It is possible to create a comfortable and, most importantly, healthy atmosphere in the house only on condition that the appropriate humidity and air temperature are maintained in it. Condensation, dampness, mold, mildew, cold bridges - all this can be avoided by using XPS foam polystyrene insulation for internal and external thermal insulation.

Everything important to know about Styrofoam

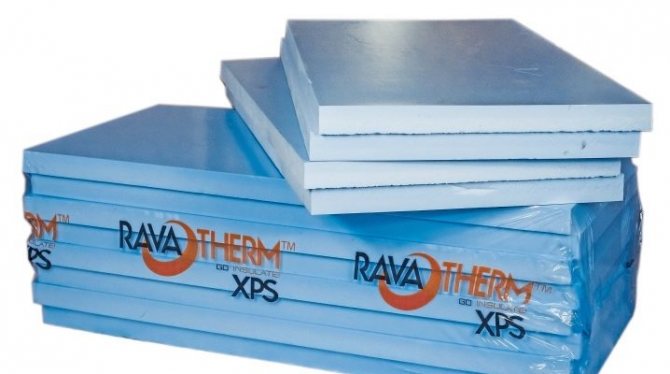

XPS insulation is extruded polystyrene foam. Quite a new invention in the field of thermal insulation technologies. However, despite this, XPS has already managed to earn great popularity, both among professional builders and DIYers. How is this justified? Let's figure it out.

How is expanded polystyrene

In the photo - equipment for the production of extruded polystyrene foam

Modern equipment makes it possible to produce insulating polystyrene foam with a uniform structure, consisting of small, completely closed cells (each with a size of 0.1-0.2 mm). At the first stage, granular polystyrene of general purpose is poured into the extruder and a foaming agent is injected, which subsequently endows the insulation with basic properties.

Note! As a blowing agent, as a rule, mixtures of light freons or carbon dioxide are used. They belong to the group of non-flammable, non-toxic and ozone-friendly substances.

After filling, all components are mixed and melted, resulting in a homogeneous mass. Then, under pressure and pulling rollers, the molten mass is squeezed out of the extruder through a die, which gives the expanded polystyrene to a specific shape. At the next stage, the residues of the foaming agent are replaced with air in the cells of the material, after which it is cut and placed in thermal packs.

For information! XPS expanded polystyrene is available in slabs, mats, cylinders or segments in various thicknesses and colors.

Characteristics of expanded polystyrene

The positive qualities of XPS insulation make it perhaps the best option among the entire range of insulation materials on the market:

- Extruded polystyrene foam is characterized by minimal hygroscopicity;

- Low heat and steam conductivity;

- Does not absorb moisture;

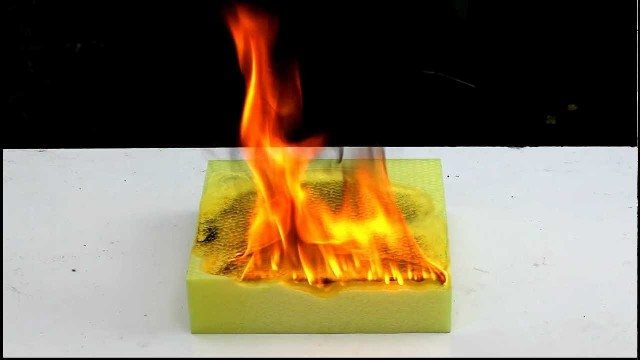

- Resistant to fire;

- Due to its structure, XPS has an unusually high compressive strength and biological stability (i.e. insects and rodents are not in it);

- It is an environmentally friendly and safe material;

- It should be noted the simplicity and ease of installation - all work on thermal insulation can be done by hand, without helpers;

- Expanded polystyrene is not the cheapest insulation, but its price is quite adequate. Of course, it is slightly higher than, for example, mineral wool or ordinary foam, but the costs will pay off doubly. We will talk about this a little later.

Reliable thermal insulation of residential, municipal and industrial buildings plays a major role in reducing heating costs. And, as you have already noticed, extruded polystyrene foam is quite capable of providing effective insulation - with its help you can get rid of heat loss for a long time and save a good budget.

Note! With expanded polystyrene XPS, you can insulate a loggia, walls, floors, foundations, roofs, communications, garages, and many other structures.

Thermal insulation of the balcony with XPS plates

Answers to important questions

- Why is XPS foam more expensive than conventional thermal insulation materials?

Of course, a cubic meter of XPS costs a little more than the same mineral wool or foam, but in the case of expanded polystyrene, a much smaller thickness of the material will be required, plus you will not have to purchase additional hydro and vapor barrier films.

Based on the foregoing, the total cost of insulation with expanded polystyrene is lower in comparison with insulation with the help of other materials. And the XPS will last much longer without causing problems during operation.

You also need to take into account the fact that extruded polystyrene foam does not absorb moisture, which means that over time its thermal insulation properties will not decrease, mold and mildew will not appear in it.

- Is it possible to insulate wooden structures with polystyrene foam?

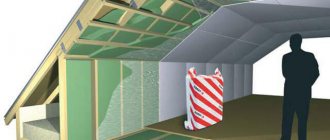

Yes, you can. True, for this you will need to perform a vapor barrier from the inside of the room. The thing is that wood has a much higher vapor permeability than expanded polystyrene. It turns out that the layer of insulation will not allow steam to come out, and the wooden wall will begin to damp and rot.

Thermal insulation of a wooden house outside with XPS plates

In order to avoid this, a vapor barrier made of foil-clad polyethylene with a thickness of 200 microns should be carried out from the inside of the room. All joints of the vapor barrier material are glued with metallized tape. After that, a frame is assembled for the construction of a decorative wall made of plasterboard, wood, panels and other materials.

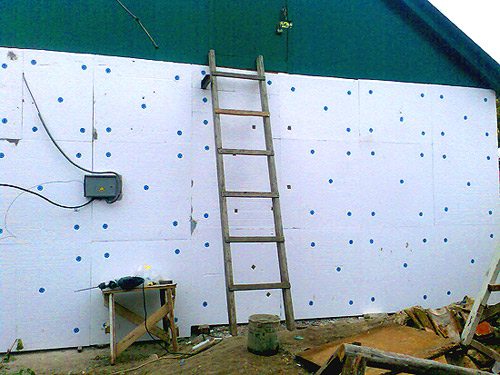

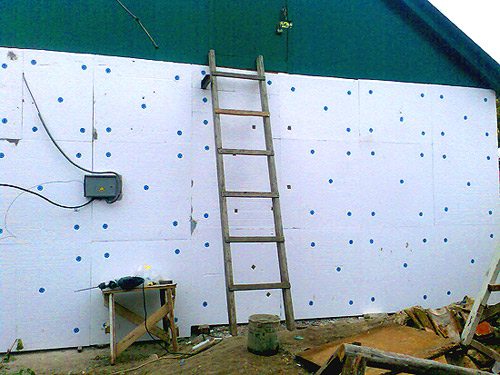

Outside, polystyrene foam insulation is attached to the facade using screws with a pressure disc. On top of the thermal insulation there is a decorative finish (for example, lining or siding).

- What is the XPS insulation attached to?

Here's a quick guide to help you choose the right mounting method for your application:

- First of all, it must be said that cement, acrylic and polyurethane glue are suitable for expanded polystyrene. With their help, you can glue the insulation anywhere (to walls, facade, foundation, loggia, etc.).

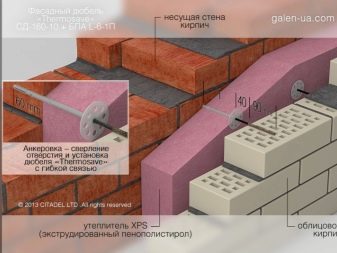

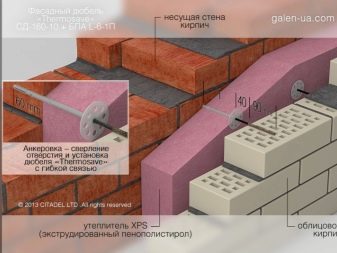

- If the surface to be insulated is not too flat, you can additionally strengthen the XPS with disc-type dowels.

- To insulate a flat surface, fastening without adhesive solutions, only for one dowel, is permissible.

Foundation insulated with expanded polystyrene

- When insulating the foundation or soil of the slab, polystyrene foam is simply sprinkled with earth. And above the ground, it is fastened with dowels (5 pieces per one plate).

- If there is a layer of bitumen-polymer waterproofing on the foundation, then you should not use glue for installing the insulation. It is better to melt the waterproofing layer at 5 points and press the expanded polystyrene plates tightly to it.

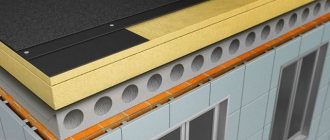

- When insulating attic floors, floors, or inverted roofs, the XPS can be simply installed without mechanical fastening.

Extruded polystyrene foam Tepleks

Thermal insulation material made by extrusion is found on the construction market under the name extruded polystyrene foam. Insulation Tepleks provides effective thermal insulation due to its technical characteristics. First of all, it is worth noting the predominant feature of the material - its closed porous structure. It provides the insulation with high moisture resistance and explains the low specific gravity.

Insulation production.

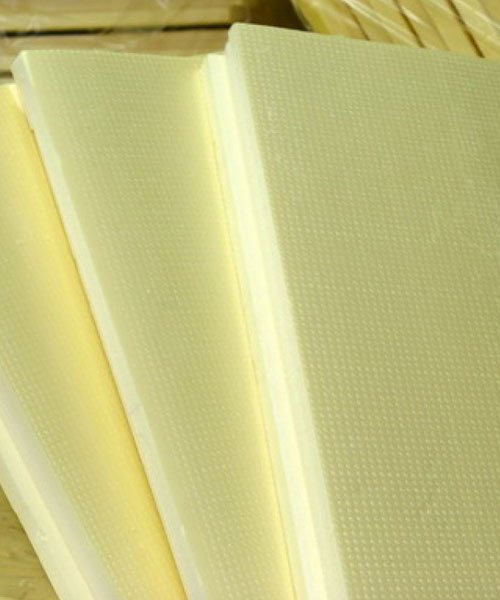

Insulation Extruded polystyrene foam

Extruded polystyrene foam, unlike foam, has an integral structure, which includes a number of closed cells, the cavity of which is filled with gas molecules. The material is impermeable due to the absence of micropores in these granules. The special strength of the insulation is achieved due to the unique production technology. The extrusion method involves a multi-stage process for manufacturing a heat insulator. First, a homogeneous viscous mass is obtained by melting the granules and only then it is passed through a special tool.

Insulation material specifications:

- the insulation belongs to the category of environmentally friendly materials. It is safe for human health and the environment. The foaming agent used in production does not contain toxic substances;

- possesses moisture-resistant properties, resistant to vapor diffusion;

- low thermal conductivity, high strength;

- withstands the process of thawing and freezing, while maintaining its heat engineering qualities;

- has a low weight, easy to use, amenable to processing;

- chemically resistant.

Advantages of using insulation:

- slabs have a relief surface that provides better adhesion of materials in the case of a plaster facade or sandwich panels;

- insulation is produced in various thicknesses (20-120 mm), due to which it has found its application in various industries;

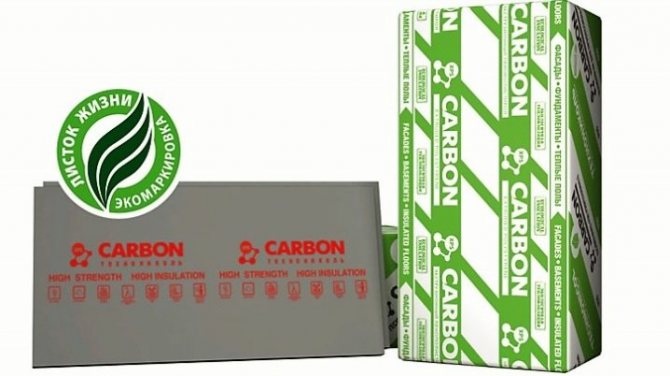

- insulating material goes on sale in a special sealed package that guarantees the protection of the finished product from direct sunlight;

- the heat insulator is environmentally friendly, which means it can be used for the arrangement of any residential premises. To work with insulation, no special protective equipment is required, as is the case with glass wool;

- "Stepped" edge provides a hermetic docking, eliminating the likelihood of cold bridges;

- range

Scope of application of extruded polystyrene foam.

The problems of thermal insulation of residential and industrial premises are easily solved by Tepleks products. Extruded polystyrene foam is successfully applied in civil and road construction. The heat insulator is indispensable for the construction of take-off sites for airfields, swimming pools, saunas, skating rinks, pipelines. The use of insulation in private housing construction will create optimal, comfortable conditions for year-round living.

Thermal insulation of walls, foundations, roofs, attic floors, floors are the main directions of extruded polystyrene foam. In addition, the technical characteristics of the material make it possible to use it in the construction of gas pipelines, oil pipelines, railways, airfield structures, highways. Besides the "thermal insulation" function, the boards solve the problem of poor sound insulation.

Tepleks products:

DSP sandwich panels are three-layer plates filled with extruded polystyrene foam. One or two sides of the insulation are glued with cement-bonded building material. It performs the following functions: protective, makes the plates fireproof and acts as a surface ready for decoration (finishing).

... Material advantages:

- the ability to maintain thermal insulation qualities throughout the entire operational life;

- durability, strength, resistance to vapor permeation;

- minimal water absorption;

- repeated freezing / defrosting without loss of heat engineering properties.

Application features:

- the plates are laid on a horizontal surface without the use of adhesives;

- installation of additional protection against steam penetration is not required;

- use a hacksaw or a knife to cut the material;

- fixing plates with a vertical arrangement is carried out using self-tapping screws or special glue;

- the main application is the thermal insulation of attic spaces. Building facades - an additional use case;

- installation of insulation is carried out with preliminary preparation of the insulated surface (alignment, removal of wet areas).

Soundproof plate STOP SUND. The product is laminated on both sides with foamed polyethylene, which has excellent thermal and sound insulation performance. The main purpose of the insulation is the arrangement of residential and commercial buildings. Construction panels WD.On both sides, the slabs are reinforced with fiberglass and coated with a polymer-cement composition.

Advantages: moisture resistance, wear resistance, good sound insulation and thermal insulation. Often it acts as a waterproofing layer, therefore it is successfully used in the arrangement of basements, bathrooms, foundations, facades, pools, showers. Ideal for any topcoat. The area of application of the panels largely depends on their thickness. For example, 8 mm insulation is used to level the walls.

As for the thermal insulation of pipelines, extremely high-strength heaters are applicable for these purposes. Semi-cylinders, segments are of two types: with and without a flame retardant content. Their geometric dimensions depend on the diameter of the hole in the pipeline. The assembly of such thermal insulation is carried out using polymer tapes or special tightening rings.

tstinfo.ru

Output

Thus, it turns out that expanded polystyrene is a versatile material with unique qualities. After all, it meets absolutely all the requirements for insulation.

In the video presented in this article, you will find additional information on this topic. In addition, our construction portal has step-by-step instructions for installing polystyrene foam insulators.

The modern market offers customers a wide range of different types of heaters. The material is used not only in regions with harsh winters and capricious weather conditions. It is a practical tool for creating comfortable temperature conditions in various types of premises: residential buildings, government agencies, warehouses and much more.

Extruded polystyrene foam, which is abbreviated as XPS, is very popular. Let's talk about the characteristics and use of the material in more detail.

Styrex expanded polystyrene

- In stock

- Wholesale / Retail

- 10.01.20

Always low prices. Free calculation of materials. Delivery to any area of the city, NSO, Siberian Federal District. Convenient form of payment (cash, bank transfer, payment on the spot).

- Not available

- Wholesale / Retail

- 09.01.20

Thickness 50 mm. Insulation of floors and plinths Size 50x580x1180 mm. The package contains 8 plates.

- In stock

- Wholesale / Retail

- 09.01.20

Thermal conductivity, not more - 0.03 - Compressive strength at 10% linear deformation, MPa, not less - 0.25 - Ultimate strength in static bending, MPa, not less - 0.4 - Water absorption in 24 hours,% by volume , no more - 0.4 - Flammability group - G3,

- In stock

- Wholesale / Retail

- 10.01.20

- it is profitable, reliable, fast with us. Individual approach to each client. We will make a free measurement and calculation of the material. A wide assortment will allow you to buy all the material in one place.

- In stock

- Wholesale / Retail

- 10.01.20

Size: 30/580/1180 mm Large selection of products from.

- In stock

- Wholesale

- 09.01.20

It is a heat-insulating material made of extruded polystyrene foam. It is produced by extrusion, therefore it has a homogeneous structure consisting of microcells filled with air molecules.

- In stock

- Wholesale / Retail

- 10.01.20

Retains heat 1.5 times more efficiently than conventional foam and 2 times more effective than stone and glass wool; Not afraid of moisture, not susceptible to rodents, operating temperature from -70 to +75, universal sheet insulation, thickness 50 mm.

- On order

- Wholesale / Retail

- 24.12.19

In you will find a wide range of products. We deliver to any city in RUSSIA. We offer our customers quality products at a favorable price.

- In stock

- Wholesale / Retail

- 10.01.20

Plates of extruded polystyrene foam are produced by extrusion, which allows the finished product to have a strong, solid structure, which is a mass of microscopic closed cells filled with air molecules.

- In stock

- Wholesale / Retail

- 19.12.19

The use of this type of insulation allows for reliable thermal insulation of buildings.It is made of high quality mineral wool using modern technologies.

General characteristics and use

Insulation is used for cladding:

- balconies and loggias;

- basements;

- facades;

- foundations;

- expressways;

- blind area;

- runways.

The material is used for cladding horizontal and vertical surfaces: walls, floor, ceiling.

Renovation specialists point out that XPS boards are among the most common insulation materials. A wide range of applications and technical features played an important role in the popularity of the products.

Due to the high demand in the market, you can often find products from unscrupulous manufacturers who disrupt the manufacturing process. As a result, customers run the risk of buying a low-quality product. Any inaccuracies in production cause a significant reduction in the service life of the insulation and its characteristics.

You will learn more about how to use extruded polystyrene foam in a residential environment.

Insulation material production.

Insulation is made from environmentally friendly components using modern automated equipment. The extrusion method used for the production of thermal insulation boards involves a multi-stage process for obtaining a high-quality product. Pre-melted polystyrene granules are passed through a special tool with the addition of a blowing agent to the mass. The final product is a fine-pored insulation. The density of the material depends directly on the ratio of the two main components - the blowing agent and polystyrene.

Advantages of Styrex insulation:

- the percentage of water absorption is close to zero. Plates made of extruded polystyrene foam do not absorb moisture, therefore, they are able to provide reliable protection of the foundation from the effects of groundwater;

- low thermal conductivity of the material makes it in demand in the construction market;

- due to the low weight of the insulation, it is easy, simple and convenient to work with it. When adjusting the material, use a knife;

- extruded polystyrene foam can withstand heavy loads, which makes it possible to use it as a heat-insulating layer when arranging railways and laying a roadbed;

- the ability to resist such processes as decay, the appearance and development of fungi and mold, is due to its biological stability.

Dimensions (edit)

XPS insulation comes in a variety of sizes. The most common sizes: 50x585x1185, 30x585x1185, 20x585x1185, 100x585x1185, 1200x600x50 mm. Choose the appropriate option depending on the size of the structure. If necessary, the canvases can be trimmed without problems.

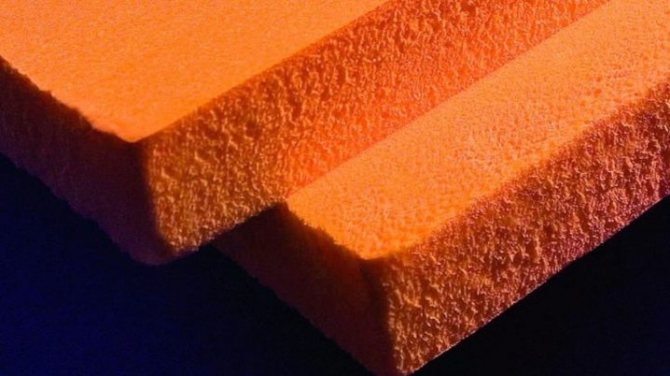

Structure

Extruded polystyrene foam, made according to all the rules, must have a uniform structure. Be sure to evaluate this when purchasing a finishing material. There should be no voids, grooves, seals or other defects on the canvas. Flaws indicate poor product quality.

The optimal mesh size ranges from 0.05 to 0.08 mm. This difference is invisible to the naked eye. Low-grade XPS insulation has larger cells ranging from 1 to 2 mm. The microporous structure is essential for the effectiveness of the material. It guarantees minimal water absorption and high efficiency.

Styrex or Penoplex?

Styrex is extrusive polystyrene foam, like penoplex. In essence, the applicability of Styrex is justified where the applicability of Penoplex is, that is, there are no decisive differences. Preference can be given to one material, only if it is convenient to cut a given dimension of boards, to reduce waste and in the case of increased strength requirements, since styrex has better bending strength.

Physical properties of Styrex:

- density - 0.35-0.38 kg / m3;

- thermal conductivity - 0.027 W / m * K;

- moisture absorption, no more - 0.2%;

- compressive strength - 0.25MPa;

- flexural strength – 0.4-0.7;

- vapor permeability - 0.019-0.020mg / hour * m * Pa.

At large deltas of external and internal temperatures, a slightly lower thermal conductivity of styrex makes this material more profitable, however, with an average difference of 0.003 W / m * K, this will be hardly noticeable. The production of heaters under the Styrex trademark is located in Ukraine.

Weight and density

There is an opinion that reliable and durable thermal insulation should have a high density, which is denoted as weight per m³. Modern experts think this is wrong. Most manufacturers use low density extruded polystyrene foam, while maintaining the quality of the material. This is due to the cost of XPS's main raw material, polystyrene, which is over 70%.

In order to save raw materials (stabilizers, foaming agents, colorants, etc.), manufacturers deliberately make the boards denser in order to create the illusion of quality.

Outdated equipment does not make it possible to produce durable XPS insulation, the density of which is less than 32-33 kg / m³. This indicator is not able to increase the thermal insulation properties and does not improve the performance in any way. On the contrary, unnecessary pressure is created on the structure.

If the material was made from carefully selected raw materials on innovative equipment, then even with a low weight, it will have a high density and excellent thermal conductivity. To achieve this result, it is necessary to comply with the production technology.

Which is better: penoplex or expanded polystyrene?

The production of penoplex involves the extrusive method of production, in which the boards are formed by the method of extrusion (extrusion). Ordinary polystyrene foam is produced without a press and may be called polystyrene foam. It is obtained by foaming, resulting in the formation of gas-filled balls. The structure of expanded polystyrene obtained in this way differs from extrusive expanded polystyrene. This reduces the strength of the material and increases thermal conductivity. The structure of the cells in the foam is more ordered, has a high density, which makes this heat insulator the best in terms of physical parameters.

Theoretically and practically, there is no exact separation between foam and expanded polystyrene of press-free production, since polystyrene is a raw material for all types of such products. A special method of foaming and extrusion makes it possible to obtain penoplex or other materials with a structural distribution of cells.

Physical properties of non-pressed polystyrene:

- density - 17-18 kg / m3;

- thermal conductivity - 0.040-0.043 W / m * K;

- water absorption - 0.8-1.2%;

- compressive strength (10%) - 0.15-0.20MPa;

- bending strength - 0.22-0.27MPa;

- vapor permeability - 0.05 mg / m * hour * Pa.

How are these two materials different? Comparison with the previously indicated physical. indicators of penoplex shows that non-pressed expanded polystyrene (polystyrene) has the worst performance in all parameters, except for vapor permeability. This indicator must be taken into account during the design of thermal insulation for rooms with high humidity. For the insulation of dwellings and buildings that do not provide for the appearance of excessive moisture inside, it is advisable to use polystyrene foam or other extrusive polystyrene foam.

The form

By evaluating the shape, you can also say a lot about the quality and efficiency of the material. The most practical XPS boards have an L-shaped edge. Thanks to it, installation is faster and easier. Each individual sheet is overlapped, eliminating the possibility of cold bridges.

When using plates with standard flat ends, foaming will be necessary.This is an additional repair process that requires not only time, but also financial investments.

Thermal conductivity

The main characteristic of the material is thermal conductivity. To verify this indicator, it is recommended to demand from the seller the corresponding document. Comparing the certificates for the goods, you can choose the highest quality and most reliable insulation. It is almost impossible to assess this characteristic visually.

Experts identify the optimal value of thermal conductivity, which is about 0.030 W / m-K. This indicator can change up or down depending on the type of finish, quality, composition and other aspects. Each manufacturer adheres to certain criteria.

Fields of application of insulation made of extruded polystyrene foam Styreks

Application area STIREKS material can be in demand as thermal insulation for gas and oil pipelines, as well as for reliable thermal insulation of water pipelines, water intake facilities, sewerage systems and heating mains. Due to the high mechanical strength, STIREKS does not require additional external protection and provides reliable protection of pipelines from mechanical damage. This preserves the waterproofing of the pipeline and minimizes the impact of the soil in the event of earth movements.

The inclusion of a heat-insulating layer made of STIREKS slabs into the roadway structure protects against the destructive effects of the forces of frost heaving of the soil, extending the service life of the road lane. The use of STIREKS slabs makes it possible to reduce the total thickness of the layered embankment for new roads by eight times. As a result, it is economical not only from the point of view of financial costs, but also from the point of view of the deadline for the execution of construction works.

Effective and reliable thermal insulation of foundations can be achieved by using extruded polystyrene foam "STIREKS" with a thickness of usually 50 mm as a heater. The thermal insulation layer is installed after the completion of waterproofing work. When insulating the ground part of the basement wall, STIREKS slabs are fastened with dowels. There is no need for fastening underground, because STIREKS slabs are pressed with soil.

Heat loss through the walls of the building is up to 15%, so any wall insulation will help keep your home warm. As a heat- and sound-insulating material, the most effective are plates of extruded polystyrene foam "STIREKS", which have a low thermal conductivity of 0.026 W / (m * K). Plates are attached to a previously prepared flat wall surface with glue. After gluing the boards, it is recommended to fix them mechanically using dowels. The finishing layer is applied directly to STIREKS boards. It can be various types of plasters applied on a reinforcing fiberglass mesh.

www.stirex.ru

Water absorption

The next important quality to pay attention to is water absorption. You can visually evaluate this characteristic only if you have a small sample of insulation with you. It will not be possible to evaluate it by eye. You can conduct an experiment at home.

Put a piece of material in a container of water and leave it for a day. For clarity, add a little dye or ink to the liquid. Then estimate how much water is absorbed into the insulation, and how much has become in the vessel.

Some experts use the prick method when evaluating a product. Using a conventional syringe, a little liquid is injected into the web. The smaller the spot sizes, the better and more practical the XPS finish.

Strength

XPS quality insulation boasts excellent durability, even at mid-weight. This characteristic is important during the installation process. Durable slabs are easy and convenient to cut and attach to the structure. Such material does not pose any problems during transportation and storage.High strength allows you to keep the shape of the slabs for a long time, without fear that the material will turn into dust.

If during the installation process you notice the formation of cracks, chips, deformation, and also hear a crack, it means that you have purchased a low-quality product. Be as careful as possible during the installation process so as not to damage the slabs.

What types of insulation and what to use?

Today, there is a division of the materials of this group directly according to their destination. They also differ in appearance and shape.

Quite tough piece heaters are on sale (plates, segments, cylinders, etc.), flexible products (cords, wide and narrow mats, bundles), as well as loose ones (perlite sand, vermiculite and cotton wool).

By their structure, they can be divided into fibrous, granular and cellular.

By the nature of the main raw materials, materials for thermal insulation are traditionally divided into organic and inorganic.

Environmental friendliness and safety

Premium extruded polystyrene foam is an environmentally friendly finish that is completely safe for health and the environment. On the domestic market, there is only one type of XPS material on sale, which has been awarded the Leaf of Life certificate. The document officially confirms the environmental friendliness of the products. The material is safe not only for people, but also for animals and the environment.

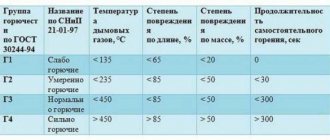

The use of XPS insulation fully complies with the norms of SNiP 21-01-97. This regulation refers to the section "Fire safety of buildings and structures". SNiPs - approved rules and regulations in the construction industry.

Specifications

The main parameters of the insulation of this category: thermal conductivity coefficient (0.029-0.034 W / (m * C)), moisture absorption index no more than 0.4%, density (within 38-45 kg / m3), insignificant vapor permeability (0.013 Mg / (m * h * Pa)).

Insulation specifications

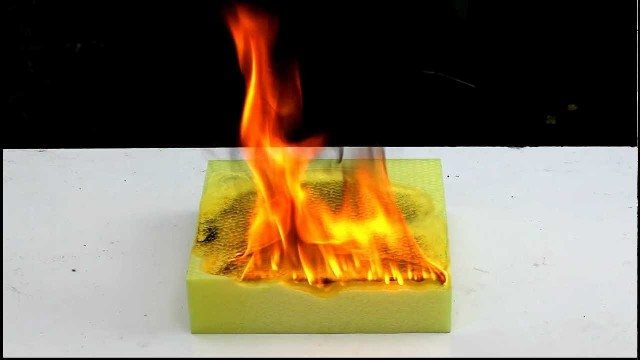

Technical characteristics also include the flammability class, and polystyrene foam plates represent the highest hazard classes: G3, G4. In addition, the dimensions of the material determine a number of parameters (absorption of impact noise, strength, thermal insulation properties).

Dimensions (edit)

The standard width of the slabs is represented by the only option - 600 mm. However, other sizes can vary significantly. For example, the length of the product is mainly found in two values: 1200 mm and 2400 mm.

Types of structure and material edges

Polystyrene foam thickness: 30-100 mm, with the exception of 70 and 90 mm. Regardless of what dimensions of the plate are chosen, it will be easy to work with the material due to its low weight.

However, thicker polystyrene foam products are characterized by increased resistance to heat outflow from the room. This means that with the help of such thermal insulation, it is possible to provide increased comfort on objects.

Flammability class

Expanded polystyrene products burn well, therefore they are ranked among the highest flammability classes: G3, G4. Also, this insulation is not prone to self-extinguishing. If a manufacturer claims that its products have similar specifications, it is best to contact those who offer reliable information about the material.

In theory, it is not recommended to use plates for thermal insulation of an object with increased fire safety requirements. However, there is SNiP 21-01-97, according to which the use of such materials is allowed. But it is better to use products of the G3 flammability class.

On the fire safety of expanded polystyrene: using European standards that differ from domestic ones. There, combustibility is determined by three evaluative characteristics: biological, chemical and complex.

In addition, in order to reduce the hazard level of the insulation at one of the production stages, fire retardants are added - substances with the help of which the technical characteristics of the material change somewhat and the plates go into the category of less hazardous (flammability class G1, G2).

Testimonials

Let's summarize the article with opinions about XPS insulation. The Internet has collected many responses about the product, both laudatory and negative. It is safe to say that most of the reviews are positive. Buyers note qualities such as environmental friendliness, easy installation, excellent performance and much more.

Customers who were unhappy with the purchase said that more effective and practical insulation can be found on the domestic market.

Thermal insulation at any temperature will not hurt. If it is carried out correctly, then in the winter the rooms will become noticeably warmer, and in the summer heat - cooler. Wall insulation will help create a comfortable microclimate both in the apartment and in the work room. Manufacturers have tried and the types of insulation today shine with a variety.

Having come to the market or to the construction supermarket, one can only be surprised at the variety of heaters produced. They lie rolled up and bundled, poured into containers in the form of granules, powders and perlite sand, looking out of the packaging with cotton wool. And they are also made in the form of a variety of cylinders, bricks, blocks and slabs. What should you choose? In principle, it is not the form that is most important, but the content. More on that later.

If you understand the characteristics of insulation materials, then you can easily choose exactly the one you need. The main property of a heat insulator is its thermal conductivity. It shows how much heat can pass through a given material. There are two types of thermal insulation:

- Reflective insulation reduces heat consumption by reducing infrared radiation.

- Thermal insulation of the preventive type (it is used in most cases) involves the use of insulation with a low thermal conductivity. In this capacity, one of three types of materials can be used: inorganic, organic or mixed.

Strirex. We tell about the plant, production and materials

released the first batch of heat-insulating materials - expanded polystyrene boards made by the extrusion method, in March 2007. The enterprise was promptly equipped with equipment allowing to set up large-scale production of a new generation of heat-insulating material - extruded polystyrene foam.

Even then - 9 years ago, STIREKS extruded polystyrene foam was manufactured on units with a production capacity of 250 thousand cubic meters per year. This indicator is constantly increasing due to the high demand for insulation.

Buyers - individuals, construction companies, like it:

• low thermal conductivity, • water resistance, • strength, • durability.

Safety should be mentioned separately: we use raw materials from large polystyrene producers, whose products do not contain harmful chemicals. regularly updates the assortment, offering thermal insulation for country houses, outbuildings, public and commercial establishments. Individual clients are offered thermal insulation "STANDARD", "STANDARD +", construction organizations - "PROFI", "PROFI +", "SPETS".

Preventive type thermal insulation

Organic heat insulators

Organic heaters are widely represented in the modern construction market. For their manufacture, raw materials of natural origin (waste from agricultural and woodworking industries) are used. Also, some types of plastic and cement are part of organic heat insulators.

The resulting material has a high resistance to fire, does not get wet, does not react to biologically active substances.It is used where the surface does not heat up above 150 degrees. An organic heat insulator is often used as the inner layer of a sandwich construction. These are, for example, triple panels or plastered facades. Next, consider what types of organic insulation are.

1. Arbolite insulation.

This fairly new building material is made from small sawdust, shavings, chopped straw or reeds. Cement and chemical additives are added to the base. These are calcium chloride, sulphate alumina and soluble glass. At the last stage of production, the products are treated with a mineralizer.

The characteristics of wood concrete have the following:

- Density - from 500 to 700 kilograms per cubic meter.

- The coefficient of thermal conductivity is from 0.08 to 0.12 watts per meter per Kelvin.

- Compressive strength - from 0.5 to 3.5 megapascals.

- Flexural strength - from 0.4 to 1 megapascals.

2. Polyvinyl chloride foam insulation.

PPVC consists of polyvinyl chloride resins, which after porization acquire a special foamy structure. Since this material can be both hard and soft, it is a versatile heat insulator. There are various types of insulation materials for walls, roofs, facades, floors and entrance doors made of PVC. The density (average) of this material is 0.1 kilograms per cubic meter.

3. Chipboard insulation.

Chipboards are basically fine chips. It is nine-tenths of the total volume of the material. The rest is synthetic resins, antiseptic agent, antiprene, water repellent.

The characteristics of the chipboard have the following:

- Density - from 500 to 1000 kilograms per cubic meter.

- Tensile strength - from 0.2 to 0.5 megapascals.

- Flexural strength - from 10 to 25 megapascals.

- Humidity - 5 to 12 percent.

- The absorption of water by the material is from 5 to 30 percent.

4. Insulation from DVIP.

The composition of the wood fiber insulation board is similar to particle board. The basis is either wood waste, or trimmings of straw and corn stalks. It may even be old paper. Synthetic resins are used to bond the base. The additives are antiseptics, fire retardants and water repellents.

The characteristics of the DVIP are as follows:

- Density - no more than 250 kilograms per cubic meter.

- Flexural strength - no more than 12 megapascals.

- The thermal conductivity coefficient is up to 0.07 watts per meter per Kelvin.

Wood fiber insulation.

5. Polyurethane foam insulation.

Polyurethane foam is based on polyester, to which water, emulsifiers and diisocyanate are added. Under the influence of a catalyst, all these components enter into a chemical reaction, forming a new substance. It has a good level of noise absorption, is chemically passive, and is not afraid of moisture. In addition, PU foam is an excellent heat insulator. Since it is applied by spraying, it is possible to process walls and ceilings of complex configuration. In this case, cold bridges do not appear.

Characteristics of polyurethane foam:

- Density - from 40 to 80 kilograms per cubic meter. Upon reaching a density of 50 kilograms per cubic meter, PUF becomes moisture resistant.

- The thermal conductivity coefficient is from 0.019 to 0.028 watts per meter per Kelvin. This value is the best of all modern thermal insulation materials.

Application of polyurethane foam insulation to the surface of the walls.

6. Mipora (penoizol).

If you beat the urea-formaldehyde resin, more precisely, its water emulsion, you get a mipora. To prevent the material from being brittle, glycerin is added to the raw material. Sulfonic acids derived from petroleum are added to form the foam. And the organic acid serves as the catalyst that promotes the solidification of the mass. Mipora is sold both in the form of crumbs and in blocks. If it is supplied in liquid form, then it is poured into special cavities during construction. There, at room temperature, it becomes hard.

Mipora characteristics:

- Density - no more than 20 kilograms per cubic meter. Compared to cork, this figure is about 10 times less.

- The thermal conductivity coefficient is about 0.03 watts per meter per Kelvin.

- The ignition temperature is over 500 degrees. If the temperature is below this value, then this material does not burn, but only undergoes charring.

- The disadvantages of the Mipora are its vulnerability to the effects of aggressive chemicals, as well as strong absorption of water.

- See material >> Technical characteristics of penoizol, its properties and disadvantages as a heater

7. Expanded polystyrene.

Expanded polystyrene, aka PPS, aka polystyrene, is 98 percent air. The remaining 2 percent is polystyrene, which is obtained from petroleum. Even in the composition of expanded polystyrene there is a small amount of modifiers. In particular, they can be flame retardants.

Properties of PPP:

- The thermal conductivity coefficient is from 0.037 to 0.042 watts per meter per Kelvin.

- Waterproofing qualities are high.

- Corrosion resistance - high.

- Resistance to bioagents and microflora is high.

- Flammability is low. The material is capable of decaying on its own. If polystyrene foam nevertheless ignites, then it emits heat energy 7 times less than wood.

Expanded polystyrene plates.

Plates of simple foam, can also be attributed to this type of insulation.

8. Foamed polyethylene insulation.

If a foaming agent (one of the types of hydrocarbons) is added to polyethylene during the manufacturing process, then we get a material with numerous small pores inside. It has good vapor barrier properties and excellent protection against external noise.

Foamed polyethylene properties:

- Density - from 25 to 50 kilograms per cubic meter.

- The thermal conductivity coefficient is from 0.044 to 0.051 watts per meter per Kelvin.

- Application temperature range - from minus 40 to plus 100 degrees.

- Moisture absorption is low.

- Chemical and biological passivity is high.

Foamed polyethylene in rolls is often produced in a special shape for pipe insulation.

9. Fibrolite.

Taking as a basis narrow and thin wood shavings, which are also called wood wool, adding cement or a magnesian component for binding, we get fibrolite. It comes in the form of slabs. This material is not afraid of chemical and biological aggressive influences. Good protection against noise, and can also be used in rooms where it is very humid. These are, for example, swimming pools.

Fiberboard characteristics:

- Density - from 300 to 500 kilograms per cubic meter.

- The thermal conductivity coefficient is from 0.08 to 0.1 watts per meter per Kelvin.

- Fire resistance - high.

10. Sotoplast insulation.

As a rule, this material consists of hexagonal cells that resemble honeycombs - hence the name. However, there are types of honeycomb, where the shape of the cells is different from the hexagon. The filler is a special fabric or paper based on carbon, cellulose, organic or glass fibers coated with a film. These fibers are bonded with thermosetting resins - phenolic or epoxy. The outer sides of honeycomb panels are thin sheets of laminated plastic.

Artificial heat insulator properties

The material for thermal insulation is made from polystyrene granules with the addition of a blowing agent. Freon or carbon dioxide is used as such an additive. Substances are heated to a high temperature, and a viscous polymer mass is forced through an extruder (molding mechanism). The result is expanded polystyrene extruded with small closed cells.

This technology provides a homogeneous material structure and the same particle size of 0.1-0.2 mm. Closed, gas-filled cells perform heat insulator not heavy, give low water absorption and heat conductivity. The material does not let moisture inside and is not afraid of contact with it.Extruded foam (EPPS) can be used in places where it comes into contact with water without installing a hydro-barrier.

The tight placement of closed capsules creates an impenetrable barrier to the vapor in water and air. The material has a low vapor permeability coefficient.

This quality in different situations becomes an advantage or disadvantage of a heat insulator. If you need a vapor barrier device, for example, when insulation inside

EPPS comes with the word. But in many cases it interferes with the normal movement of air and requires additional ventilation in order to destroy very high humidity.

In terms of heat saving, synthetic-based material surpasses:

- foamed polymer - 1.5 times;

- mineral wool - 2 times;

- tree - an order of magnitude.

Insulation plates

have greater strength and resistance to mechanical loads, which makes it possible to use them in areas with high loads (foundation, construction of highways and additional structures).

Ignoring the artificial components, the material differs in environmental purity and is less dangerous to humans. It is resistant to mold and mildew, but rodents can upset the slabs. The insulation is resistant to most chemical compounds, but decomposes under the influence of gasoline, acids and organic solvents.

Characteristics of extruded polystyrene foam

- heat conductivity - 0.028-0.034 W / m * K;

- steam permeability index - 0.015;

- density - 28-45 kg / m3;

- water absorption - 0.4% of the volume of the material;

- heat insulator is in operation in the temperature range - from? 50? up to +75? C;

- service life - 40-50 years.

Reflective insulation

Heaters, called reflex, or reflective, work on the principle of slowing down the movement of heat. After all, every building material is capable of absorbing this heat and then emitting it. As you know, heat loss occurs mainly due to the exit of infrared rays from the building. They easily penetrate even materials with low thermal conductivity.

But there are other substances - their surface is capable of reflecting from 97 to 99 percent of the heat reaching it. These are, for example, silver, gold and polished aluminum without impurities. By taking one of these materials and building a thermal barrier with a polyethylene film, you can get an excellent thermal insulator. Moreover, it will simultaneously serve as a vapor barrier. Therefore, it is ideal for bath or sauna insulation.

Reflective insulation today is polished aluminum (one or two layers) plus polyethylene foam (one layer). This material is thin, but gives tangible results. So, with a thickness of such an insulation from 1 to 2.5 centimeters, the effect will be the same as when using a fibrous heat insulator from 10 to 27 centimeters thick. As an example, let us name Armofol, Ekofol, Porileks, Penofol.

A type of reflective insulation.

So, we have listed all types of insulation and their characteristics. When choosing one of them, pay attention to the possibility of its complex application. After all, it's not bad if this material not only insulates your house, but also protects against noise and gusts of wind.

Material advantages

Extruded insulation has a lot of characteristics that are attractive to the consumer.

Durability and reliability

XPS is characterized by increased resistance to deformation of various types. It can be bent, squeezed or stretched - this will in no way affect the decrease in its quality characteristics.

The unique strength of the insulation allows it to withstand even a 50-ton load applied to 1 m2, which is explained by the strong bond between the material molecules.

Moisture proof

Insulation is considered to be quite durable due to its immunity to moisture absorption (expanded polystyrene plates have zero capillarity).This property is not even affected by the proximity of groundwater and humid land. Only the outer shells of the material are filled with moisture, and its core is reliably protected.

Incombustibility

The fire safety of the material has been confirmed empirically and is explained by the addition of flame retardants (substances that prevent combustion) with increased efficiency in the production process.

According to the modern classification, XPS can have different flammability classes: from the weakest - G1, to G4. However, even a material with a high flammability class does not support the spread of fire and extinguishes within a short period of time if there is no open fire nearby.

It is important to understand that extruded polystyrene foam can only catch fire when exposed to very high temperatures, and at low temperatures it simply melts and does not pose a particular threat.

Given the fact that most fire deaths are caused by carbon monoxide or chemical fumes, XPS's low toxicity is important. In the event of smoldering or fire, this insulator practically does not emit harmful substances into the atmosphere.

Optimum thermal conductivity

The thermal conductivity of a material depends on how much air is in its composition: the more there is, the higher the thermal insulation characteristics. Extruded insulation consists of 10% polymer and 90% air, which is due to the foaming process.

For comparison: a 20 mm thick extruded polystyrene foam board has the same thermal conductivity level as a 30 mm piece of foam, a 200 mm thick wood board, 370 mm thick brickwork or about 40 cm thick mineral wool.

Other advantages

There are several more significant advantages of insulation:

- The XPS Isolator can be frozen and thawed 500 to 1000 times. At the same time, it will not change its quality characteristics for the worse, and the thermal resistance of the material will not exceed 5%.

- Expanded polystyrene is immune to alkalis, acids and mineral fertilizers, does not react in any way to contact with soap, soda, gypsum, bitumen, asphalt or cement.

- The insulation has a high biological resistance. This means that the material does not attract insects, harmful rodents at all, it is not afraid of mold and other microorganisms.

- The material is resistant to climatic and temperature extremes and can be used in the range from -75 to +75 degrees. Also, it practically does not deteriorate under the influence of active ultraviolet radiation, which cannot be said about foam.