Liquid foam Penomassa foam

LLC Plant TIS Channel

"Foamassa" is a liquid foam, which, during normal manual mixing in a bottle, after pouring a mixed liquid into a cavity or a mold, increases in size by 10-12 times and acquires unique physical and mechanical properties. There are many types of foam, this is the usual expanding polystyrene foam in plates and granules, extrusion plate foam, but Penomassa is a special foam, it is liquid, which in the process of polymerization increases 10-12 times and acquires the required shape with unique foam characteristics that are not inferior to conventional foams and even surpass them in many respects. "Penomassa" has an orange color, high mechanical strength (withstands compressive strength up to 33 tons per 1 sq. M.), Low water absorption (almost does not absorb moisture), low thermal conductivity (lower than that of conventional granular PSB foam and approximately the same as compared to extruded foam such as Penoplex, those hnoplex), great adhesion (adhesion) to many materials, high buoyancy index (does not sink), and most importantly, it can take any shape and completely fill all voids. Penomassa liquid foam is produced according to Technical Specifications TU 2254-007-86901126 -2015 in the city of Yekaterinburg on - is intended for filling voids, cavities, thermal insulation, sound insulation, thermal insulation of building structures, making beehives, making sculptures, for filling voids in floating means, assembly joints of building structures, insulation of equipment and pipelines. "- very simple. One set of "Foam mass contains two containers", in one of which there is "foam", and in the other "mass". For the successful application of "Penomassa" both bottles must be preheated to a temperature of +20 - + 25ºС. After that, it is necessary to open the bottle with "FOAM" and pour it into the bottle with "MASS", close the bottle with "MASS" with a lid and shake the resulting substance in the bottle for 20-25 seconds. Then open the bottle with the resulting composition and pour it into the cavity to be filled, form. After you pour the material into the cavity to be filled, after 20 seconds the "Foam mass" will begin to increase in size by 10-12 times and fill all available cavities. "Foam mass" hardens within 2-3 minutes after pouring. Foam mass has a closed-cell structure, which prevents moisture and steam from penetrating through the material.

Original link: https://www.youtube.com/watch?v=5bzfHiL5cx0

How to apply liquid foam yourself - a step-by-step scheme

Step 1: preparatory phase

There is no way to go without this stage, before you start working directly with the insulation, you should prepare the surface to be treated. So, it doesn't matter what it is: a brick wall, a metal or plastic pipe, or maybe even a wooden structure, in any case it should be cleaned of all dirt, degreased and thoroughly moistened. Only after that you can proceed directly to the thermal insulation.

Step 2: Preparing the insulation

Having lowered the cylinder into the water, we bring the liquid foam to the desired temperature (it is indicated in the attached instructions). Then, in order for it to foam properly, shake the container vigorously at least 25 times, and, removing the protective cap, screw on either the gun or the adapter tube. In any case, the container must be in the "bottom up" position. Please note that you can start this step only after the surface preparation is completely completed.

Step 3: Direct insulation

So, now we move on to the most important thing - applying the foam. This is done by simply pressing the corresponding lever, while the more efforts are applied, the more foam will come out, and vice versa, if you stop acting on the lever, then the feed will stop altogether.Thus, we process the specified wall surface. After half an hour, you can cut off all excess with a construction knife.

- Author: Mikhail Malofeev

Rate the article:

- 5

- 4

- 3

- 2

- 1

(3 votes, average: 2.3 out of 5)

Share with your friends!

The use of penoizol for home insulation

Penoizol is produced by foaming urea-formaldehyde resin and its further polymerization. The convenience of this material lies in the fact that it is produced directly on site. Penoizol under pressure in liquid form is supplied to the insulated surface, filling it with itself. Insulation with penoizol not only significantly saves time and effort, but also has a fairly reasonable price. At the same time, money is not spent on loading and unloading operations, transport services, fastening materials, and there is no need for an area for storing insulation.

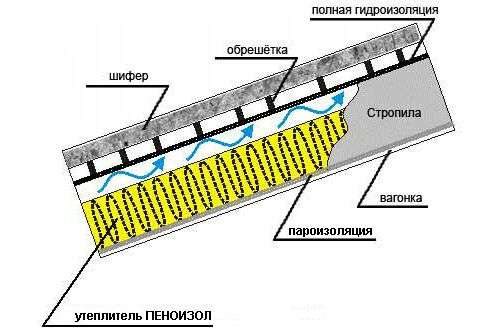

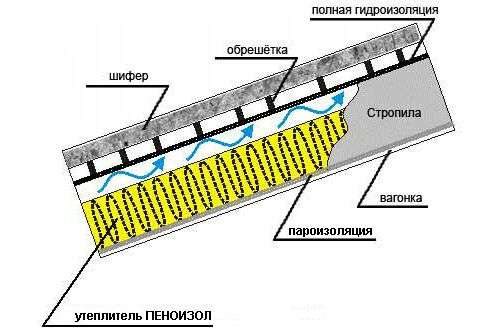

Roof insulation scheme with penoizol.

Differences and advantages of penoizol

- Penoizol differs from other materials in the peculiarity of the insulation work. The process consists in the fact that a hinged facade is initially built, and then the cavity is filled with penoizol under the vapor-conducting membrane. This method can be used to insulate walls, attics, roofs, and so on.

- Having low thermal conductivity, the material also has a low bulk density. After drying, it has a fine-mesh elastic structure, absolutely odorless. Its air absorption is almost zero, it is not hygroscopic, fungal mold does not form on its surface, and mice do not eat this insulation.

- It should be noted that working with penoizol is possible only at a certain temperature, it should not be lower than 5 ° C.

- The material is environmentally friendly, for which manufacturers must have licenses and certificates. Penoizol is not only high-quality insulation, but also excellent sound insulation.

Insulation of houses with penoizol

Wall insulation scheme.

To insulate a house, you will need a foam generator, with the help of which not only penoizol is produced, but also it is poured or foamed directly. The technology of work with this insulation allows you to fill it almost anywhere. This material is very convenient because it can be used almost anywhere. They can:

- insulate loggias and balconies;

- fill the gap between the main wall and drywall;

- to make pouring for siding, wooden floors, panels;

- insulate the bosom of the inner and outer walls.

It is very convenient to insulate ready-made, finished structures. For example, to fill voids in the walls, it is not at all necessary to disassemble the structure, it is enough to drill several holes taking into account the diameter of the steam generator hose and fill the voids with foam insulation through them. In such cases, experts recommend pouring from the bottom up.

For this job, you will need very few materials and tools.

Insulate the house with liquid foam: the technological process

Strict adherence to the rules and regulations for the installation of sprayed polystyrene foam is a guarantee that the created layer of heat insulator will really serve those declared by the manufacturers for 70-80 years. In case of violation of the formation process of foam material, incorrect dosage, uneven coating, the use of cheap and low-quality raw materials - all this will become the reasons that the insulation will turn into dust, in the literal sense of this expression.

On the net you can find detailed instructions on how to carry out insulation with liquid foam, video and photo reviews, tips and tricks.

However, it is much safer to turn to specially trained professionals. Those who have vast experience in working with liquid foams - to the masters of InnovaStroy.Moreover, if you decide to order the construction of a brick house, the construction of an aerated concrete cottage, a monolithic palace, or the construction of a turnkey combined house, the price of insulation work will already be included in the estimate documentation, and our specialists will carry out all the work with high quality and in compliance with the technological sequence:

1. Cleaning and preparation of the surface from debris and third-party formations;

2. Spraying the material in accordance with the calculated data and the insulation project;

3. Ensuring normal crystallization;

4. External surface treatment in preparation for the application of primers, paints, interior finishing components.

One of the applications for this type of material is a process in which liquid foam is supplied to the walls of a building - that is, in the cavity of finished structures, in order to improve thermal and acoustic insulation properties.

This method is used in cases where the cottage is already ready and needs to be improved - then the process looks a little different: 1. Drilling holes to access the space between the cladding layer and the load-bearing walls; 2. Injection under pressure of foam, which spreads clearly throughout volume, does not protrude, does not expand; 3.After shrinkage, the foam is re-installed; 4. Sealing the holes with cement compounds or any other materials, in accordance with the appearance of the cottage. Wall insulation with liquid foam has become a very popular means to improve the thermal insulation of a building - there is no need remove the cladding of facades, the volume of construction and installation work is reduced, it is possible to ensure the filling of even the most inaccessible places.In any use, liquid polystyrene foam must be applied by professionals working on the basis of design documentation - it is much easier to avoid the undesirable consequences of using a new type of insulation spruce. And the effect of its use is quite easy to see by conducting a thermal imaging examination of the building after the expanded polystyrene finally hardens and takes the desired shape. It is difficult to live in an age of innovation, every decade carrying a doubling of information - there is no stability! Things that were familiar yesterday, today or tomorrow, may well become an anachronism. Innovation is in everything and everywhere, including in such a conservative industry as construction. New technologies, dozens of new finishing materials, fasteners and accessories, materials for walls and insulation.

Fundamentally new window systems, which have changed the idea that the window is a constant source of cold, can now partially function as a heat insulator. New building materials, technologies or tools appear almost daily. Unfortunately, not everything worthy of use in construction is widely known. And the purpose of this article is to acquaint you with a rather little-known liquid insulation - penoizol (it can also be called "Mipora", "Unipor" or "Mettemplast") So, penoizol

The uniqueness of this technology is that the production process takes place directly at the insulation object, where the product in liquid form and under pressure is supplied into the insulated cavities, allowing them to be completely filled with insulation. It saves time, effort, money, on transportation, handling. There is no need to occupy space for storage and storage of large volumes of insulation. There is no need to fasten the insulation to the wall and the related work. The whole difference in the use of penoizol from the usual insulation, in the order of work.

If soft rolled and solid sheet insulation is attached to the wall and only then covered (protected) with a vapor-conducting membrane with a hinged facade or plaster, then a hinged facade is pre-built for insulation with liquid foam insulation and only then a liquid insulation is poured into the cavity under the vapor-conducting membrane. , penoizol can have a density of 10 - 30 kg / m3 and has excellent thermal insulation properties with a thermal conductivity of 0.028-0.038 W / m2 C. Compare, the thermal conductivity of a classic foam, depending on the density, varies in the range - 0.038 - 0.043 W / m ° C. Mineral wool slabs with a density of 125 kg / m3 - 0.07 W / m2 C (to prevent mineral wool shrinkage during operation, a density of 120 kg / m3 and higher is recommended by manufacturers of mineral wool heaters for thermal insulation of vertical walls), and with a density of 200 kg / m3 - 0.08 W / m²C, i.e.

Penoizol as a heater retains heat better than polystyrene and twice, in this parameter, surpasses mineral wool. Urea foam, at one time, passed a number of tests and was repeatedly investigated in various laboratories in our country and abroad. and licensing Gosstandart, the State Committee of the SES, Gosstroy, after detailed studies for compliance with medical standards, certified the urea foam. In addition, penoizol was tested for fire resistance at the State Enterprise TsNIISK im. Kucherenko. The conducted studies have confirmed the coefficient of thermal conductivity in the range from 0.028 to 0.038 W / m2 C. The fire safety of penoizol is also high enough, the material corresponds to the flammability group of at least G-2.

Penoizol does not support combustion, which is unique in itself, given the organic basis of the material. When exposed to an open flame, penoizol gradually loses mass, charring and evaporating without the formation of melt droplets, emitting neither harmful gases nor soot. It tolerates significant cyclic changes in temperature and humidity well and without changes in its structure. At the same time, it has an enviable durability.

Laboratory studies gave an estimated service life of 60 - 80 years. At the same time, the Institute of Chemical Physics of the Russian Academy of Sciences, after studying penoizol for durability, in the conclusion wrote that "the operating time of penoizol is not limited." This is confirmed by the study of samples of penoizol taken from the walls insulated 60 - 70 years ago (the first experiments with the use of insulation). There are also no obvious signs of degradation.

The internal fine-mesh structure of the insulation effectively passes water vapor towards the lowest partial pressures. According to this indicator, penoizol corresponds to the best samples of heaters on the market.

This characteristic refers it to the category of "vapor-permeable" heaters, which is a prerequisite for the insulation of walls and ceilings of the house. and the appearance of accompanying mold. Which is very valuable for any walls, especially wooden ones. A well-built and well-executed curtain facade with penoizol, as a heater, guarantees a long life for a wooden house. Like most heaters, penoizol is an excellent sound insulator.

Its five to seven centimeter layer reduces the average frequency airborne noise by three times, structural (transmitted through structural elements) by two. Penoizol can be effectively used for insulation and sound insulation of walls, floor ceilings and internal bulkheads of houses built from almost any modern structural materials.The efficiency, low cost and fire safety of penoizol made it attractive for the insulation of houses, as well as utility and industrial buildings. Penoizol is an effective, if not the only, material for repairing the heat-insulating layer of a building damaged during operation. The material can be used, for example, to fill cavities formed as a result of poor-quality installation or shrinkage of mineral wool, filling cavities formed from expanded polystyrene (foam) destroyed by rodents, voids formed as a result of shrinkage of bulk insulation - expanded clay, ecowool, etc. with settled mineral wool Disadvantages of penoizol. Like any other material, penoizol has advantages and disadvantages.

Within the framework of this article, I will give the main ones: - penoizol has a rather low mechanical tensile strength, compared to extruded polystyrene foam, and it needs protection from mechanical influences. decrease in the thermal insulation properties of the insulation. But I note that, again, thanks to the capillary structure, the accumulated moisture evaporates very quickly. - during the polymerization and drying period, it releases a small amount of gaseous formaldehyde with water, but after 2-3 weeks, when the material gets rid of moisture, this indicator does not exceed the MPC. - due to hygroscopicity, penoizol cannot be used to insulate the underground part of the foundations, and also cannot be used as insulation under a reinforced concrete screed. - in the case of pouring the material not into main walls (brick, concrete), but for example into a frame wall between two films, in due to the impossibility of creating high pressure in the frame wall, penoizol has an unpleasant feature - the shrinkage of the material during drying, which can reach 1%, in the main walls, the shrinkage is leveled by the high pressure created in the wall during pouring penoizol. To solve the problem of shrinkage of penoizol in light frame structures, the specialists of the Armoplast company developed a set of measures: - technology of micro and macro-reinforcement of penoizol using mineral additives and additional preparatory special measures, which allows you to completely get rid of the negative phenomena associated with material shrinkage in frame walls, ceilings, attics and guarantee reliable operation of the insulation throughout its entire service life - fast drying is unacceptable material, because.

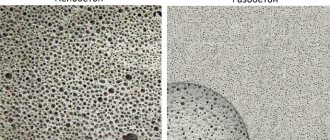

during fast drying, penoizol does not have time to sufficiently polymerize and gain sufficient strength, which leads to a high percentage of material shrinkage (penoizol must be between the vapor barrier and windproof vapor-transparent membranes and dry within 2-4 weeks) - the mandatory use of the "correct" components, the so-called "Foam-insol" resin VSG and Mettemplast technology. Below are images taken using an electron microscope (magnification 500x - 600x), which show the structure of conventional and micro-reinforced penoizol. Photo 1 Photo 2 Photo 1 shows an opened empty capillary of a unit cell (“bubble”) ordinary non-reinforced penoizol, photo 2 shows the capillaries of reinforced penoizol filled with mineral fillers, which helps to fight shrinkage during material drying, as well as gives additional strength and fire resistance to penoizol. Thus, we see that penoizol has its own fairly wide area Part of the application, and many of the above disadvantages of the material can be eliminated by technological means.Aenoizol must be protected from external mechanical and climatic influences (this requirement is the same for almost all modern heaters). Penoizol in frame house building and open fillings must be reinforced, which will eliminate the shrinkage of the material and get an excellent monolithic seamless heat-insulating layer connected throughout the entire volume by reinforcing mineral fibers. The effect of using penoizol to restore the thermal insulation of a brick house is perfectly demonstrated by the thermogram taken before (photo on the left) and after additional pouring of insulation into the walls (photo on the right).

So, by choosing Penoizol as the main insulation for walls and ceilings at home, you will get an economical, reliable and durable material. A material that does not burn, “breathes” and does not start mice in it (the lack of most modern heaters). - foam insulation is cheap, using it, you save at the construction stage, but you will get even more savings during the operation of the house on heating, since this insulation has one of the best thermal resistance characteristics.

Penoizol is a combination of low price, good quality and high characteristics - since penoizol in its original form is liquid foam, poured under pressure, free volumes in walls of any configuration are completely filled. This eliminates their subsequent purging and the associated heat loss. - the material has a low price, therefore, using it, you will be able to increase the insulation layer in the house without additional financial costs, thereby automatically laying the foundations for its future energy efficiency. : Penoizol has both positive and negative properties. But for a specific, narrow use of the material - insulation of walls, ceilings and ceilings of a house, the pros outweigh its minuses. Good thermal resistance coefficient, durability, affordable price and excellent performance make it one of the best heaters on the market.

Subject to the observance of the production technology of the material, it can be recommended as a heater and sound insulator for walls, ceilings and partitions of almost any houses and structures. At the moment, there are quite a few different options for facing work. First of all, this concerns the facade insulation with the help of special materials. Of all the huge variety, liquid foam is very popular. So, for example, abroad it has been used for more than 30 years and for all the time it has managed to prove itself from the best side.

Especially liquid foam for insulation of facades is popular in Germany, the Czech Republic, Switzerland, England, the USA and Denmark. Experts call liquid foam for walls expanded polystyrene, which is directly explained by its composition and scope. Liquid foam can be used to insulate any buildings - both residential and public. It also makes absolutely no difference what they will be built from - brick, cinder block, concrete slabs, gypsum block and much more. It can also be used to insulate foundations and the basement of large country houses.

Liquid foam in cylinders as insulation

I have been producing liquid insulation for over 10 years. I have a higher technical education and sufficient experience to help you insulate your house with your own hands, in a quick and relatively inexpensive way, or to open your own business.

Through his mistakes and experience, he was convinced of the truth of the classic statements of two geniuses.

But, if the cost is not important to you, then you can buy, for the appropriate price, at least 5 times more expensive than the ready-made equipment for penoizol

even with microprocessor, computer control. But it must be with the official specifications for the penoizol trademark. Otherwise, there may be a fake. The general technology is the same though.Or, if you manage to find it on the Internet, which is unlikely, and I'm not sure that together with them you will get all the necessary experience at once, which I offer you in a video tutorial on self-production of equipment for the production of urea foam and detailed instructions for home insulation. You decide!

The price of a high-quality and reliable installation of GZHU and a quick-disassembling foam generator, made independently according to my video instructions

80% depends on the cost of the pumps. Russian or Chinese are cheaper, European ones are more expensive.

DIY production technology

If the owner is to insulate a private house, it is worth considering whether to acquire own equipment for the production of penoizol. A careful calculation should take into account:

- the area of all surfaces and structures subject to thermal insulation: from the foundation to the roof;

- the range of heaters that will have to be purchased for certain parts of the building;

- the cost of basic and related materials and tools;

- the cost of the work of the involved specialists;

- duration of work.

On the other side of the economic scales will be the acquisition or manufacture of one set of equipment, which will be enough not only for the whole house, but also for further work for sale or hire. The well-established production of penoizol with your own hands can be a good help to the family budget.

Equipment assembly

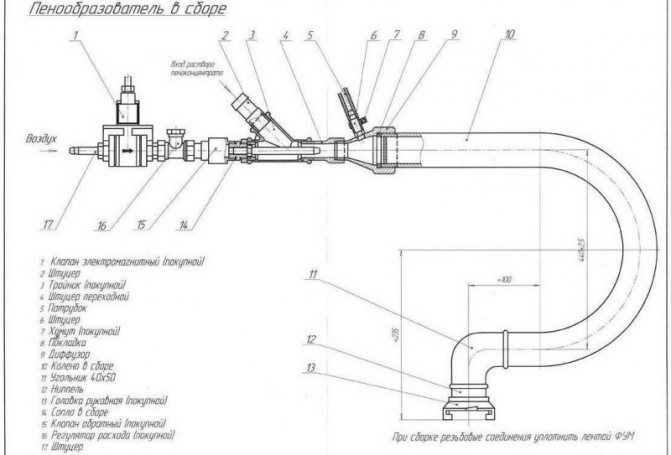

The market offers a large number of ready-made units for the production of penoisol. They consist of the following parts:

- gas-liquid module, or foaming agent;

- connecting and shut-off valves;

- supply hose;

- compressor or other source of compressed air.

Equipment for the production of penoizol

If the price of the unit does not suit you, then you can take the drawings from the network and make it yourself. Some units and parts can be made from scrap materials. If the master does not have a turning or milling machine, the most critical parts of the gas-liquid module are best ordered in production: they must be manufactured with high precision.

To mix the components of the working solution, barrels with a volume of 20 to 300 liters are used, depending on the planned production volumes.

There are two separate containers: for a stock of prepared resin and for foam. The compressor must be used with a receiver, oil separator and dryer. The quality of the supplied air and the stability of the pressure will directly affect the quality of the manufactured products.

The tanks are supplied with electric heating, this is also necessary to obtain a product of a given quality.

The pump delivers the initial components of the composition to the mixer, where they are mixed by the passing compressed air stream. Ready-made liquid foam insulation through a supply hose to the place of spraying or casting into a mold.

Practical instructions for warming houses with penoizol

Video of equipment operation and house insulation

Here there will be only practical information on how to insulate a house with any urea foam without consequences

Even when you order insulation of a house with penoizol officially, it is important to understand yourself how to do it correctly. After all, private houses and walls are different, different size of the layer, the strength of the masonry and you need to immediately navigate and adapt to each house

I have heard questions on the phone many times ... - Don't you ruin the house ?! I have never destroyed a single house. Sometimes, it was necessary to carefully pour penoizol into the walls, which were swinging with their hands. How to do it? Everything in the video course.

More than 30 people from all over the CIS have already made GZHU and are insulating houses according to my instructions!

Russia

: Moscow and St. Petersburg, in Bryansk, in Krasnodar, Voronezh, Stavropol, in Chelyabinsk, Samara, Novosibirsk, Perm, Omsk, Kirov, Ufa, in Rostov, Tyumen, in Belgorod, Barnaul, Armavir, Krasnoyarsk, in Yekaterinburg, Taganrog, in Nizhny Novgorod, Saratov, Izhevsk, Stary Oskol, Astrakhan, Tomsk, Kemerovo

Ukraine

: Kiev, Donetsk, Lugansk, Kharkov, Simferopol, Dnepropetrovsk, in Vinnitsa, in Zaporozhye, in Krivoy Rog

Belarus

: in Brest and in Mogilev

Kazakhstan

: in Almaty and Kostanay

How to make urea liquid foam foam with your own hands.

Description of liquid foam - penoizol.

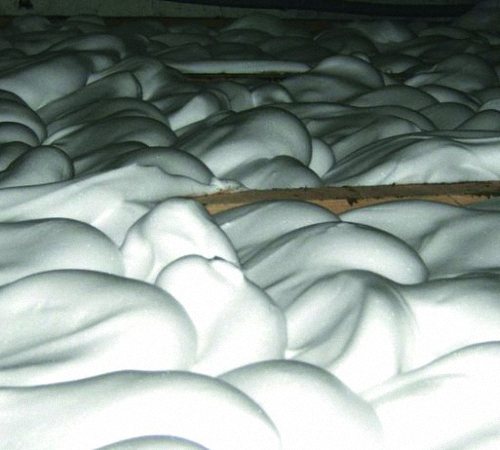

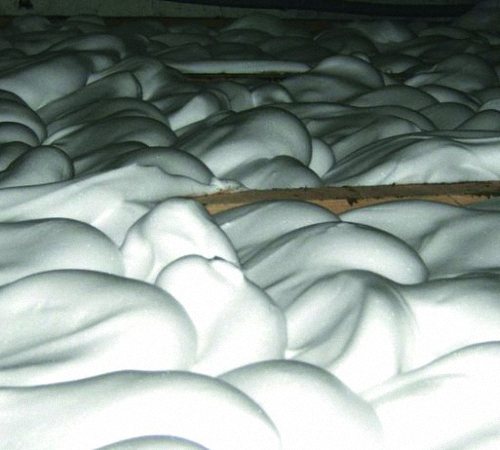

Urea insulation is a foamed plastic 98% composed of air and 2% of urea-formaldehyde resin with approximately the same number of both open and closed pores. The structure of its liquid foam is similar to the well-known meringue-type soufflé, and from afar many people confuse it with expanded polystyrene (polystyrene), but upon closer inspection, a material completely different from foam is guessed. Other names for insulation are mipora, liquid foam - penoizol, liquid insulation, urea foam, bipor and mettemplast.

Video: Appearance of liquid foam - penoizol and its mechanical properties.

Thermal insulation with liquid foam - penoizol.

- insulation of hollow walls: timber frame houses, timber houses with insulation for siding, hollow pockets in brickwork;

Video: Thermal insulation of the wall of a frame house with liquid foam - penoizol.

- floor insulation, for example, if the house is on piles with a ventilated underground;

- insulation of attics;

Video: Filling the floor and attic with liquid foam - penoizol.

- insulation of the attic roof;

- insulation of industrial refrigerating chambers and containers;

- insulation of industrial premises.

Obtaining urea liquid foam - penoizol.

It is quite simple to obtain liquid foam - penoizol - it is a process consisting of several stages:

- Preparation of components: pouring resin and water into working containers, mixing the foaming agent and hardener with water, heating the water to 40 C;

- Filling the hydraulic system of the unit with resin and mortar;

- Trial pouring into a test container to control the quality of the insulation;

- Direct pouring of insulation into a building structure or mold.

The price of liquid foam - penoizol.

The cost of raw materials for obtaining liquid foam - with a 10th density at 2020 prices does not exceed 1000 rubles, even taking into account delivery.

Per cubic meter of liquid foam 10th density

required:

15 l. resin * 45 rubles = 675 rubles;

0.085 l. orthophosphoric acid * 120 rubles / l = 10.2 rubles;

0.170 l. foaming agent ABSK * 160 rubles / l = 27.2 rubles.

Total: 712.4 rubles / m3

Per cubic meter of liquid 20 density foam

required:

30 l. resin * 45 rubles = 1350 rubles;

0.085 l. orthophosphoric acid * 120 rubles / l. = 10.2 rubles;

0.170 l. foaming agent ABSK * 160 rubles / l. = 27.2 rubles.

Total: 1387.4 rubles / m3

One liter of resin contains 1.3 kg. The usual packing is 200 liter drums, about 260 kg in a drum.

In one liter of orthophosphoric acid - 1.75 kg. The usual packing is 20 liter cans of 35 kg each.

In one liter of ABSK foaming agent - 1.25 kg. The usual packing is 20 liter cans of 25 kg each.

For Siberia and the Far East:

LLC "Sibtem" Diller, Nizhny Tagil

Novosibirsk, Bordernaya street 3 (Pervomaisky district, Matveevka),

tel. 8-913-923-30-72 Yuri Gennadievich

Delivers: Resin: Criterm, phosphoric acid, ABSK foaming agent

OJSC "UralChemPlast"

Nizhny Tagil, Northern Highway, 21. Supplied by: Resin Criterm

Where can we apply penoizol in cylinders?

Liquid foam has found its application almost everywhere where it is necessary to carry out insulation, which means in the construction industry and during repair work.With the help of this new generation material, it is possible to provide thermal insulation for absolutely all structures, regardless of their purpose (residential or industrial). At the same time, it does not matter what exactly will be insulated, the facade of the building or its roof, foundation, attic, and maybe even the walls of the basement.

Moreover, thanks to the convenient form of release, the insulation of the floor and walls of houses with liquid foam is available even to inexperienced builders, it will not be difficult to insulate even a pipeline or other industrial equipment. This building material is in great demand not only because of its thermal insulation characteristics, which are better than the properties of sheet form, but also because of other positive nuances. For large-scale tasks, you will have to rent or purchase special equipment, and for small jobs, a very convenient form of release is suitable - cylinders.

Liquid foam

At the same time, sprayed heaters are known for their technological parameters, which ensure practical application:

- These materials have the highest thermal conductivity, which is about 0.020-0.028 W / mC. In more modern heaters, this figure is even lower - 0.017 W / mS

- Excellent sound insulation performance. This category of insulators successfully neutralizes even impact noise, providing quietness in the room when working with construction tools.

- The vapor permeability of sprayed heat insulators allows moisture to be absorbed without creating comfortable conditions for the formation of condensation

- The use of this material allows you to insulate even hard-to-reach places due to its consistency.

- The adhesion parameters inherent in this thermal insulating material make it possible to insulate surfaces made of any materials.

Warning. Even with all the positive feedback on the adhesion of the sprayed materials, one should not neglect their preliminary preparation. Smooth, oily, and surfaces made of polyethylene and other materials can poorly adhere to the insulation without degreasing, especially if the structure of the heat insulator is with open cells.

- The term of work with this insulation can also be called a record - 8-9 hours are enough for insulation of 100-120 square meters with a low labor intensity of the process

- This is one of the few heaters, during the construction of which it is not required to equip hydro and vapor barrier

- In the characteristics of the spray-type insulation, resistance to manifestations of biological and chemical origin is also noted.

Asking the question - what kind of insulation does not mice gnaw? Another plus of sprayed insulation is that it does not arouse interest in rodents, which have become a real problem when insulating with some other categories of insulation.

Material features

Penoizol was developed at the end of the 20th century as a modern alternative to foamed polyurethane, a proven insulation that had a number of operational drawbacks. The main difference in the physicochemical properties of penoizol is that it retains its elasticity after foaming. This greatly increases its strength and useful life when insulating and soundproofing loaded structures, such as floors and ceilings. There are other features of the material:

- resistance to temperature and humidity changes;

- immunity to biological threats: microbes, mold, insects, rodents;

- fine porous structure contributes to high vapor permeability;

- resistance to fire and high temperatures;

- environmental friendliness: does not emit harmful substances even when smoldering.

The elasticity of the material facilitates its installation in a sheet version. When spraying, high adhesion and penetrating ability of the solution allows you to insulate both large surfaces and hidden cavities, and hard-to-reach places.

Separately, it is worth noting the excellent sound insulation.Penoizol copes with both airborne noise and sounds transmitted through building structures.

The production of penoizol does not require special technical knowledge and particularly sophisticated equipment and can be adjusted by hand.

Scope of liquid urea foam

As already noted, Liquid Penoplast is absolutely universal. Today we can talk about successful application:

- For interior work (gluing light structures, thermal insulation of shower cabins, bathtubs (both tin and metal), sound insulation).

- For outdoor work (facade work, waterproofing of joints, bodywork, installation of concrete blocks (round) and a number of other areas).

The method of using foam insulation is quite simple. The surface is preliminarily cleaned of dirt, moistened with water (except for situations when the process is carried out at a temperature below 0 ° C).

According to reviews of foam in a liquid state, the optimal temperature is + 20 ° C, but if it is lower, then it is recommended to warm up the packaging in advance using a container with warm water, but not higher than 50 ° C. In hot seasons, overheated packages are also cooled with water.

We recommend that you familiarize yourself with the reviews of people who have already tested liquid foam insulation in the case to make sure that its description and characteristics are correct.

Testimonials

“Last year I faced the problem of insulating a private house. I decided to take the advice of friends and use liquid foam. In principle, I was satisfied, but the unpleasant smell lasts for a long time in the premises, which is why, after work, my family and I had to move to my parents. "

Igor Rumyantsev, Chelyabinsk.

“Last fall I flooded a private house with liquid foam. I decided to do the same as my neighbors, who praised this product very much. The price of Liquid Penoplast was fine. He did not take up the work himself, he hired a team of specialists. At the end of the work, I had to move in with friends, as the house smelled terribly of chemicals. Now there is no smell, and it has become warmer. "

Nikolay, Moscow.

“In June of this year I made repairs in the apartment. Since I live on the 8th floor, the house is cold as at the North Pole. After reading reviews on the Internet, I decided to use Liquid Penoplast insulation in cylinders. In principle e, I was satisfied, and only because the price is low. The disadvantages of liquid foam are a strong pungent odor that did not disappear for a long time, a mass came out of the cylinder poorly (without pressure), which made it worn out. Maybe the reason is that I purchased a low-quality product (fake). "

Vasily, Yekaterinburg.

Heaters

119 votes

+

Voice for!

—

Against!

The use of liquid foam as insulation has a lot of advantages, among which, first of all, it should be noted its ability to fill the smallest gaps. In addition, the cost of this insulation is quite affordable compared to alternative options. Let's talk about the features and scope of liquid foam further.

Table of contents:

- Liquid foam: features and characteristics

- Liquid foam insulation - scope of use

- Advantages of wall insulation with liquid foam

- Thermal insulation of houses with liquid foam - technology and properties

- Liquid foam technology

Liquid foam: features and characteristics

At the heart of the manufacture of foam is the use of a resin of a polymer composition. There are many varieties of this material, which are distinguished:

- according to its intended purpose - technical type foam is more harmful to the environment, it contains toxic substances, the foam installed in residential premises has a different composition, which is characterized by absolute harmlessness and a good degree of purification;

- according to the manufacturing technology - materials based on already hardened foam are safer; in the process of working with liquid foam there is a risk of releasing harmful substances during its hardening.

The most optimal variant of liquid foam is made on the basis of urea-formaldehyde resins.

Each of the insulation, which has a foam purpose, is formed by solidification of the material from which it is made. If the foam is applied directly to the surface that needs to be insulated, then its adhesion to it increases several times than if a foam plate is installed on the same surface.

To prepare liquid foam, you will need resin and a hardener. A special machine is engaged in mixing and whipping all ingredients into a homogeneous foamy structure. Next, it is supplied using a pump and a hose directly for insulation.

There are special units that deal with this process. Although it is possible to make your own device, which is responsible for the preparation of liquid foam. The cost of purchased devices is quite high and reaches more than $ 3000. For self-assembly of such a device, much less money is required.

Commercially available liquid foam comes in the form of a balloon. After the foam hits the wall surface, it instantly hardens and becomes an excellent insulation.

Among the advantages of liquid foam are:

1. Excellent adhesion to almost any material.

2. No need to prepare the surface before laying the foam.

3. Formation of a seamless, perfect seam that does not allow heat to pass through.

4. Excellent vapor permeability, which allows you to maintain a healthy indoor climate.

5. It is used for insulating surfaces of various compositions: concrete, brick, wood, etc.

6. Liquid foam is able to fill all the space that requires insulation.

7. Absence or easy removal of excess and smudges.

8. Environmental friendliness and harmlessness to human health is ensured if a high-quality type of foam is selected.

9. Affordable cost, which is several times lower than alternative heaters in the form of mineral wool.

10. Good resistance to mold, mildew and microorganisms.

11. Ability to function in different temperature conditions. Resistant to temperature changes.

Despite this, liquid foam has certain disadvantages, namely:

- the possibility of linear shrinkage, which appears if the foam was poured without the required pressure;

- the presence of an unpleasant odor that disappears over time;

- the ability to absorb moisture, therefore, the material should be protected from external influences on both sides;

- due to the presence of formaldehyde, it is recommended for use as an outer layer of insulation or as an intermediate layer.

Liquid foam insulation - scope of use

Liquid foam has limited indoor use, but it is still widespread in the process of insulating horizontal planes, such as the attic floors of a panel house. In addition, it does an excellent job of insulating the inter-rafter space and sloping sections.

Due to the presence of a liquid consistency, the foam perfectly insulates the space between two sections of the walls, which are tightly adjacent to each other. It is used to insulate formwork, false walls or floors made of wood.

Liquid foam is able to penetrate the most distant parts of the walls. With its help, they are filled evenly and efficiently.

The use of liquid foam is associated with the insulation of containers.In addition, the unit with which the insulation is performed is also used for the manufacture of any kind of foam products, such as skirting boards, baguettes, slabs, embossed elements, etc.

Please note that all materials used in the liquid foam manufacturing process should be carefully checked. As there are many scammers or pseudo factories that produce liquid foam at low cost. In this case, a low quality hardener is used, which is not only harmful, but also hazardous to human health.

Liquid foam in cylinders is used as an adhesive. In relation to the form and application, it has similar properties to polyurethane foam, although in comparison with it it has a higher thermal conductivity and vapor permeability.

It is suitable for fixing various types of insulation boards on the surface. To do this, you must follow the instructions:

1. Make sure there are no defects on the surface. It should be flat, without rusty spots, cracks and chips.

2. Clean and dust the surface.

3. In places where the adhesive comes into contact with the board, apply water to improve their adhesion.

4. The option of applying foam to the full surface is possible. If you plan to save money, then it is applied only in the horizontal and diagonal directions.

5. Once the liquid foam is applied to the surface of the board, press it firmly against the wall.

6. Further slabs are laid in the same way.

Please note that thermal insulation with foam, in the absence of a properly organized ventilation system, leads to the formation of condensate masses.

Liquid foam application does not require careful surface preparation. This explains its wide popularity. When using a special installation that produces foam, only water and electricity are required for insulation. The application of the foam is carried out using a hose, the size of which is limited by the distance from the unit producing the foam to the place of insulation.

Liquid urea foam is used in such cases:

- internal work on gluing various kinds of structural elements, for thermal insulation of bathrooms, in order to ensure sound insulation;

- when carrying out outdoor work - facade insulation, waterproofing, installation of blocks made of concrete, etc.

Using liquid foam is pretty straightforward. Before applying it, the surface should be cleaned of dirt and dust, apply water to it to improve the adhesion of the foam. It is better to carry out work at a temperature of about twenty degrees Celsius. If the air temperature is lower, then the finished mixture is heated with warm water. If the weather is too hot, then the mixture is cooled in the same way.

Before using the purchased liquid foam, shake the container in which it is located about 10-15 times. Thus, the material will be evenly distributed inside the cylinder.

Advantages of wall insulation with liquid foam

If the foam is made directly at the facility where construction work is being carried out, then its quality is much lower than that of balloon liquid foam. The use of commercially available foam, which is sold in balloon form, has the following advantages:

- durability;

- environmental friendliness and harmlessness to health, provided that the foam is made of quality materials;

- fire safety and fire resistance;

- resistance to biological effects;

- resistance to insects and rodents.

Thermal insulation with liquid foam has an excellent ratio of cost and quality of thermal insulation material.It is able to insulate both already erected walls and structures that are under construction. In addition, liquid foam is different:

- excellent thermal insulation characteristics;

- high manufacturability of use;

- service life of 45 years;

- resistance to high temperatures;

- affordable cost;

- fire safety;

- high density;

- good sound insulation characteristics.

Thermal insulation of houses with liquid foam - technology and properties

Filling with liquid foam is carried out directly at the construction site, therefore, the insulation work is done quickly and easily. Penoizol is not prone to increase, but still differs in the presence of a slight shrinkage, in order to avoid the appearance of cracks that form as a result of shrinkage, the technology of pouring with penoizol should be strictly followed.

The material must be tested and of high quality. The minimum temperature for work is six degrees. If a purchased type of foam is used, then you should first study the instructions for working with it.

Sometimes slab or tiny materials are used. Since the foam, when dry, is excellent for any surface. After pouring, a seamless layer is formed with excellent heat and sound insulation characteristics. This design is practically impervious to moisture, despite the presence of small cracks in it.

The use of liquid foam is associated with insulation:

- external fences;

- insulation of walls of simple or combined composition;

- thermal insulation brick construction, consisting of three layers;

- filling of panels made of reinforced concrete;

- providing sound insulation and sound absorption;

- as insulation in laminated panels;

- interfloor insulation;

- insulation of roofs, attics, attics and balcony structures;

- insulation of garages, boxes, outbuildings, hangars, open areas, etc .;

- thermal insulation of summer cottages, basements, vegetable stores;

- thermal insulation and sound insulation of wall panels, which are installed on a frame made of both metal and wood;

- soil insulation.

Liquid foam technology

To buy liquid foam, you should contact the manufacturers directly. They must be checked in advance with all the documents necessary for the work. In addition, you should worry about the availability of certificates confirming the quality of products.

The price of purchased liquid foam is higher, so the process of making it yourself is several times cheaper.

With the help of a properly made liquid foam, it will be possible to perform all the work efficiently, quickly and efficiently.

The procedure for making liquid foam involves mixing water foam with urea resin and a hardener. This is followed by polymerization, that is, solidification of the finished substance.

After drying is completed, the material takes the form of foam plastic that is familiar to us. Styrofoam is applied to the surface in the form of a thick foam, which has a thick consistency. It insulates various building structures well. In order to fill all air gaps, it is necessary to ensure the supply of a certain pressure, under which the foam is supplied.

Further, the material hardens and begins to function as insulation. A house properly insulated with liquid foam requires several times less heating costs than a building without insulation.

You should start work by directly pouring the material onto the surface. To get high-quality material, you should adhere to a certain technology for installing liquid foam.

It will take about six hours of work to carry out thermal insulation in houses with a total area of 70 square meters.If you hire specialists who are engaged in insulation using liquid foam, then the cost of the work will be about $ 25 per square meter. Self-insulation will cut costs by two or even three times.

Thermal insulation with liquid foam involves pouring liquid foam into all empty areas of the walls. This procedure is carried out by pre-drilling the holes into which the hose is inserted. It is the pressure that ensures a snug fit of the material to the wall, filling all cavities and the absence of cracks.

Subject to the correct manufacture of liquid foam and its application, the use of this material as insulation allows you to obtain high-quality, inexpensive and effective insulation.

Liquid foam video:

Where to use sprayed insulation

Due to compliance with safety standards, sprayed insulation can be used for the arrangement of public and residential buildings. The range of its application is quite versatile:

- Roofing and attic structures

- Warming of floors

- Thermal insulation of wall surfaces

By objects, you can make a classification as follows:

- Industrial buildings

- Outbuildings

- Refrigeration equipment

- Pipeline communications

- Tanks for technological purposes

It is important to consider! Although spray-on insulation is considered environmentally friendly, thoughtful precautions must be taken when insulating residential buildings. At the time of application of the material, a polymerization reaction occurs, accompanied by a high degree of toxicity. And only after the final solidification, the risk of poisoning disappears completely

And only after the final solidification, the risk of poisoning disappears completely.

As for the type of materials for which it is possible to carry out insulation, there are no restrictions in this regard.

Do-it-yourself sprayed insulation

Many owners of private houses, and even apartments, try to do all the housework with their own hands. But in this case, it is not easy to do this without theoretical training and the necessary equipment.

In any case, for self-insulation with polyurethane foam, you will need a balloon installation and the components necessary for this procedure, namely:

- Polyol to be mixed in a container with freon

- Isocyanate, also combined with Freon 134

Both cylinders must be inflated until the pressure in them is at least 8 atmospheres.

Further, spraying is carried out on the treated and prepared surface - just press the spray gun and direct a stream of insulation to the desired area.

Attention! When working independently with sprayed insulation, it is imperative to use personal protective equipment!

Sprayed insulation in cylinders

Since an independent process is not as difficult as preparing it, it will be easier to immediately resort to ready-made sets of insulation in cylinders. In addition, there will be no tangible difference in cost.

Sprayed insulation in cylinders is more practical, since it has a professionally performed factory training, including the optimal pressure regime.

The price of sprayed insulation

The cost of this insulation may seem slightly higher than materials in other categories. However, the economic efficiency of this thermal insulator is obvious when calculating, of course, the cost of costs for other materials with the inclusion of additional equipment - profiles, sealants, fasteners and payment of the cost of professional work.

In the long term, the cost of insulation with sprayed insulation pays off by reducing energy costs.

Spray-on polyurethane insulation Polynor

An example of a successful choice of such insulation is the Polynor insulation.Its advantages are evidenced by reviews of the sprayed polyurethane insulation Polynor and instructions provided by the manufacturer in video format. The price for sprayed polyurethane insulation Polynor is identical to similar sprayed insulation in this category.

Thus, this type of thermal insulators is a priority in the choice of material for a number of technological indicators and for reasons of practical and budgetary value.