Consumer properties

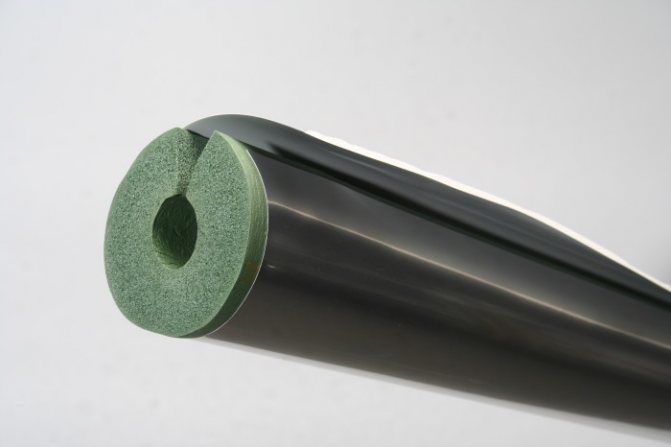

The insulation is made of synthetic rubber. It may contain various additives that change the technical characteristics of the material. For example, the ST model has proven itself equally well in the arrangement of engineering systems both in ordinary residential premises and in industrial facilities.

All materials have a porous structure with small closed cells, thereby reducing the thermal conductivity and vapor permeability of the material. Also, pipe insulation has a wide range of operating temperatures. It is durable and meets the requirements of fire and sanitary safety.

In addition, K Flex insulation is acid-neutral and does not absorb moisture, thus providing reliable pipe corrosion protection.

Technological advantages

Of the technological advantages, the flexibility of the material should be highlighted. This property allows you to mount insulation on any type of surface, even the most complex ones. Regardless of what kind of material we are talking about, be it ST or another model, clamps and unnecessary fasteners are not required to fix the finish.

The insulation adheres tightly to the surface of the pipes, creating a tight seal and preventing thermal energy leakage. The average service life of the material is 25 years.

Range of products of the company

The main component of the Kaflex insulation is synthetic rubber with all kinds of additives. At their expense, the technical parameters of finished products are transformed, allowing each variety to be used for specific purposes. There are both universal and modifications designed for certain types of work.

A decrease in the thermal conductivity and vapor permeability of materials is achieved by imparting a porous structure to them, consisting of small closed cells. Thermal insulation Kaflex is distinguished by a wide range of temperatures at which it is effective, durability, compliance with sanitary and fire safety standards.

Today in the consumer market there is a large assortment of thermal insulation products, which allows buyers to choose the necessary pipes according to technological criteria.

Technological advantages

Insulation K-Flex is a high quality product with a wide range of positive properties. In addition to increased heat savings, it is also characterized by:

- Unlimited service life, during which all its properties, declared by the manufacturer, are preserved.

- Resistance to corrosion and aggressive environments.

- Hydrophobicity.

- Large temperature range at which it remains effective - from -195 to + 105 ° C.

- Easy installation without additional fasteners.

- Environmental Safety.

- No pungent odor.

- Increased elasticity and tensile strength allows you to work with valves and bent pipe sections.

- Aesthetic appearance.

- Affordable price.

Manufacturing techniques

The production process consists of extrusion foaming. As a result, the main raw material is pushed through the die with subsequent vulcanization. This method is constantly being modernized to impart new quality and technological properties to the finished product, which are required by the consumer.

K-Flex thermal insulation is based on the use of synthetic butadiene-nitrile acrylic rubber, which gives the material high plasticity. During the manufacturing process, polymers, minerals and antipyrins are added to it. With their help, various modifications of the insulation are obtained.

During the gluing of the material, it was possible to achieve the effect of cold welding, and the seams obtained in this process become stronger than the insulation itself. No complicated equipment is required to install the insulation. Any operations can be carried out using a knife.

Types of products

All brand products were divided into categories that differ in their characteristics and scope. Today the manufacturer offers such types of Ka-Flex insulation:

- A range of products in the ST series are pipes made of porous rubber and suitable for operation in the temperature range from -200 to +105 degrees. Thermal conductivity at standard +20 is 0.034, and at -20 - 0.038. The material is used in petrochemical plants, industrial pipelines, in water supply systems, heat supply, air conditioning and ventilation, in refrigeration plants. Fire protection class - G1. The products are odorless, biologically and environmentally friendly. Depending on the conditions of use, there are types with coating ALU, IC CLAD, PVC, IN CLAD, AL CLAD.

Pipes made of porous rubber are suitable in industrial pipelines, in water supply systems, heat supply, air conditioning and ventilation systems, in refrigeration plants - Sheet insulation Koflex SOLAR HT is used in solar panels, high-temperature isolation, factory equipment and steam pipelines, whose temperature does not exceed the product's limits of use, which is +150 degrees. The thermal conductivity coefficient is 0.04 and 0.045. The density is 70 kg / m³ with a tolerance of 25%. IC CLAD, IN CLAD, AL CLAD coatings allow laying for pipe insulation in any soil.

- Insulation KaFlex of the ECO line is laid on pharmaceutical and food enterprises, offshore platforms and ships, in hospitals, schools, kindergartens, airports, bus stations and other places where people gather. Fire resistance class - G2, RP1, T2, thermal conductivity - 0.036 and 0.04, respectively, the operating temperature range is -70- + 150 degrees. Products are produced in the form of odorless green sheets coated with AL CLAD, IC CLAD, IN CLAD.

- AL CLAD SYSTEM composite insulation with aluminum coating is used both inside and outside buildings.

- For insulation of ventilation and air conditioning complexes, as well as for sound insulation, K-FLEX AIR is used, operating at temperatures from -30 to +80 degrees with a thermal conductivity index of 0.034 and 0.038. The permissible deviation is 15% at a normal density of 40 kg / m³. It is a gray metallic coated material.

K-FLEX AIR is used for insulation of ventilation and air conditioning complexes - The IGO model range is odorless black products with a density of 130 kg / m³ with a maximum error of 25%, IN CLAD coating. They are used in thermal insulation of underground and aboveground pipelines and welded joints.

- ST / SK pre-cut products have a special adhesive layer, which makes this material suitable for use as a pipe material. The stacking speed is high. Product color is black, coatings - AL CLAD, PVC, IC CLAD, IN CLAD.

Each insulation of the K-Flex brand has its own characteristics that allow it to be used most effectively in certain conditions.

In addition to model lines, there is a division depending on the protective coating, which can be of the following types:

- Alu with 3 layers of 9 micron aluminum foil and colorless polymer spacers.

- Al Clad, self-adhesive, including foil, polyethylene and polypropylene films.

- In Clad, completely polymer, serves to protect the surface from moisture and chemicals.

- Ic Clad BK with fiberglass, therefore particularly durable.

Products differ in the form of release. It can be:

- Pipes with a diameter of 6 to 160 millimeters with a wall thickness of 6-32 mm.

- Tees and elbows used to isolate joints and elbows.

- Sheets measuring 1 × 2 or 0.5 × 2 meters.

- Rolls 1 m wide.

- Tape with a self-adhesive polyethylsiloxane coating, 3 mm thick. Its width is 1.5, 5 or 10 centimeters.

- Suspension from two pipe segments with PVC reinforcement on the outside.

Assigning insulation models

The K-Flex product line includes the following brands of thermal insulation materials:

- ST and ST / SK - for finishing surfaces with negative and positive temperatures;

- ECO - for the isolation of engineering systems in rooms with increased safety requirements;

- ST DUCT - for work with ventilation systems;

- ST FRIGO - for insulation of components of air conditioning and refrigeration equipment;

- SOLAR HT - for finishing surfaces with positive temperatures;

- AIR - for sound and heat insulation of ventilation systems;

- EC-H ROLLS - for insulation of heating and water supply pipes, as well as air conditioning systems.

Material abilities

Each of the listed materials has its own unique performance properties and is intended for use in a specific temperature range. For the purpose of arranging heat supply complexes, it is best to use products of the ST, ST / SK, ECO and SOLAR HT models.

The first two brands can withstand temperatures up to 104-116 ° C heat. ECO remains operational when heated up to 150 ° С, and SOLAR HT - up to 175 ° С. The rest of the models, with the exception of the EC-H ROLLS, will not withstand the stress associated with high temperatures.

Scope of use

Mainly, K-Flex manufactures products for industrial facilities. The products supplied by this company are used for finishing such engineering communications as:

- technological pipelines;

- heating networks of underground and aboveground laying;

- low temperature pipelines;

- air conditioning and ventilation systems, air ducts;

- pipelines for the supply of petroleum products, crude oil and gas;

- technological pipelines in production with increased requirements for sanitary safety, for example, in the field of microbiology;

- storage tanks for water, fuel and other liquids.

K-Flex thermal insulation is used in the automotive and mechanical engineering industries. In everyday life, the products of this company are recommended to be used for finishing elements of heating, ventilation, air conditioning and water supply systems.

ECO insulation is designed for use in kindergartens, schools, canteens and other institutions where special hygienic requirements are imposed on the quality of building materials.

K-Flex St: European quality for Russian conditions

K-Flex St is a material that is based on synthetic foam rubber and is designed to insulate and protect utilities, in particular various pipelines. It is produced and supplied to the Russian and European markets by the company of the same name. K-Flex is a recognized world leader in the production of technical and household engineering insulation from elastic polymers. Their solutions can significantly save resource consumption and create energy-efficient facilities.

Installation of heaters K Flex

Before fixing the thermal insulation, the surface to be treated must be cleaned of traces of dirt. This is done using a cleaner. In the case of insulating metal parts, it is also necessary to get rid of corrosion. The thermal insulation is fixed to the surface with K-Flex glue. It is thoroughly stirred before use, and the rest of the time is kept in tightly closed containers. Cured glue can be thinned with K-Flex to make it runny.

To apply the adhesive, a brush with stiff short bristles is used. First, the reverse side of the ST insulation or another brand is lubricated with glue, and only then the surface of the pipes. The composition is applied in one continuous uniform layer. It is important that no threads form during this process. When the glue dries, the insulation is pressed tightly to the surface to be treated. At the same time, it is undesirable to stretch the material; it is better to glue it with light compression.

Work is permitted only on disconnected systems. It is allowed to turn on the system only 36 hours after the installation of thermal insulation: during this time, the glue has time to dry.

Characteristics of glue k 414

The k flex glue k 414 is specially designed for fixing insulation made by K-FLEX. It resists aging and does not react to weathering. All surfaces treated with this adhesive are provided with additional properties.

The mass has a one-component composition based on polychloroprene rubber. The glue is resistant to all external influences. Available in different volumes: 220 ml, 500 ml, 800 ml, 2.6 liters. The container is yellow. After use, it closes tightly until the next need. The composition is applied at a temperature in the range of 5-30 degrees.

There are no aromatic additives. Has excellent adhesion to metal. Does not adhere to surfaces containing paint, asphalt, bitumen, oil build-up. It can be used at temperature extremes, for complex structures (tees, sliding parts, elbow, etc.).

When thickening, glue to 414 is diluted with a cleaner of the same TM.

Main characteristics:

- drying is achieved after 10 minutes;

- open time up to 20 minutes;

- working temperature within -40 - +105 degrees;

- with a closed container and a temperature regime of 15-25 degrees, the mass is stored for a year with the preservation of its original properties.

View this post on Instagram

Posted by (@ santehtorg116) Feb 28, 2020 at 1:33 am PST