Calculator for calculating the power of the heating element for heating water

The proposed calculator, based on the capacity of the water heater tank, the initial and final (required) water temperature and heating time, makes it possible to calculate the required electrical power of the heating element with a sufficient degree of accuracy, which is influenced by the design features of the heating element and the actual voltage of the mains.

When the voltage in the network is lower than Uoperating the heater (for example, as a result of a voltage drop in the line), it is obvious that its operation will be less efficient and a decrease in the temperature of the heating surface will increase the duration of water heating to the required temperature.

The result of the calculation does not mean that the mandatory use of a heating element of such a rating: the received power can be collected by several parallel-connected heating elements.

Please note that the calculation is made without taking into account the possible heat loss of electric water heaters to the environment, arising from a variety of factors, from the design of the boiler to the state (presence) of thermal insulation

Replacing the mechanism in a water heater with your own hands

Replacing a heating device in a boiler with your own hands is quite simple. The main thing is to follow the instructions exactly:

- Disconnect the boiler from the mains and from the cold water supply pipe.

- Empty the tank.

- Remove the outer cover.

- To make sure that power is not being supplied to the device, check the voltage at the terminals with a phase meter.

- Unscrew the nuts securing the heater and fold out the outlet wires.

- Take out the old heating element.

- Before installing a new one, check the condition of its terminals, they must be absolutely dry.

- Together with the replacement of the heating device, the magnesium anode must also be replaced.

- Remember to use rubber seals when replacing, they should be of good quality without damage, cuts or dents.

- Install a new heating element and do all the operations in reverse order.

- Now you need to fill the tank with cold water and bleed the air from the hot water tap, make sure there are no leaks.

- Connect the boiler to electricity.

If the boiler leaks after reassembly, it means that the heating element is not installed correctly. The device needs to be rebuilt.

How to check the heating element with a multimeter yourself

The main breakdown of household appliances is considered to be the failure of the heating element. If the washing machine does not heat the water during washing or the iron spiral does not heat up, then the heating element needs to be ringed with a multimeter. In this article, we have presented to your attention information on how to check the heating element with a multimeter at home.

Also in our article you will find detailed pictures and videos that will explain each process in detail. If you are interested, then you can read about how to properly drain the water from the boiler.

How to check the heating element

First, you need to consider how the heating element is dialed. To make it clear to you, we tried to delve into the practical moments. You can check the heating element according to the following scheme:

- Before testing, you should try to calculate the resistance. To perform the calculation, you can use the formula R = U2 / P. In this formula, U will mean the voltage in your article. Indicator P is the rated power of the heating element, which can be found in the passport of the device.

- Before checking, the device must be disconnected from the power supply. Only then can you start checking.

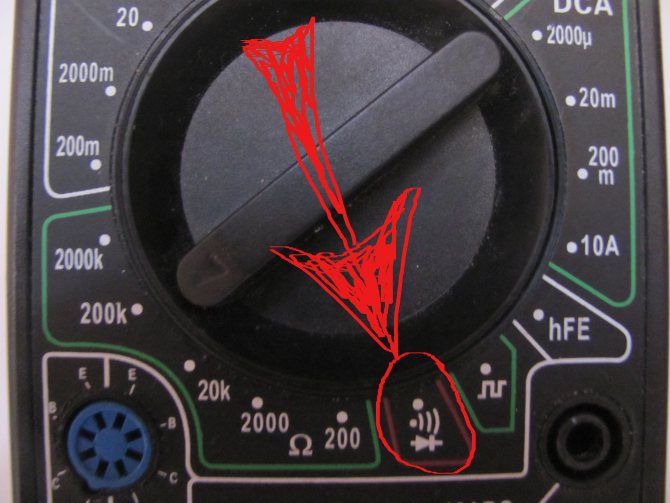

- Now turn on the multimeter in resistance test mode.

If you don't know how to use a multimeter, then don't worry. Our website already has information on how to use a multimeter correctly. If you touch the pin with the probes, then you may encounter the following situations:

- If the value on your screen is approximately the same as in the picture, then this means that the heating element is operational.

- If “0” is displayed, then it means that the device needs to be replaced.

- Indicator "1" will mean that there was a network break during the test.

Also, using a multimeter, you need to check the heating element for breakdown. For this to work, the device must be set to buzzer mode. You need to touch one of the probes to the output, and the other to the heating element. In the photo below you can see how to properly check the heating element for breakdown.

It's important to know! If the buzzer beeps, then it is necessary to replace the part. You can also perform an insulation resistance test if required

It is easy to do this and for this you need to switch the device to the "500 V" range. Normal resistance will be 0.5 Mohm. Detailed information on how to check the heating element with a megohmmeter and a multimeter can be seen in the video below:

You can also perform an insulation resistance test if required. It is easy to do this, and for this you need to switch the device to the "500 V" range. Normal resistance will be 0.5 Mohm. Detailed information on how to check the heating element with a megohmmeter and a multimeter can be seen in the video below:

Perform a visual inspection before checking. To do this, descale the device and then dial the element. If you find visual damage, then the device should be replaced.

You can also check the heater for an open circuit using an electrician's warning lamp. If the light is on, then there is no break. You can make such a lamp from scrap materials and we have an article on how to make control with your own hands. These are all ways to check the device.

In some situations, you can also test the device without a multimeter. Below you can also find videos that allow you to understand how to check the heating element in a washing machine, boiler or dishwasher.

Video lessons

If the boiler does not heat the water, then it is necessary to check the heating element of the water heater according to the following instructions:

If you need to ring the heating element of the washing machine, then you should proceed to study the instructions below:

So that you can check the iron with a multimeter, you need to disassemble the device case and touch its terminals:

If you do not know how to ring the kettle, then the instructions can be seen below:

As you can see, it is quite easy to check. The videos that we have provided for your attention will help you do everything right. We hope the information was helpful and informative.

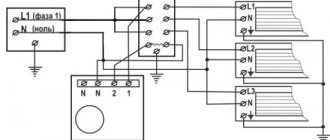

Connection of several heating elements

To speed up the process, two or more heating elements are sometimes installed in the water heater. In this case, the type of connection matters. He can be:

- consistent;

- parallel;

- combined.

With a serial connection, all elements are connected one after the other, while the failure of one link leads to the shutdown of the entire network. In parallel, the network elements are connected in parallel and even if one of them fails, the network continues to work. A combined connection is when links are connected in different ways at different parts of the chain.

Several heating elements significantly increase the rate of water heating, but at the same time the amount of energy consumed also increases. Typically, such water heaters have a switch between different modes of operation with one or more heaters.When there is no need to rush, you can do with one and save on energy, but if you need hot water urgently, you can turn on several heating elements.

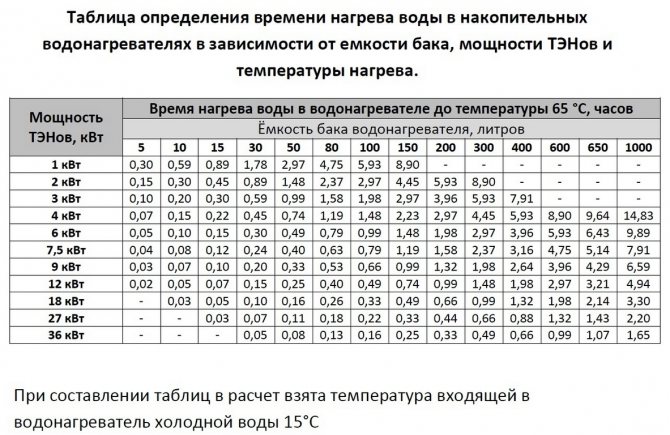

The amount of electricity kWh and the cost of heating water.

The calculator will calculate the time for heating water in storage water heaters, depending on the capacity of the tank, the power of the heating elements, the heating temperature and the temperature of the incoming water.

You can specify the efficiency of the storage water heater (usually 95-99%).

The calculator is taken from the site: https://nagrev24.ru/voda

Electricity is converted into heat and the efficiency depends on the material of the heating element (on electricity losses in it and on thermal conductivity), on the contact area of the element with water, contact resistances and losses in the power cord. At each stage, some of the energy is lost. Depending on the type of device, the efficiency is in the range of 95-99%.

The more effective the thermal insulation properties of the material separating the inner tank from the environment, and the thicker its layer, the more economical the water heater. Modern boilers guarantee a decrease in water temperature of no more than 0.25 - 0.5 degrees per hour and an electricity consumption of less than 1 kW / h per day in standby mode.

The most optimal operating temperature of the water heater is 55-60 ° C. This reduces energy consumption for maintaining the temperature of hot water, reduces the formation of limescale, and provides a more gentle mode for the internal tank.

How to choose the right device

When choosing, you need to pay attention to the following parameters:

- boiler volume;

- device power;

- desired water heating rate;

- desired electricity consumption.

The larger the tank, the more power you need to get the results you want.

In order not to be mistaken with the choice, look at the marking on what is installed in your device and purchase a similar one. Especially picky in this regard are water heaters with dry heating elements.

Different manufacturers produce different heating elements for their storage and flow-through structures. When choosing a device, it is important to consider this point.

Water heaters Termeks

All models of heating elements from Termex are equipped with a thermostat, and some also have a thermostat, which greatly simplifies boiler control. The maximum heating temperature is 75 degrees. The heater tube can be made of copper or stainless steel.

Termeks also produces magnesium anodes from a special alloy for its devices. It significantly extends the life of the device.

Water heaters Ariston

The average power of Ariston models ranges from 1 to 4.5 kW. There is also an opportunity to purchase a heating element for water with a thermostat. The maximum temperature is 85 degrees.

The design feature of Ariston heaters is the oval shape of the flange; moreover, it is additionally fixed from the outside with a bar. When replacing, you must first unscrew this bar, and push the heater into the tank with the loan. The element is replaced in an inclined position.

Water heaters Electrolux

Electroluxe prefers closed heating elements. In addition, two elements are usually installed in each heater at once to accelerate heating. The maximum water temperature is 90 degrees.

General data required for calculations

The more powerful the electric heater, the faster it heats up a given amount of water. Therefore, devices for this parameter are selected in accordance with the tasks, the required volume and the allowable waiting time. So, for example, heating 15 liters to 60 ° C with a 1.5 kW heater will take about one and a half hours. However, for large volumes (for example, to fill a 100-liter bath) with a reasonable waiting time (up to 3 hours), a 3 kW more powerful device will be needed to bring the liquid to a comfortable temperature.

To fully calculate the estimated power, a number of parameters must be taken into account:

How to check the heating element with a multimeter and without a tester

A popular malfunction of household appliances and heaters is the failure of the heating element. If your washing machine does not heat the water during washing or the iron spiral does not heat up at home, be sure to ring this circuit element with a tester. In this article, we will tell you how to check the heating element with a multimeter at home, and also provide several useful video instructions on the topic.

Verification technology

First of all, we will consider how the heating element is dialed, after which we will delve deeper into practically the moments associated with the repair of household appliances. So, you can check the heating element according to the following scheme:

- Calculate the resistance of the heater. To do this, use the formula: R = U2 / P, where U is the voltage in the network (220 volts), and P is the rated power of the heating element, which can be found in the passport of the device.

- Next, be sure to disconnect the device under test from the mains, get to the heating element and disconnect the wires from it.

- Turn the multimeter into resistance measurement mode (200 Ohm range) and touch the probes to the terminals, as shown in the photo below:

- The value on the scoreboard is about the same as the calculated one, which indicates the efficiency of the heating element.

- "0" is displayed, which means short circuit, replacement is required.

- "1" or infinity is displayed - an open circuit has occurred, the heater needs to be replaced.

You also need to check the heating element for breakdown (current leakage) using a multimeter. To do this, we transfer the device to the buzzer mode, with one probe we touch the output, and the other with the body of the heating element, as shown in the photo below:

The buzzer sounded - there is a breakdown, which means that you cannot do without replacing the part.

It is also advisable to check the insulation resistance of the heating element with a megohmmeter. To do this, you need to include it in the "500 V" measurement range. With one probe, touch the contact of the heater, with the second one touch the body of the electrical appliance. An insulation resistance of more than 0.5 megohms is considered normal.

You can learn more about how to check the heating element with a megohmmeter and a multimeter by watching the video data:

The work of the master

Continuity scheme

By the way, also, before making a dial-up, you need to visually check the condition of the heating element. To do this, remove scale from the heating element and inspect the surface for bulges, cracks and other mechanical damage. If any, the part must be replaced.

Another way to test the heater for an open circuit is to use an electrician's test lamp. To do this, one contact of the heating element is supplied with zero from the network, and to the second phase through this lamp. If the light is on, then there is no break. Anyone can make a control lamp from the available means, we wrote about this in detail in the article we referred to.

Here, in fact, are all the ways to check the integrity of the heating element. As you can see, in some cases it is possible to check the heating element even without a multimeter. Below we will look at a video that clearly explains how to ring the heater of a washing machine, boiler, dishwasher, kettle and other household appliances.

Visual video tutorials

If the boiler does not heat the water or knocks out the RCD when it is turned on, you can check the heating element of the water heater as follows:

We check the health of the heater in the boiler

The reason why the water heater can be shocked

If you want to ring the heating element of the washing machine, before that you have to get to it. All instructions are provided step by step in this video:

We disassemble the body of the washing machine and call the heating element

https://youtube.com/watch?v=5oV3E7b08Xc

To check the iron with a multimeter, it is enough to disassemble the case and touch the terminals with the probes, as shown here:

We repair the iron

https://youtube.com/watch?v=KnTYT_qWeXA

As for the kettle, you can call it using the following method:

DIY electric kettle repair

https://youtube.com/watch?v=KC7cdowo8P0

Similarly, you can check the health of the heating element in a dishwasher, heater (for example, in a coil of a heat gun) or other household electrical appliance. We hope our instructions helped you and now it is clear how to check the heating element with a multimeter at home!

What tasks does the heating element perform?

The abbreviation TEN stands for a tubular electric heater. The center of the boiler structure is a thin nichrome wire coiled into a long spiral. A current is passed through the wire. Since the resistance of nichrome is high, 90% of the energy received goes into heat, due to which heating occurs. For protection from water, the coil is placed in a copper or stainless steel tube, and in order to better transfer the temperature from the coil to the water, the metal tube is filled with quartz sand or magnesium oxide.

Heating elements are of two types:

- open or "wet";

- closed or dry.

Manufacturers equally often use both types of heating elements, since it is impossible to unequivocally decide which heating element for a water heater is better. Each of the two types has its own pros and cons.

Open heating element

In this case, the heating tube is located directly inside the water tank, like in an electric kettle, so this heating element is also called "wet". Open mechanism advantages:

- low price;

- fast heating of water.

However, this type of device is not safe. Contact with water often leads to short circuits. In addition, lime settles on the metal. And the harder the water flows from the tap, the faster the scale will cover the heating element. Open element water heaters need regular cleaning.

But even with regular maintenance, the service life of the "wet" heating element is not too high.

A metal tube can be straight or bent in one direction. This is usually determined by the boiler model. Products are fastened with a nut or flange. This is an important point, since for additional protection against corrosion, it is advisable to install a magnesium anode on the heating element, and on the element with a nut fastening there may not be a socket for the anode.

Closed heating element

In this case, the heating element tube is located inside a ceramic flask made of steatite or magnesium silicate. The flask is durable and transfers heat well. Thanks to it, the heating element is protected from direct contact with water, which increases the reliability of the electrical device. In addition, scale does not accumulate on the ceramic surface.

Advantages of a "dry" heating element:

- guarantees safety, since a short circuit is impossible in this case;

- it is easy to maintain;

- its service life is much longer than that of an open one;

- as there is no scale, less energy is required to heat the water.

However, in this case, it takes more time to heat the water. They are also less versatile. Closed heating elements are made individually for each model of a water heater and in case of a breakdown, you need to change it to the same one.

Instantaneous water heaters

When calculating the amount of heat for heating running water, it is necessary to take into account the difference in voltage standards in Russia (220 V) and Europe (230 V), since a significant part of electric water heaters are manufactured by Western European companies. Thanks to this difference, the nominal indicator of 10 kW in such a device when connected to a Russian 220V network will be 8.5% less - 9.15.

The maximum hydraulic flow V (in liters per minute) with given power characteristics W (in kilowatts) is calculated by the formula: V = 14.3 * (W / t 2 -t 1), in which t 1 and t 2 are the temperatures at the inlet heater and as a result of heating, respectively.

Approximate power characteristics of electric water heaters in relation to household needs (in kilowatts):

- 4-6 - only for washing hands and dishes,

- 6-8 - for taking a shower,

- 10-15 - for washing and showering,

- 15-20 - for the complete water supply of an apartment or private house.

The choice is complicated by the fact that the heaters are available in two connection options: to a single-phase (220 V) and three-phase (380 V) network. However, heaters for a single-phase network, as a rule, are not available above 10 kilowatts.

Tubular electric heater device (TEN)

In order to competently check the heating element, you need to imagine its internal structure. As can be seen from the drawing below, the heating element is a metal tube made of copper, stainless steel or iron, in the center of which a nichrome spiral is laid, twisted in the form of a spring.

The inside of the tube is completely and densely filled with sand, which makes it possible to effectively remove heat energy from the coil and to exclude its contact with the tube. The ends of the spiral are connected by welding with contact rods, which are fixed inside the tube using ceramic insulators. To supply the supply voltage, the ends of the contact rods are threaded or welded onto the contact plates.

Tubes for the manufacture of heating elements are used of different diameters and, depending on the purpose, give them various shapes up to a spiral. An electric boiler is a good example.

Possible malfunctions

The heating element is the most vulnerable element in the boiler. The reason is that it is the most exploited element, and in addition, it is exposed to scale. To prolong its life, it is recommended to periodically clean it. This can be done without completely disassembling the case using special tools. But I recommend carrying out a full set of procedures to clean not only the heater, but also the tank itself from scale and dirt.

If the node is broken, then it will have to be changed, but first check what exactly is out of order. There are several types of faults:

- The incandescent thread inside the heating element is burnt out.

- The glow wire on the heater body has burned out. This can lead to electric shock if the water heater is not equipped with an RCD. Otherwise, the protective mechanism will constantly turn off the equipment.

- Scale appearing.

Non-standard methods of checking heating elements

For example, connect a cord with a plug directly to the terminals of the heating element and then insert the plug into the outlet for just a few moments. Heating of the heating element, which will occur in this case, will show that it is in good working order. But you should act carefully so as not to burn yourself.

It is just as easy to check the insulation resistance. It is necessary to disconnect one of the ends of this cord (disconnected from the socket) from the output of the heating element and connect to the tube. This must be done through a fuse rated for a protection current not exceeding 5 A.

Now you can connect the plug to the outlet and wait a while. It doesn't count for seconds. Gradually, heating indicates that the heating element is working properly, a short circuit of the spiral with the case is not observed.

In fact, there are a huge number of different ways to check the heating element. They can be done, for example, using a landline telephone. The heating element is simply connected to a break in one of the telephone wires that connect the device to the network. If, after that, you call on the norm, and there is a signal, then this means that the heating element is working normally.

Electric heating boiler power calculation

»Heating» Electric heating boiler power calculation

The boiler is the main unit of the heating system, the performance of which determines the ability of the engineering network to provide the structure with the required amount of heat. A competent preliminary calculation of the power of the heating system guarantees a comfortable microclimate in the room and will help to eliminate unnecessary costs when purchasing it.

Basic calculation of the power of an electric heat generator

Definition! The power of an electric heating unit must fully replenish the heat loss of all rooms.If necessary, the power that will be spent on heating the water is taken into account.

Professional calculation of the power of electric heating equipment takes into account the following factors:

- Average temperature during the coldest period of the year.

- Insulation characteristics of materials used in the construction of building envelopes.

- Heating circuit wiring type.

- The ratio of the total area of door and window openings and the area of supporting structures.

- Specific information about each heated room - the number of corner walls, the estimated number of radiators, etc.

Attention! To perform particularly accurate calculations, household appliances, the number of computers and video equipment that also generate thermal energy are taken into account. Usually, professional calculations are rarely carried out, and when buying, a unit is chosen whose power exceeds the approximately calculated value

Usually, professional calculations are rarely carried out, and when buying, they choose a unit whose power exceeds the approximately calculated value.

For an approximate calculation of power (W), the following formula is used:

W = S * Wsp / 10m2, where S is the area of the heated building in m2.

Wsp is the specific power of the unit, the value of which is individual for each region:

- for a cold climate - 1.2-2.0;

- for the middle band - 1.0-1.2;

- for the southern regions - 0.7-0.9.

Determination of the power required to supply hot water

The power required to heat water for technical needs is determined by the number of permanent consumers, water points, the total amount of warm water used.

Advice! To roughly determine the power of a heating unit operating simultaneously for heating water, add 20% to the calculated power for heating the room. In cases of frequent drawdown, the power is increased by 25%.

Calculation of the volume of the storage water heater

If it is planned to use a storage water heater in conjunction with an electric heating system, then its volume (Vv) can be calculated using the following formula:

Vw = V * (T-T ') * (T ”-T'), where V is the required amount of heated water, T is the required temperature of heated water, T 'is the temperature of the water to which hot water is mixed from the heater, T” - the temperature of the water heated in the water heater.

Having selected the power of the electric heating installation, and having determined the volume of the water heater, using the formula, you can calculate how long (T, sec) the water will be heated:

Т = m * CB * (t2-t1) / P, where m is the mass (kg) of water in the storage device, CB is the specific heat capacity of water, which is taken equal to 4.2 kJ / (kg * K), t2 and t1 - the final and initial water temperature in the boiler, respectively, P is the power of the heating unit, kW.

Additional factors taken into account when calculating the power of an electric boiler

The operation of any heat generator, including an electric one, may be accompanied by additional losses:

- If the house building is ventilated too intensively, then due to the accelerated air exchange, the premises will lose about 15% of the heat.

- Weak wall insulation can cause a loss of 35% of thermal energy.

- About 10% of the heat goes through the window frames, and if the windows are old, then this amount can be even more.

- Uninsulated floors will reduce heat supply to rooms by about 15%.

- About a quarter of the heat can be lost through an improperly arranged roof structure.

Attention! If at least one of the factors of unproductive heat losses is present in the heated room, then it must be taken into account when calculating the power. https://www.youtube.com/embed/_n_cZSAT4ZE

If desired, the calculation of the required power and the required volume can be carried out using an online calculator that takes into account all the characteristics of the heated object as much as possible.

kotel-otoplenija.ru