First of all - autonomously.

The answer, as you can see, contains the name itself.

This is its charm, and a lot of advantages, including:

- Complete independence from main gas.

- The ability not only to work without electricity, but to generate it.

- Exceptional safety, comfort in use.

- Environmental friendliness.

- Efficiency as well as economy due to the high calorific value of liquefied gas.

- Durability as a result of low sulfur content.

The principle of operation of the autonomous gas supply system (SAG) is based on the distribution of the propane-butane mixture between the consumption objects, which is stored under pressure in a gasholder - a tank made of high-quality steel.

SAG is widely used in gasification of not only production facilities where interruptions in gas supply are unacceptable. Civil construction also cannot do without it. It is used as the main, inexpensive source of energy for private houses, country cottages, summer cottages, in a word, everywhere where the main pipe does not reach.

In Western Europe and the American continents, SAG has long become the norm. Its implementation in our country is expanding.

We can say with confidence that an autonomous gas supply system is an alternative to main gas, an urgent solution to the energy problem.

In a word, a guest from tomorrow.

What is a gas tank

Gas holder is a steel tank designed for storing liquefied propane-butane gas. It is the main element of autonomous gasification. Any. And a small one - "dacha", and a "monster" in a giant enterprise.

He is the heart of the system. With its content, it provides autonomy - independence from everything outside.

The variety of species and types is very great. Consider "household". The one that in the overwhelming majority of cases is installed in cottages, country houses, in summer cottages - horizontal, underground location.

There is nothing complicated, there is no supernova in the device. In essence, this is the same gas cylinder, only of a larger size. But it was made using a special technology from high-quality, corrosion-resistant steel, followed by its processing with polymers.

Each gasholder is equipped with a mandatory minimum of devices that ensure trouble-free operation.

It is no more difficult to operate than a gas cylinder. Requirements for strict observance of safety regulations are increased. The volume is solid!

Having bought a gas tank for a cottage or for a summer cottage, in, you will give yourself unsurpassed comfort. Immediately.

And you will also find new, reliable partners. For a long time.

Gas tank design

Gas storage manufacturers offer a wide range of models that differ in configuration, parameters, dimensions, and other criteria. Accordingly, the design of each of them may have certain differences. But there is a basic configuration that is common to all gas holders without exception, and it looks like this:

- Filling valve.

- Safety valve.

- Liquid phase take-off valve.

- Level gauge.

- Ready phase take-off valve (also includes an emergency valve).

- Pressure gauge in front of the gearbox.

- Pressure regulating reducer.

- Pressure gauge after the reducer.

- Condensate collector.

- Pressure gauge at the basement entry.

These are the main components of the gas tank, but, we repeat, their equipment can be supplemented depending on the features of the model.

What is an autonomous gas supply system and what does it consist of

An autonomous gas supply system is a closed complex of technical structures and units isolated from gas mains.

Allows for complete energy independence of detached buildings - private houses, country cottages and summer cottages.

It is used in most cases, provided there is no possibility of connecting to the main pipeline.

In recent years, it has been widely used in the presence of main gas, as it gives owners independence from possible unforeseen circumstances.

It includes:

- Gas holder - a tank for storing liquefied gas (analogous to the well-known gas cylinder, but with a larger capacity, equipped with additional equipment).

- Additional equipment for control over work, security:

- gas contamination sensors with shut-off valves, warning signaling devices;

- automatically controlled thermal shut-off valves;

- pyrotechnic means of fire protection:

- reliable grounding, as a prerequisite for trouble-free operation.

- Main pipes with shut-off valves.

An autonomous gas supply system is a warm, bright future for every citizen of the Russian Federation.

Propane

Filling the gas tank with propane is possible when using only a certain mixture of propane - technical (C3H8). Its distinctive parameter is precisely its elasticity, which in its performance reaches 35 ° C. The standard temperature at which propane reaches boiling point is minus 42.1. The required vapor phase selection procedure must be followed even under natural evaporation conditions. This approach allows the collection of the first phase and the use of gas liquefaction even at critically low temperatures.

Do I need permission to install a gas tank

In a word, NO!

Not necessary!

Nevertheless, rumors are circulating.

Many people confuse two, similar in sound, but different in meaning, legal interpretation of the concept:

- Autonomous gas supply of the site (country house, cottage, summer cottage).

- Documentary support of gas equipment with appropriate certificates, verification certificates, etc.

In the first case the prerogative of the decision belongs only to you.

No agreements with neighbors, local authorities, other authorities.

The only limitation is the capacity of the gas tank.

The volume is not more than 10,000 liters.

Taking into account that gas tanks of exactly this capacity are used in the private sector, all questions automatically disappear.

In the second case a dilemma arises:

Option "A": you ordered the installation of gas equipment from a specialized company. Wisely. Resolving "paper issues" became the responsibility of the contractor.

Option "B": you decided to become a "noble economy": you are ready to dig a pit, pipe trenches with your own hands, and now you are looking for a cheaper capacity on the Internet. That is to say, used. It doesn't matter, from under the herring or something. There would be more.

In this case, permits become necessary.

There is now a guiding tome called TS 032/2013. It regulates the rules for the use of high pressure equipment.

Professionals know and honor him.

Read this document, please, and you.

It will be cheaper for yourself.

Individual certification will be required.

And this is a lot for the money.

And troublesome.

By saving money when buying something unknown, or ordering work to a dubious manufacturer, you will not only be left behind, but risk getting acquainted with the Criminal Code.

After all, because of "cunning" stinginess, others risk suffering.

Your capacity is with "blue gold", not another.

Be judicious.

Order autonomous gasification of your personal household only from a reputable company. This will deprive yourself of the hassle of collecting permits.

Your business:

- Make an order (you can call).

- Make payment for the service.

How to save on gas station

Consumption and the number of gas stations throughout the year strongly depend on the area of the house and the level of its thermal insulation. Our average figures are a 200 sq. m. and the most "popular" volume for it is 4500 liters. With such initial data and permanent residence in the climatic zone of the Central Federal District, 2 refueling will be required per year: one at the beginning of the season in autumn, the second at the end in spring.

Gas tank filling machine

The nuance is that the price of gas fluctuates throughout the year with an amplitude of 25-30%. The maximum is in autumn, the minimum is in the spring. In order to refuel all the time at the lowest price, we recommend buying a gas tank with a larger capacity - 6000 liters or more. What capacity is better to choose for a country house, read the article: volume of a gas tank for a country house. The increased volume makes it possible to adjust your own consumption and wait for a period of low prices. Saving on refueling will very quickly pay off the increased cost of the device due to the higher capacity, and then there will be very decent savings.

What rules should be followed when refueling a gas tank?

Safety rules when refueling a gas tank

From time to time, each owner of an autonomous gas supply system has a need to replenish the tank with a supply of gas.

The frequency of the periodicity of this process depends on the manner of consumption of the stored volume and capacity of the gasholder. On average - from one to three times throughout the year.

With strict adherence to simple rules, the refueling process is absolutely safe.

Basic safety rules when refueling a gas tank, the failure of which may be influenced by the customer:

- Make sure that two people from the supply company will unload the LNG carrier. If only the driver is arriving, call the supplier.

You yourself, as an assistant, do not connect to the unloading under any circumstances.

This is not just "none of your business", but something to which you have no right.

- Before starting the discharge of gas, the driver and freight forwarder must:

- turn off the car engine;

- substitute wooden "shoes" under its wheels (metal, as well as other improvised items - say a brick - are unacceptable);

- ground the gas carrier;

- it is prohibited for the driver to stay inside the car until the end of unloading.

- all further operations are performed only with the engine off.

- The fastening of the hose to the drainage tip of the tank is carried out with special steel clamps. Only!

- The personnel of the LNG carrier are obliged to drain, wearing special clothing, hats and goggles.

- It is strictly not allowed:

- Leaving working equipment unattended;

- draining in the dark and during a thunderstorm.

Summary.

The gas tank is yours.

Take care of him.

If you violate the rules, immediately call the dispatcher of the supplier company.

Gas tank and safety

The scary terms "pressure", "explosion hazard", etc. should not confuse you. When manufacturing the equipment, it is mandatory to test the pressure of 25 atm at an operating pressure of only 3-6 atm. For additional safety net, pressure relief valves are built into the device, which are triggered already at 16 atm. In the entire history of operation, there have never been any cases of bursting of underground devices due to high pressure.

The main axiom of safety is that the device should be filled no more than 85% of its volume. The remaining volume is a reserve for the resulting vapor cap. For safety reasons, it is strictly forbidden to exceed this standard, since such a violation can cause excessive pressure.

Entrust the filling of the gas tank to professionals

It is advisable that the gas was emptied by no more than ¾ of the volume.Experience shows that this volume is enough for a full-fledged work for 1-2 months. During this time, you can have time to "swing" and order the filling. If you empty it "dry", then a very unpleasant moment arises. When the device is empty, the switched on gas boiler sucks in air, and the gas system is breathed in. In order then, after filling, to push through the air locks and make the system work again, you have to make multiple starts and stops of the gas boiler.

The entire gas system should only be serviced by qualified personnel authorized to do this work. Do not try to fill the device yourself or repair the system, which may contain gas residues, work with welding or perform any other manipulations.

Place gas tank on the site it is necessary so that from the place of the likely parking lot of the tanker to the tank there is no more than 40-50 meters. This is the typical length of the filler sleeve. The tanker is a truck with a decent axle load. It would be a good idea to plan in advance where the car will park for refueling so that it does not interfere with other transport, does not crush your flower beds or get stuck in the wheels in loose soil.

The machine that fills the gas tank with gas

How often do you need to fill the gas tank

The frequency of filling the gas tank depends on two factors:

- Tank volume.

- The manner of consumption.

Kaleidoscope of volumes

offers residents of Moscow and the Moscow region a wide range of storage tanks for liquefied propane-butane gas.

The capacity of the containers ranges from 2.700 to 10.000 liters and forms the following row:

– 2.700;

– 4.800;

– 6.400;

– 10.000.

A gas tank of smaller volume is much cheaper than its “older brothers”, but requires more frequent filling.

The largest - 10,000 liters - allows you to refuel once a year and save on seasonal price fluctuations. At the same time, the cost of it and its installation is the highest.

All are characterized by the following indicators:

- ability to withstand high pressure;

- great anti-corrosion resistance;

- long (decades!) Period of operation;

- absolute safety.

Which of the proposed volumes to choose is a matter of taste and capabilities of the customer.

About the manner of gas consumption

Here, instead of general words, we offer two examples for consideration:

- Leokadia Ksenofontovna is a great lover of cooking. That fries, then bakes, then rolls up the conservation. Her stove does not turn off.

She also loves to gossip with gossips. They sit in the kitchen, flushed as in a bathhouse, watching the cooking so that something does not burn. The heat, they think, comes from the stove.

But no. The heating boiler went off scale for a long time. The hostess would have to turn off the gas, tighten a little, but the trouble is: there is always a lot of news in the village. Once.

But 10,000 liters of gas is enough for a year.

Surprisingly.

- The grandchildren gave a gas tank to Grandfather Peter. For 4.800 liters. With installation. In order not to bother with firewood in my old age, I did not suffer.

The old man was always known for his zeal. Shore every penny. And now, he brews seagulls in a businesslike way, and proudly paces around the house in a sheepskin coat.

One filling is enough for two years.

No, he's not greedy. He is frugal.

True, very thin.

But tea is tea.

You won't get much better.

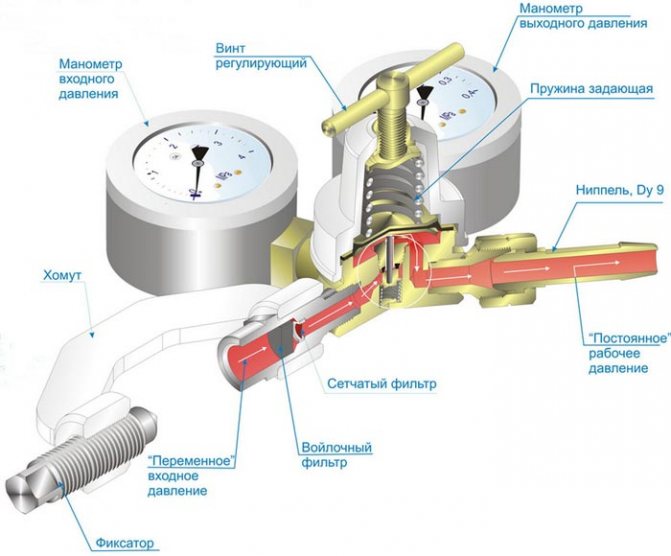

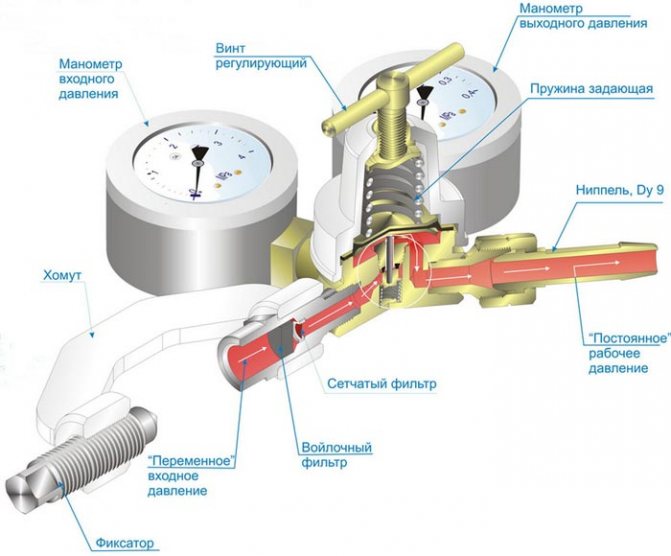

Pressure reducer for gas tank

The pressure reducer, as already mentioned, is one of the main elements that ensures the pressure stabilization and the normal operation of the equipment. Its principle of operation can be compared with a stabilizer in the power grid. It helps to stabilize the pressure of the gas that is supplied from the storage facility to the equipment. Also, gas pressure regulators for a gasholder maintain a certain pressure, which we receive at the outlet of their vessel, throughout the engineering network.

This element can have different mass and dimensions, body shape and throughput. But, despite this, it consists of a basic set of elements:

- has a body;

- supplemented by two gas chambers;

- is completed with inlet and outlet fitting;

- there are main and auxiliary springs;

- includes two valves - safety and pressure reducing;

- there is a membrane and a pressure gauge (1 or 2);

- equipped with an adjusting screw;

- complete with transfer disc with font.

The gas flow entering the reducer has a pressure of 1 - 16 bar. After passing through the gearbox, these indicators decrease to a stable value. For GOK models - 37 mbar, for REGO - 37-87 mbar. If the pressure exceeds the permissible norm, the safety valve is triggered and the gas supply stops.

Cylindrical high-pressure gasholders are designed for a working pressure in the gasholder of 0.25-2 MPa, and therefore their walls can have a thickness of up to 30 mm.

The gearbox operates fully automatically and does not require human control or intervention. You may need help only in case of flooding and getting wet, after which you will have to remove and dry the case.

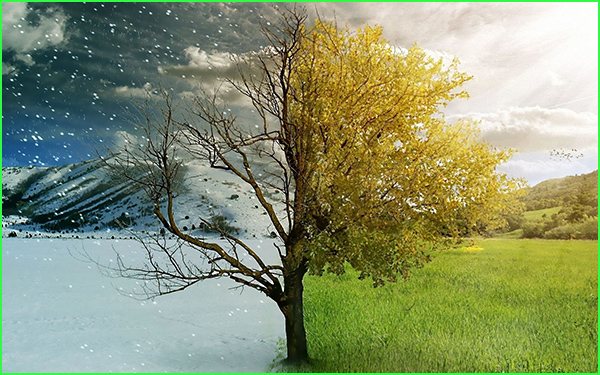

What time of the year can a gas tank be installed?

At any.

When it comes to the autonomous gasification of personal farmsteads (cottages, country houses, summer cottages), we mean the installation underground gasholder of horizontal type in conjunction with a set of other works that fully provide the concept of "turnkey work".

And we do not only mean.

strongly recommends just such a configuration when implementing a project "from" and "to" by the company.

For the optimal functioning of the autonomous gas supply, it is necessary to create conditions under which the system will constantly be in favorable ambient temperature conditions.

This is possible when you are below the level of soil freezing.

Consequently, there is a large amount of excavation ahead:

- pit for a gas holder;

- trenches for the pipeline.

What time of year is more appropriate for digging the ground?

Of course, warm - spring and autumn.

Two more arguments in favor of summer jobs:

- What matters is the quality of the concrete pad on which the tank is to rest. Concrete hardens and is responsive to preliminary compaction only at positive temperatures.

- The gas main from the tank to the house is made of plastic pipes, the joints of which are welded with a special tool. The ambient temperature for this type of work is standardized by technical conditions.

At the same time, the cold season is not an obstacle for the installation of autonomous gasification. Why wait for the onset of spring if you decide to order a SAG when a blizzard is howling on the street. Enjoy the comfort immediately.

We carry out work at a temperature of minus 40.

And our people are seasoned, with experience in working in the north, and the equipment is appropriate for solving such problems.

When the professionals get down to business, the time of year does not matter in the slightest.

Book even in summer or winter.

Enjoy the warmth!

Choosing a gas tank. Important nuances

Now on the market there are imported and Russian-made devices. Foreign manufacturers trump special grades of strong steel, which allow making the walls thinner, and the equipment itself lighter. Russian counterparts, on the contrary, are made of thicker metal with a decent margin of safety. In fact, this device is an ordinary barrel without any peculiarities and, in our subjective opinion, it is better to buy it with thicker walls. Read more in the article: which gas tank is better: information for the curious.

You can also watch a video about the installation and connection of the gas tank:

A fundamental point for those who want to save money. In no case do not buy a used container, this is a time bomb. In 99% of cases, a gasoe "with history" lay in the ground for 20-25 years, somewhere in Poland or the Czech Republic. They took it out, removed the outer protective tar layer, painted it and are trying to sell it at a reasonable price.The problem is that propane and butane contain a small amount of moisture, so the inner surface of the walls corrodes and gradually becomes "loose". There were cases when after filling such gas reservoirs a characteristic smell appeared on the site. Correcting the situation together with pumping and degassing will cost a lot of money.

Do not buy used gas tanks

Every spring, many owners of underground gas tanks call and complain about a gas supply failure. This is due to the flooding of the tank reducer with a seasonally high level of groundwater. Therefore, it is better to buy equipment with a high neck, in which the reduction group (reducer, filling valve, etc.) will always be located above the flooding level.

How to reduce gas consumption?

The savings are made up of little things.

Often, we forget about them, and as a result, it turns out that our huge gas tank has almost dried up.

SUDDENLY.

Here are some tips on how to reduce your gas consumption.

There are two ways to reduce gas consumption: active and passive.

Passive savings.

- Insulate your home:

- thoroughly eliminate all kinds of cracks in windows and doors. Even "microscopic". They are the main reason for the loss of heat in the house (and heating of the areas surrounding the house);

- pay attention to the insulation of walls, ceilings, floors;

- check (if necessary, reconstruct) the correct functioning of the chimneys and ventilation pipes. Install heat exchangers.

- Automate the heating process:

- install external and internal temperature sensors that regulate the gas supply to the boiler;

- use temperature controllers for radiators, which will provide different, preset heating parameters in each separate room of the house.

Active savings.

It is more connected with being in the kitchen, cooking.

- having cooked one dish, turn off the gas without waiting (oh well, it will “burn” for 5 minutes) until the ingredients for cooking the next are ready;

- do not waste a two-liter kettle, when you are going to drink tea, warm water just as much as necessary.

- cook food for the future for two days, as when heating a finished dish, gas is consumed much less than when cooking;

- use “smart” dishes with a wide bottom and appropriate material for the dish:

- for long-term heat treatment - with greater thermal inertia (cast iron);

- for fast - with low inertia (aluminum);

- check the oven is working properly:

- door tightness;

- the integrity of the foil.

And the last tip: refuel the gas tank only from trusted, reputable suppliers. They have "summer" (cheap) gas superior in quality (including propane content) to "winter" gas from the newly-minted, unknown "Caliphs for an hour."

supplies liquefied gas of excellent quality.

The principle of operation of the stabilization device

Modern pressure reducers for gasholders work on the principle of reverse action. Gas coming from the inlet rod tends to close the pressure reducing valve.

The adjusting screw compresses the main spring and when air escapes from the working chamber, the flexible diaphragm understands the transfer disc with the pin up. At this moment, the pin compresses the return spring, removing the reducing valve from the seat, the gas enters the working chamber.

Two-stage reducers are less susceptible to "freezing"; therefore, such devices must be installed on gas tanks in regions where extremely low air temperature values are noted

After moving the substance into the low pressure chamber, the gas is released into the system. As a result, the spring relaxes, the transfer disc with the pin lifts the valve, the gas from the upper chamber enters the low pressure chamber, the process is repeated.

With a decrease in gas release, the pressure in the chamber will increase, the spring will assume the “closed” position, the valve will sink into the seat, the gas supply to the reducer and the low pressure chamber will stop.

To stabilize the pressure of the gas in the gasholder, two-stage reducers are used. The fuel in such regulators goes through two stages of reduction before entering the outlet fitting.

To increase the life of the gearbox, it is necessary to minimize the contact of the membrane and other elements with moisture. For this, at the stage of installation, decorative or standard protection is installed above the tank.

Two stages of the reducer ensure maximum stability of the outlet pressure, therefore they are safer during operation.

In addition, the two-stage devices are frost-resistant, so they provide a continuous supply of gas in summer and winter. If the gearbox is still frozen, we recommend reading our other article, where we described in detail how to fix this problem. Read on for more details.

Where and how to locate the gas tank on the site?

Every land owner who dreams of acquiring his own gas facility - to install a gas tank, sooner or later, regardless of whether he lives in a city or in a rural area, thinks about how to place the tank in such a way as not to turn the unfortunate several hundred square meters into an industrial zone ... How to do it beautifully, tastefully. So that both the benefits of gas and the aesthetic appearance of the site are preserved.

This is not difficult to do:

- Focus on the design engineer aspect.

- Refer to "free" designers

- Get creative with yourself. More expedient and cheaper.

Whichever choice you make, the main thing is to withstand technical standards. Distances to objects located on the territory should be:

- to the neighboring site - 20 m;

- to the street lighting line - 15 m;

- to buildings - 10 m;

- to the road, water supply, sewerage - 5 m.

It is impossible to get closer than the indicated distances. But further, please. The price of a couple of extra meters of pipe will not have a significant impact on your budget.

Possible design solutions:

- sow the protective zone of the gas tank with lawn grasses;

- the flower garden will look great.

What to do with the throat protruding from the ground?

Organize an alpine slide.

In this case, the nameplate must be easily accessible.

Shrubs, let alone trees, cannot be planted in the security zone.

By showing initiative and thoughtful approach during the design and installation stages,

then for several decades you will enjoy your own creativity - landscape design created by personal imagination and hands.

At the same time, in the cold season, contemplating your creation through the window, you will feel the enveloping heat emanating from the boiler powered by autonomous gas.

Gas storage in gasholders

⇐ Previous Page 22 of 22

Gas holders are called large-volume vessels designed for storing gases under pressure. There are low (4000 Pa) and high (from 7 * 101 to 30 * 101 Pa) pressure gas tanks. In gasholders of the first type, the working volume is variable, and the gas pressure changes insignificantly during filling or emptying. They are wet and dry.

Fig. 16.1. Daily gas consumption schedule

| - average daily gas consumption; |

| - actual gas consumption; |

| - excess gas; |

| - gas shortage; |

Fig. 16.2. Principle diagram of low pressure gas tanks: a) wet; b) dry;

1 - reservoir; 2 - bell; 3 - rollers; 4 - gas pipeline; 5 - washer; 6 - seal; 7 - travel stop.

Wet gasholders(Fig. 16.2 a) consist of two main parts - a vertical cylindrical tank 1 filled with water (stationary part) and a bell 2 placed inside the tank and representing a cylinder open at the bottom and having a spherical roof (movable part). To facilitate the movement of the bell, rollers 3 are used. Gas injection and extraction are carried out through gas pipeline 4.

The principle of operation of a wet gas tank is as follows.When gas is pumped into the gasholder, the pressure under the bell increases and water is partially displaced into the annular space between the reservoir and the bell. It acts as a hydraulic seal. As soon as the gas pressure exceeds the load created by the mass of the bell, the latter begins to move upward, freeing up the volume for new amounts of gas. When emptying the gasholder, the gas pressure under the bell decreases and it goes down.

For a fuller use of the volume of the bell, its height should be equal to the height of the tank. In gas tanks of large (over 6000 m!) Volume, the movable part is divided into several links, which fit into each other like a telescope. To avoid distortions when moving the moving parts, as well as for the perception of horizontal loads (for example, wind loads), guides are attached to the tank along which rollers fixed in the upper part of the bell move (not shown in the figure).

Dry gas tanks(Fig. 16.2 b) consist of a vertical body of a cylindrical or polyhedral shape with a bottom and a roof, inside which there is a movable washer (piston) equipped with a special seal. The principle of operation of a dry gas tank is similar to that of a steam engine. Under the pressure of the gas supplied under the washer, it rises up to a certain limit, and when gas is withdrawn, it goes down, maintaining a constant pressure in the gasholder with its mass. Dry gas tanks are less reliable than wet ones, but also less metal-consuming.

The disadvantage of low pressure gasholders is that they have a relatively low storage capacity.

High pressure gas tankshave a constant geometric volume, but the pressure in them changes with filling or emptying. Although the geometric volume of gas tanks of this class is much less than the volume of low pressure gas tanks, the amount of gas stored in them can be significant due to the high pressure. So, if in a wet gasholder with a volume of 100 m3: (104 m3 of gas can be stored under a pressure of 4000 Pa, then in a gasholder with a pressure of 1.6 MPa of the same geometric volume - 1700 m3, i.e. almost 17 times more.

High pressure gas tanks are cylindrical and spherical. Cylindrical gas tanks (Fig. 16.3) have a geometric volume from 50 to 270 m3. Since all of them have an inner diameter of 3.2 m, they differ only in the length of the cylindrical part - shell 1. On both sides, bottoms 2 are welded to the shell, which have the form of a hemisphere. To control the gas pressure in the gas tank, manometers 3 are used. The gas tank is installed on the foundation 4 horizontally or vertically.

Cylindrical gas holders are designed for pressures from 0.25 to 2 MPa. Their wall thickness can be up to 30 mm.

Spherical gas tanks in our country have a geometric volume from 300 to 4000 m3 and a wall thickness from 12 to 34 mm. The spherical shape of the high pressure gas storage vessel is the most advantageous in terms of metal consumption and overall cost. Spherical gas holders are mounted from individual petals, cut in the form of orange slices, as well as from the upper and lower bottoms, which have the shape of a spherical segment. The gasholders' supports are made in the form of a cylindrical glass made of reinforced concrete with a steel support ring or in the form of columns-columns attached to the ball along the equatorial line and interconnected by a system of stretch marks.

Batteries of high-pressure steel gas tanks (up to 1.5 MPa) were used in Moscow to compensate for the uneven consumption of gas supplied in relatively small quantities through the Saratov-Moscow gas pipeline. However, with the development of gas pipelines and an increase in gas consumption, gas storage facilities with a capacity of millions of cubic meters were required. Only underground gas storage facilities could provide storage of such quantities of gas.

Underground gas storage

An underground gas storage (UGS) is a gas storage created in rocks.

The world's first UGS facility was built on the basis of a depleted gas field in the province of Ontario (Canada) in 1915. In our country, the first underground gas storage facility, the Bashkatovskoye UGS facility in the west of the Orenburg Region, was commissioned in 1958.

Fig.16.3. Cylindrical high pressure gas tanks: a) - horizontal; b) - vertical.

There are two types of UGS facilities: in artificial workings and in porous formations. The first type of storage has received limited distribution. So, in the USA as of September 1, 1994, they accounted for only 6% of 371 UGS facilities: 1 - in a converted coal mine and 21 - in rock salt deposits. The remaining 349 UGS facilities belong to storage facilities of the second type: 305 of them are located in spent oil and gas fields, and 44 - in aquifers.

The widespread use of storage facilities in depleted oil and gas fields is explained by the minimal additional costs for UGS facilities, since nature has already “made” the trap with a permeable formation.

A schematic diagram of an underground gas storage facility is shown in Fig. 16.4.

Gas from the main gas pipeline 1 through the gas pipeline branch 2 enters the compressor station 4, having previously been cleaned in dust collectors 3. The compressed and heated gas during compression is cleaned from oil in separators 5, cooled in a cooling tower (or AVO) 6 and through oil separators 7 is supplied to the gas distribution point (GSP) 8. The gas distribution to the wells is carried out at the hydraulic fracturing.

The pressure of the gas pumped into the underground storage reaches 15 MPa. For injection, as a rule, gas otopressors are used.

When gas is taken from the storage facility, it is throttled at the hydraulic fracturing station 8, the gas is cleaned and dried in devices 9, 10, and then, after measuring the amount with a flow meter 11, it is returned to the main gas pipeline 1. If the gas pressure in the underground storage is not high enough, it is preliminarily compressed and cooled ( not shown in Figure 16.4).

Cleaning the gas from dust, scale and oil particles before pumping it into the storage is very important, because otherwise, the bottomhole zone becomes clogged and the well injectivity decreases.

The optimal depth at which underground gas storage facilities are created is from 500 to 800 m. This is due to the fact that with increasing depth, the costs of well construction increase. On the other hand, the depth should not be too shallow, because sufficiently high pressures are generated in the storage.

The underground storage is filled with gas for several years, pumping in each season a slightly larger volume of gas than that which is being taken.

Fig. 16.4. Schematic diagram of UGS surface facilities:

I - main gas pipeline; 2 - gas pipeline branch; 3.9 - dust collectors; 4 - compressor station; 5 - separator; 6 - refrigerator (cooling tower); 7 - oil separator; 8 - gas distribution point; 10 - gas dehydration unit; 11 - flow meter

The total volume of gas in the storage consists of two components: active and buffer. The buffer volume provides the minimum required filling of the storage, and the active volume is the volume of gas that can be operated on.

As of September 1, 1994, the total volume of natural gas in US UGS facilities exceeded 206 billion m3, of which 86.9 billion m3 (42.3%) is active gas and 119.1 billion m3 is buffer gas. The total maximum injection rate into the US UGS facility is 865 million m3 / day, and the withdrawal rate is 1,900 million m3 / day.

In 1995, the volume of active gas in UGS facilities in Russia was about 45 billion m3. According to forecasts, by 2000 it will reach 50 ... 55 billion cubic meters! -70 ... 75 billion m3.

Gas distribution networks

Gas distribution networkrefers to a system of pipelines and equipment serving for the transport and distribution of gas in settlements. At the end of 1994, the total length of gas networks in our country was 182 thousand km.

Gas enters the gas distribution network from the main gas pipeline through the gas distribution station. Depending on pressurethe following types of gas pipelines of gas supply systems are distinguished:

- high pressure (0.3 ... 1.2 MPa);

- medium pressure (0.005 ... 0.3 MPa);

- low pressure (less than 0.005 MPa).

Depending on the number of stages of pressure reduction in gas pipelines, the gas supply systems of settlements are one-, two- and three-stage:

^ one-stage (Fig. 16.5 a) is a gas supply system in which gas is distributed and supplied to consumers through gas pipelines of only one pressure (usually low); it is used in small settlements;

2) a two-stage system (Fig. 16.5 b) ensures the distribution and supply of gas to consumers through gas pipelines of two categories: medium and low or high and low pressure; it is recommended for settlements with a large number of consumers located on a large territory;

3) three-stage (Fig, 16.5 c) is a gas supply system, where the supply and distribution of gas to consumers is carried out through gas pipelines of both low, medium and high pressure; it is recommended for large cities.

Fig. 16.5. Schematic diagram of gas supply to settlements: A - one-stage; B - two-stage; B - three-stage;

1 - branch from the main gas pipeline; 2 - GRS; 3 - low pressure gas pipeline; 4 - medium pressure gas pipeline; 5.6 - gas control point; 7 - high pressure gas pipeline.

When two- and three-stage gas supply systems are used, additional gas reduction is performed at gas control points (GSP).

Low pressure gas pipelines are mainly used to supply gas to residential buildings, public buildings and public utilities. Gas pipelines of medium and high pressure (up to 0.6 MPa) are designed to supply gas to low pressure gas pipelines through urban hydraulic fracturing, as well. also for gas supply to industrial and large utilities. Gas pipelines of high (more than 0.6 MPa) pressure supply gas to industrial consumers, for whom this condition is necessary according to technological requirements.

By appointmentin the gas supply system, a distinction is made between gas distribution pipelines, gas inlet pipelines and internal gas pipelines. Distributiongas pipelines provide gas supply from gas supply sources to gas pipelines-inputs. Gas pipelines-inputsconnect gas distribution pipelines with internal gas pipelines of buildings. Internalis called the gas pipeline running from the gas pipeline input to the connection point of the gas appliance, heating unit, etc.

By location in settlementsdistinguish between external (street, intra-quarter, yard, inter-workshop, inter-settlement) and internal (intra-workshop, intra-house) gas pipelines.

By location relative to the surface of the earthdistinguish between underground and aboveground gas pipelines.

By pipe materialdistinguish between metal (steel, copper) and non-metal (polyethylene, asbestos-cement, etc.) gas pipelines.

Connection and disconnection of individual sections of gas pipelines and gas consumers is carried out using stop valves - valves, taps, valves. In addition, gas pipelines are equipped with the following devices: condensate traps, lens or flexible expansion joints, control and measuring points, etc.

Gas control points

Gas control points (GRP) are installed at the junction points of gas pipelines of various pressures. Hydraulic fracturing are designed to reduce pressure and automatically maintain it at a given level.

Fig. 1 6.6. Hydraulic fracturing flow chart:

1- inlet gas pipeline; 2 - disconnecting devices; 3 - filter; 4 - safety shut-off valve; 5 - pressure regulator; 6 - outlet gas pipeline; 7 - manometer; 8 - safety relief valve; 9 - bypass; 10 - bypass control valve

The hydraulic fracturing scheme is shown in Fig. 16.6.It includes inlet gas pipeline 1, gate valves 2, filter 3, safety valve 4, pressure regulator 5, outlet 6 and bypass 7 gas pipelines, pressure gauges 8. Gas entering the hydraulic fracturing unit is first cleaned in filter 3 from mechanical impurities. Then it passes through the safety valve 4, which serves to automatically shut off the pipeline in case the outlet pressure rises above the set value, which indicates a malfunction of the pressure regulator 5. The operation of the regulator 5 is also monitored using pressure gauges 8.

Some hydraulic fracturing stations are equipped with instruments for measuring the amount of gas: diaphragms complete with differential pressure gauges or rotary meters.

⇐ Previous22

Recommended pages:

Equipment selection

The responsibility for the choice of any gas equipment is best left to the designers.

It is they who will be able not only to correctly determine the required characteristics of the gas holder, but also to correctly place it on the personal plot.

What characteristics are we talking about?

- Depending on the number of gas-consuming appliances and their unit costs, the total gas demand of the house is determined. Based on this value, experts decide what the minimum capacity should be at the tank.

- Gas tanks can be installed on networks with different gas pressures. Industrial equipment is installed on high-pressure gas pipelines, while low-pressure gas is supplied to residential buildings.

- The tank can be either horizontal or vertical. The choice of design depends on the availability of free space on the site, the degree of landscaping and landscaping, distance from residential buildings and communications.

- Gas storage can be installed underground or above ground. In this case, the ability to comply with the standards for the minimum distance from the equipment to the residential part of the house and the organization of safe operation is of decisive importance.

An important point: at negative temperatures, the gas evaporates worse, so the installation of aboveground tanks is undesirable. Not only does overhead equipment take up space. For normal gas supply, you will need to take measures to heat the gas.

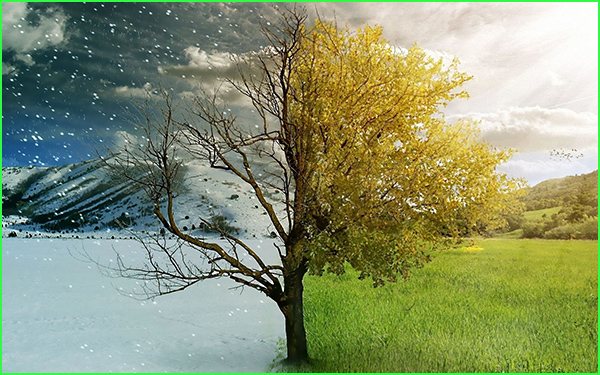

Influence of the environment

Gas holder device Gas consumption may vary depending on the season. This is explained by the fact that in different seasons the gas mixture differs in the percentage of substances included in it.

Typically, LPG is produced by mixing butane and propane. The properties of these gases are not the same. They have different boiling points, due to which in summer butane prevails in the gas that enters the devices, and propane in winter.

If the owner of the house is going to live in it all year round, it is necessary to buy gas with a higher propane content for the winter period. This is done so that the gas supply to household appliances is constant and reliable.

The gradual consumption of gas during the cold period leads to the fact that more butane remains in the gasholder. To explain this fact is simple: at low temperatures, butane practically does not evaporate and remains in the storage in a liquid state.

Thus, in winter, the devices consume a maximum of propane. The moment comes when the pressure in the gas tank will drop so much that gas supply interruptions will begin.

What should be the pressure

Consider Pressure Sensors... There is a lot of everything, a lot of all kinds of cranes. You need to pay attention to them when a gas carrier arrives at you. This is very important so that you can understand what quality of gas came to you. Good quality propane gas - it has a higher pressure than butane. And for gas tanks it is exactly propane gas that is required so that the gas contains as much propane as possible.

In winter, you need to watch that the pressure is at least 5, and in summer it should be at least 8, or even 9 atmospheres. This means that you have received high-quality gas. This is an indirect indicator, but very important. Few people know about this.This is a moment that we even define for ourselves. If we arrived at some wholesale base and refueled with low-quality gas, the pressure will be very low. This will be a signal for us that we need to check. Something is either wrong with the system, or we were simply flooded with low-quality gas. Then we start using a density meter, with which we check the quality of the gas. Thus, we understand that we need to change it, or we agree that everything is fine with us and we are already transporting this gas to the customer.