If you have purchased a boiler for heating water, you should use it very carefully and follow the instructions attached. Remember that the operation of this device must be carried out with all possible safety measures in mind.

As you know, a boiler consists of a container where water is directly heated. When heated, the water begins to expand and its volume also grows. Accordingly, this creates pressure on the walls of the water heater, and if it is handled carelessly, problems may arise. To avoid them, when buying and installing a water heater, do not forget to equip it with a special safety valve. It is needed then so that the water heater does not break down, and if an emergency occurs, the valve will help to relieve pressure and remove excess liquid from the tank.

What is it needed for

When water heats up, it expands and increases in volume, and the pressure rises accordingly. If it exceeds the level of strength of the boiler, then it will simply explode. To prevent this from happening, a safety valve is installed. It does not allow the pressure inside the heater to rise above normal.

In addition to protecting against a possible accident, the valve performs the following functions:

- does not allow warm water to return from the tank to the water supply;

- protects against water hammer;

- if the water supply is cut off, it will not be necessary to refill the container with water.

If you think that your device will be protected by a thermostat, then you are mistaken. They control the degree of heating of the water and do not allow it to boil. However, like any other device, they can fail, with the result that the consequences will be irreversible. Therefore, it is not worth the risk.

You can read about the types of thermostats for a water heater on the page.

Serviceability check

At home, it is quite easy to find out if the safety valve installed on the water heater is working properly. To do this, you just need to set the temperature regulator to the maximum value, and open the hot water tap. If, after the water in the boiler heats up to the desired temperature, excess liquid begins to flow out through the safety valve, then it is quite suitable for work. If water does not flow through the valve, it is most likely defective.

How it works and works

When talking about a safety valve for a water heater, it is better to use the phrase "valve system", because there are two of them in the device.

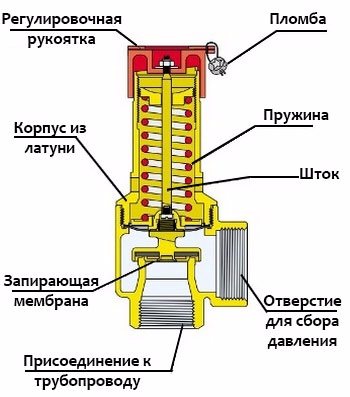

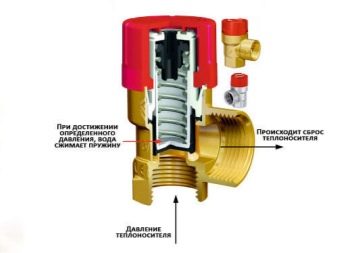

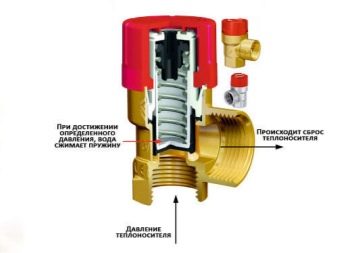

Boiler safety valve device

They are located in a brass or nickel-plated case. A non-return valve is installed at the bottom of the body, which, at the moment of decreasing the pressure in the system, prevents the outflow of water from the water heater. In the perpendicular branch there is a second valve, due to which, at the moment of pressure increase, part of the water is released through the nozzle.

How the safety valve works

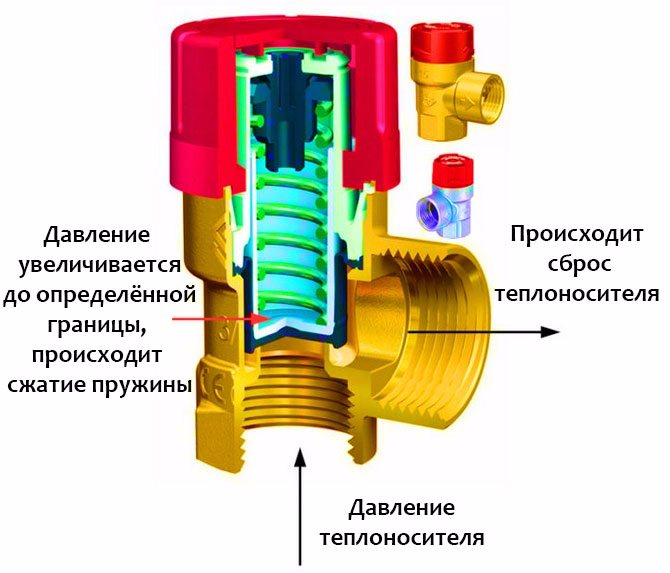

Principle of operation:

- As long as the pressure is normal, the valve is closed and does not allow the liquid to flow out, as soon as it becomes equal to the pressure in the water supply, the spring presses the plate against the protrusions of the body and blocks the flow of water.

- When heating is turned on, the temperature of the water gradually increases, along with it, the pressure rises.

- As soon as the pressure exceeds the spring force, an outlet opens to the fitting, through which excess water is drained. When the pressure returns to normal, the spring closes the passage and the flow of water stops.

Based on the principle of operation, it becomes clear that water from the nozzle will constantly drip. To drain the draining liquid, a tube of the appropriate diameter must be put on the branch pipe and secured with a clamp. The pressure required for the normal operation of the water heater is 6-10 bar.

The tube on the fitting must be transparent so that you can control the process of the device functioning.

With release handle

One of the most common options for non-return valves, which are equipped with water heaters, is a valve with a drain handle. Let's briefly describe its structure and principle of operation.

The handle design of the check valve has the following elements: a body, a water drain connection, a forced pressure relief handle, a safety valve spring, and a check valve spring.

Under the influence of water pressure, the spring of the check valve is compressed, as a result of which the poppet valve rotates and allows water to enter the reservoir. After enough water has been collected, the check valve returns to its original position.

The trigger handle is needed in order to, if necessary, carry out a forced release of pressure inside the system. As soon as the pressure exceeds the permissible maximum, the safety valve is activated, through which excess water is released, due to which the pressure is normalized.

Views

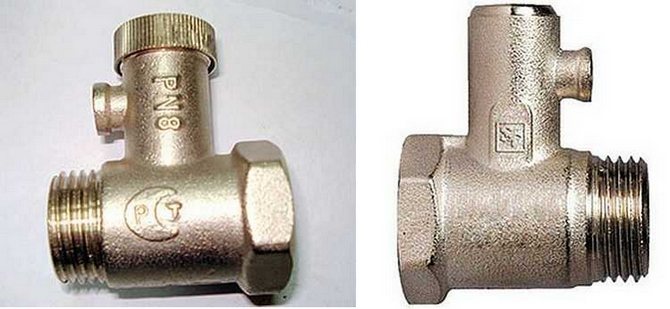

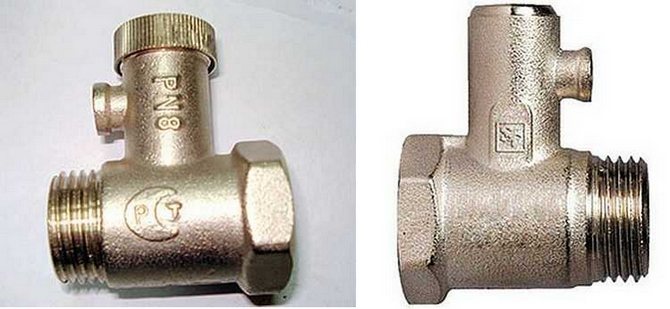

Conventional safety valves are similar in appearance and differ only in small details, but they are responsible for the practicality of use.

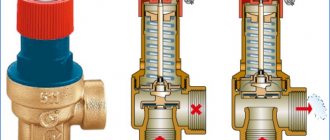

The figure shows two safety valves with release levers. They allow you to check (need to be done monthly) of the device's performance.

Boiler safety valves with forced pressure relief

The difference between the two presented modifications is that in the sample in the photo on the left, the lever is fastened with a screw, which eliminates the possibility of accidental opening or complete discharge of water.

Another discrepancy: the shape of the fitting. The sample on the left has an oblong, nonlinear fitting. It is easy to put on a hose and is long enough to install the clamp. But the fitting on the right model is short, with an extension towards the end. It will be very difficult to pull the clamp on such an instance.

The following illustration shows a relief valve without a positive pressure relief flag. The model on the upper left has a screw cap. If necessary, it can be unscrewed and cleaned of all kinds of blockages.

Safety valve without forced pressure relief

The sample on the right is the worst of the options, since it cannot be serviced. The only plus of these models is the low price.

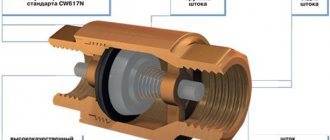

The above models are suitable for water heaters with a volume of 50-60 liters. For larger boilers, other models are suitable with built-in accessories: a ball valve or a pressure gauge that controls the pressure.

Safety valve for large boilers

In such devices, a water discharge connection with a standard thread, therefore, the fastening is strong. Such models are of high quality and reliability, and therefore are not cheap.

What is a safety valve

Boiler accessory such as a safety valve externally resembles a plumbing tee and includes the functions of the following valves:

- directly safety;

- shut-off;

- reverse.

All these elements in the water heater play the role of removing unnecessary water, which is obtained as a result of the expansion of the liquid in the tank under thermal pressure.

Depending on the capacity water heater safety valves can be as follows:

- for devices with a capacity of up to 50 liters;

- for boilers from 50 to 200 liters of water;

- for water heaters with a capacity of more than 200 liters.

The smallest devices can be equipped with safety valves of the first and second types, they are inexpensive, while their service life is also quite short and they have a non-separable structure. If necessary, they can be easily replaced with similar valves.

But accessories for the most capacious water heaters are already more expensive and have such functions:

- complexly constructed;

- able to withstand a pressure of about 7 bar;

- equipped with a nozzle for connecting the sewer;

- with their help, it is possible to control the discharge of water.

Today, the most famous companies in the production of powerful water heaters immediately equip them with high quality safety valves.

If it becomes necessary to replace an element, then it can be purchased at a specialized store. When buying it, you should be guided by the color of its handle. If it is red, then such a valve works at a pressure of 0.6 MPa, if it is black, then at 0.7 MPa, and if it is blue, then at 0.8 MPa, respectively.

How to choose

When choosing a safety valve for a water heater, pay attention to the following components:

- the temperature for which it is designed;

- threaded connections (usually half an inch);

- pressure;

- whether the design provides a handle for forced draining.

When purchasing a relief valve, be sure to check its pressure, because this is one of the most important indicators. If you buy a device with a smaller size, you will constantly have to face the problem of water leakage. If with more, then it may be useless and will not protect the container from an explosion.

You will also need to install a water filter, which will protect the water heater.

Selection Tips

When choosing a safety valve for a domestic water heater, use the recommendations that experts have compiled for you.

- Among the variety of designs, the spring mechanism is the most reliable, since it is able to resist water pressure well.

- Do not forget about such a factor as the flow capacity of the valve. We advise you to give preference to a low or full lift device.

- Consider the plumbing and sewerage systems in your home. If excess liquid will be discharged into the atmosphere, choose an open safety valve, and if into a specially equipped pipeline, then a closed one.

- When choosing a safety valve, remember the maximum allowable pressure in the water heater system. If it is higher than indicated in the data sheet of the device, the valve will not be able to function normally.

Installation

Before starting the installation of the safety valve for the water heater, be sure to drain the water from the device and turn it off.

The location of the device is the inlet of cold water to the boiler. The installation process is quite simple: with a key for 3-4 turns using seals, the second threaded end of the valve is connected to the cold water supply system.

Be sure to check the direction of the incoming water - it is marked with an arrow on the valve body.

If the water pressure constantly jumps and often exceeds the norm, then you must first install a water reducer.

Water leaks from the valve from time to time. This is an absolutely normal phenomenon, which indicates the normal operation of the boiler, but not everyone likes it. In this case, the drainage pipe must be connected to the sewer system by means of a flexible transparent hose, which will allow you to control the device's performance.

Installed safety valve on the water heater

Some people in the street do not want the valve to be visible and place it away from the water heater. Such manipulations are quite applicable, but subject to two important conditions:

- shut-off devices must not be installed at the distance between the valve and the boiler inlet;

- a long vertical section of the water supply will by itself increase the pressure on the valve and unnecessary leakage may occur.

The distance between the valve and the boiler should be no more than 2 m.

Principle of operation

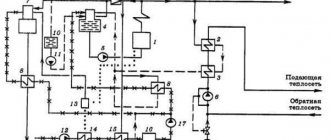

The standard water heater fuses consist of three separate valves:

- the safety valve itself (in rare cases, disruptive);

- check valve;

- drain (drain) valve.

The safety valve includes a metal stem, a plug at its end, a powerful spring and a fluid drain connection. As soon as the pressure inside the boiler exceeds the value specified in the documents, the device is triggered, the rod will compress a tight spring and it will open access to water to the fitting, through which it will flow out. This happens so smoothly that the flow of water is simply a large number of droplets.

The check valve includes a plastic stem with a rubber plug at the end and a weak spring. Unlike water pipes, the boiler check valve is not designed to hold the high pressure water pressure and serves as an ordinary damper, which is why the spring is so weak. It just does not allow water to flow into the pipes in case of an emergency or a water cutoff in the central water supply system.

Why is tap water dripping

Dripping water signals a malfunction of the part, but even if water drips under high pressure, do not panic in advance. This can be triggered by several reasons:

- spring stiffness is poorly adjusted;

- the pressure in the pipeline exceeds the norm.

In the first case, a malfunction could arise due to the fact that the installation was carried out by non-professionals. Many check valves are manufactured with the ability to change the factory settings for the spring rate. A specialist should adjust the stiffness. If the settings have not changed, then most likely the spring has weakened, in this case, it is advisable to replace it with a new one.

If the cause of the breakdown lies in the increased pressure in the pipeline, then before installing the safety valve, it is recommended to install a pressure reducing valve.

If there is excessive pressure in the pipeline, you can install a pressure reducing valve at the entrance to the apartment, so you will protect all devices in your home at once.

You will spend very little money on the purchase of a safety valve, and you will get the safety and long service life of the water heater.

Installation

Before installing safety fittings on an installed water heater, it is necessary to study the offer of the construction market and select a quality product.

Good valves have several distinguishing features.

- The body of a good unit is made of seamless brass alloy. It is sometimes nickel-plated to prevent corrosion and scale formation. Unlike cheap copper or aluminum alloys, brass is heavier and can be easily distinguished.

- When you press the stem of a high-quality shut-off valve, you can see how the plug goes tight inside the body. Even its slight jamming at the end is allowed.

- A bad valve can be identified simply by blowing into it. If, even with a strong pressure on the rod, air comes out freely, then it is better not to take the product. At the same time, if water periodically drips from the fitting of the installed constipation, this does not mean its breakdown. Perhaps you just need to clean the plug from the sediment and everything will work again.

If you follow these tips, you can choose the right fuse the first time and start installing it right away. There are few requirements for her.The valve is always installed in a cold water line. It is placed between the shut-off valve and the pipe inlet to the boiler body. You can cut it directly into the water supply pipe or install a special tee at a distance of no more than 200 cm from the heater inlet.

In addition to the fuse, nothing should stand in this area. Most models are installed so that water enters them vertically from below. An arrow must be marked on the body of the fuse to indicate this movement.

A PVC tube is connected to the fuse fitting, connecting it to the sewer pipe. It is better if this tube is transparent - you can see if the device is working properly.

The installation process itself is divided into several stages.

- Disconnecting the installed boiler from the power supply and draining the water from the tank. You need to make sure that the water supply to all pipes is shut off, otherwise, at the time of cutting the required area, you can simply flood all the apartments located below.

- The valve body is purged with air to remove accidental debris and dust. A tow or FUM tape is being prepared, which will serve to waterproof the threaded connection.

- The valve is screwed in with a wrench at the junction of the pipe and the boiler. The arrow on the valve body must line up with the direction of flow of the fluid. The union nuts must be well tightened, the joint can be additionally coated with silicone sealant.

- Before connecting the boiler to the power grid, it is worthwhile to pressurize the connection using cold water. If, after 5 minutes of fluid flow, drops do not appear at the junction, then everything is connected correctly.

Also, the safety and non-return valves are checked for "cold". In the first case, you need to press the trigger flag at first weakly (the first drops of water should appear), and then at full strength. When pressed fully, water should flow quickly through the transparent discharge tube. The check valve can be checked by filling the tank completely and shutting off the central water inlet. When you open the tap in the bathroom or kitchen, the flow of water should quickly stop. If water continues to flow from the tap for several minutes, then the check valve needs adjustment.

Malfunction valve and its adjustment

With a safety device, only two things can happen: either water does not flow from it, or, on the contrary, it drips very strongly.

To understand the principle of operation of the safety valve, let us clarify that it is normal when the water is heated, the pressure is adjusted, and the water is released. This can also happen when the boiler is off, that is, it does not heat up the water. This is because the response limit of the safety device is lower than the water pressure in the water supply system, that is, if the device can withstand 6 bar, and the water supply system supplies water at a pressure of 7 bar. If the bleeding of water for this reason occurs often, then you can equip the water supply system with a special reducer. It will be more convenient to install it immediately at the water inlet to an apartment or house. But you can choose a small model and put it directly in front of the boiler to regulate the pressure in it.

You can check the serviceability of the valve in another way. After turning off the boiler, you need to raise and lower the emergency pressure relief lever several times. Water will stop dripping from the boiler safety valve and will drip again when heating starts.

If water continues to flow from the boiler safety valve, it may indicate a blockage in the device. The collapsible model must be removed, cleaned and replaced. The non-collapsible option can only be replaced.

Of course, the constant dripping of water is not a pleasant sight, but it is not dangerous. But if, on the contrary, water does not appear in the nozzles when the pressure rises, then, most likely, the outlet fitting or the safety valve itself is clogged.You need to clean them, or replace them if this does not help.

Is the normal operation of the water heater important?

It is likely that the stories about the principle of the check valve and its structure did not clarify the problem of why this device is so important. So let's (purely hypothetical) consider the situation that can happen in the absence of a valve.

So, we did not install a valve that would block the return flow of the water entering the device. As long as the internal pressure remains stable, the boiler will function correctly. One of the laws of thermodynamics explains all this - the higher the temperature of the liquid in the tank, the higher the pressure becomes. Soon the moment will come when the pressure will exceed the pressure of the incoming water and, as a result, hot water will begin to flow into the water supply system. In turn, this heated water will be able to flow out of the taps or even from the cistern of your toilet.

Note! Despite the criticality of the situation, the temperature controller will continue to function properly, while the heating element will consume electricity in vain.

A moment will bring greater criticality to the situation if the pressure in the pipeline suddenly drops for one reason or another. And this, you see, happens quite often, for example, if at night at water pumping stations they decide to reduce the load on the system. There is another option - an accident has occurred or repair work has begun, as a result of which the pipeline is completely emptied. All the liquid that was previously in the storage tank is drained into the water supply system, and the heating element will begin to heat the air, as a result of which it will quickly burn out.

See also, the main pipework that must be observed when arranging a boiler room in a private house. Learn more

Perhaps you will say that there must be an automation in the boiler, which stops it working in such cases. First of all, such automation often fails, in addition, it is not available on all models of water heaters.

There are those "smart guys" who install a conventional check valve and believe that this will be enough. In fact, it is more like planting a bomb in your own house, because it is creepy to even imagine what could happen if the thermostat breaks down! The water in the boiler will start to boil, but there is simply nowhere for excess pressure to escape and it will continue to grow. It's also good that if the enamel coating just cracks inside the tank, it means that you've got off well. But the boiler can explode!

If the pressure drops sharply due to such cracks, then the water temperature returns to the legal hundred degrees, but the internal temperature in the boiler will be much higher. But all this may not happen if you have installed a good water heater check valve. So, as a conclusion to all of the above, we note once again what we get from such a valve.

- The valve releases excess fluid from the device if it becomes hot, thereby keeping the internal pressure within a safe range.

- It also prevents water from flowing back into the pipeline.

- The valve softens possible pressure drops in the water supply system, and water hammer is no exception.

- And if the device has a corresponding lever, then it can be used to completely empty the boiler if repair work is required.

Operating principle

The principle of operation of the device, as well as its structure, is characterized by simplicity. Cold water coming from the mains pushes the plate on the non-return valve, so that the storage tank is filled with water. When the filling procedure is over, and the pressure in the tank is higher than the external pressure, the valve automatically closes. In the future, when the water gradually decreases, the same valve will provide a constant amount of it.

The second valve has a stronger spring, which is calculated for the increased pressure inside the boiler. The higher the water temperature rises, the higher this pressure becomes.

An important point: after the internal pressure in the device exceeds all permissible standards, the spring will be compressed, while opening the drain hole. Excess water flows into this hole, and the pressure in the storage tank returns to normal.

As we can see, the check valve for the water heater is necessary so that the pressure in the boiler is always within the normal range.

Note! In most cases, the water heater device is already equipped with a safety valve, and the operation of the device without preliminary installation is strictly prohibited. At the same time, the boilers do not provide that a tap can be installed from below to turn off the check valve, because this can really pose a threat to the entire system.

You can find out how to connect the boiler to the water supply on your own here

Video - principle and scheme of work