Expanded polystyrene is a gas-filled material obtained from polystyrene and styrene copolymers. The gas-filled styrene granules are dissolved in the polymer mass, then the mass is heated with steam, as a result of which the initial granules multiply in volume. The granules occupy a block shape and are sintered together. This technology is used to produce expanded polystyrene.

Natural gas is used for standard styrofoam. For fire-resistant - carbon dioxide. Expanded polystyrene is an inexpensive building material that does not require special knowledge and special equipment to work with it. The material is used mainly as thermal insulation and less often as decorative elements.

- 2 Scope of application of expanded polystyrene

- 3 Advantages and disadvantages of expanded polystyrene

- 4 Technology of insulation with expanded polystyrene

4.1 Thermal insulation of a concrete floor using expanded polystyrene granules

- 4.2 Insulation of floors with expanded polystyrene sheets under a concrete screed

- 4.3 Insulation of floors on logs

How to choose polystyrene foam

So, you have decided to insulate your house with expanded polystyrene. Let's take a look at how to choose the right quality material. When buying insulation, pay attention to the following criteria:

- Appearance... The material should be free of peeling granules, uniform white color, no damage or debris.

- Smell... The material must not have any chemical or other foreign smell.

- Structure... Granules should be well sintered, approximately the same size, the fracture line at breakage should pass both between the granules and directly inside them.

- Packaging... Buying material in unique labeled packaging with information about the manufacturer, regulatory document, its brand and recommendations for use, you can be sure that you are purchasing high-quality expanded polystyrene.

- Information on the characteristic of expanded polystyrene... The packaging must indicate the thermal and physical and mechanical characteristics, as well as the dimensions of the sheet.

- Place of sale... Material you need to buy at legal points of sale, in the presence of which there is a covered warehouse.

You can read about the main characteristics of extruded polystyrene here:

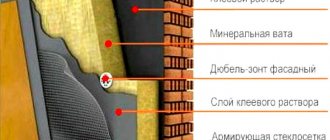

How to install the material under the facade plaster

So that the thermal insulation layer does not lose its integrity, the expanded polystyrene sheets must be joined with cut pieces. If too large gaps appear between them, they are sealed with liquid polystyrene foam or wedge-shaped pieces of insulation.

In this case, polyurethane foam cannot be used, since it can spread the insulation layer and thereby violate its integrity. The joints between the thermal insulation must be sanded with a float.

For attaching expanded polystyrene sheets, disc dowels are used, equipped with hats in the form of umbrellas, which help to press the heat-insulating material to the wall surface. If you take other elements such as nails or screws for fastening, there will be a high risk that the thermal insulation layer will be deformed under the influence of atmospheric phenomena. After the installation process is over, the dowel heads must be carefully putty.

Scope of application of expanded polystyrene

Depending on the density of the material, expanded polystyrene is used in the following areas:

- As unloaded thermal insulation slabs with a density of up to 15.0 kg / m3used in enclosing structures such as: floors, internal partitions, pitched roofs, attic floors, insulation of balconies, containers, etc.

- For loadable thermal insulation slabs with a density of 15.1 to 25.0 kg / m3 used in the production of sandwich panels and in the insulation of walls, floors, rabbits, three-layer walls with a protective and decorative layer of brick.

- Any facade brands of slabs with a density of 16 to 20 kg / cubic meter. used for thermal insulation of vertical enclosing structures various facade thermal insulation systems with external plaster layers.

- Plates with a density of 25.1 to 25.0 kg / m3 used in structures with significant loads - Self-leveling floors in civil and industrial construction, insulation of foundations, walls in basements. And also in the manufacture of packaging products.

- Plates with a density of 35.1 to 50.0 kg / m3 are used as thermal insulation for surfaces that are particularly loaded during operation. - basement floors, zero cycles of buildings, garages and parking lots, in the construction of floors and roofs used for automobile and pedestrian loads, etc.

The consumer must know all the properties of the thermal insulation material in order to make the best decision for himself. Consider the pros and cons of expanded polystyrene.

The fact that polyurethane foam or expanded polystyrene is better can be learned from this material:

Features of the use of disc dowels when fastening

When installing insulation by means of disc dowels, you can use special adhesives. This is especially advisable in the presence of irregularities on the surface, as well as all kinds of pits and defects.

The sheet of extruded polystyrene foam must be soaked in the adhesive and pressed against the wall. The glue mixture should be applied using special combs, which are usually used when laying tiles from tiles.

Evgeny Filimonov

Ask a Question

It is necessary to alternate layers of glue so that the sheets fit better to each other, regardless of the unevenness at the base of the wall.

After the glue is dry, you need to make holes for the disc dowels using a hammer drill or hammer drill. They are not recommended to be installed until the glue is completely dry, since during installation the sheets may shift or press in too much, and this will require additional costs of putty and plaster. Dowels should be placed along the edges of the sheets and in their center.

Advantages and disadvantages of expanded polystyrene

TO positive the qualities of the material include the following points:

- Ease of use... Styrofoam plates are easily processed with a household knife or fine-toothed hacksaw. Easily attached with mounting accessories, glued with glue or cement mortar.

- Light weight... Due to their low weight, the slabs can be lifted to a height without additional mechanisms.

- Environmentally friendly product. Expanded polystyrene is not poisonous, does not emit dust during processing, is odorless and does not cause skin irritation.

- Resistance to biological and chemical influences... Due to the fact that foam is a synthetic product, animals and microorganisms do not use it for food. It is also not a habitat for bacteria and fungi.

The advantages of the material include such qualities as sound insulation, moisture resistance, low price and durability of the material (more than 50 years).

Negative the qualities of this insulation are much less:

- Deformation... Low heat resistance allows the development of thermal deformation at a temperature of + 80-90 degrees.

- Flammability... Gas-filled expanded polystyrene granules are capable of igniting at very high temperatures.

- The need for protection from mechanical damage

Having familiarized yourself with the basic properties of the material and opting for polystyrene foam, you can use the following options for floor insulation.Warm floors are an integral part of an energy-efficient home. Floor insulation with expanded polystyrene under the screed will help reduce heat loss and will make the temperature in the room comfortable and cozy.

Insulation with expanded polystyrene is an affordable and simple way of thermal insulation.

Performance characteristics of expanded polystyrene

Extruded polystyrene foam, like polystyrene, is made of polystyrene. But in terms of thermal insulation qualities and technical characteristics, polystyrene foam is in many ways superior to foam plastic and other modern heat insulators.

Extruded polystyrene foam has the following advantages:

Physical and technical characteristics of expanded polystyrene.

- strength (can withstand a load of 1 m² up to 35 t);

- waterproof (not prone to deformation and mold formation in a humid environment);

- resistance to external factors (temperature extremes, ultraviolet rays, atmospheric humidity);

- does not deteriorate by rodents, insects;

- low vapor permeability (no vapor barrier installation is required);

- fire safety;

- environmental friendliness (the material is used for the manufacture of containers for food);

- durability (service life - 50 years).

Extruded polystyrene foam has a thermal conductivity of 0.027-0.033 W / (m.K), high compressive strength and zero capillarity.

The cost of this heat insulator is several times higher than the cost of other heat insulators (PPS, PSB-S). But this price is fully justified by excellent performance, durability, versatility.

Back to the table of contents

Insulation technology with expanded polystyrene

Insulation of a concrete floor using expanded polystyrene granules

Adding granules to the concrete solution allows the concrete floor to acquire thermal insulation properties. To do this, mix the concrete solution. Add dry cement to a small amount of water and stir with a drill with a special nozzle until the consistency of sour cream. Without stopping to interfere, polystyrene granules are added to the solution. This can be the ratio of concrete to granules as 1: 3 and 1: 6. Than the more filler, the warmer the floor... Depending on what hard floor covering the concrete-expanded polystyrene screed will then be covered, the ratio is determined. The more granules, the lower the strength. Also, the screed with granules has a soundproofing quality.

Insulation of floors with expanded polystyrene sheets under a concrete screed

To begin with, the soil is compacted, crushed stone is poured and a layer of sand and a film are covered on top. Then the sheets of material are laid tightly around the entire perimeter of the floor. The joints are filled with polyurethane foam or glued. Lay another layer of film. To protect sheets from mechanical stressto which the floors are exposed must be laid on the sheets durable mounting mesh... Fill the surface with a 40-60 mm thick screed mortar. When the solution hardens, the floor covering is laid.

Insulation of floors on logs

If the floor is made using a log, then it becomes much easier to insulate the floors. To begin with, wooden floor elements are processed antifungal drugs and moisture protection agents. Then, boards or sheets of chipboard are attached to the self-tapping screws from the lower side of the lags, and sheets of material cut to the size of the opening are laid on them. From above, the covering is covered with foil and floor covering.

An article dedicated to floor insulation with penoizol is here:

- TECHNONICOL #xps_carbon Do you want to know how extruded polystyrene foam is produced in the TECHNONICOL company? ... Production of extruded polystyrene foam TECHNONICOL 145 views ⌚9 months ago

- I plaster foam plastic, expanded polystyrene on the foundation (plinth) with my own hands Second Channel - I LIVE IN THE VILLAGE ...

- Garny peregryazі friends. Preparing the wall for tiles with expanded polystyrene. Steam room floor tiles 1,341 views ⌚10 months ago

- Wedge shaped acoustic diffuser.ACOUSTIC POLYSTYRENE PANEL ECHOTON STYROFOAM AURA 138 views ⌚10 months ago

- 8-903-743-27-96 8-903-724-77-28 n-dom.ru ceresit.msk.ru terraco.pro How Ceresit CT84 glue foam is applied to the sheet ... How to apply foam glue to the expanded polystyrene sheet, plaster facade on a frame house 2 ⌚10 months ago

- It is not the first year that SIBUR has been producing AlfaporTM expanded polystyrene in Perm. It has found wide application ... Extruded polystyrene foam CARBON ECO VS CARBON ECO FAS_with_titer 159 ⌚10 months ago

- 8-903-743-27-96 8-903-724-77-28 n-dom.ru ceresit.msk.ru terraco.pro How to insulate the basement of a house with extruded ... "Green" expanded polystyrene: a new word in sustainable construction 24 264 views ⌚10 months ago

- Thermal insulation of a balcony is a relatively simple measure that can increase the level of comfort in ... How to insulate the basement of a house with extruded polystyrene foam, glue it on Ceresit CT84 glue-foam on bitumen 4,019 views ⌚10 months ago

- Preparation of the site for laying, and trimming of expanded polystyrene. Thermal insulation of a balcony with TECHNONICOL extruded polystyrene foam with finishing with plastering compounds 3 ⌚10 months ago

- We disassemble the expanded polystyrene under the Intex Frame Pool after 3 years. What happened to the sand pillow? Me ... Mats contour penoplex expanded polystyrene 3 views ⌚10 months ago

- Reinforcement of a floating screed on expanded polystyrene using a Shtrek mesh laid on 6mm beacons as ... Warm pool, preparation of a warm base for the pool, made of extruded polystyrene foam 423 views ⌚10 months ago

- Line for the production of extruded polystyrene foam-PENOPLEX PRODUCTION e-mail:… We disassemble the expanded polystyrene under the Intex Frame Pool after 3 years. What happened to the sand pillow? 5 ⌚11 months ago

- 8-903-743-27-96 8-903-724-77-28 n-dom.ru ceresit.msk.ru terraco.pro Replacing Penoplex with Expanded polystyrene when insulating ... The best REINFORCEMENT of a screed on expanded polystyrene 1 ⌚11 months ago

- This video demonstrates how you can reduce your work time by choosing an XPS façade. Extruded polystyrene foam production line-PENOPLEX PRODUCTION ⌚11 months ago

- Don't be fooled !!! Part No. 1 Inspection of polystyrene and Penoplex (TECHNONICOL CARBON) with a thermal imager. Replacing Penoplex with expanded polystyrene when insulating reinforced concrete lintels of an aerated concrete house 2 ⌚11 months ago

- Hives from PPU and PPP. What does a real master choose? Extruded polystyrene foam CARBON ECO VS CARBON ECO FAS 323 views ⌚1 year ago

- Dimensions 600 * 600 * 130 mm Echoton Pixels StyroFoam (2 pcs.) is a set of acoustic diffusers (diffusers), ... Don't be fooled !!! Part No. 1 Inspection of polystyrene and Penoplex (TECHNONICOL CARBON) with a thermal imager. 89,325 views ⌚1 year ago

- Subscribe https://www.youtube.com/channel/UCP0ANXE—yOAWiV7bVMLx2w?... # UlyaPPS ... V. G. Kashkovsky "Hives made of polyurethane foam and expanded polystyrene (PPU and PPS)" 04/24/2019. 13 ⌚1 year ago

- ACOUSTIC POLYSTYRENE PANEL ECHOTON PIXELS STYROFOAM 656 views ⌚1 year ago

- Styrofoam hives, EPS, (XPS) Part three. 363 views ⌚1 year ago

Tags:

By dates: 05/27/2020 - 05/28/2020 - 05/29/2020

Commented video:

Passenger filmed a hard landing in Buryatia

⇒ “God forbid to get into such a situation. Since you yourself cannot change anything, and the only hope is for the design of the aircraft (that it will withstand such a landing), for the fire extinguishing and safety system, as well as for the skill of the pilots. As it turns out, there were no casualties. And pog ... "Watch in full ... Added - 05/28/2020

Funny videos. Stop, grandmothers!

⇒ “My grandmother, the kingdom of heaven to her, would call such a shame. She died at 92. But, even at that age, she behaved as she would skash, decorously. On the holiday, everyone asked her to sing. She danced in flops, it was fashionable, I suppose, in her youth to dance like that. Never refused ... "View in full ... Added - 05/28/2020

Cartoon - WHAT IS LOST in our city? - New Cartoon - 112

⇒ "how to download a cartoon" Watch in full ... Added - 05/28/2020

THE MOST FORBIDDEN VIDEO ABOUT VICTORY DAY. WHAT did our ancestors fight for?

⇒ “Strong! Crying, honestly. Everything is true, to a single word, to a single breath, as in confession.It is a shame that in such a huge, and most importantly rich country, the people are becoming impoverished, dying out, and our rulers not only do not prevent this, but also contribute. Pension reform alone is worth it. D ... "View in full ... Added - 05/28/2020

DSF Foundation Sergiy Volodymyrovych Dyadechko represents: Ukrainian Championship for strongmen, professionals

⇒ "cool" View in full ... Added - 05/28/2020

Toluene production

⇒ "cool, very interesting told" Watch in full ... Added - 05/28/2020

How to avoid common mistakes

To work with expanded polystyrene to be of high quality, avoid the following mistakes.

- Special attention to the base / plinth rail... If horizontal cracks suddenly appear on the plaster, then the plinth rail was not fixed correctly. To correct the errors, you need to remove 10 cm of plaster from the bottom edge and cut off part of the insulation that covers the rail. Fasten the rail and cover it with a net to the bottom edge. Then the new mesh is overlapped by 10 cm with the old one and covered with fresh plaster.

- Contact of polystyrene foam with the ground... When expanded polystyrene comes into contact with the ground, the material quickly gets wet and becomes unusable. Here, a plinth strip is needed, which performs a protective function. To fix the error, you need to cut off the bottom edge of the insulation and replace it with extruded polystyrene foam.

- When using three-layer enclosing structures, in which the outer and inner walls are made of small blocks or bricks, polystyrene foam should not be used. In this case, mineral wool in slabs is more suitable. Also do not use expanded polystyrene as insulation for wooden houses... The material traps the release of water vapor to the outside, thereby causing wood to rot.

- Weather conditions are very important in the work on insulation. Work should be carried out in dry weather at temperatures from + 5 to + 25 degrees.

- Failure to comply with the thickness of the insulation... If too thin a slab layer is applied to walls made of concrete hollow blocks or large slabs, the buildings will still be cold.

- The appearance of thermal bridges... When used in fixing the plates with dowels of an unsuitable quality (in the future, the supporting discs disappear), thermal bridges arise, which contribute to intense heat leakage.

Whichever insulation you would use, we can say with confidence that after installing thermal insulation, the house will become warmer, and the atmosphere in it will be pleasant for residents.

Internal thermal insulation of walls with extruded polystyrene foam

Due to its good thermal insulation properties, simplicity, ease of installation, expanded polystyrene is widely used in the reconstruction of residential buildings. The technologies for laying this insulation inside and outside the building have their own characteristics, which must be taken into account when performing thermal insulation work.

When insulating walls with extruded polystyrene foam inside the room, it is necessary to leave a small ventilation gap so that the wall dries out if condensation penetrates outside. For thermal insulation, polystyrene foam sheets from 20 to 40 mm are used, which are stacked in one layer.

Wall insulation inside the premises is carried out in the following sequence:

The scheme of warming a room with extruded polystyrene foam from the inside.

- The old finish (wallpaper, paint layer) is removed, the plinth is dismantled, the wall surface is cleaned of dust and dirt.

- The wall is covered with an anti-fungal agent to prevent mold and mildew from forming under the thermal insulation.

- The surface is primed (the primer is applied with the window open to ensure good ventilation of the room).

- After the primer layer has dried, the sheets are installed from the bottom up. Insulation sheets are attached to an adhesive solution.

- Application of a plaster layer 4 mm thick.

A few days later, finishing work begins. On the insulated walls, you can glue wallpaper or other finishing materials, you can simply paint the walls.

Thermal insulation of walls inside a building has its advantages:

- The cladding of the interior walls provides heat conservation in winter and keeps the room cool in summer.

- Thermal insulation works can be carried out in any weather, at any time of the year.

- There is no need to change the appearance of the facade.

Internal thermal insulation is not recommended in small rooms, since after laying the insulation sheets, the useful area will become even smaller.

Internal wall insulation is carried out as a last resort, only if it is impossible to make the building heat insulation from the outside. The reason for this may be the facade decoration with decorative elements, the cultural or historical significance of the building being reconstructed.

Back to the table of contents

Basic properties

Expanded polystyrene should be taken only for arranging the middle layer of structures. It perfectly tolerates temperature fluctuations from -40 ° C to 80 ° C. It is not used for warming saunas, steam rooms, heating mains. However, the properties of the material do not limit its use as insulation for buildings. Even with prolonged exposure to direct rays, it will not begin to melt or lose its structure.

There is no need to worry about the safety of the material. Styrene foam contains styrene, a substance found in many products. Its safety has been officially confirmed, styrene is recognized as non-carcinogenic, non-mutagenic, therefore it is allowed to make food packaging from this material. Donor organs and medications are even transported in polystyrene foam containers. Since it does not come into contact with the interior of the house as a heater, oxidation is impossible, therefore, styrene is not released from the heat-insulating layer.

Polystyrene granules from which this material is obtained is a refined product. Therefore, it is a combustible material. It belongs to the G3 group ("normally combustible"). Often, special fire retardants are added to the plates, the action of which is based on reducing the ability to spread fire. So some modern types of material can burn on their own for no longer than 2 seconds.