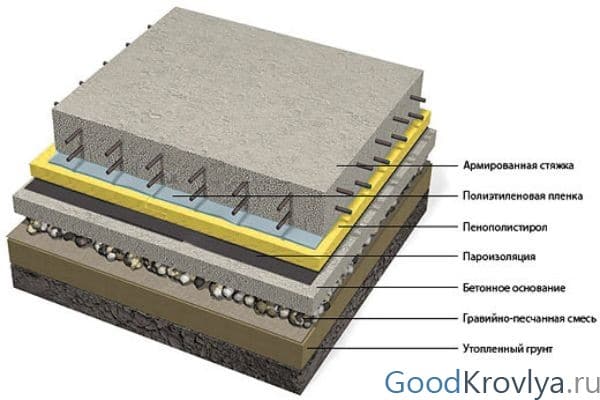

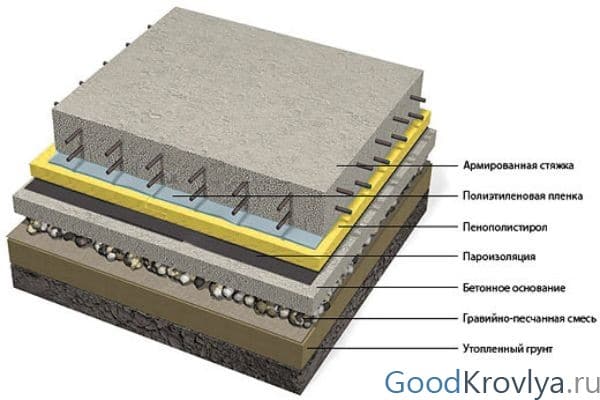

The vapor barrier of the floor must be performed in baths, saunas, swimming pools and in rooms located above the basement. The vapor barrier is laid over hydro and thermal insulation materials.

Vapor barrier for underfloor heating

Wall insulation against steam penetration can be performed both from the inside and from the outside of the building. The choice of method depends on the location of the insulation. With external thermal insulation, it is recommended to place the vapor barrier on both sides of the insulation - this measure will significantly reduce heat loss.

Vapor barrier in external walls

A monolithic concrete foundation has a porous structure and needs high-quality hydro and vapor barrier. The protective barrier is placed on top of the concrete base in front of the insulation. The dense film minimizes the penetration of ground moisture and prevents dampness in the basement.

Monolithic foundation structure

Izospan is rightfully recognized as the leader of film moisture and vapor barrier for roofs.

In order for the material to maximize its protective qualities, it is necessary to take a responsible approach to the issue of choosing its modification and perform installation in accordance with technological requirements. The ideal option is to entrust this difficult work to professionals with a good reputation.