Thermal insulation of premises from the inside

The heat-and-energy-saving coating is intended for thermal insulation of premises from the inside. The coating 1 mm thick has a barrier protection (does not release heat, does not allow cold to pass through), effectively eliminates freezing and condensation. The finishing layer has a solid surface on which wallpaper can be glued or decorative paint and plaster can be applied.

With the help of a special paint, you can insulate:

- The front part of the building;

- Metal constructions;

- Basements and attics;

- Cars;

- Pipes;

- Manufacturing enterprises;

- Walls, floors, ceilings.

High efficiency is ensured by the following qualities:

- Moisture resistance;

- Excellent tightness and adhesion;

- Corrosion resistance;

- Fire safety;

- Resistance to mechanical damage;

- Low thermal conductivity;

- Fast application;

- Durability.

You can buy heat insulating paint using our website - there is a wide range of heat insulators in the assortment. 10 years is the minimum warranty period that can be expected under very difficult operating conditions. These include a difficult climate, an overly viscous coverage area, a heavy surface treatment material, etc.

Insulation paint composition

Thermal insulating paint contains active and auxiliary components. Includes:

- fillers;

- water;

- acrylic based dispersion;

- fiberglass;

- foam glass;

- perlite, ceramic microspheres.

The enamel has the following structure:

- binder base - water-acrylic consistency contributes to uniform distribution of the layer and adhesion of the coating to the surface;

- filler - a high level of thermal insulation is provided by metal granules filled with gas;

- additional substances - rubber, silicone increase the elasticity and water resistance of the enamel.

Attention! Heat loss is reduced by almost 40%. The coating prevents moisture absorption and does not allow water to pass through. The painted surface "breathes".

Due to the constituent components, a protective film is formed against mold and mildew. One advantage to look out for is the reflection of thermal radiation. The advantages include a long service life, a high level of heat resistance.

Universal ultra-thin thermal insulation

A universal material based on water dispersion, has thermal insulation and waterproofing properties, intended for industrial and domestic use with operating temperatures from –60 ° C to 150 ° C.

The unique composition makes this product practically indispensable and versatile for various surfaces. Heat-insulating paint is characterized by practicality - the material is easy to apply to the surface, it dries quickly, saving you time and effort. You can apply the paint yourself, without using the services of professionals.

The base of the paint is varnish or water. Special fillers and additives determine the functionality of the material - you should pay attention to them when choosing paint for various surfaces. Consistency - liquid or pasty.

The opinion that the thicker the layer of the heat insulator, the better is not true in relation to the paint. With a minimal layer, it gives excellent results. An important advantage is that there is no need to prepare the surface for the application of the substance. It can be either flat or deformed or in microcracks - the paint does not lose functionality on any surface.

The price of heat-insulating paint is quite democratic and does not inflict a significant blow on the budget - this material is economical to use, especially if it is used correctly.

The range includes paints for various surfaces that will reliably protect your home from the cold.

Ease of application is a big plus. Thermal insulating paint can be applied in a variety of ways, including roller or spray. When the area to be treated is large, a spray gun will be more useful.

Akterm is a liquid thermal insulation similar to paint. It is a practical consistency suitable for various types of surfaces. With prolonged exposure to air (about 24 hours), the mixture will polymerize. So it becomes a thermal barrier. In summer, 95% of the sun's rays are reflected with thermal paint. And in the winter months, on the contrary, they return (this volume will be about 70%).

Today, energy-saving technologies are gaining more and more relevance as a construction issue. The modern market brings to the attention of consumers innovative developments in this area, embodied in high-quality universal materials. They are designed to provide maximum protection of the home from adverse natural factors and proper thermal insulation of the premises.

Thermal insulating paint is a novelty in the building materials market. Its purpose is to reduce heat loss in the building, in particular in the house. Possessing a liquid consistency, the material is easily applied to all types of surfaces, even deformed ones. The material is completely safe for human health and the environment, being a composite thermal paint, which includes a polymer matrix and a filler - hollow microspheres.

The spectrum of properties of heat-insulating paint is very wide:

- Interferes with the penetration of cold into the room

- Prevents corrosion on metal surfaces

- Excellent heat retention

- Prevents moisture ingress, relieves mold

- Eliminates condensation

- Saves electrical energy

The thinnest layer of paint-insulation can fully replace the traditional thermal insulation system at home. Liquid insulation has a very acceptable cost and economy, which also serves as one of the factors in favor of its choice.

Heat insulating paints are used in the following areas:

- insulation of industrial equipment;

- coloring of technological containers;

- agricultural production;

- basement insulation;

- protection of heat transport systems;

- processing of automobile and other types of transport;

- thermal insulation of housing (both internal premises and building facades);

- protection of utilities, pipelines, ventilation and air conditioning systems.

Protective paints and varnishes are used in almost all industries where it is necessary to protect the material from freezing. Thus, heat-insulating paints are a direct competitor to building insulation materials.

The advantages of thermal insulation compounds include:

- heat saving;

- high resistance to mechanical stress;

- excellent adhesive characteristics (adhesion of dissimilar materials);

- long service life of coatings;

- insignificant heat transfer coefficient;

- resistance to ultrasonic waves;

- resistance to atmospheric precipitation;

- heat resistance;

- high strength of coatings;

- ease of thermal insulation;

- almost complete preservation of the dimensions of the object after painting (due to a thin layer of paint);

- fire safety;

- environmental friendliness;

- resistance to the development of corrosive processes;

- low coating weight (especially important for facades and pipelines).

However, liquid insulation cannot be classified as universal materials, since it also has negative characteristics:

- High price.

- Not all super-thin coatings provide good thermal insulation.

- The best results can only be achieved when there is a significant difference in temperature between the environment and the coating. In other words, insulating paints and varnishes are the ideal choice when it comes to hot pipes. But thermal insulation for walls outside or inside the building is sometimes more expedient to perform with traditional materials. The use of thermal insulating paints is justified in those places where the use of standard insulation is impossible or difficult.

Liquid insulation is a thermal insulation coating consisting of a polymer binder and hollow glass microspheres. The consistency of the material resembles ordinary paint, which makes it possible to apply thermal insulation and process structures of any shape, where traditional thermal insulation materials are difficult to apply.

And thanks to the unique properties of hollow glass spheres, the effectiveness of liquid thermal insulation is several times higher than that of traditional insulation (such as polymer foam or mineral fiber).

We offer you to familiarize yourself with: Insulated floor in a bathhouse on screw piles

After drying, the material forms a durable and light elastic heat-reflecting coating with unique heat-insulating and energy-saving properties.

Liquid ultra-thin thermal insulation Teplocor-Facade belongs to this class of innovative energy-saving materials.

| Liquid insulation of the facade Teplokor-Facade |

| from 369 rubles / sq.m. |

Liquid insulation of walls Teplokor-Facade is a heat-insulating material, which is a composition based on acrylic polymers, hollow glass-ceramic microspheres, pigments and auxiliary substances.

The thermal insulation coating is resistant to weathering, temperature extremes, ultraviolet radiation, aging, cracking and destruction.

The heat-saving coating Teplokor-Facade is used in the field of construction and housing and communal services to reduce heat losses, eliminate fungus, condensation, and icing. In this case, the following tasks are solved:

- insulation of building walls (internal and external ultra-thin insulation);

- effective increase in energy saving;

- combating freezing of the walls of residential premises;

- lower costs for exterior finishing during the reconstruction of houses;

- aesthetic appearance of the treated surface.

As a result, the use of Teplokor-Facade liquid insulation allows to reduce the weight of building structures, reduce the consumption of building materials, reduce energy consumption for heating buildings and improve the comfort inside living quarters.

- thermal insulation of the facade of the house, basement, foundation and blind area;

- basement insulation (including from the inside of the basement walls);

- insulation of the walls of the house from the inside and outside;

- insulation of balconies, loggias, attics, window slopes;

- roof insulation from the inside and outside to reduce heat losses in winter and reduce the cost of air conditioning in summer;

- processing of interpanel seams allows you to combine the process of hydro and thermal insulation;

- processing of the ends of monolithic floors in frame construction, etc.

Facade insulation is used for processing concrete, reinforced concrete, plaster, brick, slate, wood during work both inside buildings and structures, and for structures in the open air.

It is recommended to insulate the outer walls of the house at a positive ambient temperature, preferably in the range from 15 ° C to 70 ° C.

The heat and energy saving coating is used for thermal insulation of metal structures, tanks, containers, pipelines, furnaces with operating temperatures up to 200 ° C.Effectively reduces heat loss, eliminates condensation and freezing, protects against corrosion, improves the microclimate in boiler rooms, and ensures the safety of personnel from burns.

Thermal insulating, anti-condensation coating based on water dispersion, designed to prevent the formation of condensation, mold and mildew in industrial and domestic use with operating temperatures from –60 ° C to 150 ° C.

Weatherproof, heat-and-energy-saving coating for facades and structures is resistant to UV, reflects up to 85% of the solar and infrared radiation spectrum. Reduces heating of internal premises in summer, in winter it reduces heat loss by up to 35%.

Winter liquid thermal insulation based on an organic solvent, applied to various surfaces at an air temperature of -35 ° C. up to 45 ° C. It is used in industrial and domestic applications with operating temperatures from –60 ° С to 150 ° С. AKTERM Nord possesses anti-corrosion properties, high resistance to aggressive environment. (alkalis, acids).

High-temperature, heat-insulating, energy-saving material is used at facilities with operating temperatures up to 500 ° C. The coating additionally has anti-corrosion properties and protects personnel from industrial burns.

Evaluation of effectiveness from experts

Liquid insulation today is only gaining the confidence of consumers, however, there are already opposite opinions about the effectiveness of the use of "liquid ceramics". For example, the calculations are given:

- extruded polystyrene foam in fact (50 mm) costs 300 rubles. (sq. m);

- assume that the thickness is 1 mm, the price per sq. meter - 6 rubles;

- the total cost in the equivalent of ultra-thin thermal insulation is obtained - 450 rubles / liter;

- at the recommended consumption of thermal paint, its price is for a similar 1 sq. m. (thickness 1 mm) with a single layer application is 100 times higher than that of expanded polystyrene.

Related article: Fastening a timber beam to a concrete wall

In contrast to such reasoning, other experts give an example of the fact that the thermal insulation properties of the extruded polystyrene foam given in the example are at least 50 times lower, and the emissivity of the surface due to the roughness of the heat paint is much higher. When the surface is treated with "liquid ceramics", the effect of a "thermal mirror" is obtained. Believing one reasoning or another is an individual matter, but experts agree that there is no alternative to liquid ceramics in hard-to-reach places. It is difficult to imagine thermal insulation with mineral wool under a windowsill or in other places, and the paint for thermal insulation does an excellent job with this task, leaving no seams or bends.

Functional features

The composition of the thermal insulating paint and varnish material contains the following components:

- water;

- acrylates;

- fillers;

- additives.

Basically, heat-insulating paint and varnish compositions are divided into two types:

- Water based. Used for painting heating systems. They are distinguished by the absence of toxicity and odor.

- Acrylate based. They are a versatile option. Such paints are used to treat all types of surfaces.

Ceramic granules, foam glass, fiberglass, perlite are used as additives. The consistency of the protective paints resembles a gray or white paste. The composition is applied to the surface in a very thin layer (from 2 to 4 mm). It is enough to replace tens or even hundreds of millimeters of insulating materials.

An important advantage of painting is the ability to get to almost any site. It is not always possible to do the same with traditional insulation.

The paint is applied with brushes, rollers or sprayers. Moreover, the latter are preferable, since they allow you to create a uniform surface.

The thermal insulation properties of the coating are also determined by its thickness. The more layers, the higher the protective properties of the surface.

The service life depends on the type of material painted and the operating conditions. The coating does not lose its properties for 10-50 years at ambient temperatures from -40 to 250 degrees.

The choice of coloring composition

The thermal insulation material is chosen taking into account the place where the work will be done (inside or outside the room), as well as the type of surface. Before buying, you should study the products of well-known manufacturers and read reviews about them. There are the following recommendations for choosing paint:

- for the treatment of indoor surfaces, the most non-toxic composition is chosen;

- for painting external surfaces, waterproof and heat-resistant paint is required;

- for painting gas pipelines and water pipelines, paint for thermal insulation of pipes with the highest degree of heat resistance is suitable.

Do not forget to read the recommendations for choosing paint

In order not to overpay an extra amount for expensive thermal insulating paint, you need to immediately calculate the amount required for work. It depends on the area and type of surface. The following factors are also taken into account:

- The presence of irregularities and cracks on the surface. The processing of such areas will take an additional amount of paint (sometimes up to 40%).

- The number of coats to be applied to the surface.

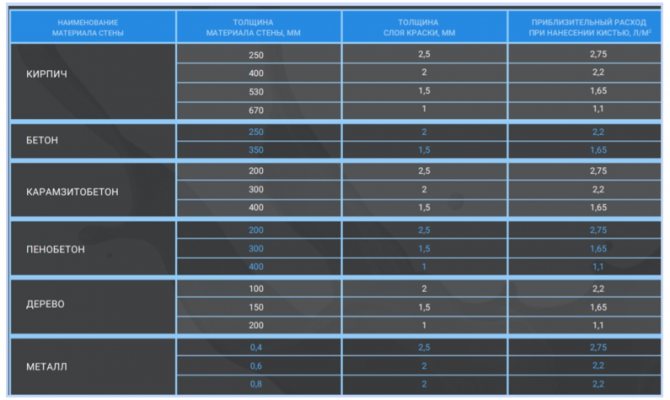

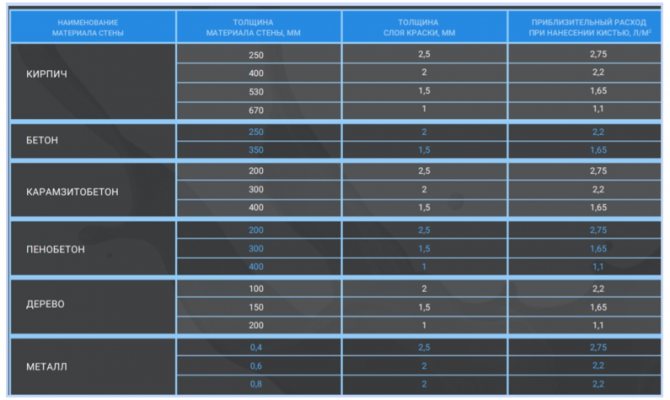

The recommended coating thickness depends on the type of surface. For different materials, it will be as follows:

- wood - 2 mm;

- concrete - 1.5 mm;

- metal, brick, expanded clay - 2.5 mm.

Advantages and disadvantages

- prevents overheating and cooling;

- protects against corrosion;

- blocks the formation of condensation;

- extends the service life of surfaces;

- can be applied with a spatula.

Thermal insulating compositions "Akterm" are easy to apply, do not exfoliate and are not a source of unpleasant odor, are resistant to temperature extremes, atmospheric influences and ultraviolet light. Durable finishing coatings serve for more than 12 years or more without loss of properties, are safe for human health and the environment.

The main parameters and advantages of insulating paint

The paint that is used for thermal insulation, in comparison with traditional types of insulation, has the following distinctive features:

- The manufacturer's declared thermal conductivity of 0.001 W / (m * K) allows you to replace 50 mm. a layer of mineral wool - this allows you to reduce the volume of the space occupied by the insulation.

- The material has good adhesion, can be applied to metal, concrete, wood, plastic, glass.

- When applied, the wear layer of the material is usually 1 - 4 mm.

- The coating is waterproof, therefore it performs anti-corrosion functions, its use prevents condensation from appearing on the metal surfaces of water pipes and gas pipelines.

- The material is resistant to biological effects, inhibits the development of fungus and mold.

- The paint is resistant to sunlight and temperature extremes, reflects about 85% of thermal radiation.

- The material does not lose its properties at temperatures from -60 to +250 С.

- The heat paint is applied to a surface with a temperature of 5 to 150 C. In many cases, this allows you not to turn off the pipeline supply system.

Fig. 4 Thermal insulation of the surfaces of communications and tanks with heat paint

- Due to the airless content of microspheres in the acrylic base, the thermal insulating paint is lightweight (a 20 liter bucket weighs 9.5 kg).

- The application technology is not very complex and does not require special equipment; the surfaces can be independently coated with your own hands using an ordinary paint brush.

- The material is not flammable, it can be used inside any premises without additional fire protection equipment.

- Heat paint is an environmentally friendly and safe material for health; it can be used without restriction in healthcare and public catering establishments.

- The coating has a high maintainability - in case of insulation failure, a little paint is applied to the damaged area.

The main advantage of the material is the ability to cover objects (tanks, boilers, various types of containers), where the use of traditional heaters is technologically difficult or impossible. With the help of paint, you can insulate surfaces of complex shapes in hard-to-reach places.

- The heat paint is available in white or gray colors, the range can be easily changed by adding tinting to the composition.

- The finished coating is elastic and has high impact resistance.

- The paint has a long service life of 12 to 40 years.

Fig. 5 Approximate consumption of liquid insulation when finishing various types of surfaces

Thermal insulation paint: buy or use traditional insulation?

When buying thermal insulation paint, it is recommended to pay attention to the following factors:

- Heat resistance. This indicator is especially important if the pipeline is to be painted.

- When choosing a paint for exterior or interior work, the operating conditions of the surface are taken into account. For example, to insulate the facade, you should choose a paint with maximum moisture resistance and high permeability. For indoor coverage, environmental safety is considered the most important characteristic.

- Consumption per 1 m2.

- It is required to calculate the amount of paint, choose a manufacturer based on the place of its application;

- Find out if the warm paint will be applied to the outer or inner surface. For painting walls outside, the material must have low water resistance and high vapor permeability;

- If paint is needed to insulate the walls inside, then it should not contain harmful and toxic substances;

- For painting pipelines, the composition of the liquid paint should be as heat-resistant as possible;

- To insulate large areas, it is easier to use a spray or air compressor; for small objects, it is better to choose a brush or roller;

- The liquid for walls is applied in 2-3 layers.

Akterm - comparative characteristics of warm paint

Information required for calculating the amount of heat paint:

- You need to know the type of surface: concrete, expanded clay or foam concrete, wood, brick or metal, smooth or rough surface;

- Estimated layer thickness according to the instructions;

- Painting area;

- What are the components of the thermal insulation paint;

- When painting pipelines, you need to know the diameter of the pipes;

- Choose a staining technology.

It is necessary to take into account the practical overrun of liquid for different surfaces:

- For concrete, brick and wood - 5-10%, for metal -3-5%;

- For uneven surfaces - 15-35%.

- For external walls in dry weather, the consumption will be 2-3% less;

- The layer thickness for concrete is 1.5 mm, for brick, foam and expanded clay concrete - 2.5 mm, for wood - 2 mm, for metal - 2.5 mm.

Comparison of thermal conductivity of heat paint Akterm and other heaters

Corundum - scope:

- Boiler facilities and steam pipelines;

- External and internal surfaces of the walls;

- Rooms with high humidity.

Varieties of Corundum:

- Corundum Classic: containers - 3 and 10 kg cans, 20 l bucket. Working temperature -60 ° C / 250 ° C;

- Corundum Antikor: containers - cans of 3 and 10 kg, a bucket of 20 liters. Working temperature -60 ° C / 250 ° C;

- Corundum Winter: containers - cans of 3 and 10 kg, a bucket of 20 liters. Working temperature -60 ° C / 250 ° C;

- Corundum Facade: containers - 3 and 10 kg cans, 20 l bucket. Working temperature -60 ° C / 250 ° C.

Heat-protective paint Korund

Astratek - purpose and characteristics:

- Service life - 15-30 years;

- Protection against moisture and condensation;

- Covering complex surfaces;

- Thermal insulation of hot structures with temperatures up to 160C.

Varieties of thermal protection of the Astratek brand:

- Astratek Universal: Temperature resistance in the range of -60 / 260 ° C;

- Astratek Metal: Temperature resistance in the range of -60 / 200 ° C;

- Astratek Facade: white color, tinting, heat resistance in the range of -60 / 260 ° C.

Protection of the Astratek brand

Bronya paint - area of use:

- Protection of pipelines and other pipelines;

- Protection of facades and internal building surfaces;

- Thermal protection of any tanks;

- Thermal protective coating for cars, airplanes and other types of transport.

Varieties of the Bronya brand: Bronya Teplokraska

- Bronya Classic: Containers 5.10 and 20 liters, bucket. Thermal stability in the range of -60 / 200 ° C;

- Armor Anticorrosive: Containers 5.10 and 20 liters, bucket. Thermal stability in the range of -60 / 150 ° C;

- Bronya Facade: application layer 1 mm. Containers 5.10 and 20 liters, bucket. Temperature resistance in the range -60 / 150 ° C.

Even a thin layer of thermal protective paint from any manufacturer will help not only to preserve the heat of the protected object or structure, but also to save on time, labor costs and finances, since the service life of the thermal paint is several times longer than the service life of any known insulation. If compared with the coefficient of thermal insulation of brickwork, then a layer of Astratek or Corundum can replace one and a half wall masonry.

The main recommendation when working with paint is to dry the painted surfaces and clean them from dirt. Work using personal protective equipment.

Since its inception, liquid thermal insulation has significantly replaced traditional types of insulation in the building materials market. Not inferior in environmental friendliness, it provides a reduction in labor costs, consumption of building materials, has improved characteristics:

- Minimally loads load-bearing structures - a layer of several microns instead of the standard 50 - 20 mm

- Convenient to use - painting with a spray gun, roller, brush

- versatile in use - treatment of walls, ceilings, the inside of the roof, basements

- Does not require cutting - there are no trimmings, waste requiring disposal

- Convenient in storage, transportation - a bucket of paint takes up much less space than a stack of expanded polystyrene sheets, transported by car or manually

Heat insulating paint, which you can buy in our store, is available in various packaging, allowing you to choose the right amount to reduce the repair budget. Prices can be viewed on each product page.

Pros and cons of insulation from the inside

The advantages of liquid insulation include:

- The ability to resist fire, so you shouldn't worry about fire safety.

- Low thermal conductivity, due to which this material is in great demand.

- Liquid insulation can be applied to any surface, which opens up wide possibilities for use.

- There are no costs when installing the material.

- The liquid heat insulator does not lend itself to mechanical damage and sudden changes in temperature, due to which it has a long service life.

The video shows instructions for using liquid thermal insulation for the walls from the inside:

Has a liquid heat insulator certain disadvantages, which include:

- The long service life is not particularly long, but it can be increased if the material is applied correctly.

- There is no guarantee of thermal conductivity. Today there is not a single manufacturer who would indicate in their documentation the exact amount of stored thermal energy.

- Sensitivity of the material to negative conditions of transportation and storage.

- To obtain high-quality insulation, it is necessary to apply the material in a thick layer. This sometimes leads to high consumption of heat insulators. At the same time, the difference between the actual consumption and the practically is quite large.

What the disc dowel looks like and how it is used for thermal insulation will help to understand the information from the article.

Which thermal insulation plaster for interior work is one of the best and how to choose it correctly is described in this article.

For those who want to know more about the comparison of thermal insulation materials for walls, you should follow the link and read the contents of this article.

Manufacturers

There is a wide variety of thermal insulating paints and varnishes on sale. Among the most popular are the paints of the following brands:

- Liquid thermal insulation Korund. Several types of heat-insulating compounds are produced under the popular brand "Korund", differing in functionality. In particular, "Korund Classic" is intended for thermal insulation of pipes heated to 200 degrees. "Korund Facade" is used for external thermal insulation. "Korund Antikor" is used to protect metal in conditions of high humidity (for example, when covering a roof). Corundum paint is offered in cans of 3 or 10 kg, as well as in 20-liter buckets. The coating retains functionality at temperatures from 60 degrees. frost up to 250 degrees. heat.

- Astratek. It is a paint without organic solvents. In this regard, "Astratek" is completely safe from the environmental point of view. This paint is used to treat especially hot surfaces (pipelines, boilers, industrial equipment). There are modifications with anti-corrosion additives.

- Heat-insulating paint "Bronya" contains ceramic components. The anti-condensation additive together with anti-corrosion properties allows the painted coatings to be used in extreme conditions. Another feature of "Bronya" is the ability to withstand ultraviolet radiation, regardless of the duration of exposure to radiation.

- "Actor - Standard". The paint creates coatings that can withstand very high temperatures - up to 600 degrees. The minimum temperature at which the coating retains functionality is 60 degrees. below zero. The paint is notable for its versatility, it is used both for residential premises and industrial facilities (pipes, refrigerators, etc.). Versatility is achieved due to the absence of toxicity and fire safety of the composition. The paint can be applied even in winter, provided that the air temperature is not lower than 25 degrees. frost.

We suggest that you familiarize yourself with: Concrete floor on the ground: step by step instructions

There are many other paints with thermal insulation properties. Among them are such compositions as Alfatek, Teplomett, Keramoizol, Magniterm, Tezolat, Teplocor, Kare, Termosilat, Maksidom, Hydrostop pro and others.

Liquid insulation: the choice of material for insulation from the inside and outside

Under the influence of the harsh climate and unfavorable weather conditions, residents of most regions of Russia are constantly thinking about insulating their living quarters. And not in vain, because the comfort in the house depends on the favorable temperature inside. According to statistics, about 90% of houses do not meet heat-saving standards. Of course, ultra-modern buildings are already being erected in accordance with the latest thermal insulation standards. But the walls of old houses need to be insulated, due to which heat losses will be reduced by up to 40%.

The huge selection of building materials on the modern market is impressive and often leads to a dead end, among them it is not easy even for professionals to navigate. Recently, thanks to new technologies, many new heaters with improved technical characteristics have appeared. One such material is liquid insulation. If you are still pondering the question of how to insulate your walls, then surely after reading this article you will decide on the choice of insulation material.

Surface preparation

Before applying paint, it is necessary to properly prepare the surface.On a dirty, uneven base, the coating will not last long, and therefore all efforts and financial costs will be in vain.

Dust, dirt and oily formations are thoroughly removed from the surface. All cracks and cracks are repaired. They also get rid of irregularities, for which they use a metal brush, grinder or sandblaster.

When the surface is mechanically cleaned and leveled, a primer is applied. VL-02 or VL-023 are most often used as primers.

Scope of application

Thermal paint is a universal substance, therefore it is used to insulate various surfaces, depending on the composition. Heat-insulating paint is used to insulate facades, roofs and basements of buildings, walls of premises from the inside, insulate and use as foundation waterproofing, process garages and other technical premises.

In addition to construction, heat paint is used in industry to reduce the heat loss of heating pipes, especially in those places that are extremely problematic to insulate with the help of roll materials, as well as to insulate and reduce the thermal conductivity of containers where the use of insulation is impractical.

Calculation of the amount of paint

The amount of ink consumed depends on many variables, including:

- type of base coat (concrete, expanded clay concrete, foam concrete, wood, metal, brick);

- flat or uneven surface;

- the presence or absence of pores;

- surface area;

- thickness of the paint layer;

- in the case of pipes, the diameter of the pipeline;

- weather;

- paint application method (brush, roller or spray).

The excess of paint consumption over the average indicator is largely determined by the type of surface. In particular, for concrete and wood the excess is 5-10%, for metal - 3-6%. The greatest overspending is observed when painting embossed, porous or rough surfaces - from 15 to 35%.

On average, paint consumption is 1 liter per square meter, subject to a millimeter layer. However, for some types of materials, thicker layers are recommended. For example, for concrete - 1.5, brick or foam concrete - 2.5, wood - 2 mm.

Manufacturers and prices

Today it will not be difficult to purchase liquid thermal insulation. And although the material is innovative, most manufacturers are starting to produce it. But what kind of insulation for the walls inside the house is there, in addition to those listed below, the information from the article will help to understand.

Related article: Warm floor on the wall from mold

The most proven ones include:

Astratek - 450 rubles per liter;

Armor - 700 rubles per liter;

Corundum - 500 rubles per 1 liter;

Actor - 600 rubles per 1 liter.

It is impossible to give an exact answer to which one is the best. Each of them guarantees getting the desired result, but it all depends on which surface you have to work with and under what conditions.

What are the best thermal insulation materials for the walls inside, the information from the article will help to understand.

But with the help of what materials the walls are insulated from the outside most often, it is indicated in this article.

Perhaps you will also be interested in learning about how do-it-yourself siding lathing with insulation is carried out.

Which facade insulation under plaster is the easiest to make is described in detail in this article.

Paint application

Surface painting is carried out as follows:

- Stir the paint first. The process is carried out up to the even distribution of microgranules in the composition. Stirring time - 10-15 minutes. The process can be accelerated up to 5-7 minutes if there is a mixer. In this case, the rotational speed should not be higher than 200 rpm. Too high a speed will destroy the ceramic microgranules.

- If it is necessary in accordance with the instructions for use, water is added to the composition.

- For staining areas of insignificant area, use brushes with natural bristles. For painting larger surfaces, without numerous corners and irregularities, it is more convenient to use a roller. The best paint application is achieved by using a spray gun (spray gun or airless spray). When applying paint, the working pressure must be monitored: it should not exceed 6 atmospheres, otherwise damage to the ceramic microgranules is likely.

- After painting the surface, you need to wait a day until it dries. During this time, polymerization of the binder occurs and the fixing of heat-insulating microgranules. Drying speed may vary depending on environmental conditions. The manufacturer indicates on the container with the paint the recommended temperature and humidity for the normal drying process of the coating.

When working with paints and varnishes, personal safety equipment should be used. You will need a respirator, rubber gloves and goggles. In case of contact with the paint on the mucous membranes, it is necessary to rinse the affected area with water and seek medical help without delay.

Applying liquid thermal insulation

A very important feature of liquid thermal insulation is its anti-corrosion protection, which perfectly protects any surface from the harmful effects of the environment. Anti-corrosion paint is created for any metal equipment that can be used in high humidity conditions. This is a very useful thing for oil pipelines, gas pipelines, as well as pipes through which hot steam passes (ovens, saunas).

This coating can be applied to the exhaust systems of any modern vehicle. It is possible to provide reliable protection for all kinds of engine parts, as well as metal surfaces that can be used during installation in temperatures from -60 to +650 degrees Celsius. They can also be influenced by an aggressive environment and other factors.

Among the aggressive factors, it should be noted:

- Salt solution.

- Petroleum products.

- Mineral oils.

The electrostatic field does not interfere with the application of heat-resistant paint, or rather, our liquid thermal insulation. The insulation does not lose its properties even at temperatures below zero. The anti-corrosion and insulating properties of liquid thermal insulation help to avoid:

- The effect of high temperatures on a material or surface.

- Atmospheric precipitation.

- Humidity.

- The harmful influence of an aggressive environment.

At the same time, good vapor permeability is maintained. Liquid insulation can be used as a fireproof finish on both ceilings and walls. Heat-saving paint is sold in specialized stores. Prepare the surface before basic work.

To make it convenient to apply heat paint on surfaces, you should prepare the area to be treated in advance. To do this, you do not need to have special knowledge or skills, it is enough to remove any delamination, staples and other sharp irregularities from the surface. Next, let's talk about safety.

A liquid heat insulator is a chemical agent, which means it must be applied carefully and carefully. It is best to follow all safety rules, and store the substance in a proper place so that the suspension does not lose all its protective properties. Heat-insulating paint can harm the body if it accidentally gets into the stomach, so that this does not happen, the substance should be carefully applied to the material. Nano insulation is a paint for wall insulation, it just has a special manufacturing technology and more effective insulation characteristics.

If you do not know how to protect yourself during the application of insulation, then you can watch a training video that will help solve this issue.Any heat-reflecting material can be insulated with good insulation.

Paint consumption and the approximate cost of 1 sq. m depends on the manufacturer's brand you choose. Thermal insulating paint does not differ much in its purpose, but it can differ in some storage features, methods of application, choice of material of use, and much more. Nano insulation will be a good choice in any situation, but its cost will be much higher than that of conventional thermal insulation, but the degree of thermal protection is higher.

The liquid insulation coating to which the insulation paint is applied must be appropriate. More information about the effect of an insulator on a particular material or surface can be found in more detail on our website. Experts will help you determine which liquid thermal insulation for walls or which insulation paint is best for you.

Heat-insulating paint or liquid insulation for walls, presented on our website, will help to effectively protect any surface and material from heat loss, as well as any other negative impact. Liquid insulation for walls has a shelf life and operating rules.

The temperature of application of thermal insulation paint affects the external insulation of walls, or rather, its quality. For thermal insulation of walls, it is better to buy products from a trusted manufacturer. Liquid insulation for walls from the inside is actively used by many construction firms and private working groups.

What is included

Energy-saving liquid coatings differ from each other in characteristics, but in any case they consist of hollow microspheres. These elements are:

- ceramic;

- polymeric;

- glass.

The properties of the material depend on the type and size of the "balls". The characteristics of each Akterm product are on the product pages. In order for thermal insulation to perform its functions properly, it must be used correctly. We recommend that you strictly follow the instructions for use and not go beyond the specified temperature range.

Range of application

- Liquid thermal insulation of pipes, oriented as an active component in the insulation of pipelines, is effectively used for thermal insulation of such types of pipes:

- heating, both outside and inside the building;

- sewer and plumbing, also metal, both in the ground and on the street;

- engineering systems of water supply - cold and hot;

- air conditioning and ventilation systems;

- as insulation of chimney, exhaust and stove pipes;

- as insulation for laboratory equipment.

Your benefits

Is, first of all, a manufacturer. You can profitably buy any amount of thermal insulation from us without intermediaries. By ordering the product in this way, you will appreciate:

- no extra charge for certified branded insulation materials;

- fast delivery on time;

- the possibility of manufacturing a product under a contract - in laboratory conditions, with unique characteristics, according to GOST;

- individual service conditions; professional installation services in the capital.

We cooperate with wholesale and retail clients from all over Russia. Delivery of products to anywhere in the world is possible. The main office of the company is located in Moscow. Shipment in the region is carried out within 1-2 days after order confirmation. Appreciate the high level of service, leave a request on the site to receive a unique advantageous offer from our company.

Tags: residential, building, paint, insulate, facade

«Previous post

disadvantages

Nano-paint has a number of advantages over other heat-insulating materials.

The main advantages of a heat-saving dye composition:

- Lays down evenly on the surface, which allows you to hide defects and irregularities.

- Reduces heating costs.

- Possesses protective properties.Concrete walls with such a coating will be protected from destruction, and metal surfaces - from corrosive effects.

- Environmentally friendly and hypoallergenic.

- Durability (without loss of protective and heat-insulating properties).

- Fire resistance.

- Resistance to mechanical stress and temperature extremes.

- UV resistant.

- This material is easy to work with. To treat surfaces with a liquid heat insulator, you do not need any special skills; any person can cope with such work.

- Prevents the formation and spread of mold and mildew on the surface.

- Prevents condensation from forming on cold surfaces.

In addition to high technical characteristics, the material has a number of disadvantages.

The main disadvantages include:

- high consumption for surface treatment;

- high price;

- inexpediency of using for insulation of buildings as the main material.

The heat-insulating coating has a number of minor disadvantages, including: • high cost; • there is a possibility of falsification of heat-insulating paint for pipes, caution is important when buying;

Thermal paint application methods

Insulating paint can be applied with brushes or rollers. You can use a spray that transports the composition thanks to compressed air. The sprayer is economical in consumption and evenly distributes paint, allows you to paint over hard-to-reach places, therefore it is the preferred method of painting. But it is worth buying it if you plan to carry out work on a large scale. Small areas can be insulated with a brush or roller.

Thermal insulation should be applied only on a dry, cleaned surface, free of oil or other greasy stains. In some cases, for example, to reduce the consumption of heat-insulating paint, a primer is applied to the surface before painting, which evens the area and fills the pores.

Insulating paint is laid in several layers of about 0.5 mm, depending on the required thickness of the insulation. The average thickness is 1-2 mm, the largest is up to 4 mm. Interlaminar drying lasts up to 1 hour.

One day after applying the last layer, the surface can be primed and any topcoat can be applied.