Hello everyone, first the news of the blog ends tomorrow the competition "The Internet in Our Life", you still have the opportunity to send your competition work and play the prize fund of 2000 rubles.

The article facade finishing With a metal profiled sheet, we will consider the installation technology, the materials used, the pros and cons of such a finish.

The exterior of the building is its face and the main pride of many owners. The first impression about the house is formed by the view of the facade. There are many ways to decorate the facade:

- ordinary plaster, the most popular method;

- decorative plaster, "fur coat", marble chips;

- facing brick, traditional way;

- siding, an inexpensive type of finish;

- painting the plastered facade;

- stucco molding, mosaic is an individual way, the desire will stand out;

- ventilated facade, which we will talk about.

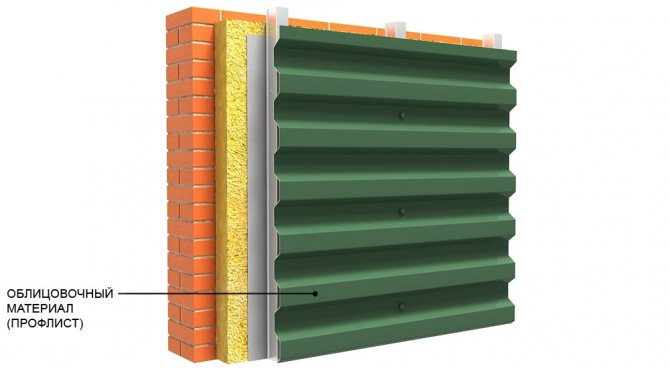

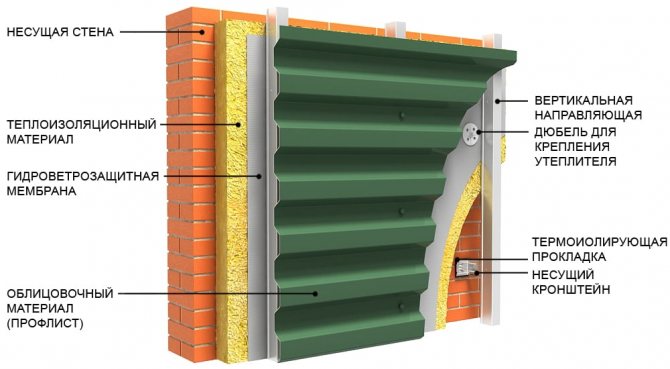

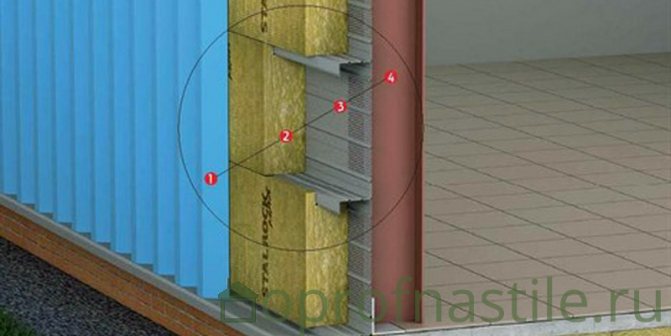

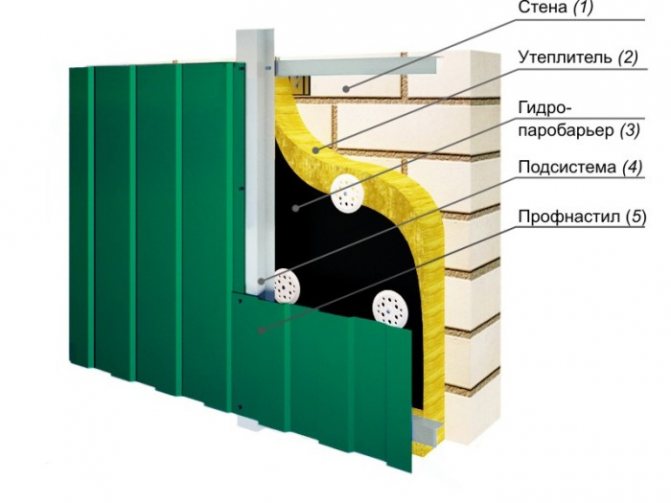

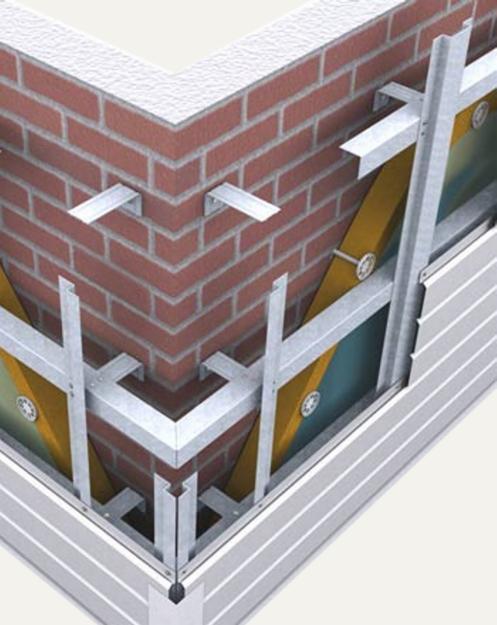

What is a ventilated facade? The hinged ventilated facade consists of facing materials, insulation, which are attached to a steel frame installed along the wall.

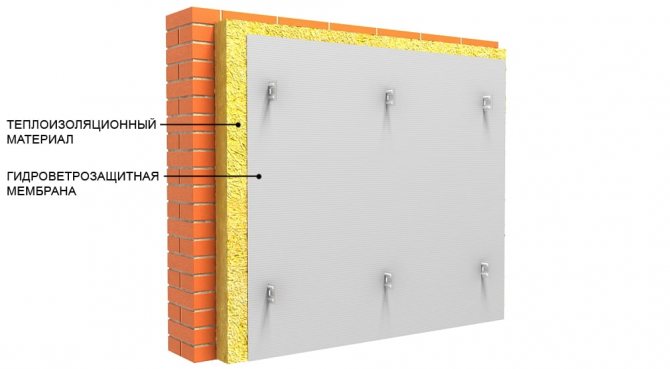

Facing materials are mounted with a gap between the insulation, through which air circulates freely. The air gap removes condensation and moisture inside the facade. The outer cladding protects from sunlight, rain, wind.

Due to this, the service life of the insulation increases and the preservation of its thermal properties, since it is in good humidity conditions.

This is one of the advantages of a ventilated facade, also due to the insulation, the sound insulation of the house increases, it does not allow the building to heat up in hot sunny weather.

In the modern construction market there is a large selection of facing materials and you can give your cottage a unique architectural look.

The advantages also include changing and repairing the appearance of the building by replacing the external elements, ventilated facade.

The disadvantage of a ventilated facade is the high price of some finishing materials, the flammability of the system elements (facade films, membranes, or plastic cladding).

At the construction site in Tobolsk, according to the project, the finishing of the facade of the buildings should be made of metal cassettes of the OLMA system. The customer replaced the OLMA cassettes with a metal profiled sheet.

Introduction

Profiled sheeting (also profiled sheet, corrugated sheet) - profiled sheets of thin sheet rolled steel with a thickness of 0.35 to 1.2 mm, with different corrugation heights from 6 mm to 260 mm, depending on the type of profile. Manufactured by cold rolling on automated profiling lines. During manufacturing, it is profiled (wavy, trapezoidal and other shapes are given) to increase rigidity. Decking can be made of galvanized steel, or with a protective coating, such as polymer.

Sheathing with corrugated board - the advantages of this type of finish

House sheathed with corrugated board

When cladding a house, special attention is paid to the quality of the building material. Corrugated sheets are used for fencing, finishing facades and roofs, building prefabricated structures (hangars and sheds).

Corrugated sheets are in demand because:

- the material is easy to clean, does not absorb dust;

- the corrugation has a neat, presentable appearance;

- quite strong, resilient;

- has reasonable prices;

- building material easily undergoes various manipulations;

- steel sheet covered with a protective polymer layer is resistant to fading, rust, temperature extremes, ultraviolet radiation;

- the possibility of using heat-insulating plates of various thicknesses;

- the corrugated board perfectly tolerates high humidity, subject to the installation technology according to the example of the under-roof space;

- the surface of the building does not require additional leveling and cladding, the processed sheets become the "face" of the facade;

- building material provides a great opportunity for the realization of design imagination;

- profiled sheet is an economical type of home decoration.

We take into account the nuances

- The surface heats up strongly under the rays of the sun, therefore, on hot sunny days, it is necessary to work with construction material extremely carefully.

- In places where the protective layer is damaged, if the technology of cutting the corrugated board is violated, metal corrosion is possible over time.

- For good ventilation, it is recommended to equip a vapor barrier system. This element will allow the accumulated condensate to be removed without hindrance. The absence of an air gap acts destructively for a building, creates conditions for mold and mildew to multiply inside. An air gap is created between the insulation layer and the corrugated board.

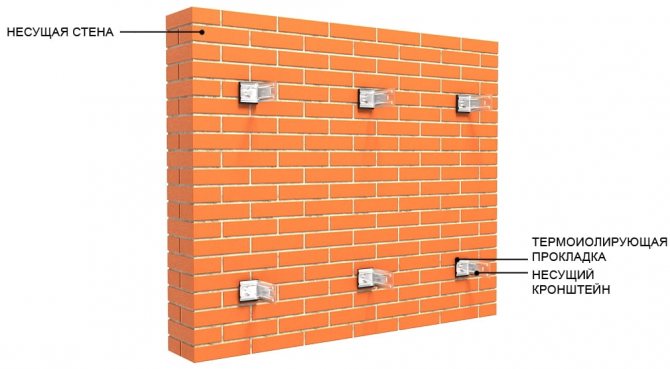

Ventilated facade substructure

Completing of the work

What are the advantages of a metal profile for facade cladding

- The modern metal profile, which is used in the cladding of the building, is made of high-quality galvanized steel with an external polymer coating, which additionally protects the profile sheets and improves the overall appearance of the facade.

- Due to the structural features, such facades, if necessary, are very easily repaired with minimal involvement of labor (we are not talking about multi-storey buildings and structures). Installation of a ventilated facade from a metal profile can be performed at any time of the year, which is important.

- Due to the uniqueness of the profile sheet as a building material and various technologies for mounting the subsystem, it is possible to use design solutions of any complexity. In addition, ventilation facades can be used in seismically unstable areas - according to tests, they are able to withstand earthquakes up to 9 points.

- Ventilated facades give the building additional soundproofing properties.

- The service life of ventilation facades is at least 50 years.

- Ventilated facades made of profiled sheet, due to their low weight and design features that evenly distribute the weight, have an insignificant load on the walls of the building.

- Well, the last advantage, but no less important, is the minimum storage area for building materials.

How to prepare the surface and make the markings

We pay attention to the surface. We give a perfectly clean state. Any delamination can be repaired with conventional construction tools. The wall is carefully primed with a deep penetration consistency using a brush.

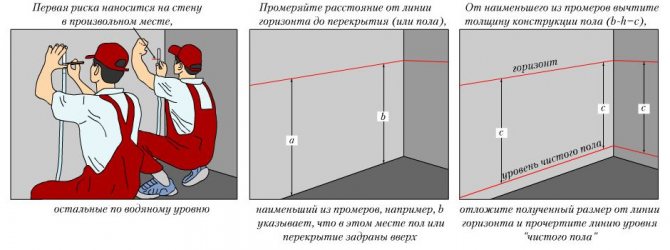

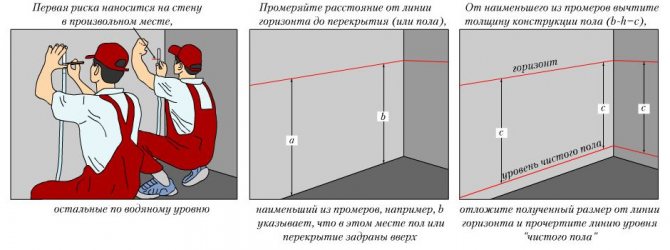

Marking is applied to a well-dried plane. It is necessary to ensure that the installation line is as parallel to the horizon as possible. Transfer of points to other surfaces is carried out using a hydraulic level. As a result, the points are connected using a nylon thread. The size is marked and the marks are connected in one line. The end result should be the correct installation lines.

How to make markup

Attention! The bottom of the finishing fragments rests not on the ground, but on the blind area. It may not be there, then you will have to make a pouring out of rubble, pour the mass with cement mortar.

Installation work on the arrangement of facades. Where to begin

Before starting work on the installation of the subsystem on which the ventilated facade will be attached, it is necessary to carry out a small examination of the building. It is made by visual inspection of the surface of the walls from the inside and outside for cracks and chips. If they are found, defects must be repaired.Shallow cracks and chips are simply plastered with cement mortar (mortar grade not lower than M100) or ready-made dry mixes. When using dry mixes for repair work, it is necessary to observe the proportions of their preparation and the application technology, that is, if the mix is for internal work, then it should be used inside the building.

When applying plaster mortar with a thickness of more than 1 cm, it is recommended to fill the cleaned surface with a metal mesh, for example, CPVS with a cell size of 20x20 mm. You can fix it using ordinary dowels, which are freely hammered with a hammer in the case of work on brick walls. If the wall is concrete, then a mounting gun or pre-drilling is used.

In the presence of through cracks, if necessary, they are anchored with anchor bolts by drilling them to the required depth - this is done in order to avoid further expansion of the crack. In addition, the crack must be filled with a special repair mortar along its entire depth, with preliminary cleaning and removal of falling off pieces.

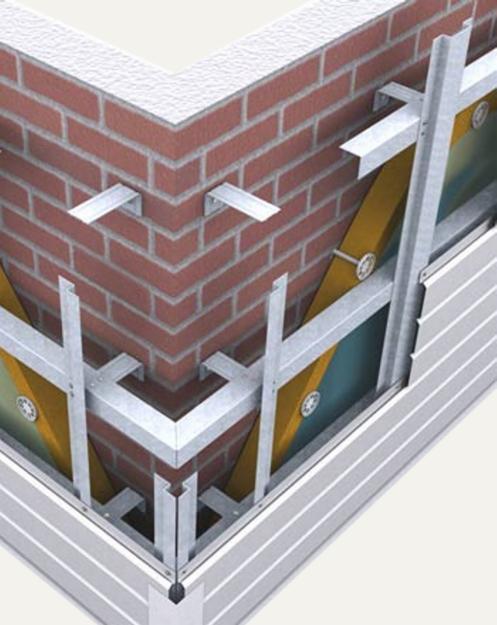

How to assemble a frame for sheathing a house with corrugated board

Frame for cladding the house with corrugated board

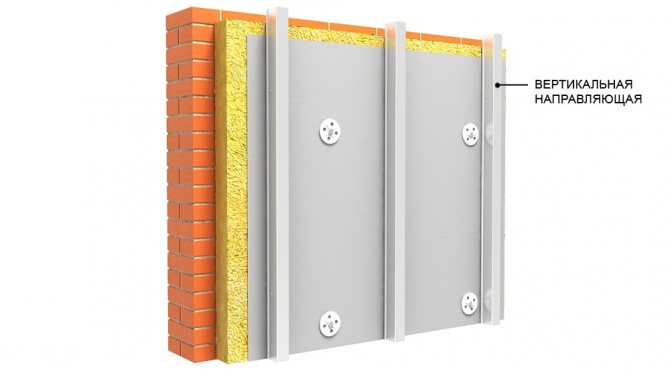

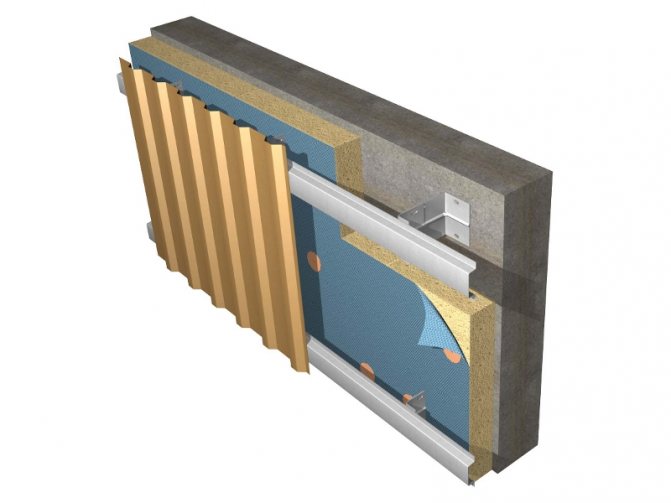

The frame is made of wooden blocks (pre-treated with an antiseptic) or Z-shaped profiles. The latter parts are in demand, as they provide excellent air circulation between the insulation and the cladding material. You will also need brackets.

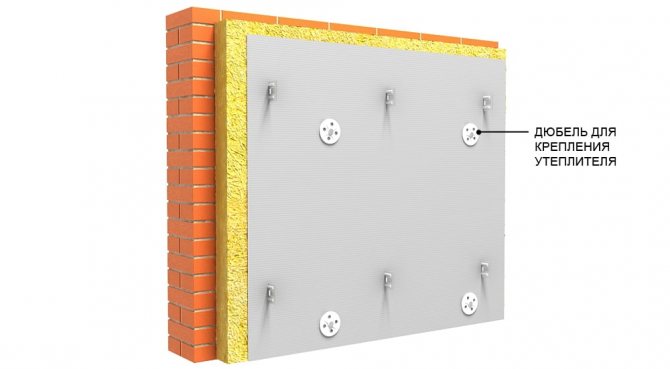

Special dowels are the optimal fastening system. A hole is made in the plane with a drill and the connection is made.

Pay attention! The self-tapping screw is bought a couple of millimeters more from the cross-section of the plastic dowel hole. Only in this version can we talk about a reliable fastening.

The principle of attaching a profile to a plane

- The corrugated board is cut to the required size and fastened along the original line.

- Tying is done along the lower and upper contours. To fasten the transverse profile, the fishing line is pulled along the diagonals of the strapping.

- According to the thickness of the insulation, the transverse profile is attached along the height. Make sure that the material after manipulation does not change its geometric shapes. A small gap will allow good air circulation.

- This is followed by a vapor barrier and installation of thermal insulation material. Films are cut to a certain size and overlapped by at least 5 centimeters.

- The hydro-barrier is followed by a heater, which is attached with special "fungi".

Facade cladding with corrugated board

How to make a calculation for insulation when sheathing a house with corrugated board

It is important to calculate the amount of building material.

To do this, you need to take into account a number of factors:

- determine the surface area. If the length of the walls is 6 and 5 meters, and the height is 3 meters, then the surface area will be (6x3) + (5x3) = 33 meters. The resulting number is multiplied by another 2 and you get 66 square meters of the processed surface;

- from the total, it is necessary to subtract the elements of window and door openings. The height and width of each opening is measured. Then the width is multiplied by the height, and the summed values are added. It turns out the perfect finishing area;

- the area of the profiled sheets is calculated. The resulting profile amount is increased by 15% (compensation costs).

Insulation of the house outside

How to mount corrugated board

The installation of a profiled sheet is its fixation to the frame.

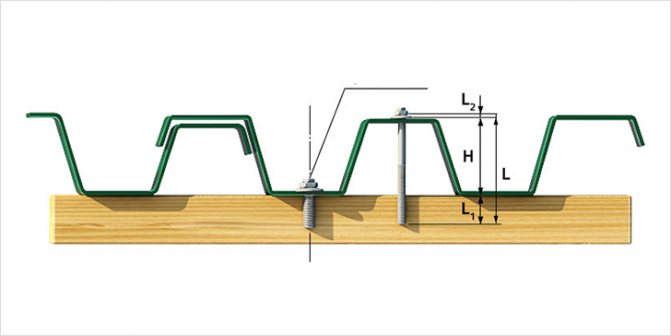

With a galvanized self-tapping screw with a rubber gasket, the corrugation is attached with a pitch of 35 cm. The self-tapping screws for the corrugated board have a thread and a special tip in the form of a drill. They are usually produced from high-strength alloyed carbon steel grade C1022 with a finishing zinc coating.The design of a self-tapping screw with such a tip allows them to be attached to the frame without pre-drilling holes.

So self-tapping screws for corrugated board with a diameter of 4.8 mm can drill metal with a thickness of 2.5 mm.

Rubberized gaskets protect the cavities of the building material from moisture.

The sheets are always stacked with an overlap of 5 cm. When cutting metal, the burrs are removed so as not to cut themselves.

Additional elements are fixed along the entire perimeter of the house (corners, doors, windows). Then the building gets a complete and neat appearance.

Attention! Punch and nails cannot be used.

Fastening the corrugated board with self-tapping screws

Technical data

Raw materials and supplies

Profiled sheeting is a sheet of profiled metal with numerous stiffening ribs, which give it high strength and reliability. It is produced from rolled steel using the cold roll forming method. The technical characteristics of the materials depend on the thickness and configuration of the profile. During manufacture, it undergoes multi-stage processing. A zinc coating is applied to both sides of the sheet, a layer of anti-corrosion protection. This is followed by a passivating layer, subsequent processing of the material with a primer. The reverse side is covered with a protective paint layer. A polymer coating can be applied to the front. Various options are available for sale: steel, aluminum or copper analogs, without polymer coating. The choice of material is always agreed with the customer. We talk in detail about its advantages and disadvantages.

Purpose of finished sheets

Decking is used in private construction. It is suitable for the construction of walls, fences, ceilings, roofing. Therefore, it is always possible to decorate the building and the adjacent plot in the same style.

Types of polymer coating:

- Zinc... The steel sheet is immersed in molten zinc. This option is more suitable for the restoration of buildings.

- Aluminozinc... Combines 3 components - aluminum, zinc and silicon. As a result, the leaf resists aggressive substances well. It has proven itself well in the sector located near the highway, the coast and large industrial plants.

- Polyester... Protects the sheet from corrosion, adverse weather conditions and mechanical stress.

- Plastisol... The thickness reaches 200 microns. Among the main advantages of such a solution, it is worth highlighting resistance to mechanical damage and exposure to aggressive substances. Disadvantages include rapid sunburn and inability to withstand high temperatures.

- Pural... Active substances extend the service life of the material. It does not fade in the sun, resists rust and aggressive substances. This solution is also suitable for the roof.

- Polyvinyl Dentafluoride... The coating protects the steel from rust and environmental factors. The brightness of the color is maintained for a long time.

- Acrylic and polyvinyl chloride... Differs in inexpensive cost, corrosion resistance.

Properties of metal plates

The dimensions of the sheet of material may vary. The length of the flooring material should be more than 3 m at 0.25 m steps, and for fences - from 2.4 m at 0.3 m steps. The maximum length should not exceed 12 m. An exception is an individual order. The width of the sheet will depend on the shape and size of the longitudinal profile. Usually, a galvanized steel strip, which is taken as the basis for the manufacture of corrugated board, has a width of 1250 mm. It comes in rolls. And the final size depends on the characteristics of the manufacturer's technological equipment. Its bearing capacity depends on the height of the profile. On average, it ranges from 8 mm to 7.5 cm.

Sufficient strength

The bending strength also depends on the depth of the profile and the thickness of the original steel. The thickness of the sheet can vary from 0.5 to 1 mm. The configuration depends on the capabilities of the rental equipment.There are no restrictions here. The quality of the sheet is influenced by the condition of the rolls and the degree of production processes. Much depends on the qualifications of the staff. We cooperate with trusted manufacturers and make sure that the material meets GOST standards and has the necessary technical characteristics.

Marks

- The first letter indicates the type of material and the area in which it can be used. "N" is a carrier, "S" is a wall, "NS" is a universal one.

- The first number indicates the profile height (from 6 to 14 mm). The higher the height, the higher the bearing capacity.

- The second indicates the thickness of the workpiece.

- The third is about width.

- The latter indicates the maximum length.

Sheathing of the gable of the house

The pediments are a continuation of the wall spans at the ends of the structure. The fragments are placed between the roof slopes. The low weight of the profiled material reduces the pressure on the supporting structure of the building, on the foundation.

Installation work is carried out individually. Sheets are attached with self-tapping screws for iron. Scaffolding and a safety belt must be used.

Sheathing the gable of the house

Advantages of corrugated board for the pediment:

- wide range of colors of polymer coating;

- convenient cutter;

- the plating process is simple;

- easy replacement of the damaged part of the sheet;

- due to the low weight, cladding is carried out even for frame buildings;

- sheets are easy to cut;

- ease of caring for corrugated board.

See also the article "How to properly sheathe a pediment with siding"

Ordering and cutting of a metal profile. Preparatory work

Before starting construction work, it is imperative to calculate the material. When ordering a metal profile at any more or less serious enterprise, you can order its cutting - that is, the material will be cut with a guillotine in production, which minimizes the use of cutting discs directly at the work site. The fact is that if you cut a profiled sheet with a grinder, then its protective properties are violated (due to the fact that the metal is overheated) at the cutting site - this place will then have to be additionally tinted with paint.

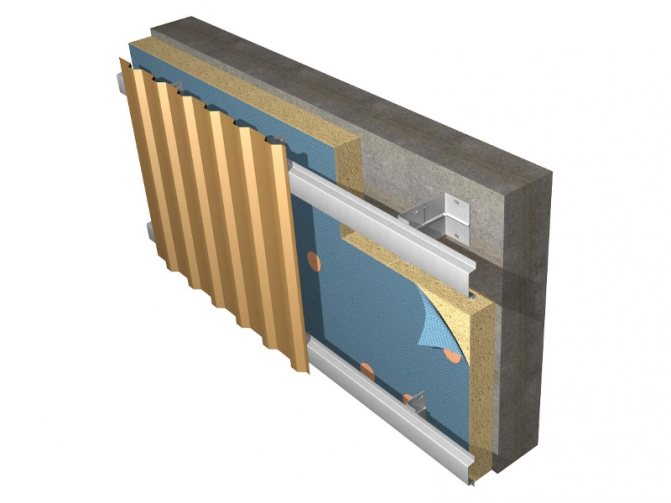

Before carrying out work on the installation of a ventilated facade, it is necessary to make a markup. The markup can be done both top-down and bottom-up. The main thing is to calculate the lower skirt of the ventilation facade in such a way that there remains a gap from the blind area or zero level of at least 5 cm - for air intake.

It is impossible to cover the lower skirt with earth or pour concrete, otherwise the ventilated facade will not work due to the lack of air intake. Ideal - if the marking will be made using a laser level or a conventional optical level.

After the marking is done, we begin the installation of the vapor barrier, for example, using the Izospan V polymer film. This film is used to protect the structural elements of the building. "Izospan V" has a two-layer structure - one side is rough, the other with a smooth surface. The smooth side of the building material allows condensation to pass through, and the rough side holds it on its surface to evaporate it. Detailed instructions for the installation of building material can be found on its packaging or in paper form enclosed inside.

Calculation of material for installation

The area of the pediments is carefully determined, taking into account their geometric shapes. The area of the window openings is not taken into account. The necessary additional elements are determined. These are framing, drainage, corner. Self-tapping screws are screwed at a maximum distance of one meter.

Installation

The sheet is fixed to the prepared wooden slatted frames. They should be pretreated with a special antiseptic against material decay. Qualitatively assembled wooden slats or brackets into a single frame will make the facade ventilated.

The windproof film is attached to the insulation. The facade is closed at the finish line. The pediment is the last.

Algorithm of actions:

- The corrugation is cut according to the additionally created patterns.

- Attachment starts from the bottom corner.

- At a maximum distance of one meter, the sheets are overlapped.

- Self-tapping screws are attached to the pre-prepared hole in the deflection of the sheet.

- A 5 mm gap is left between the wall and the outer sheathing sheet for the metal corner of the side element.

The trend of corrugated board can be different, however, the horizontal direction is widespread today. Closing the gable of the house with corrugated board is the finishing procedure for construction. As a result, the object takes a complete form. Often the same finishing sheet is used for the cladding as for the façade. Installation activities are simple and do not require special equipment, the involvement of highly qualified personnel.