Frame-panel house

A panel or frame house is being built using technologies that came to our country from abroad. The features of the technology are no heavy thick walls and a strong foundation... The house is practically built from a heat insulator, which saves on heating, makes construction faster and easier.

Serious differences with traditional construction methods caused a wary attitude towards panel houses, but the technology began to be actively used for the construction of garden or country houses.

The high cost of housing made us consider these buildings from a different angle. In order to make a full-fledged housing out of them, it is necessary to insulate the panel house, make it suitable for year-round living. Consider how to insulate a panel house for winter living and what materials will be required for this.

The procedure for installing polystyrene foam

The answer to the question of how to insulate a panel house is increasingly becoming expanded polystyrene plates. The material is very light in weight, easy to install and efficiently retains heat.

The procedure for installing polystyrene foam plates on the outer walls of a frame-panel house looks like this:

- A profile is mounted on the base, the width of which corresponds to the thickness of the expanded polystyrene plates.

- Glue is applied to the entire surface of the slab using a special notched trowel.

Expanded polystyrene plates are perfect for insulating the facade of a panel house

Please note: For the installation of boards made of heat-insulating material, a special adhesive should be selected that has high elasticity.

- Stick the boards on the walls from bottom to top, be sure to alternate their arrangement so as not to create solid lines at the joints.

- At the corners, a special corner profile or reinforcing mesh is additionally installed.

- After the plates are glued, they need to be left for about a day or two.

- Then additional fasteners are installed.

- Plates are fixed with front disc dowels (they are also called "fungi" or "parachutes"). The plates should be immersed in expanded polystyrene by 2-3 mm.

Tip: To improve the adhesion of the board surface to the adhesive, it is recommended to carefully sand the surface.

- The corners of door and window openings are additionally reinforced with mesh sections, which are laid diagonally.

- A layer of cement mortar is applied to the surface of the slabs, on which a fiberglass mesh is fixed, creating a reinforcing effect. The edges of the glass mesh sheets must overlap by at least 100 mm.

- The surface is sanded to eliminate unevenness.

- If a solution has emerged along the edges of the slabs, it must be carefully cut off with a knife.

- Where the heat-insulating material is adjacent to door and window openings, a special profile or sealing tape must be installed.

After the installation work is completed, you can proceed to the decorative finishing of the outer walls of the building.

General principles of insulation

The principle of insulation consists in installing a heat-insulating material on the surface of the walls, which reduces or completely eliminates heat loss. A relatively thin layer of insulator can radically change the thermal physics of the wall, resulting in temperature rise and heating savings... In addition, there is another important point: the ability to increase the temperature of the outer walls allows you to exclude the formation of condensation, wetting of the walls and their failure.

There are two types of insulation:

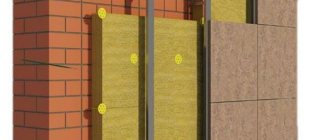

- external.The heat insulator is installed outside, which allows you to fully use the heat-saving ability of the walls, maintain their working qualities, and increase the service life

- internal. The insulator is installed from the inside, cutting off the walls from the general thermal circuit of the building. The method is recognized as less effective and successful, since the volume of the room changes, the withdrawal of water vapor becomes more difficult, the wall turns into a mechanical barrier, losing most of its functions.

The specificity of frame houses is that they themselves are made of insulationsupported by a supporting structure - a frame. Therefore, there is practically no fundamental difference between external and internal insulation for them. For panel (frame) houses, it is recommended to use both types at the same time, and if there are any obstacles, use the possible option.

In most cases, it is more convenient to insulate a panel house from the inside, since with it there is no need to look back at the weather, air temperature, and other atmospheric manifestations. The disadvantage is that you cannot live in the house during the renovation. If this question is critical, it is better to use the insulation of the panel house outside.

The structure of the panel house and the need to create its full-fledged insulation

Frame houses have appeared in our open spaces relatively recently. At the same time, they have already managed to win the favor and some popularity among the common people. The construction of similar structures allows you to create a magnificent object in the shortest possible time, which will be successfully located on any suburban area or dacha. However, modern living conditions and the widespread rise in the cost of materials are increasingly leading to a reorientation of panel houses for permanent residence. This problem will be solved by the insulation procedure, which can be carried out both during the direct construction of the object and during its constant operation.

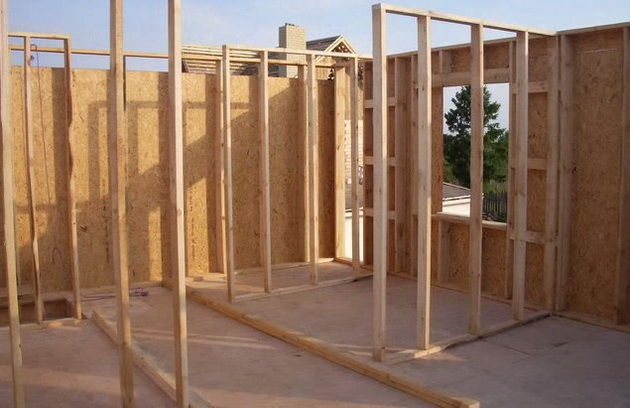

In order to understand the essence of the organization of thermal insulation of a panel house, it is necessary to consider its structure in more detail. Such objects are some kind of temporary structures. At the heart of such buildings is the use of a solid metal or wooden frame, sheathed on both sides with sheet materials or plank-type products, which makes such objects ideal for summer pastime, and the onset of winter - cold and lifeless. A similar effect is due to the absence of a massive brick or clay layer that protects ordinary houses from the effects of wind and frost. To solve the issue of organizing comfortable conditions in a panel house, the laying of a heater will help, which will play the role of thermal insulation and prevent the penetration of cold into the building.

Insulation material

There are many types of thermal insulation materials. Moreover, most of them are varieties of the same source materials. Among them it is necessary to highlight:

Styrofoam

He granular polystyrene foam... Cheap, lightweight, tough enough material. It has a convenient plate shape with precise dimensions and is easy to process. Able to absorb moisture in small amounts. Does not support combustion, but if melted, it burns well.

Penoplex

Or extruded polystyrene foam... It differs from polystyrene in greater strength, rigidity, monolithic structure. Penoplex is noticeably heavier, its cost is higher than that of foam, which is considered a significant drawback of the material.

Mineral wool

The material has many varieties - glass wool, slag wool, etc. Moreover, when they talk about mineral wool, in most cases they mean basalt (stone) wool. It is produced in rolls or mats (plates), has excellent working qualities, and is relatively cheap. Disadvantage - ability to absorb water both in the form of moisture and in the form of steam.Reacts to atmospheric humidity. When installing needs a protective waterproofing film.

Polyurethane foam

Liquid that is sprayed onto the surface. In air, the material foams and hardens, turning into a layer of rigid foam. Absolutely resistant to moisture, easy to apply on surfaces with complex relief. The disadvantage is the high cost and the need to use special equipment.

Important! Expanded clay, sawdust, vermiculite are recommended for insulation of horizontal surfaces. These materials have different properties, but what unites them is that they are all free-flowing. Not suitable for vertical surfaces, but optimal for horizontal surfaces. Expanded clay is in the lead, it does not burn, does not rot, has a huge service life and low thermal conductivity.

Among the common materials mineral wool and foam are in the lead... The rest of the materials lag significantly behind in distribution and are used much less often, so it would be more expedient to consider only the most popular and preferred materials.

Choice of materials

One of the main parameters that a material must meet is its elasticity. Styrofoam and related products may not work. The fact is that the elements of the frame (if we are talking about a frame made of wood) will change their dimensions due to changes in the temperature and humidity of the ambient air. In this case, gaps will appear between the bars and the insulation panels, which will affect the overall thermal insulation of the house.

And the elastic material will fill all the space between the bars.

For metal frame houses, you can use any materials, for example, expanded polystyrene.

Basalt wool

The most common material. It is obtained by melting rock basalt. It retains heat perfectly, has sound insulating properties. The downside is the change in properties when absorbing moisture. Therefore, you need to carefully protect it with special films.

Basalt materials are the most fire safe, withstand heating temperatures up to 1000 degrees.

When buying, it is better to focus on the material in the form of slabs, the packaging should indicate that the insulation is intended for walls, otherwise after 2-3 years the basalt panels will sit down and cold air will penetrate through the top.

Ecowool

This type of insulation is made from cellulose. There are two ways to insulate with ecowool:

With the help of special equipment, cotton wool particles are mixed with water droplets, this mixture is directed into the space between the cells of the frame. In this case, a dense coating is formed that fills the entire area of the walls;

The dry method consists in pouring ecowool particles into the space between the wall panels, after which the mass is compacted.

As a result, layers of insulation are obtained that are not afraid of changes in temperature or humidity, therefore, additional protection with various films is not needed.

The cost of the material and the prices for the work performed are the only negative aspects of this technology.

Glass wool

Produced by melting glass. It is usually sold in the form of rolls. Differs in decent heat-insulating properties and resistance to fire, does not emit toxic substances during combustion.

Be sure to check when buying that the material is intended specifically for the walls.

Bulk materials

This type includes slag, expanded clay, sawdust. They are rarely used, since there are more effective insulation materials.

Sometimes it is used for thermal insulation of the floor, as the first layer, after which other types of insulation are laid, in particular, expanded clay, which does not absorb moisture, does not burn, but its insulating properties are not too high.

Internal insulation of the frame structure

Insulation of a frame house from the inside increases the humidity of the air, therefore, when designing, it is necessary take into account the need to create a high-quality ventilation system... If you need to insulate the old panel house, then in addition to the walls, you will have to insulate the ceilings, the floor and the ceiling.

Principled honors from generally accepted methods is the ability not just to install a heat insulator that cuts off the wall from the general thermal circuit, but increase its thickness, thereby increasing the heat-saving capabilities.

In addition, it becomes possible use of non-standard materialssuch as chipboard. According to the level of thermal conductivity, a sheet of this material can replace brickwork 1 brick thick. Indoor also popular penoplex or penofol (foamed polyethylene). The choice of material is determined, most often, by the financial capabilities of the owner of the house, less often - by considerations of a technological nature.

The main stages of the insulation of the panel structure

Preparing the house for thermal insulation

This is probably the most important part of the overall insulation work. If the house has cracks and other defects that contribute to an increase in heat loss (for example, insufficiently reliable connections of structural elements, cracks), then none of the commercially available insulation materials will help. Some of the heat will most likely be "lost".

Visual inspection of the panel house

It is not necessary to remove the inner lining (trim). During the decoration work, the owner probably got acquainted with the technical condition of the building. But if the repair in the panel house was done a long time ago, then, perhaps, in some places it makes sense to bare the base.

What to check first

- Floor and wall joints along the perimeter of each room. Even obvious defects can not be detected by a simple inspection, since the cracks in these places are closed with skirting boards. Removing them is easy, so you shouldn't neglect dismantling - it won't take a lot of time. Corners. Especially the most blown ones. Window openings. The main focus is on the areas under the windowsills. They are considered one of the most problematic places in any home. Overlapping. Moreover, the inspection should be carried out both from the premises (below) and from the side of the attic (above).

Elimination of defects

Basically, the filling of cracks (joints) is done by caulking. It is not difficult to implement it, since in this case it is not a log house that is processed, but only a panel house. For this you can use jute, tow. But regardless of the material chosen, it is advisable to coat it with PVA. This will be a guarantee that during thermal deformation of the structure, the "embedment" will not shift at the landing site. Alternatively, treat the gaps (large cracks) with polyurethane foam.

You can't do that on the ceiling. Here you will have to choose between roll or bulk materials. Any country house has at least some attic. Therefore, in order not to spend a lot, it is enough to pour expanded clay on the floor of the "upper floor" room or lay roofing material (in strips, with overlapping along the edges). It will turn out quickly and cheaply. A more expensive way is to seal all cracks by spraying polystyrene foam. You can buy the appropriate equipment, but if the panel house is small, then it is hardly advisable to use such a technique.

External insulation

The most common option is to insulate a panel house for siding. This option allows you to carry out insulation, install the cladding and not to use "wet" solutions that complicate and slow down the progress of work.

Procedure:

- preparation of the outer surface of the walls

- installation of the lathing. The height of the slats above the wall surface should be equal to or slightly greater than the thickness of the insulation, the arrangement of the slats should be horizontal, the pitch of the battens is equal to the width of the insulator

- installation of polyethylene film

- laying in the cells of the sheathing of the heat insulator.Gaps or gaps must not be allowed; when gaps appear, use polyurethane foam

- a layer of vapor-waterproofing membrane is laid on top of the insulation. It is necessary to carefully monitor the position of the film - it should let steam through from the inside of the insulation cake, and not vice versa

- installation of counter-lattice strips. They are attached to the battens and are positioned vertically. Thickness - not less than 40 mm (optimal size of the ventilation gap

- installation of siding according to technology

This option for external insulation is the fastest and most effective, it is relatively cheap and allows you to do all the work yourself.

Thermal insulation of walls of a frame house with mineral wool

In a frame house, as in any other, there are two types of walls - external, one side of which is located on the street, and internal, which are located completely inside the house. So, both of them need to be insulated.

The walls of a frame house can be insulated both from the inside and outside, this does not change the materials used and their number. We will consider insulation from the inside, everything is done from the outside in the same way, only in a slightly different sequence.

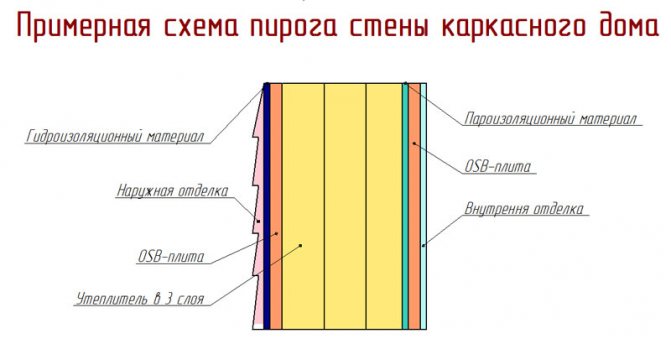

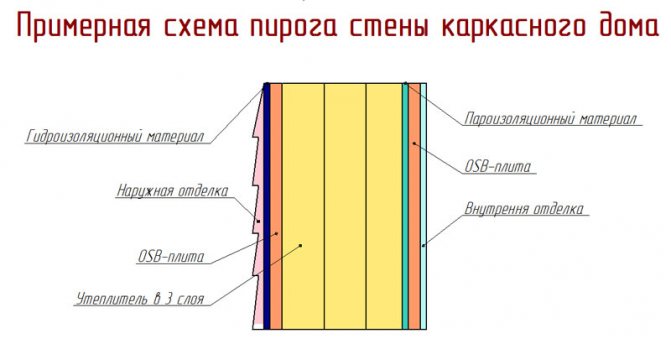

Insulation of the outer walls of the house

It is worth noting right away that when sheathing a frame house from the outside and from the inside with your own hands, various materials are used, they may be different from those that I describe in this manual. The order of actions may also differ, but in general, it turns out almost the same thing, as in the diagram. This is an approximate scheme, for example, instead of OSB boards, on one side you can pierce the crate with strips or a board 25mm thick. The board, as a rule, breaks through a certain distance - about 40 cm between the axes, but it is worth remembering that in this case the stiffness of the walls will suffer a little.

The process of insulating walls with mineral wool with your own hands is almost identical to the thermal insulation of the floor, and is performed as follows:

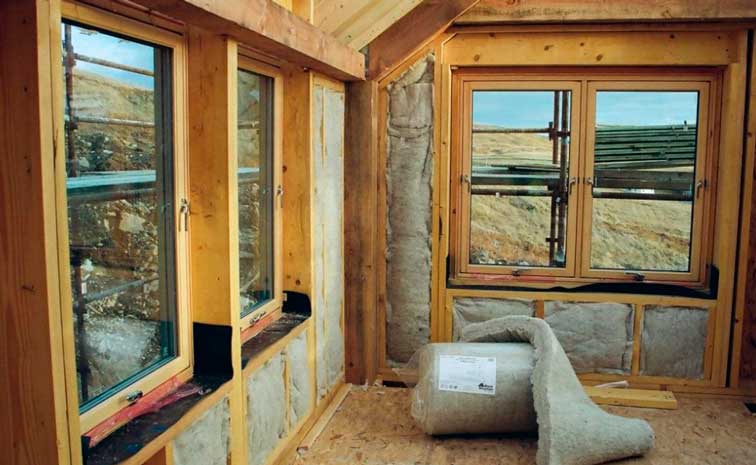

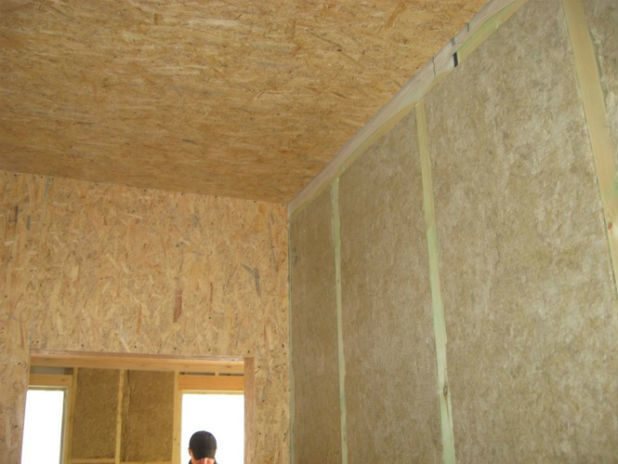

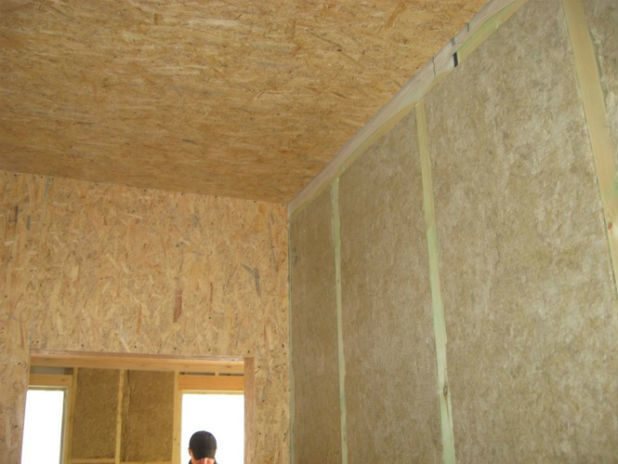

- Outside, the frame is sheathed with OSB plates, with the gaps between them specified by the manufacturer, as a rule, it is 2-3mm. After installation, the gaps can be foamed. This is how it looks from the inside of the house:

- Then, also outside, a waterproofing membrane is stretched, which will protect the mineral wool, the frame of the house, as well as the OSB sheets from external moisture, on top of which external finishing work will be carried out, such as installing siding, for example. Some manufacturers make waterproofing materials with self-adhesive strips in order to make the joint tighter. If there are no such stripes, it is advisable to glue the joints with double-sided tape.

- From inside the frame house, between the frame posts, which, if you did everything correctly, are located at a distance of 58-59 cm from each other, sheets of mineral wool are tightly inserted.

- It is better to use mineral wool with a density of at least 35-50kg / m3. Less dense insulation will settle or roll downward, which will entail the appearance of voids and cold bridges. As a rule, manufacturers write on the packaging what material can be used for.

- As with the floor, the layers of mineral wool should be laid in such a way as to overlap the previous joint of the sheets by at least 15-20cm. The total thickness of the insulation depends on the climatic zone, but the average value is also 15 cm.

- After all the insulation is laid in the walls, it is necessary to fill with polyurethane foam all the small voids formed at the joints of the boards and beams.

- A prerequisite for insulation with mineral wool is that from inside the house, over the insulation, it is necessary to pull a vapor barrier membrane, which will protect the insulation from moisture emanating from the inside of the house. On top of which the same OSB sheets are most often stuffed as outside, but you can also use a board, slats and similar materials, depending on the further finishing.An important point in the installation of a vapor barrier membrane is not to overtighten it at the inner corners, and the vapor barrier completely repeats the corner of the frame. Otherwise, in the future, it will be difficult to nail the trim at the corners.

It is worth noting that this whole procedure can be done the other way around, first pull the vapor barrier membrane from the inside, then the inner cladding material, and the process of insulating the walls with mineral wool from the outside.

Thermal insulation of the inner walls of a frame house

Distinctive features of the insulation of the internal walls of a frame house are:

- Insulation of the inner walls of a frame house is made, to a greater extent, for sound insulation. Therefore, if you have the opportunity, it would be better to use soundproofing material. But this does not mean that ordinary thermal insulation mineral wool, or other types of insulation will not work.

- There are no such stringent requirements for the insulation of internal walls as for external ones, therefore, in principle, waterproofing and vapor barrier materials are not required.

- Otherwise, the insulation is identical to the outer walls of the frame house.

If there is no possibility, or strict requirements are not imposed on the sound insulation of internal partitions, it will be enough to use the same insulation as for the external walls. The thickness of the insulating layer can be much less.

Insulation of the foundation and floor

The foundation is insulated during construction. We are talking about strip or slab bases, the installation of thermal insulation on which is either part of the technology or a construction stage. Nevertheless, the base can be insulated along the inner perimeter in parallel with the floor insulation, which in a panel house is usually performed on the ground.

Procedure:

- understands the floor. The boardwalk is removed, the logs are removed, the soil under the house is opened

- the soil is leveled and carefully rammed

- a layer of sand 15-20 cm is poured, leveled, rammed

- a 15-20 cm layer of crushed stone is filled in. The work is done in layers, 5-10 cm each. It is carefully rammed. Sharp stones produce additional compaction of the underlying sand layer

- a leveling layer of sand of about 5 cm is filled in

- a layer of geotextile is laid with an overlap on the walls along the edges of about 20 cm

- pouring a heat-insulating concrete screed with expanded clay filler (option - a filler made of foam crumbs)

- filling the leveling screed

- laying flooring

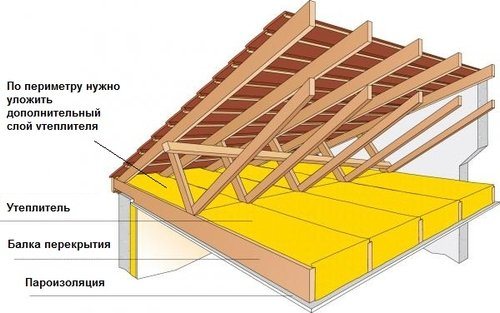

Insulation of the attic

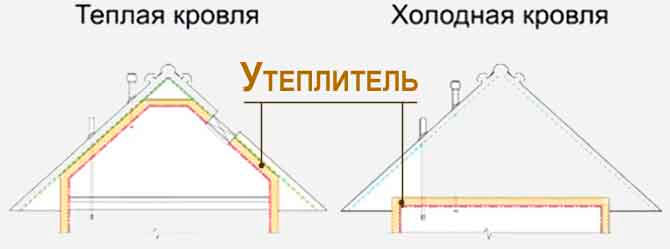

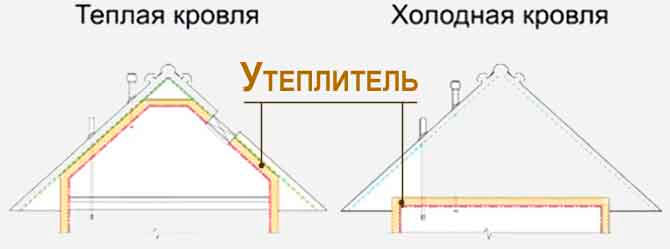

There are two options for thermal insulation of a frame house from the roof side - a cold attic and an attic (the so-called combined roof).

Cold attic

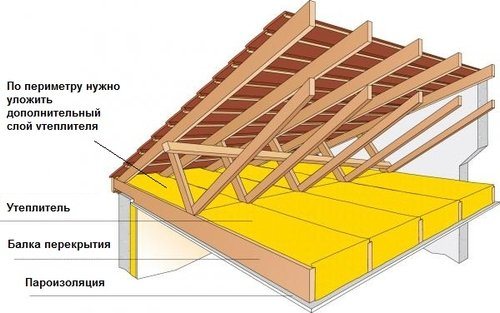

In this case, there is no thermal insulation in the roofing pie. Insulation is carried out on a wooden floor.

The vapor barrier layer is attached to the false ceiling from the side of the room. Insulation from steam protects not only a purely insulation, but also floor beams, a rough ceiling. Other wood elements are humidified by the action of steam in warm air, and excess moisture will not evaporate due to the vapor barrier.

Films with anti-condensation properties are used for vapor barrier. They are 2-3-layer polymeric materials with a rough fleecy surface facing the room. The film is able to retain condensate until natural conditions for its disappearance appear.

A layer of thermal insulation is placed on the false ceiling between the floor beams. A waterproofing superdiffusion membrane is laid on the insulation.

In the case when the height of the floor beams is not enough to form a ventilated gap above the thermal insulation layer, spacer slats of the counter-lattice are mounted on the beams. And already the attic floor boards are attached to them.

Attic insulation

There are two ways to insulate the attic of a frame house - insulation of the roof or the building outline.

Thermal insulation of the attic (attic) circuit can also be carried out in different ways. But all the same, in front of the lathing on the side of the roof, it is necessary that a layer of waterproofing be laid.

For a metal roof, it is necessary to make a gap between the waterproofing layer and the roof covering. This is necessary so that the condensate can go to the drip, and the excess moisture evaporates from under the roof space. If the membrane has poor vapor permeability, then there must be a ventilation gap between it and the thermal insulation layer, which is necessary for the weathering of water vapor from the mineral wool.

Roof insulation

Thermal insulation of the entire roof is a much simpler option than arranging a warm attic circuit. Especially in the case of a small house.

Thermal insulation is performed as follows:

Mineral wool mats are laid between the roof rafters. In the case when the pitch of the roof rafters is greater than the width of the mat, an additional sheathing is mounted. And if less, then the mats are trimmed. However, the width of the mat should still be less than five centimeters of the rafter pitch.

A continuous layer of vapor barrier is attached to the crate and rafter legs along the insulation. The insulation can be anti-condensation or reflective. The material is overlapped: both horizontally and vertically. Joints and abutments are glued with self-adhesive vapor-tight tape.

The reflective side must face the attic. To form a gap and install the sheathing, wooden beams are attached to the rafters.