After installing a condensing double-circuit boiler, many users are considering installing an additional pump in the heating system of a country house. The need to use an additional pumping device is explained by the uneven heating of the living quarters of a two-story house with sufficient boiler equipment power.

Advice! If the temperature differences of the coolant in the supply and return pipelines exceed 20 degrees, it is necessary to switch the circulation pump to an increased speed or get rid of air jams.

Installing another pump is necessary in such cases:

- When installing heating in a private house with an additional circuit, or in the case when the length of the pipes is more than 80 meters.

- For uniform supply of heating agent through the heating system.

There is no need to install an additional pump if the heating is balanced with special valves. Therefore, before purchasing pumping equipment, bleed the air from the heating radiators and add water, check the circuit for leaks using a manual pressure pump. If, after carrying out such procedures, the autonomous heating of a private house will work normally, then another pump will not be needed.

Why do I need a hydraulic arrow

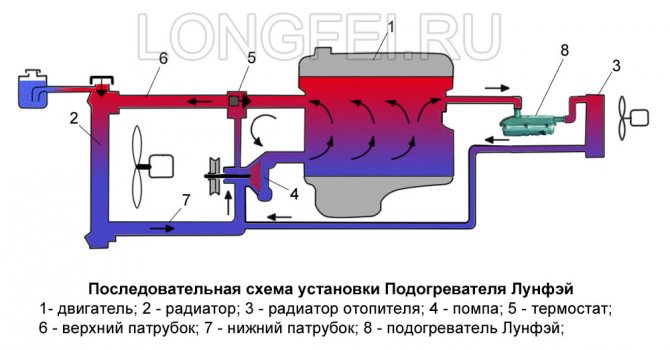

If several pumps are installed in the heating system of a summer house or cottage, a hydraulic separator or a hydraulic arrow must be included in the circuit. The specified device can be operated together with a single-circuit diesel boiler or solid fuel unit. In the latter case, the device regulates the supply of the coolant in different phases (fuel ignition, combustion phase and attenuation). Installing a hydraulic arrow allows you to balance the operation of the heating system. The main tasks of the hydraulic separator are:

- Automatic removal of accumulated air;

- Capturing dirt from coolant streams.

Important! The hydraulic arrow in heating allows you to balance the operation of the system, protects it from airborne air, and prevents the accumulation of dirt in the pipelines. Such a device must be installed without fail in the presence of several booster units.

Installation nuances

When installing the heating on a turnkey basis, the master plumber installs a circulation pump with a wet rotor. Such a device does not create much noise, its rotor rotates without lubrication. A heat carrier is used here as a coolant and lubricant. When installing pumping equipment, you need to take into account the following nuances:

- The shaft of the pressure generating device is positioned horizontally in relation to the floor plane.

- Install in such a way that the direction of the water coincides with the arrow on the device body.

- Install the instrument with the terminal box facing up to prevent water from entering the electronics.

Important! Experts recommend installing the pump on the return pipe of the heating system of a one-story or multi-story residential building. Despite the fact that such equipment is designed to work in hot water with a temperature of up to 110 degrees, a warmer liquid on the return pipeline will only extend the service life.

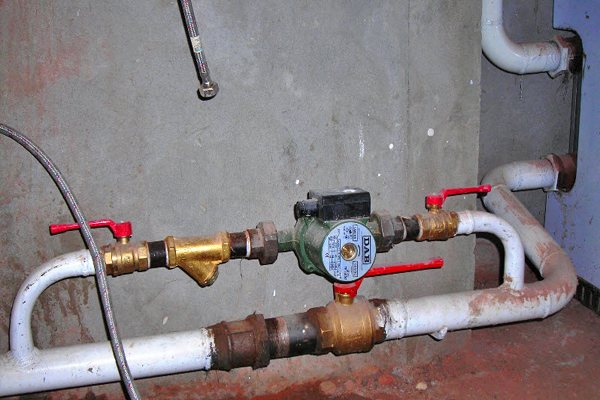

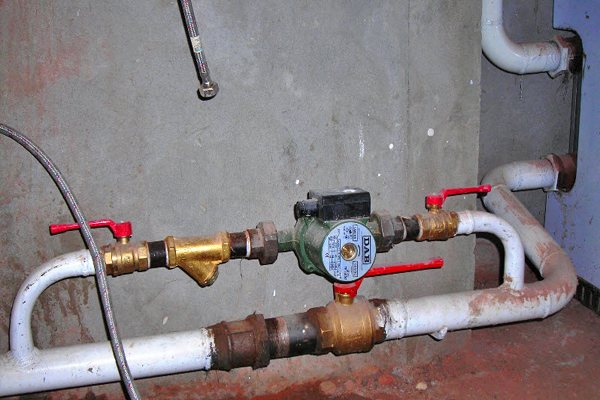

The installation of the unit is carried out only after the water has been drained from the system. In the event of a power outage, the pump will not be able to pump the coolant, therefore it is connected through the bypass, a mesh filter is installed in front of the inlet pipe to prevent scale and debris from entering the impeller.In addition, shut-off valves are provided at the inlet and outlet of the device for possible replacement and repair of the device.

As we can see, the installation of a circulation pump requires certain skills, therefore, the installation of this equipment should be carried out by a professional. To order the service, you can leave a request on the website or call

Benefits

Using a pump of this type has many advantages:

- increasing the efficiency of the system;

- rapid heating of air in rooms and an increase in the heated area;

- alignment of temperature indicators in the pipeline;

- exclusion of airborne pipes;

- reduced fuel consumption;

- the ability to install heated towel rails, thermostats;

- the use of small diameter pipes;

- democratic cost of equipment.

A circulation pump is an opportunity to quickly improve the quality of heating a house without dismantling the entire system and spending big money.

Parameters

The installation of this equipment requires taking into account its parameters, the diameter of the pipes, the pressure force and temperature of the water, the density of the coolant.

H - designation of the pressure, the ability of the device to raise the liquid to a certain level. The parameter is measured in meters. Q - liquid flow rate in the heating system for a certain period of time, calculated in m3. This value is equal to the boiler power parameter. The flow rate of the coolant depends on the diameter of the pipes.

The circulation equipment is not designed to raise water, therefore, when purchasing it, you need to pay attention to the Q parameter. If the boiler is not equipped with a pump, then the liquid flow rate must be calculated. A similar unit is already built into modern heating devices.

Additional pumping equipment is installed in the event that the boiler is of an old modification, the heating design has been increased due to the expansion of the house area.

It makes no sense to buy a high-power unit: they will not use it in full force anyway. Moreover, such a device is too noisy. The length of the pipeline determines the capacity of the pumping equipment: for every 10 m of the pipeline, 0.6 m of pressure is required from it. A ring 100 m long will work efficiently and efficiently with a pump head of 6 m.

When buying pumping equipment, you need to remember that its power should be 10% more than the value that was calculated.

Advantages of preheaters and their disadvantages

The list of the main advantages includes:

- Reducing the total fuel consumption of a car by reducing the cost of warming up the engine;

- Reducing the amount and level of toxicity of emissions into the atmosphere due to the same decrease in the amount of fuel burned for heating. This is especially true for electric heaters;

- Prolongation of the engine's service life, it is not a secret that during a cold start and engine operation before warming up, the degree of wear of the internal combustion engine increases;

- The ability to generally start the engine in severe frost conditions;

If we talk about the shortcomings of this device, then they, in addition to the cost and installation difficulties, are practically nonexistent in relation to branded quality products. At the same time, it is not recommended to install the heater unnecessarily when the car is located in regions with mild and temperate climates, that is, there is no significant decrease in the outside air temperature in winter.

For this reason, it should be noted that there is not always a general need to purchase and install this device. For example, when the car is put in an insulated garage at night, as well as when the air temperature rarely drops below 5-10 degrees, a hood insulation, engine compartment or a regular car blanket will be enough.These features should also be taken into account when buying a vehicle, especially in the case when the heater can be included in the list of standard vehicle equipment and is already included in its final cost.

Types of pumps

For the energy carrier to circulate efficiently, dry and wet pumps are used.

Dry

In equipment of the first type, the contact of the rotor with the coolant is not provided. The seal used in such a device hermetically separates the pump itself from the motor. The efficiency of this equipment is 80%, so it is advisable to use it when constantly pumping a large amount of liquid.

The area of application of dry pumps is shopping centers, factories, factories. In private houses, such structures are not used due to the high level of noise generation.

Wet

The rotor of wet pumps is in the coolant, which they are pumping. Water cools down the engine. The stator included in the structure serves for the supply of electricity. Pumps with a "wet" rotor have a lot of advantages: long service life, rare maintenance, low noise generation, small size, ease of block replacement.

Cons - low efficiency (about 30-50%), limited scope (private houses and city apartments), inability to use pumps for drinking water and for everything related to food.

Installation technology

Installation of a circulation unit is a process that requires adherence to a certain sequence of work.

Preparation

Experts recommend purchasing a pump with split-type threads. If they are not there, then you need to buy these parts additionally. You will also need a deep filter.

Before installation, a check valve is prepared: this normalizes the operation of the heating system.

You will also need special keys, fittings, a pipe, small in size, with a diameter equal to the diameter of the riser.

A place

Modern circulating pumps can be installed both on the water supply pipe and on the return pipe.

Installation performed on a bypass (a jumper installed between the direct and return wiring of the heating radiator, a pipe segment) requires a preliminary check of the device's ability to withstand a strong pressure of hot water.

In houses equipped with a "warm floor" system, the injection device is installed at the place where hot water is supplied: this will exclude the airiness of the pipeline.

If there is a diaphragm tank, the bypass with the pump is placed on the return pipeline, closer to the expansion tank.

Installation

The heating system can be made of metal or eco-plastic. There is no difference for the installation of pumping equipment. It is inserted by tracing. If the pipeline is made of metal, then you can purchase a ready-made structure for bypassing the main highway.

First, you need to drain the water, clean the heating structure, rinsing it several times.

Then, on the side of the main pipe, according to the diagram, a U-shaped piece of pipe is mounted, in the middle of which a pump is built. Ball valves must be installed on both sides of this unit. What is it for?

First, the natural circulation of the coolant will be restored if one of them is shut off. Secondly, you can repair or replace the circulating equipment if you turn off both taps, and you do not need to drain the water from the system.

During installation, pay attention to the direction of water movement (marked with an arrow on the pump unit housing).

After that, the system is filled with a coolant and checked for operability. Any errors need to be corrected at this stage.

Then unnecessary air is removed from the pipeline using a central screw. If everything is done correctly, liquid will begin to emerge from the special hole.

Pumping equipment with manual control requires the removal of air before starting work: it is turned on for a few minutes and the valve is opened, this is repeated several times.

After filling the pipes with water, the pumping device will turn on. The presence of air in the pipeline is excluded.

Top manufacturers of double-circuit and single-circuit systems

The most popular and popular boilers on the market are Italian, Korean, German and Russian devices.

- Bosh is a line of German devices with heat exchangers made of copper pipes with a sputtered anti-corrosion coating. Equipped with advanced electronics and security systems. The service life reaches two decades.

- Viessmann - German boilers with efficiency reaching 93%.

- Beretta - gas heaters of the Italian manufacturer for high power. The devices proved to be excellent in work under severe winter conditions.

- Baxi - heating systems with a quiet atmospheric burner. There are products for any capacity.

- Olympia is a Korean-made double-circuit gas boiler with an automatic weather adjustment system.

- JSC "Borinskoye" ISHMA BSK - boilers from a reliable series of domestic manufacturers with a built-in pump for circulating liquid.

When choosing boiler equipment, you should take a closer look at domestic products and devices of German production. The main arguments are the simplicity of the equipment in service, the reliability of the structural elements and durability.

Connection features

When connecting to the mains in systems with natural circulation, an automatic fuse is used (with a flag), with its help you can disconnect. It must be installed at a distance of at least 0.5 m from the boiler.

The pumping device in structures with forced circulation begins to function when the thermal relay is turned on. In order for the additional and built-in units to work simultaneously, the first must also be connected to a relay or to the second in a parallel way.

In electric boilers, the circulation equipment is connected directly to the boiler, which makes it possible for it to operate only at the moment when the water is heated.

A cleaning filter is usually installed in front of the pump.

A special valve (automatic or manual) installed at the top of the bypass will make it possible to remove air accumulated in the heating system.

Installation of equipment of the "wet" type is carried out horizontally. Its terminals should be at the top.

All threads of the heating system must have gaskets pre-treated with a sealant. To use pumping equipment safely, you must use a grounded outlet.

Installation of a pumping unit in a heating system requires taking into account all the nuances. Only then will homeowners forget about problems with heat distribution and air pockets in the pipeline.

What parameters of the device should be considered when buying?

Before buying and installing equipment, it is worth studying its most important parameters. In order not to be mistaken when choosing, familiarize yourself with its characteristics such as the density of the coolant, the pressure force and the temperature of the water. You will also need to know the diameter of the pipes used to heat the building.

You can find out exactly what characteristics your chosen pump has on the packaging, side wall or in the technical data sheet of the unit. Manufacturers designate the pressure with the letter "H". This indicator means the ability of the device to raise water to a certain height. It is measured in meters. The second characteristic is the fluid consumption of the system. It is designated with the letter "Q" and is measured in cubic meters. This parameter is equal to the power of the boiler and depends mainly on the diameter of the pipeline.

Circulation enhancement equipment is not designed to lift fluid. Because of this, when buying a unit, special attention should be paid to the "Q" parameter. If the installed boiler is not equipped with a pump, then further fluid consumption will have to be calculated independently. Most modern heating devices already have similar equipment. It is optimal to install 2 devices to improve heat circulation in the case when the house already has a boiler of an older modification, but over time the building was completed and the heating structure increased.

It is not worth purchasing very expensive equipment. In any case, the full potential of the device will not be used. In addition, the installed unit is characterized by a high level of noise. Most often, the length of the pipe determines the power characteristics of the equipment: for every 10 m of pipe, the device must provide 0.5 m of head. In practice, a 100-meter ring will work effectively if the pump delivers a head of 5 m. When buying a unit for a pipeline, do not forget that the capacity of the device should be 10% more than the indicator calculated by the residents.

Heater types

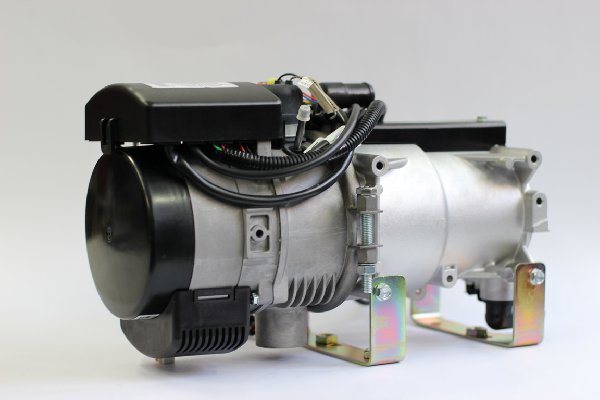

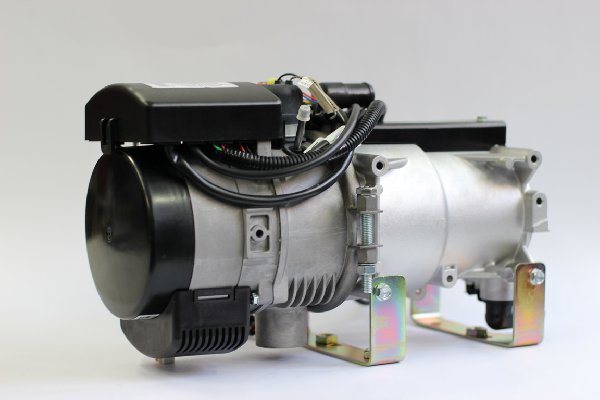

Interested in which engine heater is better to choose, you need to carefully study their technical features. The variety of types allows you to understand which option it is desirable to opt for with a guarantee of a high level of functionality of the unit.

Electric heaters

This version of the product provides for the lack of autonomy in operation, but it pleases with its reliability. The unit appeared back in 1949 thanks to A. Freeman.

Electric heaters have gained the most popularity in Canada and Scandinavia, as both regions have a climate with northern characteristics. In Russia, the application will also be appropriate.

The species under consideration has a complex structure.

- The main functional part is the heating element. Its power is 500-5000 watts. The heating element is located in a sealed heat exchanger, which is installed in special holes in the engine cooling system. In addition, a connection with a cooling jacket based on branch pipes is provided.

- An additional component is an ECU with a timer. A timer is provided that allows you to control the operating time of the charge.

- The recharging unit must be provided for by the design of the main device.

- The fan allows you to heat the interior and the engine compartment.

- Improved models include a pump that allows the engine to warm up evenly.

Despite the complex structure, the principle of operation is simple and understands the general laws of physics. The heating element interacts with a coolant that circulates until the optimum temperature is reached. For successful operation of the device, it is recommended to install it in the lower part of the cooling system, since a warm liquid always rises up, a cold one goes down. A heater equipped with a pump assumes the possibility of abandoning the upper structure placement.

The need to install an additional circulation pump

The thought of installing a second device arises with uneven heating of the coolant. This is due to insufficient boiler output.

To find the problem, measure the temperature of the water in the boiler and pipelines. If the difference is 20 ° C or more, you should clean the system from air plugs.

In the event of a further malfunction, an additional circulation pump is installed. The latter is also necessary if a second heating circuit is being installed, especially in situations where the piping length is 80 meters or more.

The second pump also not needed if the heating system is balanced with special valves. Purge air from the pipes, replenish the amount of water and carry out a test run. If the devices interact normally, then there is no need to install new equipment.

Low loss header

Used when an additional pump needs to be installed. The device is also called anuloid.

Photo 1. Low loss header model SHE156-OC, power 156 kW, Poland.

Such devices are used in heating if the water is heated when using long-burning boilers. The devices under consideration support several modes of heater operation, from ignition to damping of fuel. In each of them, it is desirable to maintain the required level, which is what the hydrostatic gun does.

Installing a low loss header in the piping creates a balance during the operation of the coolant. Anuloid is tube with 4 outgoing elements... Its main tasks:

- independent venting from heating;

- catching part of the sludge to protect pipes;

- filtration dirt entering the harness.

Functionality

Circulating pump piping performs many tasks. They must be allowed regardless of the flow rate of the working water and the possible pressure surges in the pipes. Efficiency is difficult to achieve because the fluid is drawn in from a common source.

Thus, the heating medium leaving the boiler will unbalance the system.

Because of this, a low loss header is placed: its main purpose is to create denouementwhich will solve the problem described above.

And also the following functions are important:

- contour matchingif several are used;

- support calculated expense in the primary piping, regardless of the secondary ones;

- permanent ensuring the operation of circulation pumps;

- relief exploitation branched systems;

- pipe cleaning from the air;

- catch sludge;

- convenience installation when using modules.

Where to put the second device in the house

In autonomous heating, it is recommended to install a device with a wet rotor, self-lubricating with a working fluid. Therefore, consider the following points:

- shaft position horizontallyparallel to the floor;

- the flow of water is directed one way with an arrow, installed on the device;

- the box is placed on any side except bottom, which protects the terminal from water ingress.

The device is mounted on the return line, where the coolant temperature is minimal.

This increases the duration of operation, although some experts disagree with this phrase. The latter is due to the rules of operation: the device must withstand the heating of the working fluid up to 100-110 ° C.

How to choose a heater

Every motorist who is trying to understand which engine preheater is best to use must determine the basic aspects of choosing the right device.

Autonomy

In this case, it is advisable to choose a special autonomous heater, which is comparable to a stove that runs on gasoline or diesel fuel.

Features and Benefits:

- the achievement of a suitable temperature regime involves the use of a small current, thereby ensuring the saving of battery power;

- the interior fan also turns on when the liquid used reaches 30 degrees, so it is much easier to maintain comfortable conditions for the driver and passengers;

- the transition to the "half" mode, and then to the standby mode, occurs after the liquid has warmed up to a temperature of more than 70 degrees Celsius;

- the cycle repeats automatically if the coolant temperature drops by about 20 degrees.

This option allows you to count on the successful warming up of the vehicle without unnecessary effort.

In most cases, convenient switching on of the device involves the use of a timer, with which you can program the switching on time and operating time.However, you can use the remote control, as it also pleases with maximum convenience.

Devices from Webasto, Eberspacher are popular in Russia.

Keep warm for future use

For this, we recommend a heat accumulator for the car engine, working on the principle of a thermos. Regular travel is required to use the device, as the heat remains for 2-3 days. Only regular trips allow us to note the functionality of the device.

For the first time, a heat accumulator was proposed by the Canadian designer Oscar Schatz. Currently, the domestic market offers models from the Avtoplus MADI brand, as well as AutoTerm.

Socket required

Recently, motorists have been trying to understand which 220v engine heater is better to use. This option provides for comparison with a home boiler. Despite the need to use an outlet in a car interior, the device promises to please with a high level of functionality.

Ideally, the device is complemented by a heating module with a fan, which allows the interior to be warmed up before the regular stove starts operating.

Only if you think over the features of using heating products, you can evaluate its functionality.

Wanting to understand which electric engine heaters are better, it is advisable to choose Defa or Severs products. Both brands strive to offer reliable products.

How to consistently integrate an auxiliary device into the heating system

To install the circulation pump, use one-pipe or two-pipe system heating. Before starting, be sure to read the instructions supplied with the device. During preparation, water is removed from the piping, then the pipes are cleaned from dirt, corrosion and scale. The device is mounted according to the plan, filled with a coolant and started to operate.

It is preferable to put the pump on the return, using bypass... The latter helps to shut off the fluid flow if it becomes necessary to replace parts or troubleshoot.

Consider the pipe diameter branch: it must be smaller than the main.

Cranes are placed on both sides of the bypass to protect against accidents. If necessary, they are covered. Another one is installed on the central part of the harness. It helps direct the working fluid to the circulation pump. It is advisable to put a filter in front of the entrance, cleansing water from impurities and solid salts.

How to install a 220v engine preheater

Each factory-made heater is supplied with an installation manual. However, in practice, it is far from always advisable to follow it from the first to the last letter, since the installation process in some details may vary, depending on the make and model of the car.

In order to install the pre-heater himself, the car enthusiast needs to understand the structure of his car, and also understand how the regular engine cooling is performed. Remember that improper installation will damage the appliance and may also cause malfunctions in the cooling system. Installation may require an inspection pit or overpass, since access to the engine is required not only through the upper part of the engine compartment, but also from below.

So, below is a procedure suitable for many brands and models of cars using the example of an electric heater: