Before carrying out the installation, remember one important nuance. There are certain installation standards, rules for constructing a box in the ceiling. They need to be followed clearly and flawlessly.

An incorrectly positioned pipe in the bath through the ceiling and roof is a serious violation of fire safety rules. The consequences can be different, up to a severe fire. But if you provide good thermal insulation, visiting the bath will become an absolutely safe activity. Due to numerous requests from our readers, we decided to write an article on how to make a chimney, what standards must be observed. We'll start with helpful tips.

What does a novice stove maker need to know?

Especially for you, we have made a selection of relevant recommendations that give an idea of \ u200b \ u200bdo-it-yourself installation. So let's get started!

- When you install the pipeline in the bath, the installation of the stove ceiling box is a must. It contributes to an even distribution of heat that comes from the pipe, eliminating the possibility of fire.

- What material is suitable for insulation? The use of mineral wool, foam glass, expanded clay is allowed. Earth and sand are unlikely to work. Due to the high coefficient of heat capacity, the materials will keep heat, which is not necessary in our situation.

- It is desirable that the chimney in the bath has a complete height of 4-5 meters. Usually it is placed closer to the wall of the room. Since the wood trim is very close, you should take care of the screen protector.

- The GOST rules are as follows. The distance from the pipe to the beam is at least 13 centimeters. The diameter of the pipe with additional insulation is 32-33 centimeters. The distance between the beams is from 60 cm. If you lead the ceramic pipe in the bath through the ceiling, the distance should be at least 25 cm on each side.

- From the stove, we always make a metal lead from a thick, refractory material. Even stainless steel will not work - it will not be able to withstand such a prolonged exposure to high temperatures. Height - at least one meter.

- Removing the chimney excludes the use of more than three bends (bends).

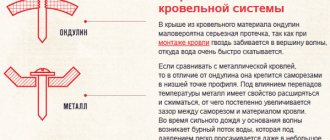

- Where the structure passes through the ceiling, we recommend using a sandwich pipe. The assortment of such products in stores is quite diverse. You can find products with a thickness of insulation from 3 to 10 centimeters and more. Take the "top ten" - it is safe and reliable.

Useful information: "What and how should you insulate the ceiling in a Russian bath?"

About distances to combustible structures

The passage of the chimney through the ceiling of the bath must be done in accordance with all fire safety rules

For the pipe in the bath, you need to make a special node for the passage through the ceiling. This is a device that provides safe distances from the outer surface of the pipe to the ceiling materials. They are regulated by SNiP 2.04.05-91. The recommendations are as follows (paragraph 3.83):

- from the outer surfaces of brick and concrete pipes to combustible rafters and battens - at least 130 mm;

- from ceramic pipes without insulation - at least 250 mm, from them with thermal insulation - 130 mm.

These figures must be taken into account when installing floor beams. Their step is usually taken small - about 60 cm. With this step, the recommended distances will be maintained only when using pipes with insulation. For example, sandwiches.

The diameter of the furnace outlet is most often 115-120 mm. If you use a sandwich with an insulation thickness of 100 mm when passing through the floor, the outer diameter will be 315-320 mm.There must be a distance of at least 130 mm on all sides. It turns out that in this case the distance between adjacent beams should be 130 mm * 2 + 315 mm = 575 mm. We just fall into the gap of 60 cm.

Combustible materials need protection

There are a lot of sandwiches on the market with insulation thicknesses of 35, 40, 45 and 50 mm. You can find a layer of 100 mm mainly in stores specializing in sauna stoves. Only in sauna chimneys there are temperatures from which a 100 mm layer of mineral wool must be protected. Can a 50mm layer be used? You can, but if you want to take a steam bath, take 100 mm - it is safer.

We calculate the minimum distance for chimneys without insulation. In this case, with an inner diameter of 115 mm, the safe distance from the outer edge of the pipe to combustible materials is 250 mm. The distance between the beams in this case should be 250 mm * 2 + 115 mm = 615 mm. Let it be a little, but it does not go away. But this calculation is for not the largest diameter of the smoke channel. There are many more. In any case, if the ceiling has not yet been made, calculate the step of installing the beams taking this factor into account.

This cannot be done - the distance from the pipe to the ceiling and the wall is very small, so the wood is also not protected

At the same time, compulsory appendix 16 contains recommendations for deviation (distance from the outer surface of the pipe to combustible materials):

- for a fire-protected partition: with a pipe thickness of 120 mm - 200-260 mm;

- with a pipe thickness of 65 mm - 380 mm.

- with a pipe thickness of 120 mm - 260-320 mm;

This appendix is about wall retreat. After all, very often chimneys pass near walls. And their material also needs protection: the temperature of the flue gases at the exit from the furnace can reach 500 ° C. If timber walls are unprotected, they will char and then burst into flames. Therefore, a layer of thermal insulation is laid on the walls (cardboard made of mineral wool is suitable), and a sheet of polished stainless steel is stuffed on top.

Choosing a reliable material for thermal insulation

High-quality overlap is impossible without the use of such materials:

- Mineral or basalt wool. Withstands heating up to 600 degrees. The main disadvantages are that it contains formaldehyde and loses its protective properties after getting wet.

- Expanded clay. It retains its beneficial properties even when wet. Arrangement of effective thermal insulation is impossible without the installation of additional tanks.

- Minerite. Like basalt wool, it can heat up to 600 degrees, but it does not emit harmful substances, does not lose its properties in a humid environment. The composition of minerite includes cellulose, cement, mineral fillers.

- Asbestos. It is considered a good insulating material, although it can also release hazardous substances when heated.

- Clay and sand. Used until more modern heaters appeared. It can be concluded that among the insulation materials listed above, minerite is considered the most optimal.

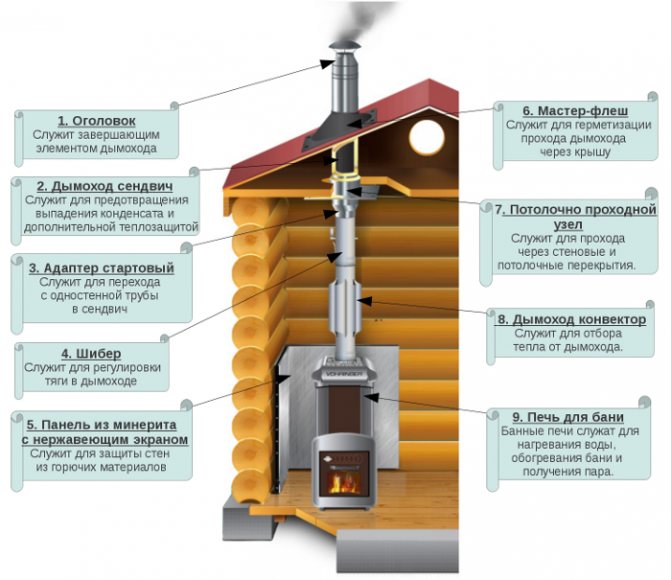

Chimney device diagram in detail

DIY installation of an insulated pipe in a bath

Photo. Chimney transition to sandwich pipe

We connect the pipes made earlier. We put on a non-insulated pipe on the chimney of the sauna stove and put a metal sheet with a hole on it, so that it can then be fixed on the ceiling of the steam room from the inside. In front of the ceiling, it is necessary to put a starting sandwich on the pipe and continue to put on the already insulated pipes. We attach a galvanized sheet to the ceiling with self-tapping screws, which you put on the chimney pipe earlier.

The technology for installing a chimney from ready-made sandwich pipes is no different from that described above. Despite the high cost of factory sandwich pipes and necessary components for the chimney. The finished products will look more aesthetically pleasing and will last much longer, especially the stainless steel chimney in the steam room. A cap should be put on the top of the chimney to protect the chimney and the stove from rain and snow.

Diagram of a typical chimney

Installation will become clearer when you know what elements the chimney consists of. There are usually nine of them:

- Bake. Water heats up in it, the room is heated, steam is formed.

- Minerite panel with stainless steel screen.Located behind the stove, it protects the walls from fire.

- A convector chimney is located directly above the stove. It serves to extract heat.

- Shiber. Regulates traction.

- Starter adapter. Located at the top, it provides a transition from a single-wall pipe to a sandwich.

- So we got to the ceiling. It is here that the ceiling-throughput assembly is placed with your own hands. It is a kind of passage through wall and ceiling coverings.

- Chimney sandwich, which was already mentioned above. Protects the structure from condensation, serves as additional thermal protection.

- Master flush. You can also build it yourself. Seals tightly the passage of the pipe through the ceiling in the rooftop bath.

- The final element of the chimney is the head.

Safety regulations

In order for the bath to be comfortable and safe, and the heating device to work without interruption and not cause a fire or injury, the following safety rules should be followed when installing and operating the chimney:

- Sagging and warping of the elements of the flue system are not allowed.

- Pipe turns are allowed, but no more than three.

- The distance from the chimney to the walls must be at least 50 cm.

- All connections must be made in such a way that none is inside the wall, ceiling or in the place where the roof passes.

- The margin for thermal insulation in the ceiling and roof made of combustible materials is made at least 100 cm when installing a single-wall pipe, at least 20 cm when installing sandwich sections and 6 cm for a chimney or a combined chimney. For the passage of a non-combustible roof, a margin of 13 cm is enough.

- If the chimney is more than 1.2 m above the roof, it must be additionally secured with guy ropes.

- All connections must be reliable and tight. If a depressurization of the unit is detected, it should be repaired immediately. If smoke appears at the junction of pipes or shaft elements, the operation of the heater is stopped, and the joint is repaired.

- During operation, it is necessary to carry out preventive measures: cleaning the pipe from soot deposits, discharging condensate from the dropper. This will extend the service life of the chimney and the heater.

- When the draft decreases or overturns, as evidenced by the smoke of the steam room or boiler room, as well as sparks and hum in the firebox, it is necessary to clean the chimney.

- After a long break in using the bath, the chimney and the heating device may become clogged or airy. In this case, it will not be possible to heat the bath. It is better to inspect, repair and clean the chimney before starting the heat generator.

We recommend that you familiarize yourself with: How to make a bed frame from a profile pipe with your own hands

How to avoid burning out?

Even with correct cutting, it is not always possible to avoid overheating. The pipe heats up to extreme temperatures, the likelihood of burning out increases.

Useful information: "What is the best ceiling to make in the bath?"

There are several ways to protect the structure and minimize damage:

- "Water jacket". It is done right on the chimney. The heated water can be used for showering. Effective but not easy to build. You will need to install a remote tank, water supply. But the temperature over the water jacket will be low, any burns out are excluded.

- Samovar type tank. A simplified version, thanks to which the water will also be heated. It is important to drain it in time or add cold, not allowing it to boil.

- Grid for stones. The advantage of this method is that the stones dry the air perfectly. Difficulties can arise only with the search for reliable support, since the stones weigh a lot.

Using any of the above methods will significantly reduce the pipe temperature. However, you can try air cooling as well. On a thermally insulated pipe, you will need to put on the same, but larger diameter.A lattice is erected above and below, providing free inflow and outflow of air.

How to insulate a pipe in a bath with your own hands

Thermal insulation of pipes in a bath with brickwork

The upper part of the chimney passing through the ceiling should be made of sandwich pipes. Their advantage is that there is already a layer of thermal insulation inside, as a result of which the outer pipe does not heat up and significantly reduces the risk of fire in wooden floors. In addition, during the cold season, the thermal insulation layer prevents the formation of condensation in the metal chimney, reducing the risk of pipe corrosion in the future.

To connect single-wall and sandwich pipes, an adapter (starting sandwich) is used. If you save money and do not buy a starting sandwich, then basalt insulation can crumble from the pipe during its operation. In addition, the characteristics of mineral wool are such that it absorbs moisture from the air. This can lead to corrosion of the metal chimney pipes, since the steam room has high humidity.

If you decide to save money and you have enough basalt thermal insulation, after the boiler room is insulated and there are several sheets of steel, then you can make an insulated chimney for the bath yourself. First, calculate the required height of the future chimney, as well as the diameter of the starting chimney of the stove, so that the pipe fits in size. So, we proceed to the insulation and installation of chimney pipes.

Ceiling cutting yourself: how to do it?

How to remove a pipe in a bath with your own hands, without resorting to the help of specialists, without using factory units?

Let's look at the workflow in stages:

- Prepare a sheet of stainless steel to cover the hole. To do this, you need to measure and cut the desired size. Please note that the metal circle should be about 0.2 cm larger than the pipe diameter. If you plan to install a sandwich type chimney, the diameter of the circle is slightly larger than the outer diameter of the sandwich.

- A hole is cut under the pipe in the ceiling area.

- Along the perimeter, its edges are sealed with cotton wool, and metal is stuffed on top of the insulator in the form of strips.

- Now we need to make a chimney for the bath through the ceiling. The first step is to put a single-wall pipe on the stove. It is necessary to put on a stainless steel square with a hole already cut out, and then install the sandwich.

- The removed pipe piece is always set vertically. To fix it from the attic side, we recommend using metal strips. Fixing them in the desired position is a snap. Please note that the slats play the role of guides, while the chimney itself does not need fastening. It is necessary that it move freely, because when it cools, the metal will change its size.

- The insulating layer is laid from the side of the room. The required amount of material is placed between the plate and the ceiling. Use self-tapping screws to secure the plate. We drill holes in advance: 4 along the edges, as well as 1-2 on each side.

- We must insulate the resulting passage - and the cutting is ready.

A self-made version of the pipe in the ceiling of the bath is not a fantasy and not an overwhelming task. This procedure is available to everyone and will not cause difficulties. The main thing is to comply with all norms and strictly follow the guidelines.

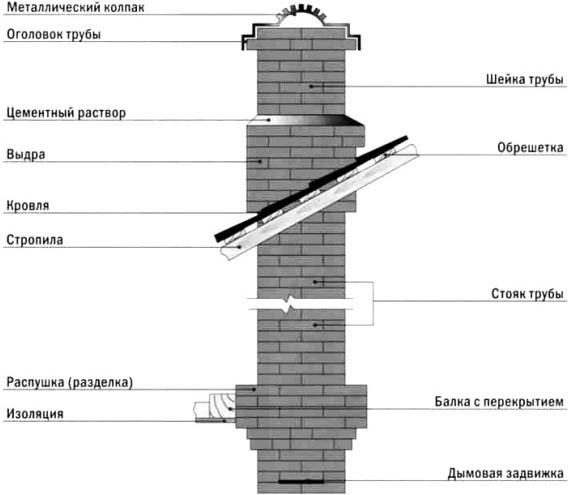

Chimney types

Smoke exhaust structures, both external and internal, can be made of various materials and their combinations:

- Single-circuit chimney. They use steel galvanized or stainless steel pipes, less often - asbestos-cement. This type of chimney is mounted only inside the bath, since the chimney without insulation and an external casing on the street quickly cools down, becomes overgrown with soot deposits and cannot maintain good draft. Especially a lot of soot is deposited on asbestos-cement pipes.At the same time, an additional foundation is not needed for a single-circuit chimney, and its construction will not require high costs either for consumables or for installation.

- Brick smoke mine. A cheap and very popular type of chimney. The brick heats up and gives off heat to the room for a long time, while its surface is more reliable in terms of fire safety. However, the construction of a brick structure is a full-fledged construction work that requires certain skills and significant time and labor costs. The structure turns out to be cumbersome and heavy, therefore, a foundation is required for it. In addition, condensate settles on the rough inner surface of the shaft, destroying the masonry, and soot forms, which is why the chimney has to be frequently cleaned.

- Chimney sandwich. You can buy a set of ready-made sections for assembling a chimney, each section consists of two pipes and a non-combustible thermal insulation layer. The pipes can be made of galvanized steel, stainless steel or heat-resistant ceramics. Installation resembles the assembly of a designer and does not take much time, and the finished chimney is less dangerous than a single-circuit one, although it can also be used as a heat source. Due to the insulation, the smoke inside the chimney cools down more slowly, soot and condensate settle less on the walls, so the chimney provides good draft and needs less cleaning.

Note! Steel sandwich pipes are lightweight and do not need foundation equipment. However, a sandwich that combines an outer steel casing with an inner ceramic pipe is much heavier and the chimney from such sections cannot be erected without a foundation.

- Combined chimney. Such a smoke exhaust system requires financial and time costs, but combines all the advantages of other types of chimneys. A smooth steel or ceramic pipe is used as a smoke channel, and the outer shaft is built of brick, foam or expanded clay concrete. A non-combustible insulation is placed between the shaft and the smoke channel. Such a chimney is efficient, safe, unpretentious in operation and durable.

We recommend that you familiarize yourself with: Dimensions and types of PVC sewer pipes and adapters for their connection

Sandwich pipe - a godsend for a bath

Modern manufacturers suggest installing a safe sandwich pipe in a bath or sauna. Choosing a sandwich chimney, you don't have to worry about insulation. The chimney consists of several sections that can be easily inserted into each other. It will be easy to assemble the structure with your own hands. A sandwich pipe is suitable for a bath or sauna with an iron stove.

The sandwich pipe immediately has built-in insulation and insulation.

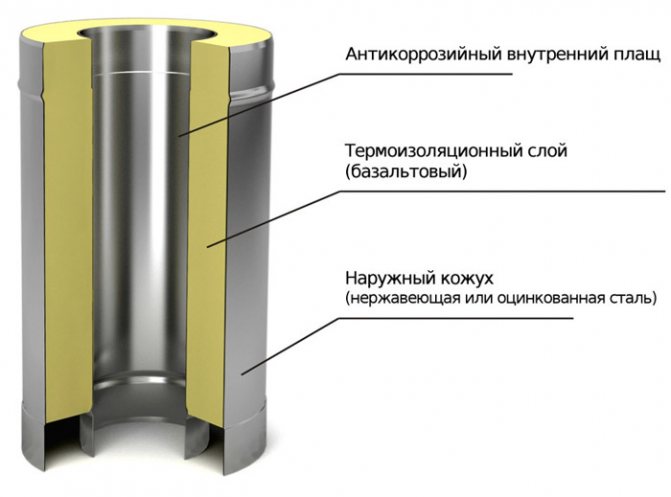

The sandwich tube design resembles a multi-layer cake. From the inside there is a layer of stainless steel, then insulation (basalt or mineral wool) is laid, galvanized steel outside. The construction is a modern method of built-in prefabricated insulation of the chimney. The design is intended to perform two functions at once: soot does not accumulate inside, and does not overheat outside.

But the iron stove to which the sandwich pipe is intended is mainly used in the sauna. What to do if you have a traditional Russian sauna with a brick stove, how to perform insulation? We'll talk about this below.

What materials are used for insulation in the bath

The chimney and stove heat up quickly. Traditionally, baths are made of wood and are easily ignited. For the insulation of walls, ceiling, chimney and stove, a layer of clay, asbestos and other available materials was used in the old days. The main thing is that the material is a poor conductor of heat and does not ignite from high temperatures. Protecting the chimney is necessary not only for fire safety purposes.Condensation will not form inside the insulated structure, the chimney will cool down more slowly and will serve the owners longer.

Chimney insulation method in a Russian bath

If a stove is installed in the bath, then refractory bricks are used for the construction of the chimney. He is able to stay warm for a long time.

When building a brick chimney, it is not worth saving, but it is advisable to approach this issue very responsibly, because its durability depends on the quality of the work performed.

In this case, the best way to isolate the pipe in the bath from the ceiling, roof and other roof elements is to mount sheet metal on these surfaces.

In places where the chimney touches the roof and ceiling, the surfaces should be protected with asbestos sheets. On the walls, near the pipe, you need to fix sheets of galvanized steel. Iron in this case is impractical to use, since it is subject to corrosion.

How to insulate a chimney pipe

With large irregularities in the pipe, the plaster layer turns out to be quite thick, therefore it is recommended to first seal all the cracks and drops with the specified solution, and then cover the pipe with a reinforcing mesh. A brick pipe can be sewn up with sheet metal using a layer of insulation. The easiest way to insulate a single pipe is to wrap it with a layer of non-combustible insulation, for example, basalt wool, and protect it from above with metal or plaster. Wrap the heat-insulated pipe with a reinforcing mesh, fix it, and plaster it according to the technology described above in two layers with a cement-lime composition. It is imperative to insulate passages when using any chimney: sandwich pipes, brick, and metal insulated.

How to insulate a metal chimney pipe in a bath: materials used

If possible, it is better to digest this super bend 45 lower and cut it into a shaft under the ceiling or even remove this shaft and make a chimney directly ... I covered my pipe (removable) with powdered asbestos (wet) with a layer of 2-3 cm, fixed everything with an asbestos cord , and when dried, wrapped it with fiberglass and secured with a knitting wire. The stove can be seen that it was bought, but where did they get the chimney from? some kind of cooked knee, why is it red? in paint chtol or rusty? So to put it, and at the same time rivet a furnace from titanium, fuck with all sorts of steels and asbestos?

Metal chimney winding

"How to wrap a metal chimney pipe in a bath?" - a popular question among summer residents. After all, there are many materials used for this summer cottage. The absence of flammable substances in the coating is the primary nuance that must be taken into account. It is preferable to use a quality material that has all the necessary properties. Also, it must be completely safe to use.

The most common materials:

- Glass wool;

- Fibrous building materials;

- Mineral wool.

Thermal insulation of chimneys of a metal chimney is a separate topic for discussion. After all, it contains a number of nuances, which will be discussed later. This is a very difficult task, therefore it is recommended to carry it out during the construction of the bath. It is more difficult to work with a finished building, because the roof may need to be rebuilt.

How to insulate the chimney, everyone decides for himself. It is important to remember that such insulation allows you to protect the chimney from the negative effects of combustion products, as well as moisture. If you do not worry about isolation in time, then there is a risk of destruction of the bath. After all, the condensate enhanced by the action of acid slowly destroys building materials.

If the brick chimney is not enough, it can be further extended with a metal pipe. The task is laborious, but quite realizable. It is important to approach it responsibly.

To begin with, a flat steel platform with a branch pipe is made.Moreover, its diameter should be the same as the diameter of the metal pipe that you plan to use. The platform must be securely fixed. It is fixed with dowels and screws. Sealing will add additional reliability.

Work order:

- On the brickwork, you need to mark the points at which the mount will be installed. They must not be placed on a masonry seam. It is advisable to place them closer to the center of the brick, and not on its edge.

- Holes are drilled in the marked places to accommodate the dowels. At the same points, holes are made on a flat platform, self-tapping screws will go there.

- A refractory sealant is applied to the brick base, then a steel platform is placed there. Self-tapping screws are screwed into the dowels. It is important to monitor the tightness and uniformity.

- Now it remains to wait for the sealant to dry completely and go directly to lengthening the chimney using a metal pipe.

A sandwich chimney in a traditional sauna can be an excellent insulation solution. Now on the construction market, you can purchase a ready-made structure. Having installed such a system, you can not think about the materials and methods of additional insulation of the chimney.

Sandwich pipes consist of several parts of a prefabricated structure, which are easy to connect together and install independently. Such a system is ideal for a sauna or iron stove.

The design resembles a puff pastry:

- Stainless steel inner layer.

- The second is made of basalt wool.

- The outer sides are covered with galvanized iron.

The sandwich pipe is installed according to the following scheme:

- Prepare an opening in the place where the structure passes through the ceiling.

- An exhaust flange is installed, which is the first stage of the design. Collecting the rest of the pieces starts from the second step.

- Double-walled pipes are gradually connected and led out through the ceilings to the roof. Mounted elements are additionally attached to the walls.

- After assembly of the structure, insulation is carried out in the places of passage to the attic. Here it is allowed to use only double-walled parts of the structure without additional elements.

- Then the chimney is led out through the roof. In the places of its passage, it is necessary to perform thermal insulation.

Outlet of the sandwich pipe through the roof

- Fastening of the bath chimney is carried out with stretch marks if it rises strongly above the roof.

- A spark arrester and a fungus are mounted on top of the finished structure.

During the connection of the elements, a chimney sealant is used. It is able to withstand temperatures up to 1000 degrees. The traction force depends on the quality of the connection and the tightness of the joints.

To increase fire safety, the passage of the stove hood to the attic is created through the ceiling-throughput unit. It is a galvanized steel box with a pipe hole. It can be purchased ready-made. The box is inserted into the prepared opening until the entire structure is assembled.

Thermal insulation in this place is carried out in the following way:

- PPU is installed in the opening. The structure is placed on the lower joists so that the connection is above the attic floor.

Strengthening the PPU structure on the ceiling

- The gap between the ceilings and the walls of the polyurethane foam must exceed 13 cm, which is filled with mineral wool.

- Further, the gaps are closed on the upper and lower sides with metal plates.

This multi-layer design allows for warmth and minimizes soot build-up on the walls. The sandwich construction is not suitable for traditional Russian baths with high humidity. This should be taken into account when building a bath.

For the construction of a pipe in a bath with a stone stove, red brick is used. He is not afraid of high temperatures, keeps warm for a long time.

The brick pipe structure must be correctly folded.The quality of the masonry will depend on how long the structure will last. Making a pipe for your bath is not worth saving, since repair work can be more expensive.

The pipe at the intersection with the roof, ceiling and other parts of the roof structure must be insulated with metal sheets.

The outlet of the pipe on the ceiling and through the roof must be insulated from high temperatures using asbestos sheets. And the walls at the inside of the pipe are upholstered with galvanized metal sheets. Plain iron sheets should not be used as they corrode. Around the pipe in places where it passes through the ceiling, you can make a box and fill it inside with expanded clay. It will additionally contain heat and protect wooden floors from fire.

Correctly insulating the pipe is only half the battle. It is also necessary to take care of the stove, ceiling and walls of the bath.

We suggest that you familiarize yourself with How to choose the right shower cabin for a summer residence

Recently, various manufacturers have begun to produce new safe sandwich pipes for baths and saunas. With such a design, there is no longer any need to worry about how to secure the pipe in the bath (for more details: “Advantages of a pipe for a sandwich bath in the construction of a chimney”). The design of such pipes assumes a quick and convenient assembly of sections that are inserted into each other. Moreover, it is optimal to use such pipes with an iron stove.

A sandwich pipe is a multilayer structure, inside which there is a stainless steel frame, then a mineral or basalt wool insulation is laid, and a galvanized casing is put on top. Thanks to this structure, soot does not accumulate inside the chimney, the outer layer of the metal does not experience overheating, and the whole structure looks beautiful and laconic.

How to wrap a metal chimney pipe is not difficult to decide. The building materials market offers many products for this.

Better to insulate with a good quality product that complies with fire and building codes. This will create additional security conditions.

Of the options offered, the most commonly used are:

- Fibrous building material;

- Mineral wool;

- Glass wool.

The metal version, and in particular its insulation, deserves special attention. The dilemma of how to insulate a metal chimney pipe must be solved during the preparation of a construction project.

It is not always possible to isolate an already created scheme without rebuilding the roofing structure.

If you build a modern structure, you can use ready-made "sandwich" pipes. Such designs are carried out quickly, with little expense for specialists.

But, they are not cheap. However, this cost is justified by the long service life and ease of construction.

In them, mineral wool is located between two blanks. The insulation thus comes out at the highest level.

With the help of insulation, they stop or prevent irreversible chemical reactions that take place under the influence of moisture and fuel decomposition substances.

The condensate, strengthened by the action of acid, slowly but intensively spoils the building materials. Condensation is especially dangerous during the thawing period of the pipe after winter.

The operation of the bath must be absolutely safe for humans. To prevent fires in contact with a hot stove or chimney, thoroughly insulate walls and ceilings, as well as hot surfaces. How to insulate the chimney pipe in a sauna will be described in detail in this article.

As the sad statistics say, during 2014, up to 70% of fires in private baths were caused by incorrect thermal insulation of metal pipes. Therefore, in order to help our readers to protect themselves and their guests, we will tell you about the materials, as well as the technology for performing pipe insulation in the bath.

The favorite material for a bath in Russia is wood.However, it tends to be very flammable. To avoid this, people have long learned to insulate the chimney in the bath, as well as the stove and all surfaces - walls, ceiling. For these purposes, we used any available means - clay, asbestos or any other non-combustible materials with a low degree of thermal conductivity.

Manufacturing of boxes

About how to insulate the iron chimney pipe, it was said earlier. Now you can move on to the next step. It seems to many that making a chimney box is too difficult a task. In reality, this is not the case. It is enough to approach work responsibly, competently.

Required tools:

- Drill;

- Metal scissors;

- Compass;

- Metal sheets;

- Self-tapping screws.

Stages of work:

- Hole preparation. Along the edges, it is necessary to fix the bars, which will act as a support for the body.

- Two blanks are cut from a metal sheet. They are given a U-shape. Then the finished parts are screwed to the ceiling using self-tapping screws.

- Again, two blanks are made, but they are already fixed on the standing sheets with a small overhang. It turns out a one-piece frame in the ceiling.

- Now the bottom for the box is made of metal sheet. In the center of the workpiece there should be a hole for the chimney, here you need a compass.

- The box contains four fasteners of two centimeters. They are cut and folded perpendicular to the bottom.

- Walls are attached to the bottom. Now a chimney is inserted into the box, it is additionally secured with clamps. The voids are filled with an insulating layer.

Many people are afraid to make a metal box for the chimney pipe on their own. But, this does not contain much difficulty.

When making a box, you need the following tools:

- Scissors for metal.

- Galvanized sheet.

- Self-tapping screws.

- Tsyrkul.

- Drill.

Further sequence of actions:

- The hole is being prepared. Its edges must be secured with support beams. They will create support for the box.

- A couple of parts are cut from the galvanized sheet. Along their edges, at a distance of five centimeters, a 90 degree fold is made. These u-shaped parts are fastened with self-tapping screws to the prepared holes in the ceiling covering.

- Similarly, two more U-shaped blanks are prepared, and they are overlapped on the already standing sheets. As a result, a solid framing of the done exit comes out in the ceiling covering.

- The next part of the action is the bottom for the box. An element is cut out of the same galvanized sheet that corresponds in size to the opening made. In its center, a circle is drawn with a compass for the entrance of the flue gas blank.

- 4 fasteners are placed from the central part of the box bottom (each of them has a two-centimeter width). Then they are cut and folded at an angle of 90 degrees. As a result, a base is formed with a hole and 4 strips for fasteners.

- The bottom is attached to the walls. A chimney is inserted through the outlet and fastened with a clamp. The empty space is filled with an insulating layer.

According to the proposed instructions, it is not difficult to make a box. If you follow everything exactly, the work will not be difficult even for an inexperienced layman.