Thermal insulation of a house from a rounded log

Insulation of a house from a log is performed when heat loss is detected at the junctions of structural elements. Thermal insulation can be in-wall, external or internal.

Important! Sealing and warming are not the same thing. If the insulation allows the house to "breathe", then the sealant does not.

Log buildings retain heat well, provided that all the gaps between the logs are thoroughly buried. If the thickness of the walls allows you to withstand frost, then you can limit yourself to caulking, preserving the structure of natural wood both outside and inside.

How to insulate a log house outside? Before the start of the insulation work, the new log house must stand for at least a year so that it has time to dry out and settle.

If the house is old, any external insulation begins with the preparation of the facade - they dismantle the hinged elements, carry out the necessary repairs, clean and level the surfaces.

Important! Before starting work, treatment with an antiseptic and fire retardant is required.

Basic requirements for a heat insulator

- the same vapor permeability as wood, if it is laid along the facade of a log house;

- moisture resistance, which will protect the tree from moisture accumulation and decay;

- fire safety;

- immunity to fungus and pests;

- have a loose structure that will ensure a tight fit of the insulation to the wooden walls.

Wood is a unique building material that not only "breathes" through the ends of the logs, but also acts as a natural heat exchanger. Therefore, for such a "living" material, natural insulation should be used, which has the same natural origin as log walls, in contrast, for example, from materials used to insulate a house from aerated concrete.

It is possible to carry out external insulation of a house from a log with the following materials:

- tow;

- a tape-type insulation made of flax and jute;

- hemp;

- moss.

When insulating old wooden houses, it is allowed to use ecowool and mineral wool for external insulation. They are simple and convenient to install and are inexpensive, and in terms of their main technological characteristics they are close to natural heat-insulating materials. It is unacceptable to use thermal insulation made of synthetic materials for log houses.

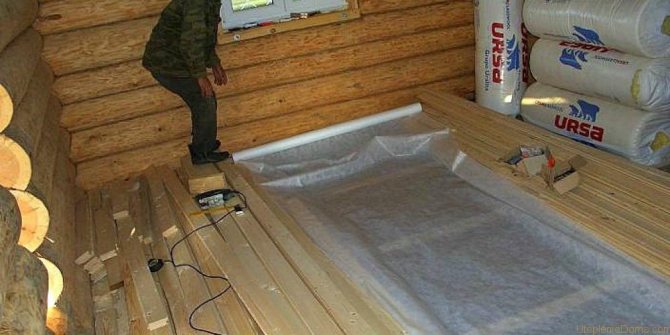

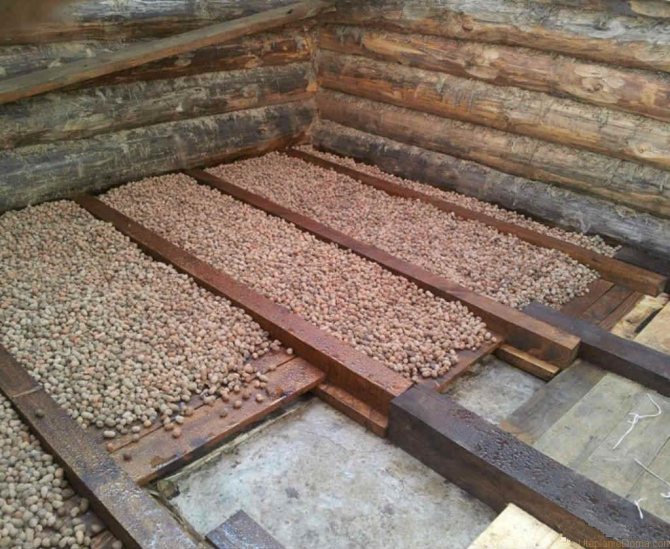

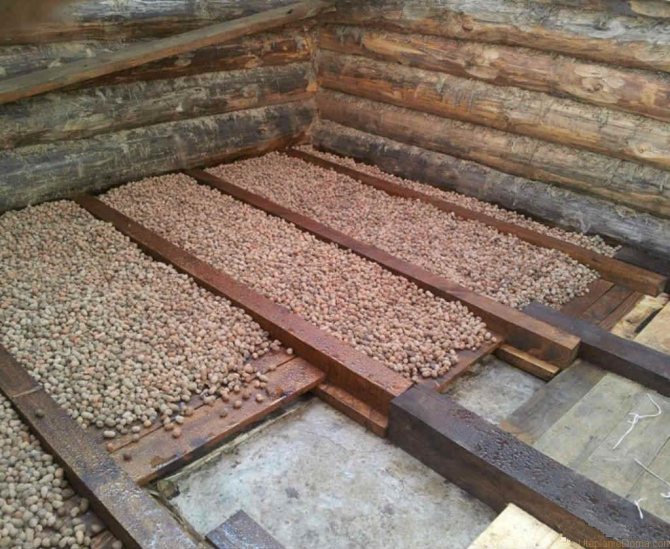

For insulation of the attic and the floor, filling material should be used: sawdust or expanded clay. Dry seaweed and straw can also be used in the attic. You can insulate the floor with roll-type mineral wool, placing it under the flooring.

When choosing an insulating material, they pay attention to the following nuances:

- The vapor permeability coefficient is the same as wood or higher. Wood perfectly permeates steam so that moisture does not accumulate in the insulation, it must have the same characteristics.

- Inert to the development of fungus and mold.

- Fire safety. Wood is highly flammable and burns quickly. Such structures always have a risk of fire, therefore it is better to select a heat insulator that burns poorly or does not support combustion.

- Plasticity and flexibility. For a high-quality arrangement of thermal insulation, the material is tightly attached to the outer wall. Since a log house does not differ in an ideal plane, the appropriate insulation is selected.

- It is important that the heat insulator does not accumulate moisture.

We offer you to familiarize yourself with: Do-it-yourself chimney gate

If you choose a material according to such criteria, then the created insulation system will last a long time and help reduce heating costs.

Elimination of gaps between logs in a log house

This requirement is met by fibrous materials, the most common of which is mineral wool.

Mineral wool is made from fiberglass, slag and rocks. The fibers are held together with organic binders and impregnated with water-repellent compounds.

- Glass wool is inconvenient to install because it has spiky fibers

- Slag wool is acidic and releases aggressive substances when the humidity rises.

- Stone wool has no disadvantages, except for the common to all fibrous materials

Mineral wool has the following characteristics:

- Thermal conductivity coefficient - 0.038 - 0.053 W / mhK

- Sound absorption coefficient - 0.95

- Density - 75 - 200 kg / cu. m

- Compressive strength - 0.04 - 0.06 MPa

- Water vapor permeability - 0.49-0.60 Mg / (m × h × Pa)

- Maximum operating temperature - over 800 degrees

The following brands of mineral wool are used in construction (the number in the designation corresponds to the density of the material):

- P-75 - for thermal insulation of horizontal surfaces without load on the insulation (interfloor floors between the logs)

- P-125 - for thermal insulation of inclined and vertical surfaces without load on the insulation (roof and walls)

- ПЖ-175 and ППЖ-200 - for thermal insulation of any surfaces with a load on the insulation (floors with cement screed and flat roofs)

Stone wool P-125 is optimal for insulating houses.

Insulation of log houses

To perform high-quality thermal insulation at home, you need to insulate all surfaces in contact with the spring environment.

These include:

- Window and door openings

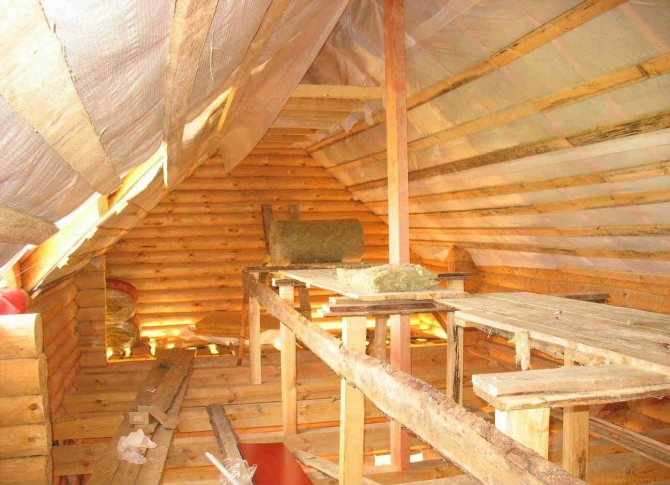

- Roof

- Floors

- Walls

Work should begin with caulking the seams between the crowns of the log house. The walls are caulked from the street and from the inside. For this, jute and synthetic tape insulation or moss are used. Next, the openings, floors and roof are insulated. This is often enough. If not, proceed to the thermal insulation of the walls.

How to insulate a log house outside?

Insulation from the outside of the facade is performed as follows:

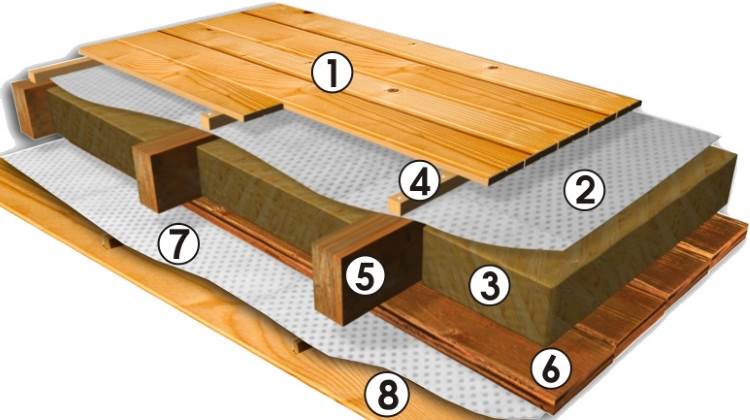

- The sheathing beams are nailed to the walls horizontally with a step, a couple of centimeters smaller than the width of the mineral wool slabs. Their width should be slightly more than the thickness of the insulation layer

- Plates are inserted between the bars. Laying is carried out in at least two layers with bandaging of joints

- Insulation for a wooden house is closed from the outside with a windproof membrane. This film material protects mineral wool from moisture, but allows vapors to pass from the insulation layer to the outside. For the membrane to work correctly, it must be hung with the rough side out.

- A vertical crate is nailed to the bars for attaching finishing materials. Thus, a ventilation gap is created between the thermal insulation layer and the outer cladding for ventilation of the walls and insulation.

- Finishing materials are attached to the crate. It can be lining, imitation timber or block house

Internal insulation of a log house

Since wood is a good heat insulator, when insulating from the inside, the dew point (the point with the freezing point of water in which condensation forms) rarely moves outside the walls.

We suggest that you familiarize yourself with Making chacha from grapes at home

Nevertheless, measures to remove moisture from the log house will not be superfluous. For this, experts recommend leaving a ventilation gap between the walls and the insulation of at least 2 cm.

Warming is performed as follows:

- To provide a gap, a vertical wooden lathing is nailed to the walls.

- A membrane is attached on top of it

- With a step slightly smaller than the width of the insulation, mount the counter-crate

- Between its beams, slabs of mineral wool or foam are inserted in several layers

- Hang up a vapor barrier film

- Walls are sheathed with finishing materials - clapboard, drywall, chipboard, etc.

This roll material is made of polyester foam, covered with foil on one side. Penofol is absolutely not afraid of moisture, which means it does not require steam - waterproofing. Penofol strips are attached to the slats providing a ventilation gap with foil towards the room. The material is laid with an overlap of 10 cm. The joints are sealed with construction tape. There should be a gap of 2 cm between the insulation and the finishing materials.

The modern building materials market allows you to choose insulation for the outer walls of a wooden house for every taste. In addition to the materials described, OSB, sprayed thermal insulation, etc. are used for internal insulation.

Caulking is an important stage in the construction of a wooden blockhouse, which helps to seal gaps, seams and openings.

If in the past seams and openings had to be caulked with dry moss for logs, linen and hemp tow, bast fiber or felt, then over the years new technologies have appeared in the production of natural materials. Now on the construction market there are heaters made of jute fiber, flax, flax, mineral wool.

Caulk from bottom to top.

Caulking should be performed from the bottom groove along the length of the entire perimeter of the log house. If only one wall is caulked, then this can lead to a distortion of the entire log house. As it dries, the timber shrinks, which is why cracks form in the walls, so wooden structures will have to be caulked even after construction is completed.

Do-it-yourself mistakes when insulating a log house

Some people believe in this myth that the more insulation you put inside the building, the better. However, in the presence of a very thick layer of insulation, the dew point may move into the material itself, and if it is with a cotton base, it may dampen its thermal insulation characteristics. As a result, your insulation just won't last long.

Another mistake is the desire of some owners to insulate the house on both sides, thereby causing damage to the wall of the building itself. The point here is that the vapor barrier feature of the insulation simply will not allow the walls to dry out, which will provoke the spread of mold and mildew.

The choice of material for insulation

Primary requirements

To insulate a log house from the outside, the materials used must meet the following requirements:

- High level of thermal insulation.

- Environmental friendliness.

- Hygiene.

- Air permeability.

- Moisture resistance.

- Fire safety.

Important! For a wooden house, it is better to use only natural materials.

For caulking, such natural materials as moss, tow, hemp, felt, jute and tape insulation based on flax or jute have proven themselves excellent.

The properties of these materials are shown below:

- Moss is resistant to decay and has antibacterial properties.

- Felt requires special processing, otherwise moth larvae will start in it.

- Jute and linen are durable, dense, rot-resistant materials with low hygroscopicity.

Insulation outside

For external insulation, mineral wool or ecowool is suitable, especially if a ventilated facade is planned.

Plates made of expanded polystyrene (foam) or basalt are used when a "wet facade" is being installed.

Important! Penoplex is not suitable for insulating a log house from the outside, as it has a very low vapor permeability.

Preparatory work

It is not advisable to neglect this stage, because after all the insulation work has been completed, the bar will be closed and to fix anything, you will have to completely dismantle all the insulation material. First, all walls are cleaned of dirt, and then all irregularities and cracks are sealed. Further, the tree is treated with a special agent that protects against rotting and the appearance of parasites.

If electrical wiring runs along the walls, it must be checked so that it is in working order and correctly insulated. Before the direct installation of the insulation material, you need to create a kind of vapor barrier to protect the insulation from moisture that will form on the wooden walls. Also, here we must not forget about high-quality ventilation, without which, when creating a vapor barrier, the effect of a thermos is formed and the walls will flutter.

The note: A special membrane film can be used as a vapor barrier. It does its job very well, but it is not cheap.

How to properly insulate a log facade, do it yourself steps

Before carrying out work, the grooves must be cleaned and treated with an antiseptic.

Important! Caulking of log walls can only be done manually.

Feature of work:

- They are performed first outside, then inside the house.

- You should start from the bottom row of logs, gradually going up.

- The lower crown is poured completely, along the entire perimeter, only after that they move to the next row.

Important! You can't completely bury one wall and then tackle another. This is fraught with distortion of the house.

Ventilated facade

If the insulation inside the wall is not enough, then it is possible to carry out external or internal insulation of the log house. A crate is placed on the prepared walls, which is treated with an antiseptic, and insulation is laid under it. For thermal insulation, mineral wool is most often used.

Ecowool has high heat and sound insulation properties, but only a qualified specialist should work with it.

After installing the insulation, a waterproofing vapor-permeable membrane is mounted. It allows moisture and air to escape, but does not allow moisture and wind to pass through.

We suggest that you familiarize yourself with Chia grains how to use

After waterproofing, a crate is placed on which siding is attached: vinyl, wood or block house.

Important! Always leave a gap between the waterproofing and the finish as this is required for ventilation.

Wet facade

The technology for making a "wet facade" requires a flat wall made of any material (wood, brick, foam blocks, etc.). The key word is flat (wall), so the method is unacceptable for cylindering, but it is suitable for a house made of timber.

It is called wet because in the production of work water is used, which is part of the building mixtures. The order of work is as follows:

- Preparation - includes thorough cleaning and leveling of the walls. It is imperative to install all the elements for attaching antennas, gutters, lighting, etc. and cover them with an anti-corrosion compound.

- After the repair or plaster layer has dried, the walls are covered with a primer.

- A plinth profile is installed. This must be done strictly horizontally and always below floor level.

- An adhesive composition is applied, in small portions, as necessary during the installation of insulation boards.

- The first row of slabs is laid on the base and glued tightly to the wall.

- The next row of insulation is laid, shifting the vertical seam to the right or left, at least 200 mm to ensure dressing.

During the installation of the plates, additional mechanical fasteners - dowels - are necessarily used.

The installed insulation is protected with a reinforced plaster layer using an adhesive mixture and a mesh. First, the corners and slopes are processed, then the remaining surface.

Important! The mesh should be immersed in the adhesive, but not in contact with the insulation.

Thermal panels are a building material that serves both for insulation and decoration of the building facade. The lower part consists of insulation (expanded polystyrene or polyurethane foam). The upper one plays the role of finishing and is made of clinker tiles, thin facing bricks, stone, porcelain stoneware.

Installation of thermal panels is carried out at any time of the year:

- To insulate a house from a log from the outside with the help of thermal panels, a wooden frame is assembled.

- Next, the basement profile is fixed. Necessarily strictly horizontally and below floor level. In some cases, you can do without it.

- It is recommended to start the installation from the left corner of the house, moving from left to right.

- Use foam glue, then fix the panels with self-tapping screws.

- The gap between the profile and the wall is filled with mounting foam and the joints are sealed.

Finish the installation of thermal panels with grouting.

The main requirements to rely on when choosing a mezhventsovy heater:

- the optimal level of density and elasticity, which provides reliable protection of the home from drafts;

- low thermal conductivity, which contributes to long-term preservation of heat;

- fast absorption and release of moisture, taking into account changes in air humidity from the inside and outside of the room;

- resistance to the development of microorganisms;

- durability, including the preservation of the microstructure of the material and resistance to the effects of natural factors;

- absence of substances posing a danger to human health.

The peculiarities of insulating houses made of rounded logs are due to the properties of wood.

- Wooden log cabins shrink by 6 - 8% during the first half of the year, therefore, insulation work should not be started earlier than a year after the completion of construction. Since new timber houses keep warm well, there is no need to rush

- Wooden walls breathe. Depending on the season and weather conditions, the moisture content of the wood changes, so the logs must be ventilated. If the surface of the walls is covered with a vapor-proof material, excess moisture will have nowhere to go and the logs will begin to rot

- Log buildings have an attractive appearance, which is why many homeowners do not want to degrade it by insulating facades. Internal insulation is less effective, but if certain rules are followed, it brings success

Techniques for external insulation of log walls

We will approach this issue from the side of choosing between independent insulation (with our own hands) and turning to third-party craftsmen or companies.

Not every insulation technology is suitable for independent work. In order to produce high-quality insulation of a log house, without unnecessary material costs and at the same time get a beautiful and accurate result, skills and experience are required. A professionally performed work will not only insulate your home, but also give it an external gloss and beauty. Of course, the work of professionals costs money and the final decision is up to you.

1. Of course, "shabashniki" and private craftsmen ask for less work. But here you need to understand and assess well the following risks:

- No guarantee

- There is no one to ask for a low-quality result

- "Unfinished"

When choosing a private master, pay attention to the willingness to show the work already done, because in pursuit of earnings, "shabashniki" can take on work in which they do not have enough skills and experience. There are no universal specialists, and in specialized construction and finishing works, a narrow-profile master always has an advantage.

2. What to look for when choosing a company for house insulation:

- Willingness to provide a detailed estimate for materials and work

- A good company gives a guarantee for the work specified in the contract

- Experience and willingness to show finished objects Every year, only in the field of insulation using the "warm seam" technology, more and more offers from companies appear, but this does not mean that each of them has specialists with sufficient experience in this area. Every year our company gets several objects "for alteration" from such.

You should immediately pay attention to the fact that all work related to insulation and finishing of walls can be carried out only after complete shrinkage of the structure. This process takes about one and a half years, sometimes up to two. Thermal insulation of a log house from the outside can be done in two ways:

- construction of a ventilated facade;

- according to the wet facade technique.

To insulate a log house from the outside to be effective, it is necessary to calculate the thickness of the insulation. This procedure is performed individually for each house, taking into account the region in which it is located. We wrote about how to calculate the thickness of the insulation in one of the previous articles. The first is a ventilated façade. According to this technique, a house from a rounded log can be insulated with both mineral wool and liquid thermal insulation.

Before insulating the log house from the outside, you need to build the first level of the lathing from wooden bars. Their cross-section must be at least the thickness of the thermal insulation layer. Mineral wool is placed between the battens or liquid insulation is sprayed on. A waterproofing is laid on top of it - this is a film that does not allow the insulation to get wet, while releasing steam from it.

Waterproofing also acts as a wind barrier. When insulating log walls from the outside, on top of the waterproofing film, the second level of the crate is stuffed, the cross-section of the bars is from 10 mm and more. It is important that there is a ventilated space between the film and the cladding, so that all moisture can be eroded. Finishing (siding, blockhouse, etc.) is stuffed on the second level of the crate.

The wet facade technique consists in fixing high-density mineral wool slabs (from 80 kg / cubic meter) to the wall and applying plaster over the thermal insulation in two layers. After applying the first layer, a fiberglass mesh is recessed into it, which serves as a reinforcement. The second layer of plaster is applied after the first one has dried. Then you can glue the finish or paint onto the finished surface, just remember that all layers must be vapor-permeable.

You will learn how to choose the most economical electric boiler for heating your home by reading this article.

Naturalness is a guarantee of quality

The best option for insulating a log house are seals made from natural materials. They are usually made in the form of ropes or ribbons. Ropes are a classic form, but it is easier to work with a tape seal, as it is distributed between the crowns of a log house quickly and evenly.

Tape mezhventsovy insulation can be made of flax, flax-jute and pure jute. You can buy it from us directly on the website or by placing an order by phone.

The width of the belt is selected taking into account the size and profile of the bar or log. The main natural products include:

- jute;

- linen;

- hemp (hemp fiber);

- moss. Batting and felt made of cotton or woolen yarn are not recommended to be used as a seal between the crowns. Such materials are really capable of retaining heat, but at the same time they tend to retain accumulated moisture, which is absolutely unacceptable for a mezhventsovy heater. In addition, pests develop well in them.

We suggest that you familiarize yourself with How to insulate the floor on the second floor

All about jute

Jute belongs to the linden family. Its natural shade matches well with the wood color. Jute fiber is a recognized leader among mezhventsovy heaters.

Jute tape is mezhventsovaya.You can buy it from us directly on the website or by placing an order by phone.

When the walls shrink, the jute tape is evenly compacted between the crowns. It practically does not rot.

Jute is the same natural material as wood, therefore it absorbs and releases moisture depending on the ambient temperature. Jute linen is not damaged by moths, birds do not take it away. Mezhventsovy insulation can also be used as a complex product, for example, in the form of jute and flax-jute felt.

Flax is not only in demand, but also a more affordable building material, which has long been used for caulking a wooden frame. Flax fiber and linseed tow are made from the stem of flax.

Caulking with flax (linen) is a good solution for insulating a wooden log cabin.

The quality properties of flax fiber have a long service life and remain elastic for many years.

A significant disadvantage of flax is its susceptibility to rotting. In addition, linen insulation is attractive for birds, which take it apart for their nests, and rodents, who equip holes and passages in it.

Hemp fibers

Hemp is a natural material made from hemp. Such insulation has a high rate of thermal insulation, is resistant to mold and mildew. However, it is rarely used as insulation between crowns, due to its high cost and limited production in the field of application.

Moss application

For many years, sphagnum moss has been considered the best option when choosing an insulation material. Moss for a log house is characterized by hygroscopicity, bactericidal properties, resistance to moisture.

And this is a moss with an exotic name "cuckoo flax". You can buy it from our company.

The disadvantages of moss include its low fire resistance, installation complexity and attractiveness for birds, which pull fibers between the crowns to arrange the nest.

The attractiveness of the frame in the seams between the joints can be given by a jute rope.

Insulation of the floor and attic in a log house

Expanded clay, although it does not have outstanding thermal insulation qualities, but mice do not live in it.

When insulating the floor in a log house, it is necessary to take into account the vapor conductivity of the heat-insulating cake and the high probability of the appearance of mice. Be sure that where there are at least minimal conditions for the life of rodents, they will not keep you waiting, and under favorable conditions they will actively reproduce. As we have already determined, for high-quality floor insulation, you can use bulk materials, mineral wool and liquid thermal insulation. Among them, rodents live only in mineral wool, even stone, besides, the deliberate rejection of vapor barriers leaves no options but to abandon mineral wool.

Only bulk materials and liquid heaters remain. With the latter, everything is so simple that there is nothing to even talk about. They are sprayed onto the work surface without any additional protection, even a waterproofing lining is not needed. Thermal insulation technique with bulk materials:

- laying the subfloor - preferably in a continuous layer to minimize the risk of film rupture and thermal insulation spilling;

- laying a diffusion membrane that allows steam to pass in both directions;

- the insulation is filled in - the layer is calculated depending on the region;

- the finishing floor is laid.

The same technique is suitable for attic floors. If the attic is heated, then the insulation rather plays the role of sound insulation and its presence is not necessary, in this case, the main thing is to insulate the roof well and correctly.

Tips and tricks for protecting a log building

This procedure includes the following steps:

- Antiseptic treatment (from decay, insects and rodents).

- Fire retardant layer device (for fire safety purposes).

- Finishing (primer and coating).

The correct process will preserve the beauty and safety of a wooden house.

Insulation of a log house from the outside necessarily includes caulking, thermal insulation of walls, ceilings, window and door openings. Further work depends on the design, purpose and age of the building. All processes can be done by hand, but to ensure guaranteed isolation from the cold, the owner of a residential building should contact a specialist.

What are the problems with old wooden houses?

Wood is a short-lived material; even the toughest tree species cannot boast a long service life. Constant exposure to moisture, temperature fluctuations and other negative factors lead to:

- violation of the integrity of the structure;

- the appearance of drafts in the premises;

- loss of visual appeal;

- distortion of the supporting structure as a result of material decay.

After the appearance of such shortcomings, it is not comfortable to be in the rooms of the old house, especially during the winter periods, since it is necessary to spend a lot of energy to create a warm microclimate. In some cases, it is simply impossible to get rid of drafts. This is due to mistakes made at the design stage.

Modern technologies of construction and processing of materials make it possible to process logs with antibacterial and moisture-repellent impregnations. Such actions can extend the life of the wood.

So, let's begin! You recently bought a log building to provide yourself and your family with additional space in high-quality, environmentally friendly, comfortable housing. The log house is made of solid wood, which is specially processed and designed for the construction of small wooden buildings.

The problem with most of these buildings is that they are not well insulated and new settlers have to think about how to insulate the log house from the inside so that the living conditions in it are not like living in a barn or stable. As a result, you will have to choose: to carry out insulation from the inside on your own, bearing the costs only for the purchase of materials, or to involve a third-party organization to carry out construction work for a certain fee.

A quick log home insulation guide will allow you to properly insulate this type of building. Regardless of whether you use a log house during the warm summer season or the cold winter season, it will maintain a comfortable temperature at any time of the year.

Do-it-yourself insulation of a log house from the inside is a very time-consuming and complex operation. The process is quite troublesome and expensive, but effective thermal insulation of a log from the inside requires appropriate investments. However, the biggest costs are precisely labor and the desire to make your home warmer and more comfortable, and the materials used are already in second place.

We suggest that you familiarize yourself with: How to properly fasten the lining with nails