Combined gas-wood boilers are, first of all, solid fuel boilers that have only a slightly modified design, into which you can install a gas burner that burns natural or liquefied gas. The burner is replaced quite quickly, on its own, according to the manufacturer's instructions, therefore combined boilers are multifunctional and, despite various opinions, retain the reliability and durability of simple solid fuel and gas models.

Despite all the advantages, we do not recommend considering combined models (with the exception of a few cases), since buying a separate gas boiler and a solid fuel boiler will cost much less, and the disadvantages of a dual-fuel design are often significant. Let's analyze everything in order.

What are combined gas-firewood boilers?

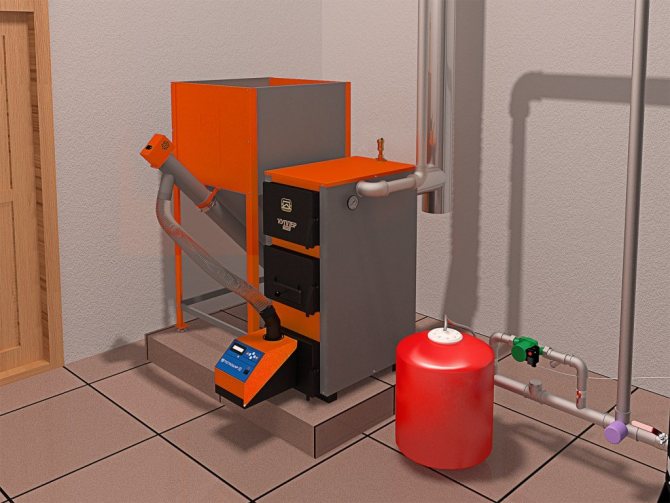

Mixed-type boilers operating on solid fuel and gas are always a floor-standing design, corresponding in size to conventional solid fuel models. Without using a gas burner, these are ordinary solid fuel boilers that burn not only firewood, but also coal, pellets, peat, anthracite. The piping, installation and connection of universal boilers is carried out in the same way as single-fuel boilers.

What are they for and how they are used

As we have already said, without special conditions, the purchase of a gas-solid fuel boiler is not justified either economically or practically.

Firstly, the total cost of separately purchased gas and solid fuel boilers is 90% lower than the combined model. The cost of gas-firewood boilers is 19,000-35,000 rubles and a gas burner is not included in this amount: it must be purchased separately. Only in rare cases are there ready-made assemblies already with a gas burner in the kit. The cost of the burner is on average 6-12 thousand rubles.

The most economical of budget simple boilers for heating a private house

Secondly, the efficiency and functionality of individual single-fuel models is almost always higher than combined ones. The usual design of a solid fuel boiler does not show the highest efficiency (at best, up to 85%) when burning natural or liquefied (balloon) gas, when even budget gas boilers have an efficiency of 88-92%. And this is, accordingly, a lower consumption with the same heat transfer. Also, combined gas-wood boilers are devoid of any functional automation, which is found even on budget gas models.

Thirdly, a small bonus of two single-fuel boilers is that if one breaks down, the second can be used as a backup.

However, there are cases when buying a universal boiler that runs on gas and wood may be more profitable. For example:

- with access to any type of solid fuel for a symbolic price. When the reserves of solid fuel are exhausted, stable combustion will be required without human intervention, or a previously absent gas main will be installed near the house, you can always switch to a gas burner;

- if the area of the house is rather small and allocate at least 8 sq. m. area for separate single-fuel boilers is impossible.

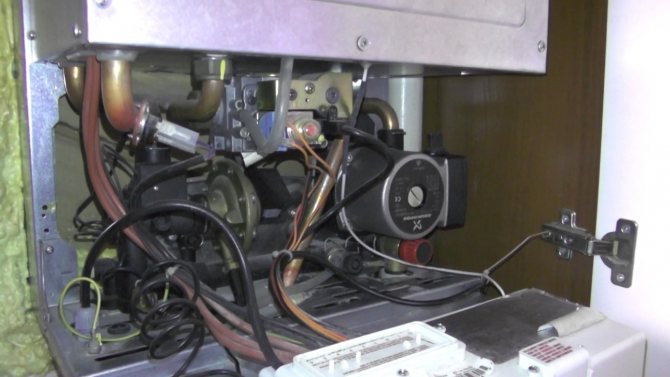

Device and principle of operation

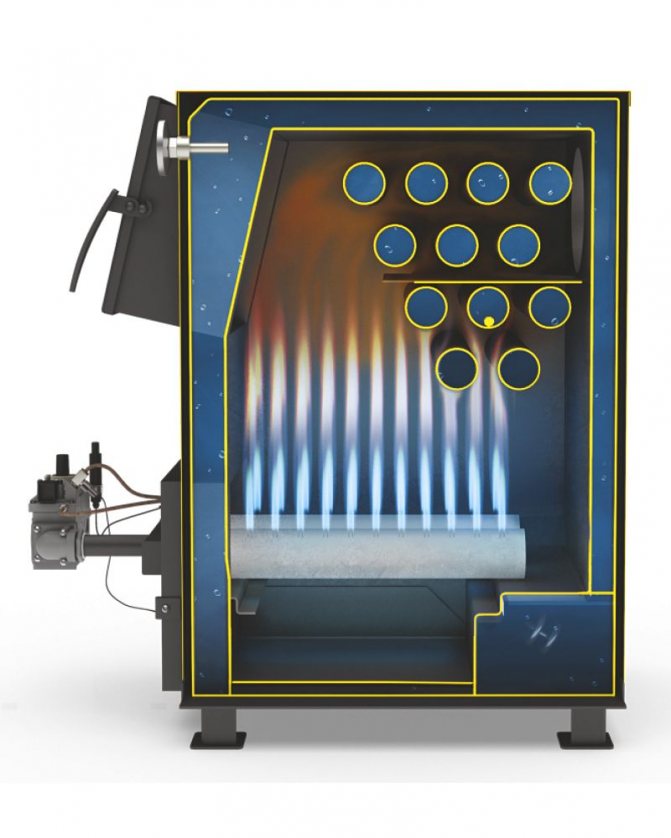

Combined model with installed gas burner. Scheme on the example of the Teplodar Kupper OK 15 model.

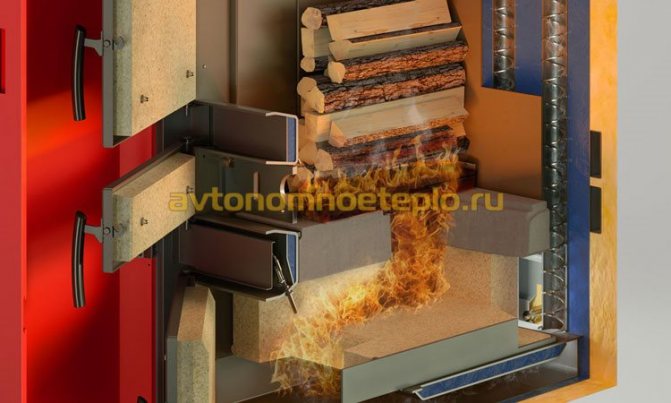

The design of such boilers is traditional: solid fuel is burned in the combustion chamber, the walls of the chamber are a heat exchanger, inside of which a coolant circulating through the system. Fuel loading takes place through the front door, ash is collected in the ash box from the bottom.

If you need to switch to gas, a gas burner with a corresponding mount (without welding) is installed on the ash pan door or a specially designated mount. However, the design of the heat exchanger, designed for a large volume of the combustion chamber, accumulates much less thermal energy when burning gas, the efficiency remains only within 75-85%, as when burning high-quality solid fuel.

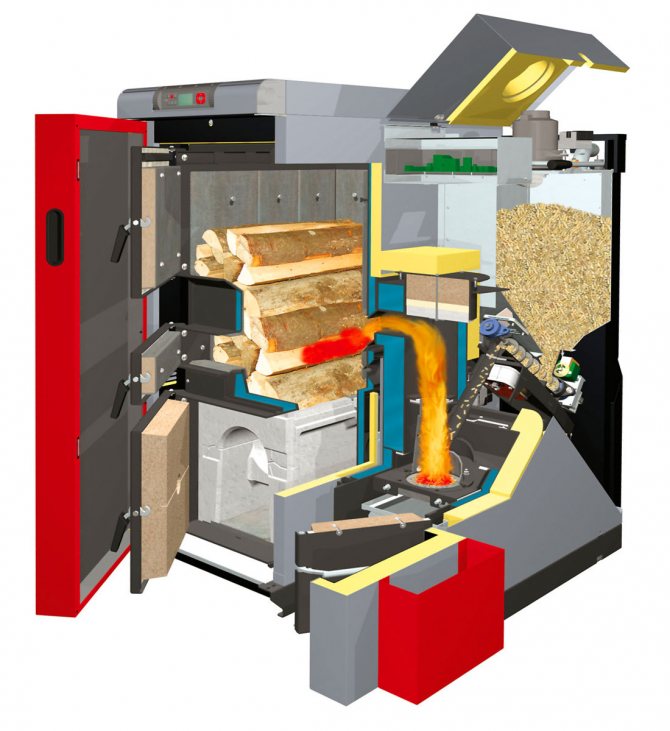

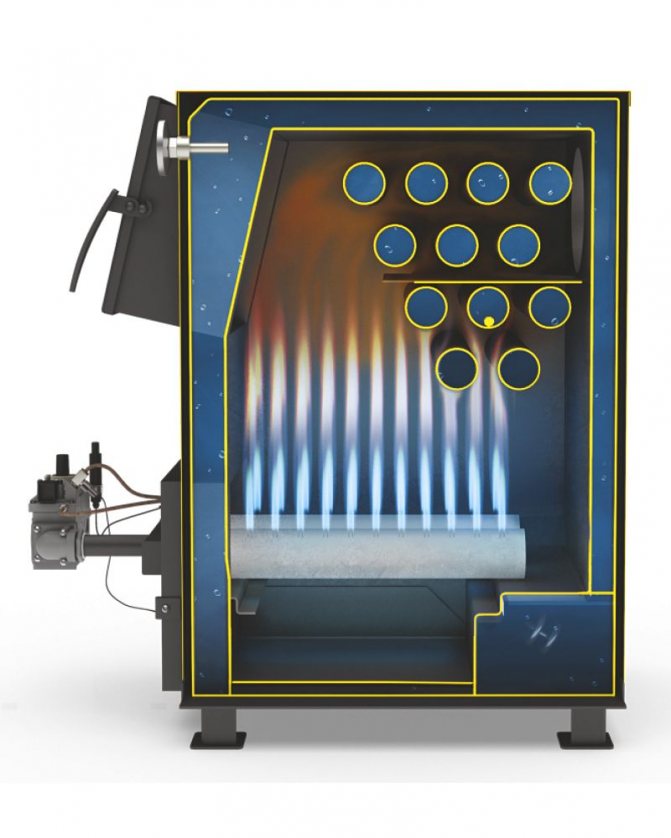

There are also high-tech hybrid models on the market with 2 furnaces, in which fuel can be burned simultaneously. In the upper combustion chamber, solid fuel is usually burned, a gas burner is installed in the lower combustion chamber, separating the combustion chambers by a compact ash box and a heat exchanger design. However, the cost of such models is in the range of 200-350 thousand rubles.

Two-fuel model.

Boilers with a burning time of one fuel tab up to 7 days

Main characteristics

The gas-wood boiler can operate on two types of fuel. If they are just going to lay a gas pipeline to an individual building, this option will be the ideal solution. The house will be heated with wood until the installation is completed.

Heating equipment has the following distinctive features:

- the boiler body is made of steel or cast iron;

- the structure is installed on the floor surface. If the device contains a cast-iron heating compartment, a cement screed is placed on top of the base to strengthen the foundation;

- units can have one or two circuits. Single-circuit designs are used only for space heating. With the help of double-circuit devices, a hot water supply system is created;

- the combined equipment may include one or two furnaces;

- if the model has two combustion compartments, a gas burner is located in the lower compartment, and a chimney is installed in the upper part. Ash is collected in a special pallet;

Reviews of universal boilers for solid fuel and gas: advantages and disadvantages

| Benefits | disadvantages |

| Significant space savings, which is especially important for small houses with an area of 40-80 m2. The dimensions of the combined models do not differ from the single-fuel ones | Primitive automation or its complete absence (mechanical draft regulator) |

| Availability of single-circuit and double-circuit models | In more than 95% of cases, a gas burner is not sold as a set with a boiler |

| Almost all models are non-volatile (do not require connection to the mains) | Owners often note a rather high noise level of the burners, which cannot be compared with standard burners of gas boilers. |

| In combined models, durable cast-iron heat exchangers are often used, when in budget solid fuel and gas almost always - steel vulnerable to corrosion | Higher requirements for chimney draft, which complicates calculations. If the design is wrong, the thrust may not be enough for full gas combustion. |

| A small selection of multi-fuel combined models, especially foreign ones |

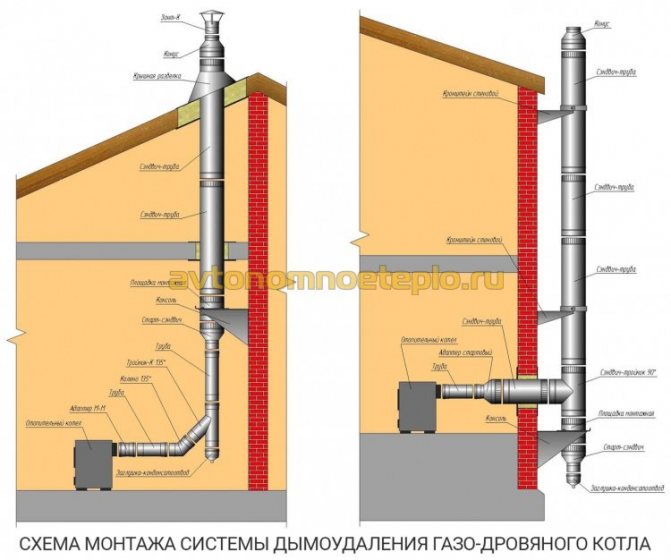

Boiler installation and safety

The combined gas boiler is installed in accordance with the instructions for use. To connect to the gas pipeline, permits are required. Heating boilers gas firewood need a chimney arrangement. It is necessary for the discharge of exhaust gases into the atmosphere.

The dual-fuel plant is very heavy. This requires a solid foundation. The floor is made of non-combustible materials. As a base, concrete blocks, refractory bricks or other building materials covered with metal sheets are used. During installation, check the correct location of the base in the horizontal plane. For this, a building level is used.

As for the installation of piping, the installation of a universal boiler is no different from the installation of products operating on solid fuels. The heat exchanger is connected to the heating.The hot water supply circuit is connected to the corresponding pipeline. The connected pipelines at the point of connection with the boiler equipment are equipped with shut-off valves. This design allows you to dismantle the product without draining the coolant from the pipeline.

How to choose a combined boiler unit

The selection criteria are practically the same as when choosing a TT model. Be sure to decide on:

- Number of contours... Single-circuit models are more common; they only heat the heating circuit. Dual-circuit models are also capable of heating sanitary water (it does not mix with service water from the heating circuit). Double-circuit models are 10-40% more expensive, but this is still the cheapest way to organize hot water supply in a house.

- Burned fuel... Basically, combined boilers are designed to burn both coal and charcoal, firewood, pellets, peat. Models with a cast iron heat exchanger are capable of burning anthracite. But some boilers are only designed for firewood. The types of fuel are always described in the technical characteristics or the boiler passport.

- Heat exchanger material... There are two options: steel or cast iron. Steel heat exchangers are inexpensive to manufacture, lightweight, resistant to temperature extremes and mechanical damage, but have thin walls and are not resistant to corrosion, their service life is on average 12-15 years. Cast iron heat exchangers are heavy, have thick walls, do not corrode and last more than 30 years, but are used in more expensive models.

- Working pressure... Some models are designed for a working pressure in the system not exceeding 1 bar, which means that they cannot be used in closed heating systems with forced circulation, where the working pressure is usually 1.5-2 bar.

- Efficiency... Not the most informative indicator when burning solid fuel, since it strongly depends on its quality (dryness and type of wood, ash content and calorific value of coal). However, when using a gas burner, 4-5% efficiency can recoup the higher cost in one heating season. The optimal efficiency factor is 80% or more.

Minimum required power

For an average non-insulated or slightly insulated house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2. We also recommend setting a power reserve of 20-30%.

For example, for the above-described average house with an area of 100 m2, the minimum required power of heating equipment is 100/10 * 1.3 (30% of the stock) = 13 kW. Boilers of this capacity are not found on the market, so we round up to the nearest higher value - 14 or 15 kW.

Also, when buying a double-circuit boiler, it is recommended to add another 10-15% to the result, since when hot water is heated, the heating circuit is not heated. Total 13 kW * 1.1 (10% stock) = 14.3 kW. If the house is located in the extreme southern or northern point of the country, it is well insulated, has high ceilings or a large glazing area, correction factors are taken into account, which change the result by 5-30% up or down.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Coal-gas

The universal gas-coal boiler is environmentally friendly and easy to maintain. However, when choosing this type of construction, you will have to constantly monitor the presence of solid fuel, because coal ends quickly. If you suddenly come to the conclusion that "two in one" does not suit you, then you can always replace the burner - and the boiler will already run on natural gas.

More details about the features of the pellet boiler can be found here.

Most often, the coal-gas combined boiler is allowed to heat with wood.For example, in the technical characteristics of the two-circuit model "Birch B" in the item "fuel" it is indicated "natural gas / coal" (see table). However, buyers use such a boiler for heating and firewood.

| Manufacturer and model | Characteristic |

| ATEM (Zhytomyr, Ukraine) Berezka V | The boiler is made of steel, is versatile and completely independent of electricity. It acts as a budget solution for heating summer cottages, utility rooms, outbuildings. Units of the "B" brand are created with the production of consumer hot water. Fuel - natural gas / anthracite (coal). The area of the heated room is 125 m². Rated thermal power - 12.5 kW. The maximum gas consumption is 1.5 m³ / h. Nominal gas pressure (min / max) - Pa 1274 + 100 (635/1794). Working pressure of water - 0.1 MPa. The efficiency when using solid fuel is 78%. The efficiency when using natural gas is 90%. Weight - 119 kg. DHW water consumption - 280 l / h. The combustion chamber is open (chimney). The number of contours is double-circuit. |

The best known manufacturers and models: characteristics and prices

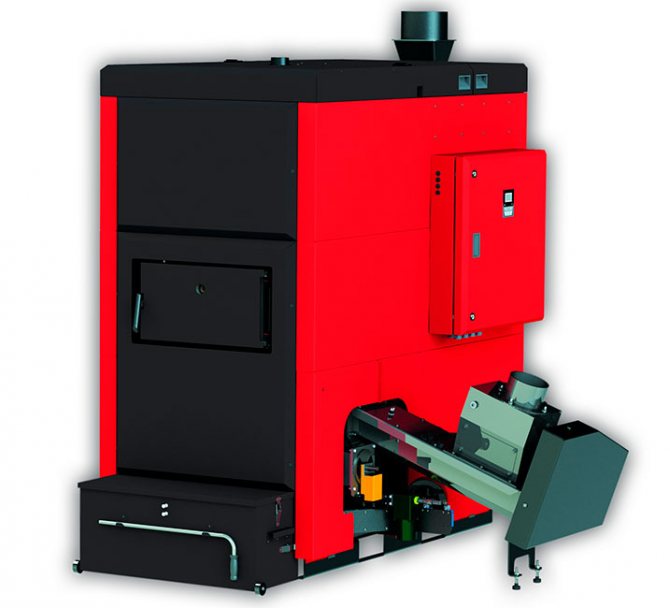

Teplodar Kupper OK 15

The most famous domestic combined boiler, operating on coal, wood, pellets, natural gas (when installing a burner). Differs in time-tested reliability at low cost, good design of the furnace, ease of cleaning. Separately, it is worth noting the presence of 6 kW heating elements, with the help of which the coolant can be heated for a long time when solid fuel is completely burned out at night. Also, the owners note a rather pleasant stylish design and build quality.

However, there are also a sufficient number of disadvantages: a small loading opening and the firebox itself (firewood up to 35 cm), steel heat exchanger, relatively low efficiency, high soot formation.

Cost: 19,900-21,200 rubles.

Viadrus Hercules U22 D-4

One of the best combined gas-firewood boilers for heating a private house, and also one of the most purchased. The Czech model with a cast-iron heat exchanger is characterized by ease of use and a well-known durability, provided by good alloys and workmanship. The boiler has a fairly good efficiency of 80%, is absolutely omnivorous, has the optimal size of the firebox (firewood is 40-45 cm long), while it also has compact dimensions and a stylish appearance.

According to the reviews of the owners, with a strongly closed thrust valve, abundant soot formation is characteristic. The cast iron construction, depending on the power variation, weighs an average of 250 kg, therefore a reinforced floor is required for installation, and at least 3 people for transportation. Also a relative disadvantage is the price of the Czech model.

Cost: RUB 63,000-67,500

Roda Brenner Classic BCR-04

Another practically reference Czech combined boiler with a cast iron heat exchanger and a technologically advanced, efficient and practical design. The body is separated by a layer of thermal insulation, which reduces heat loss through the boiler modules, keeps the body relatively cold. Everything is also distinguished by Czech reliability, practicality during operation and cleaning, good efficiency.

According to the experience of installation and feedback from the owners, no shortcomings and malfunctions were found for more than 6 years of operation. It can only be noted that the price is still high for the average Russian buyer.

Cost: RUB 53,000-55,000

GEFEST VLOOKUP KSTGV-20

Inexpensive and compact dual-circuit combined boiler of domestic production. Differs in good efficiency of 80%, achieved due to the excellent design of the heat exchanger. The primary heat exchanger is steel, but the secondary (for hot water supply) is made of copper. Almost always a BRAY-type gas burner with the well-known simple Italian SIT automatic equipment is included in the factory configuration.

Please note that the maximum allowable working pressure is only 1 bar. It is also worth noting that the model is quite rare on the market.

Cost: RUB 23,500-26,400

Karakan 20 TEGV

Another domestic double-circuit model. It has the most simple design, is not picky about fuel, has a large loading opening and a firebox, as well as a heating element unit installed from the factory.

However, the heat exchanger is made of steel, the efficiency is only 75%, the weight is 101 kg, and the maximum allowable operating pressure is 1 bar. There were no service complaints for more than 5 years of operation.

Cost: RUB 22,500-25,000

Design and principle of operation

The second category of combined heating boilers have a more complex design with two autonomous chambers for different types of fuel. There are 2 options for their location in the boiler body:

- The firewood stove is located at the bottom of the case; there is a grate in it, a chamber for ash with its own door. The natural gas combustion chamber is located above the firebox and is completely insulated. The only channel that connects them is the chimney, it must open for the camera in operation. The branch pipe of the second idle furnace is closed with a special damper, controlled by automatic equipment or manually.

- Both chambers are located side by side and have one common wall. They also have a common chimney, while the combustion products make from 3 to 5 strokes in the smoke tubes, cooling down to 150 ⁰С.

Combined wood-gas heating boiler

Some multi-fuel combi boilers are designed to fit a pellet or diesel burner, and options include a DHW circuit or even a built-in boiler. An example of such a heating system is the ECO-CK Plus of the Austrian brand WIRBEL. This manufacturer declares the value of the efficiency when working on wood up to 88%. The chamber, which can run on gas or diesel fuel, has an efficiency of up to 93%. The heating unit is equipped with all the necessary automation, depending on the energy sources used, you will not have to purchase any additional equipment.

The order of operation of two-chamber hybrid installations is as follows: the main type of fuel in them is firewood, which is put into the appropriate firebox. From ignition to complete combustion of a portion of firewood, it takes approximately 4-5 hours, provided that the boiler is operating at full power. When the first furnace begins to fade, and the temperature of the coolant decreases, the gas burner device of the second chamber is automatically turned on, maintaining the water temperature at a given level.

Domestic combi boilers for gas and solid fuel cannot automatically switch back to burning wood after the gas burner has turned on. The reason is clear: at home it is impossible to organize automatic feeding of wood into the first chamber of the hybrid installation, with the exception of pellets. Therefore, after the firebox has faded, it is necessary to load firewood into it again and turn off the second chamber.

Prices: summary table

| Manufacturer and model | Heat exchanger material | Number of contours | Efficiency,% | price, rub. |

| Teplodar Kupper OK 15 | steel | single-circuit | 78 | 19 900-21 200 |

| Viadrus Hercules U22 D-4 | cast iron | single-circuit | 80 | 63 000-67 500 |

| Roda Brenner Classic BCR-04 | cast iron | single-circuit | 80 | 53 000-55 000 |

| GEFEST VLOOKUP KSTGV-20 | steel | double-circuit | 80 | 23 500-26 400 |

| Karakan 20 TEGV | steel | double-circuit | 75 | 22 500-25 000 |

Varieties

Solid fuel boilers for heating a private house in most cases are represented by classic convection units. In them, firewood is burned directly, with the formation of a powerful flame, the heat from which is immediately taken by the heat exchanger. Disadvantages of this scheme:

- Lack of possibility of smooth temperature control;

- Not the highest efficiency;

- Virtually no automation.

With the help of traditional wood-burning boilers, it is difficult to maintain a certain temperature - the intensity of combustion, if regulated, is within extremely small limits.

Pyrolysis wood-fired boilers are an alternative to convection appliances. They are built according to the gas generator scheme. Firewood burns here in an oxygen-poor atmosphere. In fact, they do not burn, but simply smolder. Due to the high temperature, they begin to secrete pyrolysis products that are flammable.Combustible gases are burned in a separate chamber (called the afterburner), where secondary air is supplied. And in order to be able to adjust the intensity of combustion, the equipment is equipped with blowing fans.

Boilers built according to the pyrolysis type are more complex than their convection comrades. Here we see two chambers - in one, firewood is smoldering, emitting pyrolysis gases, and in the second, these gases burn out at a very high temperature, reaching + 800-1000 degrees. The released heat is absorbed by the same fire-tube heat exchanger and partially by a protective water jacket (if any).

Pyrolysis wood-fired boilers are endowed with automation systems that control blowing fans. As soon as the temperature in the heating system with batteries reaches the preset limit, the fan stops, the flame in the afterburner goes out. This happens until the temperature in the heating system drops - then the blowing fan starts up, a humming flame appears in the afterburner.

Pyrolysis gas-fired wood-fired boilers need dry wood. Using raw logs, pyrolysis will be difficult or impossible. The efficiency of this equipment reaches 90%, as the calorific value of solid fuel increases.

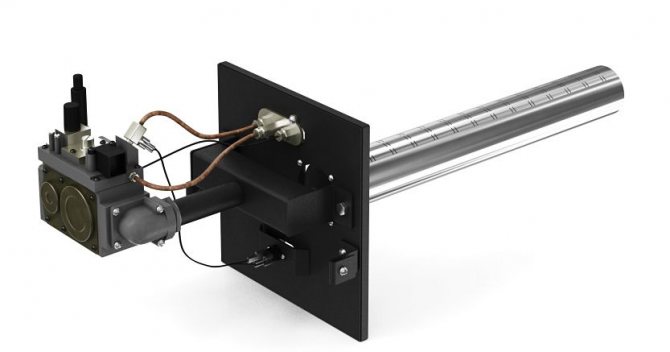

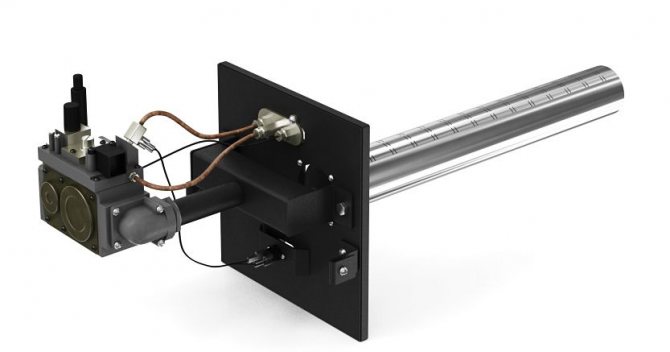

How to select a gas burner for a solid fuel boiler

Model AGG-13K

Universal gas burners for solid fuel boilers, not belonging to the factory accessories of specific models, are suitable for all boilers, since they have a fairly simple screw fastening. Exceptions are burners designed for a specific model range. Usually these are burners from the same manufacturer as the boiler. Their name or characteristics indicate, for example, "... for boilers Teplodar".

Advantages of combined designs

The gas-wood boiler has a number of undoubted advantages:

- the equipment includes a built-in heating element and a specially equipped furnace chamber;

- routine maintenance does not require special knowledge and skills;

- installation is quite simple;

- other heating circuits can be connected to the heating structure. It can be used simultaneously to heat several buildings;

- the equipment takes up a small area;

- emissions of harmful substances into the atmosphere do not exceed the permissible standards;

- high level of efficiency.

The nuances of choosing an electric gas boiler

The circulation pump will not work in the absence of electricity

The design provides for 2 chambers: for gas combustion and for electric heating elements. The change of modes occurs automatically. In individual boilers, it is possible to set a cyclical operation mode This is useful in cold temperatures that can last for a long time. When a sufficient temperature indicator is reached, the unit switches from gas to electricity. The combined use of both types of fuel allows you to save expensive resources, to make heating independent.

If the electric gas boiler does not have a tank for heating water, a boiler is required. An electric pump is used to improve water circulation. The latter does not provide the ability to operate the gas part of the unit in the absence of electricity. Such a detail limits the use of such a device in multi-storey buildings.

Compressed natural gas cylinders: requirements

Any equipment designed to store, transport, pump or use CNG, of course, must have a large margin of safety. This also applies to cylinders installed on cars for such fuel. Such containers are tested for destruction before delivery for sale:

- when fired from a firearm;

- when falling from a height;

- under the influence of open fire;

- under the influence of extreme temperatures and aggressive environments.

According to statistics, in the 90s and 2000s, out of 1360 collisions in road accidents, the blow in cars fell on gas cylinders. At the same time, such a container has never been significantly damaged in an accident. Therefore, cars running on compressed natural gas are currently considered an even safer mode of transport than cars powered by gasoline or diesel fuel.

Comparison of gas from a pipeline and a gas tank

Comparing both options for gas supply to a private house, it is necessary to look at both the cost of buying a cubic meter of gas and the estimate for installing equipment and the price of its operation in the future.

All parameters of both systems should be taken into account. At the same time, choosing what is initially cheaper - a gas tank and main gas, it is necessary to analyze what is easier in repair and maintenance.

The main advantage of a gas tank over gas from a pipe is a high connection speed, if in the first case 1-3 days are enough, in the second it can take many months

A gas holder is, first of all, complete autonomy in the power supply of a private house. The main gas can be turned off at any time. It is impossible to fully insure against accidents on gas pipelines.

In this respect, pipe blue fuel is similar to electricity. The general network collapsed, and the cottage was left without electricity and gas supply. And gasholder fuel is always available. You just need to monitor the fullness of the tank.

Factor # 1: Connection cost

If we look at the average prices for connecting main gas and installing a gas tank, then the first option wins a lot. It is now possible to connect the cottage to the gas main for 50-100 thousand rubles.

When choosing the second method, you will have to spend about 200 thousand rubles only on gas-holder equipment. The larger it is, the more expensive it is. Plus installation and excavation work. But there are a number of nuances here.

If there is no gas main in the village, then a gas tank is an excellent way to heat a house. In terms of energy efficiency and fuel consumption, LPG surpasses coal, firewood and electricity at times

The main problem with connecting the main gas is the timing of all the necessary work and approvals. If there is already a pipe in the village, then everything will happen relatively quickly and fairly inexpensively. But if there are more than two hundred meters from the house to the highway, then there will be a lot of trouble with the connection.

To connect a cottage to a gas pipe, you must:

- Prepare a calculation of gas consumption.

- Apply for technical specifications.

- Get these TUs (it takes up to a month).

- Prepare a project for a gas network in the house and from it to the mains (a couple more weeks).

- Conclude a connection agreement with gas workers, providing them with project documentation.

- Carry out the installation of gas equipment (a few days, provided that free installers are quickly found).

- A representative of the main methane supplier will check the operability of the equipment and wiring both in the house and outside with the subsequent conclusion of a service agreement (the arrival of this person can be waited for another month).

As a result, the minimum is 3-4 months. And this is if there are no problems in the course of the approvals and installation. Usually, everything is delayed for six months, the price of connecting to a centralized gas supply also makes you think about its need.

If the settlement is not included in the regional gasification program, due to which many connection issues have already been resolved, then you should not deal with this topic yourself. There will be a lot of headaches and going through the courts.

But the process of gasification of a private house with the help of a gas tank takes only 1-3 days. Private traders are not required to go through approval for the installation of such an installation on their land in the supervisory authorities.The article recommended by us will help to determine the cost of installing a gas tank.

You just need to dig a pit for the LPG tank, install it there and connect the pipes to it. All the necessary sensors, control automatics and valves are already included in the gas tank kit.

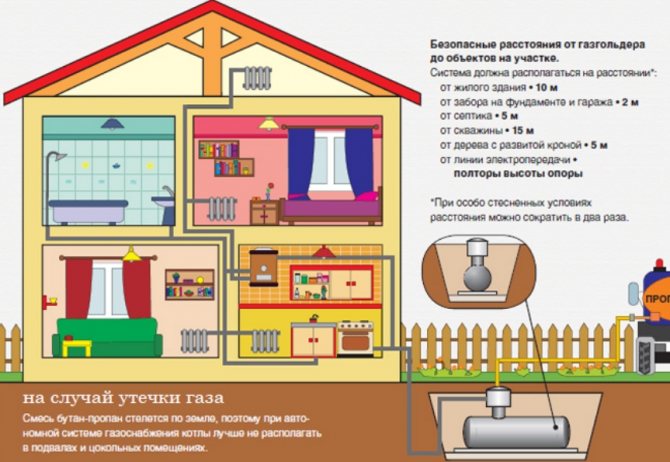

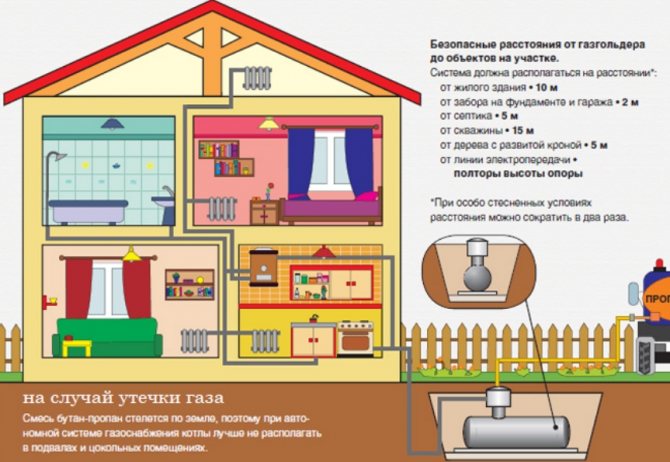

And one more nuance. The entrance from the highway to the house can be made on almost any site. The situation with the gas tank is radically different. It must be located at a certain distance from buildings, wells and roads. Not every farmstead is suitable for placing gas storage equipment; you may not find a suitable place for a container.

Factor # 2: Energy Efficiency and Maintenance Cost

When analyzing gas fuel costs, it is necessary to separate the cubic capacity (displacement) of methane in the pipe and propane-butane LPG in the car that brings liquefied fuel to the customer. If you look at the price tag in rubles / m3, it turns out that main gas costs three to four times cheaper than propane-butane.

However, in the first case, the fuel is supplied in a gaseous state, and in the second in a liquid state. As a result of evaporation, a liter of this “liquid” turns into 200–250 liters of gas. And here it is also necessary to take into account the ratio of propane and butane in the gas-holder LPG. They have different densities.

On the one hand, mainline natural gas is cheaper than LPG for a gas tank at a cost per cubic meter, but on the other hand, it has a lower specific heat capacity

If we compare the calorific value of the two types of gas fuel, then propane-butane will be ready to give a head start to methane. When one cube of a propane-butane mixture is burned in a gaseous state, about 28 kW is released, while methane is capable of producing only about 9 kW.

With an average calculation, a cottage of 100 square meters needs about 3000–3100 m3 of methane or about 1000 m3 of LPG per year for heating. At the same time, the first gas will have to pay three to four times less. As a result, it turns out that fuel costs as a whole for the year end up being approximately equal.

The maintenance of gas tanks and gas pipes from the main to the house is carried out by specialized organizations that also supply gas.

According to the Ministry of Emergency Situations, main natural gas belongs to the 4th, safest category of explosive gas substances. But propane-butane is included in the more dangerous 2nd group. Even with low concentrations of LPG in a room, it can explode from the slightest spark.

Moreover, methane itself is light; in case of leaks, it rises under the flow and dissipates or goes into ventilation. But the propane-butane mixture is heavy and sinks to the floor or ground, gradually accumulating there to critical values.

From the point of view of safety, the main gas greatly outperforms the gas holder. It is not for nothing that gas tanks are strictly forbidden to be mounted next to wells and basements, where it can seep if it leaks from the container.

The standard distances for the location of the gas tank on the site are given here. The article recommended by us sets out in detail the rules for choosing a place for installing equipment of this type.

To avoid problems with LPG, tanks for LPG and rooms with boilers are often equipped with special gas sensors. They instantly react to an increase in gas concentration, alerting the owner of the house to potential problems. Don't skimp on them.

Physiochemical properties

Thus, the compressed gas has an ignition temperature of 640-680 ° C and consists mainly of hydrocarbons. Also, such fuel is characterized by the following physicochemical characteristics:

- molecular weight - 16.4;

- polarity under normal conditions - 0.718 kg / m;

- the required amount of air for combustion - 9.52.

With a content of 5-6% in the air, methane burns at a heat source. At a concentration of 5-16%, the mixture may already explode. If the air contains more than 14-16% methane, it loses such a feature.The explosions of the methane mixture are most powerful when the gas concentration in the air is 9.5%.

Among the features of natural gas, among other things, include the fact that it has a high detonation resistance. This is also referred to the advantages of this type of fuel. Due to the detonation resistance of CNG, car engines run smoother than when using gasoline.

Also, when such a gas is throttled, for example, in a reducer, its temperature drops sharply. This feature of natural gas is called the Joule-Thomson effect. Because of this, CNG requires a high degree of drying, which must be taken into account when operating vehicles on such fuel.

How do you get

Natural gas is liquefied methane at stations using special compressors. It is stored and transported in special storage drives. Actually, natural gas is supplied to the CNG stations themselves in the usual way - via trunk pipelines. At such stations, of course, various standards for the transportation, preparation, storage and injection of compressed natural gas must be observed. GOST 27577-2000 is a document according to which all these operations must be performed.