A gas-fired sauna stove is undoubtedly the most economical option for heating a steam room. This type of fuel is much cheaper than wood or coal; it does not need to be procured and stored in specially adapted rooms. Therefore, more and more of our compatriots decide to install a gas burner in an already operating solid fuel furnace. It is much more profitable than buying a new heater for a bath or sauna.

In this article, you will learn how to choose the right gas burners for your sauna stoves. We will tell you what to focus on when buying such devices, and introduce you to several of the most high-quality and practical models from.

Benefits of using gas burners

Let's note the most important advantages of this heating equipment:

- You don’t have to waste time and effort to fire up the stove. It is enough to open the valve and simply ignite the burner. Within an hour and a half, the steam room will warm up to the desired temperature.

- You can save a lot. Gas heating is 20-30% cheaper than wood heating. And if we compare such ovens with electric ones, then the benefits will be even more impressive - about 100-120%.

- You will ensure the maximum fire safety of your bath. The gases formed during the combustion of this type of fuel do not heat up to the critical temperature that can cause a fire. Therefore, you do not have to additionally insulate the chimney at the points of contact with the roof.

Thus, a gas burner for a stove in a bath will greatly facilitate the whole process of heating a steam room and save you from the need to prepare and store firewood.

We suggest that you familiarize yourself with the varieties and features of such devices.

The nuances of installation and operation

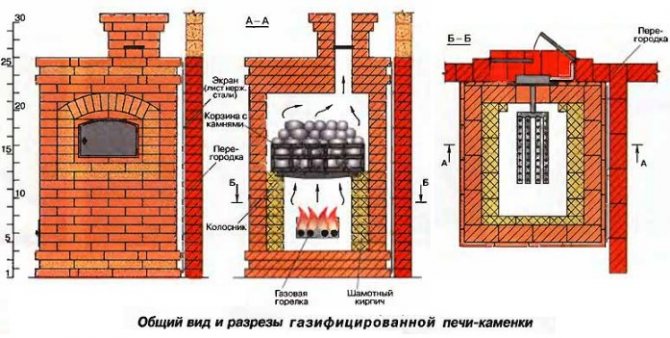

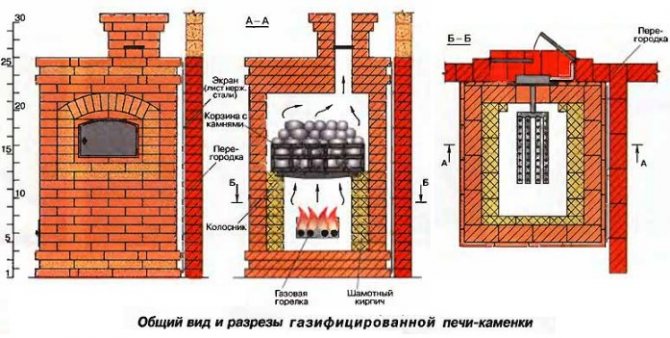

Gas burners for heating furnaces, having a block device, can heat up to + 1300C. While they are working, the temperature remains within the operating temperature, and the boiler does not overheat. The nozzle cools the incoming air. In the off state, there is no cooling, respectively, heating is in progress. This must be remembered if the gas burner installation is built into a brick oven, where temperatures reach + 5500C. With this design, it is necessary to use high-temperature heat-resistant materials to insulate the nozzle so that the automation network is not damaged.

The gas burner, after use, is turned off during brickwork, since continuous exposure to high temperatures can lead to the formation of cracks in the brick or the masonry itself. Heating up the stove with a burner is done slowly and cyclically.

In terms of operational reliability, imported (Italian, German) burners are in many ways superior to domestic models. They are easier to install, monitor operation, and additional functions ensure complete operational safety. But it is worth taking into account the reduced pressure in the domestic gas pipeline - in domestic gas burners this fact is taken into account, in European ones it is not.

Types of gas burners

There are only two main types:

- Atmospheric burners

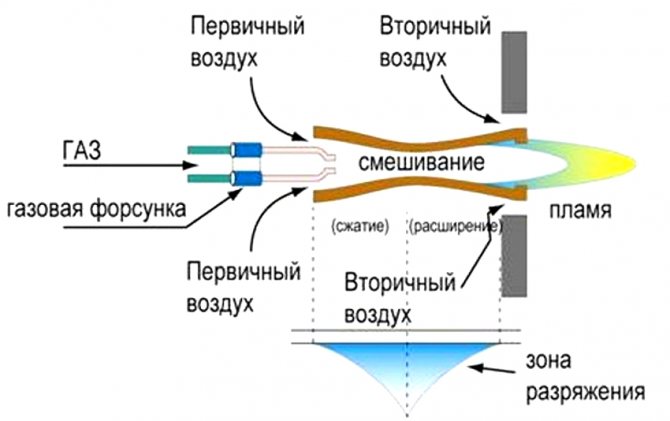

... Atmospheric gas generators are distinguished by their affordable cost, ease of manufacture and operation. Such devices provide mixing and combustion of gas in the firebox due to atmospheric pressure drops. They function without electricity, but are highly dependent on the movement of air in the room where the oven is located. With any tangible movement of air, the amount of heat generated by the firebox changes in one direction or another.When using an atmospheric burner, it is necessary to equip an additional air source in the room and constantly monitor the condition of the chimney. It should also be borne in mind that the fuel in such a furnace will not be completely burned, part of the gas will inevitably go into the pipe.

When installing an atmospheric burner, you will have to seriously improve both the fuel chamber and the burner itself. This is due to the fact that in a standard-sized chamber, the flame will touch the bottom of the stove or the metal elements of the stove. To remedy this state of affairs, it is necessary to place the fire source as low as possible and strictly in the center of the firebox.

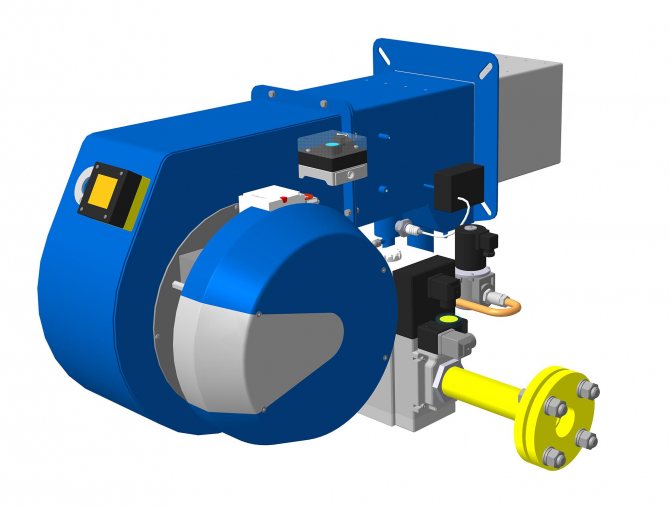

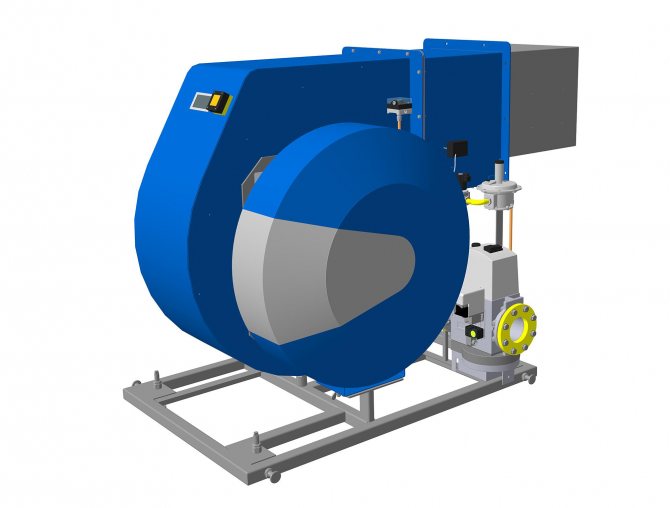

- Pressurized burners

... Supercharged gas generators are considered to be more practical and convenient in operation, since they provide a forced flow of air into the fuel chamber. Such devices are equipped with a special fan, the rotation speed of which determines the speed of fuel combustion in the chamber.The pressurized gas burner for the sauna stove is powered by electricity - and this is perhaps its only significant drawback. In the event of a power outage, she will not be able to start the process of heating the steam room, so for such situations it is good to have an alternative option. When choosing such devices, it is important to take into account the depth of the fuel chamber so that the fire does not hit its rear wall.

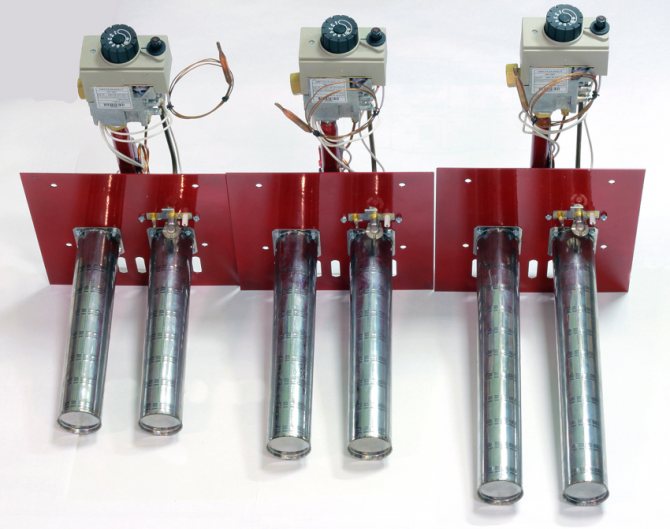

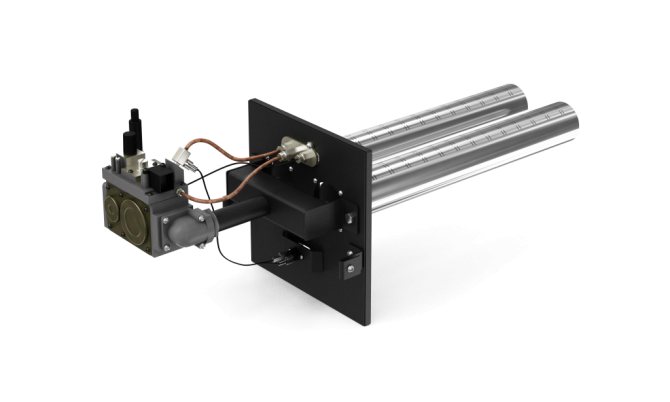

Burner AGG-40P for the Siberia 30 LK furnace, Siberian cliff 20 with a remote fuel channel.

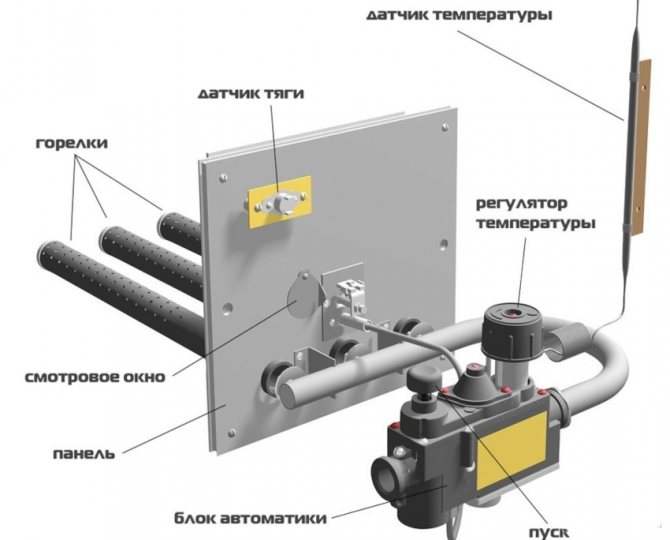

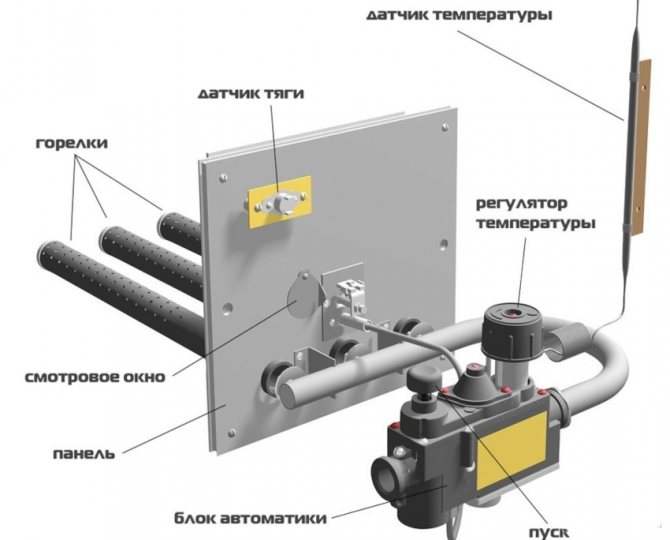

What is a gas burner and what does it consist of

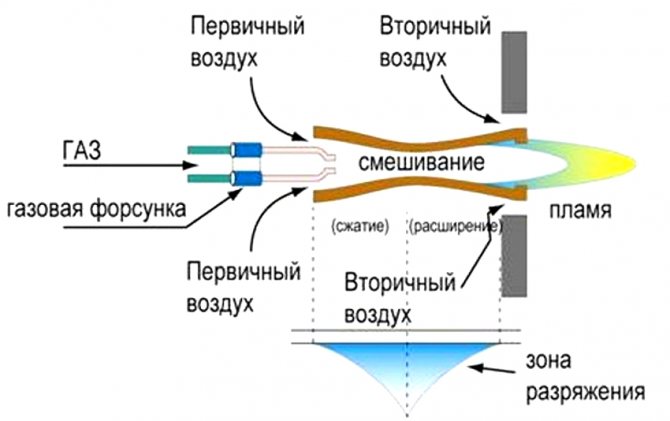

Any device designed to burn liquid and gaseous fuels has a main unit - a burner. She is responsible for the formation of a uniform flame. The fuel mixture can be of different qualities, but a well thought out method of fuel delivery will ensure complete combustion of any combustible mixture.

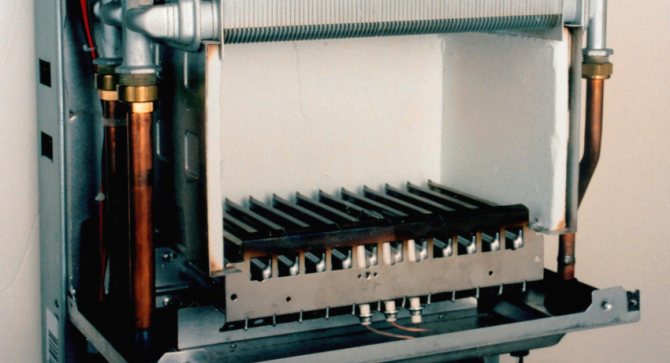

Atmospheric gas burners for boilers have a very simple design

The most important indicators of a high-quality gas combustion device are silent operation and the absence of emission of harmful compounds when burning fuel, in particular carbon monoxide. A modern household gas burner for a heating boiler is a simple device that has gone through a long modernization process. Some old structures produced during the Soviet era made a lot of noise and were far from safe, especially in strong winds.

Many parameters, including the noise level, are influenced by the design features of the combustion chambers. In new types of burners, much attention is paid to the convenience of ignition and uniform flame supply. The design features of a gas burner for space heating are very simple:

- ignition of gas is provided by the ignition system;

- the gas ignites in the nozzle;

- automation is designed to control the main indicators: temperature, uniformity of gas distribution, emergency shutdown;

- the presence of fire is monitored by a special "flame detector".

From the premises, by-products of gas combustion must be discharged outside so that harmful impurities do not fill the space. A chimney with good draft is required to remove the gas. This is the only drawback of gas heating. The gas burner device itself is constantly being improved, including the following indicators:

The noise level of a gas burner depends on the design of the combustion chamber

- heat generation schemes;

- rational oxygen supply;

- ways to remove soot and carbon dioxide.

Gas burners for boilers: basic requirements and operation scheme

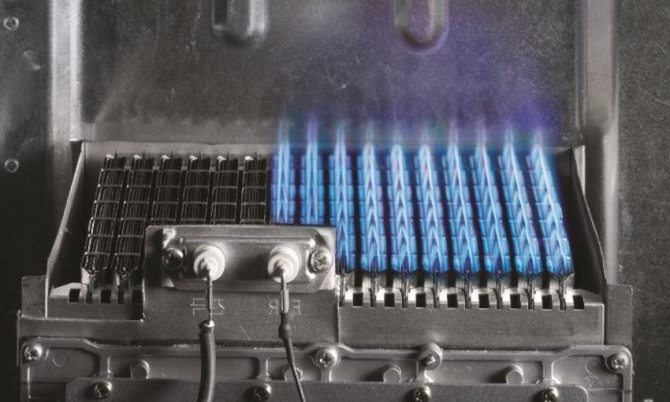

The heat released during the combustion of gas is concentrated in a heat exchanger, from where it is transferred to the heat carrier. Together with a small amount of heat, part of the combustion products is discharged into the atmosphere. A chemical reaction of heat release takes place: at high temperatures, the combustion gas combines with oxygen coming from the air.The principle of operation of a gas burner is based on the combustion of gas and the release of heat. Water vapor and carbon dioxide are by-products of the chemical reaction associated with heat production.

Hazardous substances include nitric oxide, carbon monoxide and some resinous components. Because of this, special requirements are placed on the hood and chimney - good draft is important.

According to modern requirements, in any mode, gas burners for heating boilers with automation (and other types) should be of low toxicity. It is required that during the combustion process only slightly toxic gases and a small amount of soot are released, which is a general condition for the use of most types of raw materials for heating.

A properly thought-out method of fuel supply will ensure its complete combustion

Basic requirements for a boiler burner:

- availability for self-installation;

- clear design diagram;

- long period of operation;

- operational reliability;

- insignificant noise threshold;

- convenience of switching modes;

- the ability to work on a different type of fuel;

- complete combustion of gas;

- high environmental performance (few harmful combustion products are released).

Helpful advice! In order to extend the service life of the equipment, carrying out timely repairs of the gas burner for the boiler, it is important to purchase components only from trusted manufacturers.

As you know, a cheap product indicates a low quality of products and a short service life. Often, repairs are impossible, especially if there is no warranty period and factory certificate. High-quality household gas burners for heating boilers are always on sale. Their price is quite acceptable for most consumers.

Which burner should you choose?

Thinking about re-equipping the stove for gas fuel, sooner or later you will be faced with the question of choosing the most suitable burner for this purpose.

There are the following alternatives:

- Atmospheric or supercharged.

The owners of large baths and saunas increasingly prefer more expensive, but convenient pressurized burners. Their important advantage is that they require a minimum of attention and personal participation from the user, working regardless of external conditions and air pressure drops. For heating a small steam room, an inexpensive atmospheric burner is quite suitable. - One- or two-stage.

Devices of the first type automatically turn on and off the fuel supply, while the latter have an economical heating mode. There are also models with floating control, which allow you to change the power of the equipment as smoothly as possible. The choice of a gas burner for a sauna stove depends in this case on the mode in which you plan to heat your steam room. - Exclusively gas or combined.

Gas burners are distinguished by a relatively simple device and an affordable price. However, they only pay off if there is an uninterrupted supply of fuel. Combined burners are designed to work with natural and liquefied gas, as well as with diesel fuel. The latter option is especially good for large baths, since it provides quick heating of rooms of any size.

Gas burners for sauna stoves manufactured by TMF - high quality at a reasonable price

Technical development and modernization affect even such seemingly traditional areas as wood heating of baths. TMF engineers have developed several models of gas and combined stoves, bath and heating, using gas as the main or alternative fuel.

The main element of such a furnace is a gas burner. In Novosibirsk, it is best to purchase it in company stores or order it on the website.In this case, you can be completely sure of the compatibility of the model with the proposed equipment.

Gas burner selection criteria

Experts recommend, first of all, to answer the following questions:

- What technical characteristics should the device have? Decide on the power, efficiency level and efficiency of the burner you need, focusing on the features of the heating system used.

- In what room is the oven used? For a small steam room, an inexpensive atmospheric burner is suitable, while for a more spacious room, it is better to choose a more expensive but efficient pressurized model.

- Are there power outages? If so, consider an additional power source for the forced draft burner.

- What fuel do you use to heat your sauna? Remember that there are devices that are only compatible with main gas, and there are universal burners that work with other types of fuel.

When heating a steam room, it is extremely important to ensure an even distribution of heat throughout the room. Therefore, it is better to choose burners that disperse the flame well, or supplement the selected device with a torch diffuser or distribution pipe.

Another important point to pay attention to is the correspondence of the threads on the burner and on the gas supply pipe. They should match perfectly without the slightest gaps and gaps.

And finally, the documentation. Quality burners always have an official passport confirming that the device complies with existing safety standards.

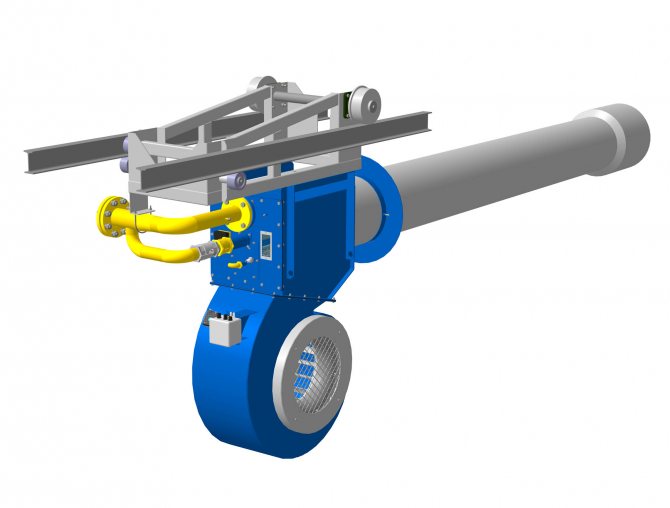

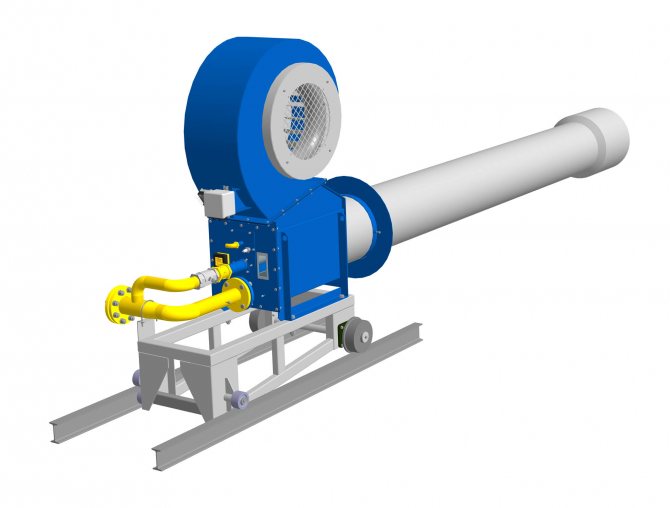

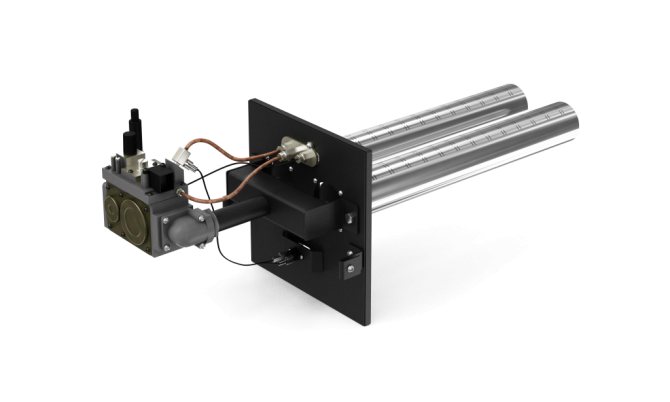

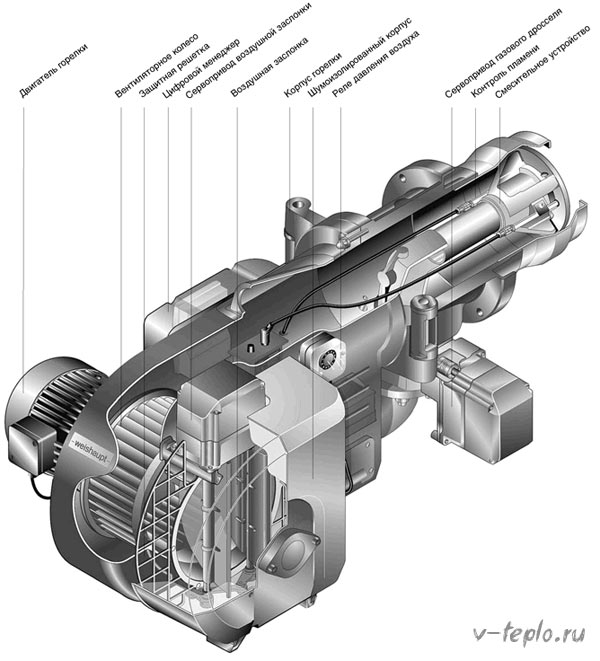

Fan burners

Fan-type gas burners operate on a slightly different principle: in this case, oxygen is supplied forcibly, and its volumes are accurately controlled. In most cases, they are used in boilers with closed combustion chambers, pressurized. In such models, the fuel is mixed with oxygen already at the outlet.

Fan burners (they are also called forced draft) are used in the boiler equipment where there is a high level of automation, and human participation in the process is almost completely excluded.

It is also worth noting that such devices are usually characterized by block execution. In such cases, there is a gas multiblock, which consists of:

- gas filter;

- pressure regulator;

- a relay, which is necessary to turn off the device in the event of a decrease in pressure and forced ignition in the event of its resumption;

- fuel consumption regulator;

- reducer.

Note! More modern multiblocks also include a relay that controls the operation of the fan. If the electric motor stops, the relay switches off the burner.

Such gas burners for boilers are volatile, therefore it is recommended to additionally equip them with a constant power source. It is not necessary to adjust the burner in the boiler, since there is a servo drive that controls the position of the air damper (it is necessary to adjust the amount of oxygen going to combustion).

Everything we've just said relates to the advantages of fan devices, but there are also disadvantages. So, in order to install them, the boilers are completely remodeled. Moreover, it is generally better not to install it in solid-fuel devices (such as "Don"), since all upgrades regarding flame modulation will still not bring results (read: savings), because the heat exchanger will be poorly insulated and ineffective.

Gas burners for the Teplodar furnace

The assortment of this domestic manufacturer includes heating systems for houses, summer cottages, garages, baths, saunas and many other buildings of any size and purpose.The company produces furnaces and boilers compatible with different types of fuel, as well as components for the conversion of already operating devices.

So, you can purchase a branded gas burner "Teplodar", capable of operating on natural gas or liquefied gas. The device is intended for sauna stoves "Rus", "Domna", etc. Installation of such a burner is easy and quick, without additional metalwork and welding works.

If you are just planning to buy a heating system for a steam room, we suggest paying special attention to the compact but powerful heater "Rus 12 LNZP PROFI". The device provides rapid heating of stones and air, an even distribution of heat throughout the room and a large amount of wet steam to create the ideal atmosphere of a classic Russian bath. Such a stove is perfect for steam rooms with a volume of 6-12 m3.

Another option - "Siberia 30 LK" - is intended for more spacious premises with a volume of up to 30 m3. Such a stove heats the air to very high temperatures (100–110 ° C) and produces dry steam, which is necessary to create a microclimate in a Finnish sauna. The manufacturer has provided a protective convector casing and stylish decorative inserts made of mirror steel.

Stove for baths and saunas Siberia 30 LK with AGG40P.

In the Teplodar catalog you will always find a high-quality and inexpensive sauna stove for a gas burner, and the company's consultants will be happy to help you choose the most suitable model and answer all your questions.

Ignition type

All burners can be divided according to the type of ignition:

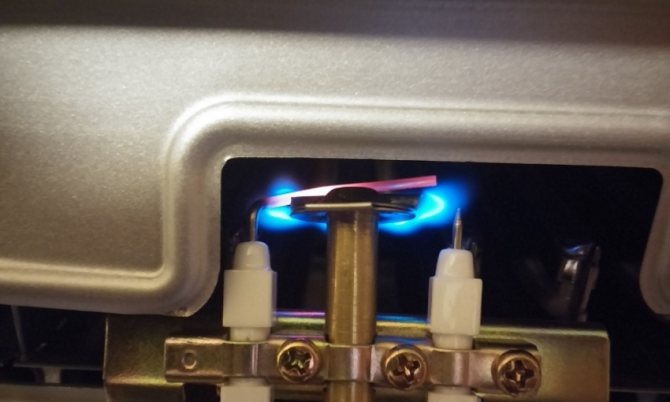

- Electronic type... They do not have a constantly working igniter. It requires electricity to work. Electric ignition is one of the most convenient inventions for modern heating units. Thanks to him, the operation of the stoves has become as comfortable as possible. Electric ignition makes it possible to ignite the burner flame safely, without using any available wicks or lighters.

- Piezo ignition burners... No electricity needed.

Sometimes special working conditions are required, for example, burners are placed in the sauna stove, which should distribute the flame well. These are splitters or conventional distribution tubes. This is how kitchen gas ovens work.

The consumption of fuel passing through the burner can vary widely and depend on its design.

Furnace gas nozzles must be safe and energy efficient. This can be achieved if all technical requirements are met. Self-activity in this matter can only harm. Therefore, the installation of gas burners must be carried out by specialists.

Delivery from 2 days

Warranty and service

Contact our manager and report a malfunction

How stove gas heating works

A modern gas stove for heating a house functions on the same principle as its wood-burning counterparts. In any case, this will be a local system, which, as a rule, does not use a liquid heat carrier, but heats the premises due to the convective movement of air heated from hot surfaces. The main difference is that it is not wood or coal that burns in the firebox, but combustible gas mixed with air in a certain proportion.

Note! A hot water heating circuit or a water tank can be integrated into a gas-fired heating furnace without any problems, as well as an air distribution system to adjacent rooms can be connected to it.

This heater uses gas as fuel and has a built-in water tank.

Sometimes gas stoves are combined with electric or solid fuel heating devices. Gas burners are also used, which, if necessary, switch to liquid fuel.

Note! Solid fuel stoves with a built-in gas burner do not cool down between the furnaces, therefore, for a number of technical reasons, their productivity increases significantly, and the temperature regime in the premises for comfort is close to that of central heating.

Gas nozzle for oven

Modern stoves and even fireplaces have long pushed firewood into the background, since today they work with gas, using special equipment - a gas nozzle.

Before you start using a home-made product with your own hands, you need to go through the following procedures:

- The burner must pass a quality check at the local Rostekhnadzor office in accordance with the regulations established in the Federal Law on the Safety of Buildings and Structures of 12/30/2009.

- After this check, it is necessary to obtain a certificate from Rostechnadzor about the suitability of the burner for operation.

https://www.youtube.com/watch?v=ytcopyright

In order to start making a nozzle, you need the following materials:

- A valve that will serve to regulate the fuel supply by the device. To supply gas to the burner, use the valve installed on the gas source.

- Steel pipe. It is desirable that it has a thickness of up to 2 mm and a length of up to 100 mm.

- Steel cap for making the fuel dispenser. You can also use a blowtorch jet.

- Steel handle. It can be made from a conventional fitting.

- Rubber for handle lining.

- Wire. It will be used for welding.

You will also need the following tools:

- Welding machine.

- Grinder for cutting parts.

For handicraft, an atmospheric nozzle is preferable due to the simplicity of its design. The procedure is as follows:

- First, the cap is screwed onto the valve. For example, if a standard VK-74 valve is used, then the cap has a tapered thread.

- Then, by cutting the existing steel pipe with a grinder to the required dimensions, the nozzle of the future nozzle is made - its basis.

- Next, the nozzle is welded to the cap using a wire. In this case, the cap and the nozzle should not touch.

- A piezoelectric element is installed, which is needed to activate the device.

After that, the product is ready for installation.

Attention! To install a system for supplying fuel to a stove from a central heating system, special equipment and experience in working with gas systems are required.

Furnace installation

When installing the finished unit in the furnace, take into account what materials it is made of:

If we are talking about a brick stove, then the obvious disadvantage will be the high cost and complexity of such a design, which is assembled only by a specialist. In this case, the nozzle is mounted inside the oven.

- In turn, the installation of the unit in a metal furnace is much easier and can be done without the involvement of specialists. In this case, the nozzle is mounted directly into the stove so that the flame enters the boiler in sufficient quantity to form a fuel mixture.

The gas nozzle - the heart of the stove - must be of high quality and correctly installed. If this unit malfunctions, fuel-related problems may arise, which can lead to irreversible consequences.