If you need to heat a small country house, as well as combine the functions of a heating boiler and a kitchen stove in one device, then there is no need to look for a better option than a two-bell heating and cooking stove. Moreover, all the work on its installation can be done by hand. The detailed instructions below will help you with this.

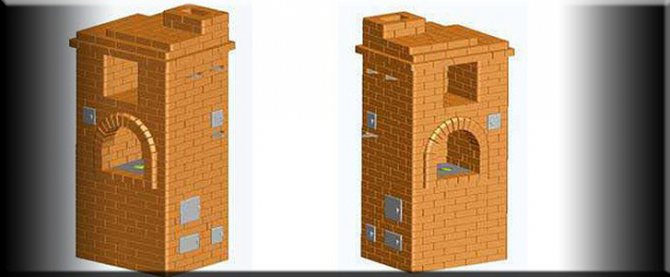

A two-bell oven is an excellent solution for a country house

Operating principle of ovens with two bells

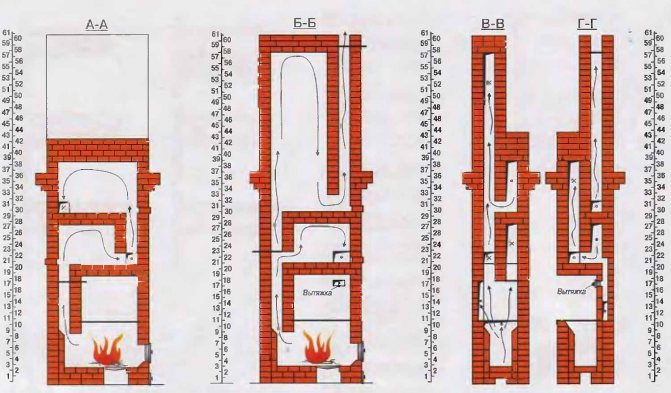

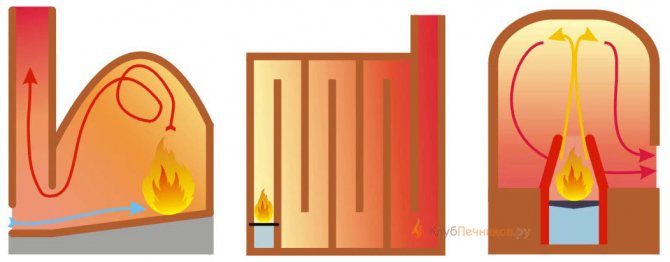

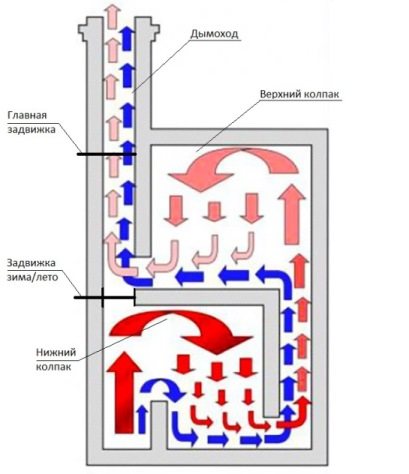

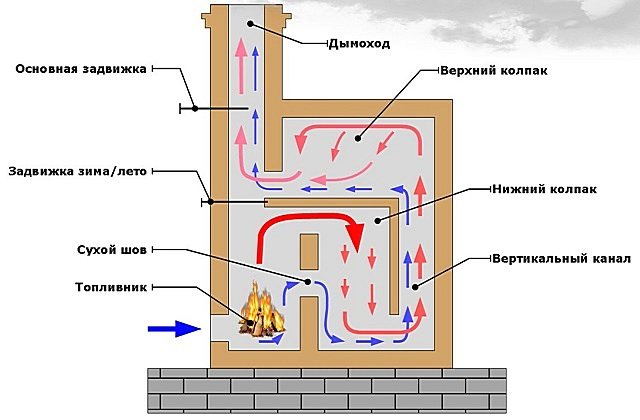

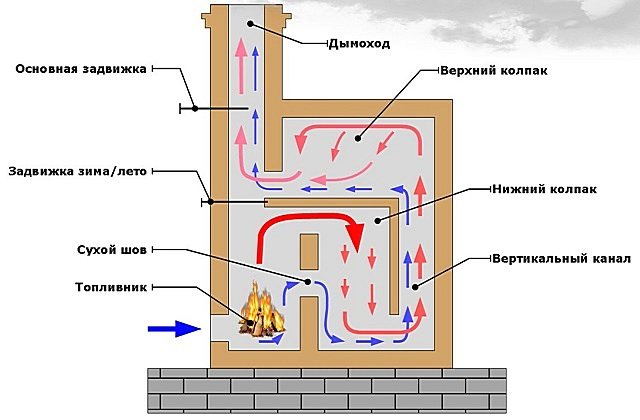

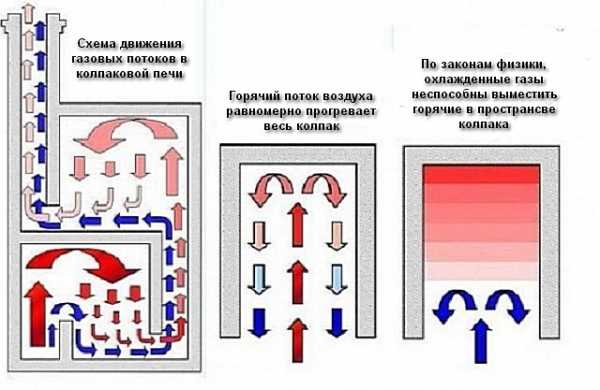

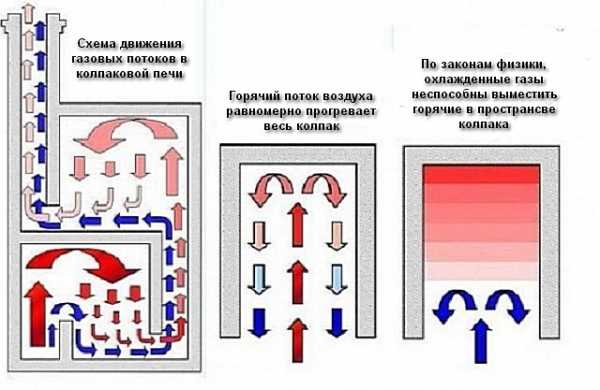

The secret of the efficiency of this stove lies in its original design, which allows accumulating and storing heat for a long time. To understand the principle of operation of a two-bell furnace, consider its structural diagram.

After firing up in winter, the incandescent flue gases rise under the roof of the lower bell, transferring heat to the surrounding walls and the hob. But new air enters the combustion chamber, the combustion process continues and the release of hot combustion products continues, displacing the cooled gases under the top of the bell. Those, in turn, descend and fall into a vertical channel leading to the upper bell, where the two-bell design of the furnace provides for the repetition of the previous process with the release of gases to the outside through the chimney.

The temperature of the flue gases coming out is lower than any other stove with a stove, as they intensively give off their heat to the walls of the stove. For this reason, the chimneys of heat sources of this design must be protected from the destructive effects of condensate. After the heating is over, the heat remains for a long time at the top of both hoods, even if the main valve remains open. Cold air entering through the blower cannot rise under the dome of the hood and passes into the chimney along the path indicated in the diagram by blue arrows.

A two-bell hob oven with a stove allows you to cook food in the summer thanks to an additional valve, the opening of which passes gases directly into the chimney. If the valve is not fully opened, then the flow of combustion products is divided into two, going along different paths. In this way, in the autumn-spring period, it is possible to regulate the intensity of warming up the hoods, that is, the heat output of the stove.

Content:

1. Oven without an oven (IP-1) 2. Oven with an oven (IP-2) I.S. Podgorodnikov belongs to the two-bell type furnaces. What kind of ovens are these? Two-bell heating devices are considered the best option for chimney systems. With a rather simple design, the stove provides maximum heat retention and uniform heat distribution in the height of the heated room. Unlike traditional foci, hot gases do not move along the back wall of the device, but arbitrarily, that is, obeying the law of natural convection. Thus, the still unheated air of the dwelling does not blow out the heat, but a stream of hot air flows around from below.

The stove is heated both in summer and winter. Consider two options for Podgorodnikov's hearths: without an oven (IP-1) and with an oven located in the lower part (IP-2).

Kuznetsov furnaces device and principles of operation, advantages, variations, drawings

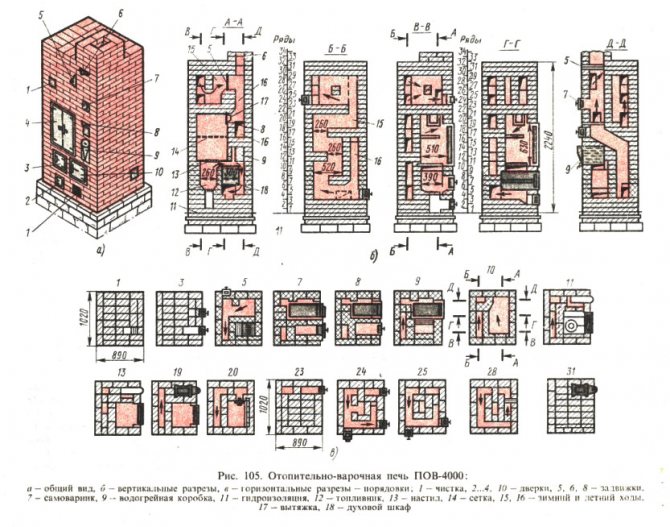

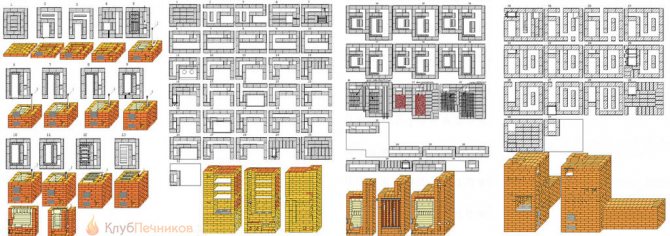

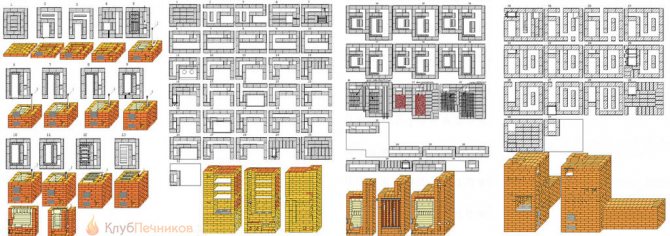

Kuznetsov's stoves are well known not only to stove-makers - they heat many houses in Russia and abroad. IV Kuznetsov has been working on improving the furnaces since 1962 and has gathered around him a strong team of like-minded people. The team has more than 150 developments covering almost the entire range of household stoves, see fig.

Some of the stoves of I. V. Kuznetsov

Many would like to fold some of Kuznetsov's stoves with their own hands, and this article is to help them. But we are not going to reveal some hidden secrets of "blacksmiths" - they simply do not exist. On the website of Igor Viktorovich stove.ru, those who wish will find a huge array of stove information for free: from information on the design and construction of stoves to detailed drawings and recommendations for installing a stove in a house and arranging a blind area around a building with stove heating. We also do not intend to criticize or correct anything in this home-stove encyclopedia: we are far from IV Kuznetsov in stove business, to put it mildly, far away.

The purpose of this article is to give a kind of introduction to the body of Kuznetsov's information, which allows one to more freely navigate the source material. Let us explain with an example why this is needed.

Let's say I'm a station wagon mechanic with a lot of experience and I want to pass it on to others interested. A car is a complicated thing. If I start to get distracted along the way, explaining in detail that how the run-in and caster (let's say, readers are not really teapots, now everyone drives) affect the handling and directional stability of the car, and the gas distribution diagram affects fuel consumption depending on the road conditions, and so on, I will eventually get confused to the point that I myself no longer understand how the car I drive works. Willy-nilly, I will have to present the material, albeit “on the fingers,” but in a professional way.

However, it will be difficult to read it even for specialists just like me, and an amateur will be dizzy in general. Therefore, I will need someone to help me, who can be conditionally called a "recipient". In fact, he is not a kettle at all, he can adjust the suspension himself, and set the valve tappets. But in this case, his task is to describe how the entire filling of the car is assembled into a single whole, controlled according to the principle: "Steer the wheel, gas the gas, brake with the brake."

In the automotive industry of the USSR, a similar situation arose in the late 50s - early 60s, when the industry began to produce cars for widespread sale to the population. Then the superbstseller of that time - "How the car works" was published. Edited by none other than the chief designer of the legendary "Victory" A. Lipgart.

The information "from the recipient" will not yet allow you to get down to work: it does not provide in-depth knowledge that will allow you to at least intuitively figure out the necessary values of the numerical parameters along the way. But it is fundamentally fundamental: owning it, a professional text is read with understanding and faster. And, if somewhere something in him is still incomprehensible, this no longer causes loss and rushing, but just a mark in the mind: you need to find out more about this.

So far, the government has not adopted any landmark decisions on stoves and stove heating. But their role in household heat power engineering in times of energy shortages is undeniable: a heating stove with an efficiency of 70%, when used massively, will save fuel on a national scale, because in the projects of new heating plants, heat losses in the mains of 35% are included, and it is not yet possible to reduce them. So with the popularization of oven knowledge, you have to get out yourself, without being neither Lipgart nor Kuznetsov. Well, let's try.

About bricks and the country club

Now about heating with stoves of 700 bricks in 100-square-meter mansions ... It doesn't happen. It just doesn't happen. To begin with, it is useless to heat more than 40 squares with one stove with ceilings of 2.5-3 meters. Convection simply won't work. It will be, but the temperature difference in the volume of one room will be so great that there is no need to talk about hygiene - only about discomfort.

By the way, there is a picture about convection in the 1943 book (see the link above). A very clear picture. Although the language is Latvian.

So you will never heat 450 cubic meters of a room with one stove. Unless it is atomic.

Let's imagine a large hall. Let there be a club in the village. The hall is cold and frosty in the corners. Bring a brick heated over a fire into it. Will the hall warm up? And what if a pallet of such bricks is transported by a forklift? I'm afraid that to warm up, I will have to import several of these pallets and place them in the corners. The same is the case with ovens.

Brick is a heat-consuming thing, and the stove heats it precisely due to the heat stored by it. No other way. But the value of this heat capacity is a finite value. The brick is not able to take more heat than it should. And with an increase in the temperature of the brick itself, this ability will fall. Attempts to heat the brick higher than it should be will either lead to a waste of fuel, or to the destruction of the brick itself. That is why all manuals strongly do not recommend overheating the stoves - they simply crumble. For the same reason, it is impossible to compensate for the lack of power of the furnace with a forced firebox.

One property of all bell-type furnaces is associated with this feature. Ignorance of it leads not only to savings, but also to the loss of up to 20% of heat.

The point is simple. The temperature difference between brick and kiln gases is called a gradient. The higher the gradient, the more willingly the brick takes in heat. As the brick itself warms up, the gradient falls, and the brick does not receive heat so intensively. Therefore, the gases, if the flow rate does not decrease, will go to waste into the pipe. Therefore, in bell-type furnaces, it is important to be able to regulate the flow rate by the blowing intensity and by changing the pipe cross-section. By the way, when illuminating this moment, Kuznetsov suddenly forgets that the gas flow ALWAYS follows the path of least resistance. In a word, if the path of gases in smoke circulation structures is always unchanged, and gases inevitably have to give heat to the walls of the furnace, then in bell-type systems, gases have the opportunity to choose this path arbitrarily. No amount of beautiful words and calculations will make them follow the path of least resistance.

As a bell-type stove, we can recommend a really good stove by A. I. Podgorodnikov, known as the "Two-tier bell". Its order is below.

And in this Podgorodnikov's furnace there is, for example, an afterburner. Unexpected, right?

Design and principle of operation

Bell furnace design

The stove with a hood was developed by engineer Igor Kuznetsov in the early 60s of the last century. Subsequently, the Russian metallurgist Leonid Kotlyar improved the design so that it retains heat up to 19 hours. The peculiarity of "blacksmithing" is that the heated air does not leave the pipe, but is collected under the hood. It gradually cools down and is displaced by rising hot streams. The advantageous difference between a bell-type stove used for heating a house and a duct stove, where hot air under the influence of draft, freely goes out into the street, lies in saving heat.

A two-meter-high structure with a base of 1m * 1m can reach a heat output of 3.5–4.5 kW. Such a bell-type stove is enough to heat a house of 50 square meters in a temperate climatic zone, if you heat it twice a day.

The inventor has improved the design by adding another hood. In Kuznetsov's two-bell heating furnace, the first covering element is connected to the combustion chamber and separates the cold and heated streams. The second bell is located in the upper part of the stove, trapping hot air, which, before entering the chimney, gives off heat to the bricks for a long time.

A two-bell oven is more economical in fuel consumption and is usually equipped with a hob. This allows you to prepare delicious meals without consuming electricity or gas. The design of the stove already includes an extractor hood - there is no need to install an additional ventilation system.

Varieties

As already noted, "caps" are subdivided into several types according to their purpose. Let's take a closer look at each of them.

Bell stove for home heating

Today, more than 20 standard schemes for the construction of a home for heating stoves stand out.

The center of the room is selected as the location. This placement has a number of clear advantages:

- the room heats up evenly and efficiently;

- no cooling element (outer wall of the house);

- free access for service;

- you can additionally equip a hob, dryer, hot water circuit, etc.

Such designs take up little space, are very attractive outwardly, a wide range of design solutions.

Hob devices

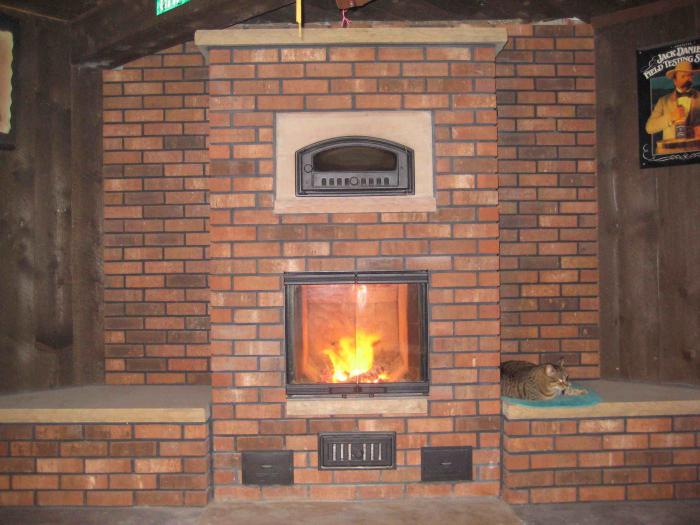

In order to cook food on an ordinary Kolpakov brick oven, it is enough to add a metal plate with several burners and slightly change the structure of the base. Full-fledged cooking facilities in their design have a pair of auxiliary horizontal surfaces, as well as an oven.

Hob oven

On such an oven, you can cook full-fledged meals, absolutely the same as on gas and electric stoves, which city dwellers are used to using.

Users often prefer “blacksmiths” with a hob, because such designs allow you to effectively heat the room and cook food at the same time. It is better to choose a kitchen or a large room combined with a kitchen as a location for such stoves.

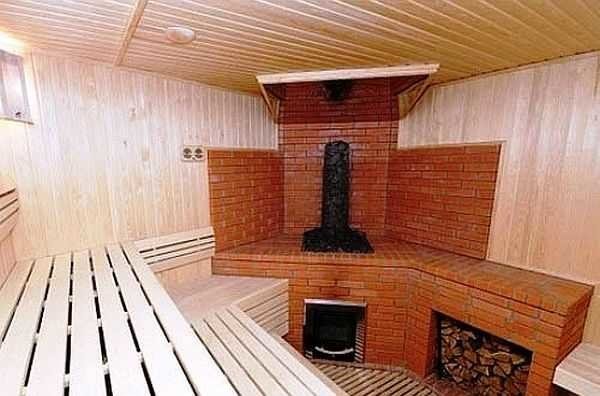

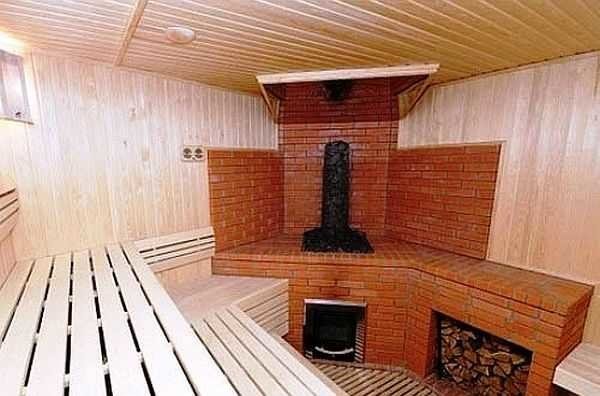

Bell stoves for a bath

Sauna stoves are marked with a special marking - BIK. The finished hoods differ in appearance from other heaters. First of all, the material from which they are constructed is selected very carefully. Secondly, the installation of the dome does not in any way affect the neat appearance and practicality of the stove. Models with rounded corners are very popular, due to which the risk of burns or injury is minimized.

Read more about the types of wood-burning stoves for baths and saunas in this article.

Having carried out the installation of the “blacksmith” in the right place, you will be able to simultaneously heat and supply hot water to several rooms at once - a shower room, a steam room, a rest room.

Bell stove for a bath

In the bath, the principle of long-term preservation of heat, which is characteristic of bell-type furnaces, comes into play.

Fireplaces, built on the principle of bell-type stoves

Kuznetsov's fireplaces are distinguished by an open design and the efficiency here is slightly lower, however, the heat transfer rates are high. Due to the hood, the heat does not escape quickly into the chimney, but is retained at the top of the device. If we compare a fireplace designed according to the principle of a hood and a conventional one, then after the end of the combustion process, the first will give off heat for a long time, which cannot be said about the usual one. With such a unit, the room will begin to cool very quickly.

There are many variations on how to make a fireplace more functional. You can equip dryers for shoes or clothes, shelves, etc. You can also decorate your fireplace with ceramic tiles or tiles.

Outdoor cooking models

Especially for the opportunity to cook food on the street, whole oven complexes have been developed, which, in addition to their functionality, are very convenient to use. The simplest version of such designs is a brick mini barbecue oven.

Those who love to cook kebabs and grilled dishes will be surprised by the wide selection of outdoor ovens with layer-by-layer, pyrolysis, bottom and top burning methods.

More about plump

In theory, round ovens generally have a lot of advantages, only they are not very convenient in the house.However, there is a considerable demand for compact mobile furnaces, and here the extremely high efficiency of round multi-caps can be a decisive factor, because when the size of the furnace decreases, its efficiency drops sharply due to the square-cube law.

Such ovens, of course, would have to be made of metal. This solves the problem of cleaning, the stove can be made collapsible. But the choice of metals suitable for the ratio of heat capacity and thermal conductivity is extremely limited. Of the inexpensive - only cast iron, but it is heavy and fragile.

However, there is a lighter and stronger metal material with similar properties. These are products of powder metallurgy. When applied to scissor knives, "powder rubbish" is quite justified, but for a furnace in which nothing works for shear, powder parts can be a godsend.

The second problem, which has already been mentioned, is the heat-resistant lining on the roof of the first bell. If it is possible to solve it, then, perhaps, the works and efforts of Igor Viktorovich Kuznetsov will bear fruit more extensive and significant than it seems now.

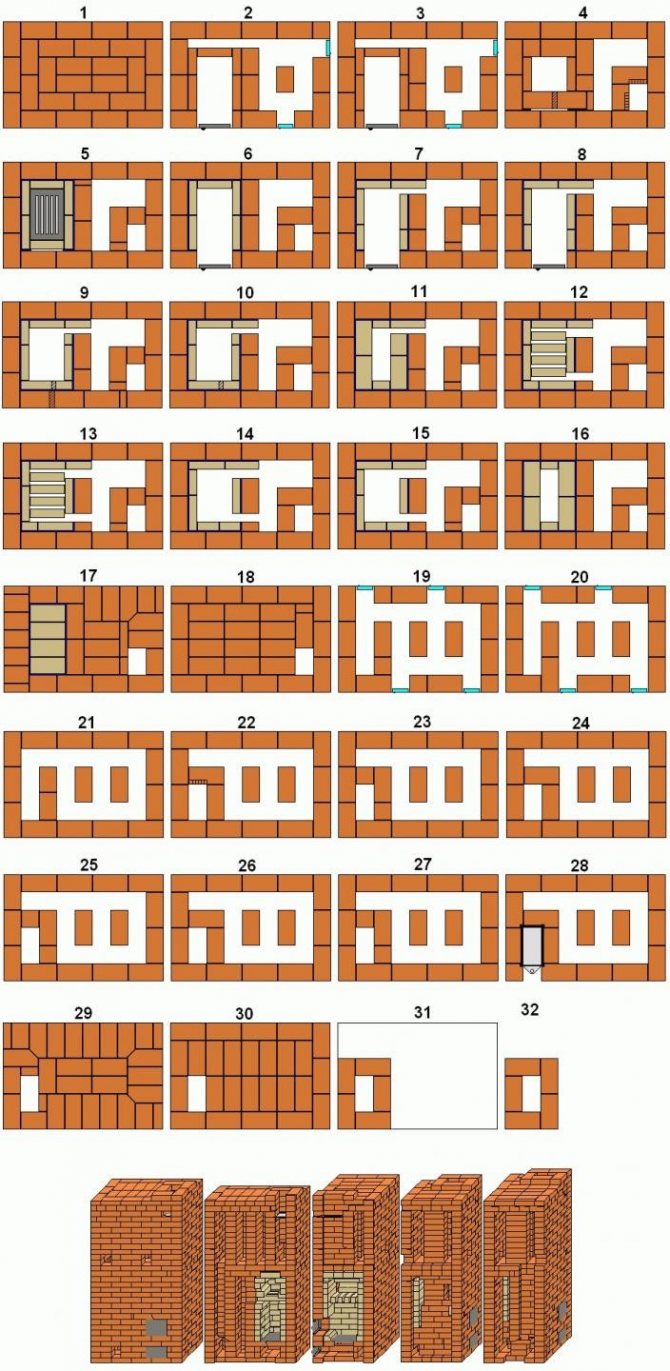

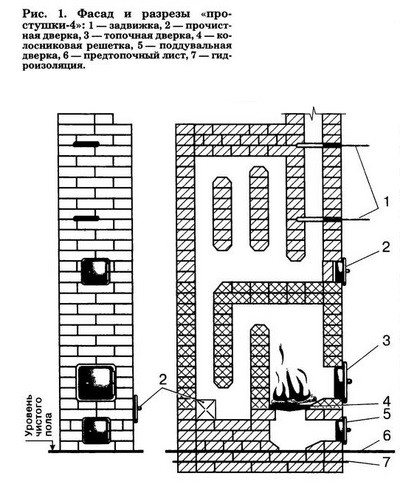

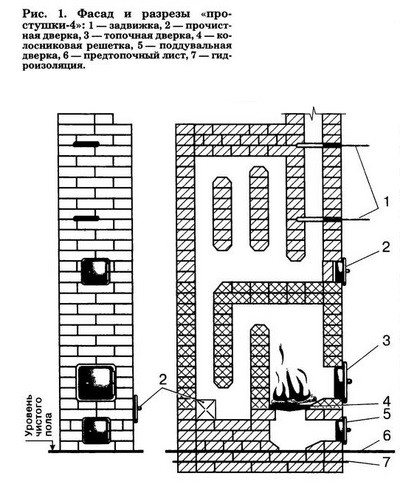

Description of the device

The two-bell heating and cooking system stands out for its modest dimensions and is suitable for heating a room with a total area of up to 45 square meters. For a similar model, the highest heat transfer power is characteristic in the form of 4200 kcal / hour. The firebox is made of specialized fireclay bricks, resistant to high temperatures. A stove with several burners is installed in the middle of the combustion chamber. If the desire arises, the structure is formed with a beautiful arch, making the brick structure an attractive interior component.

If the client wishes, an additional drying chamber is often installed.

Second heat load

Nothing works on bare principles. In order for a theoretically absolutely correct stove to heat, dry and cook well, it must also be performed correctly in the material. With regard to bell-type furnaces (and especially to two-bell ones), this means that the thermal load on the material must be high. To make a massive bell-type stove with thick walls is like making a fire in a cave. To feel the warmth, you need to sit by the fire itself, and there will be soot ...

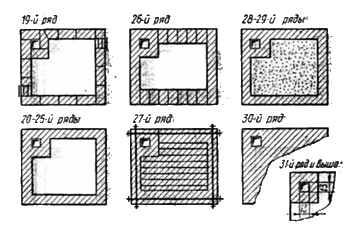

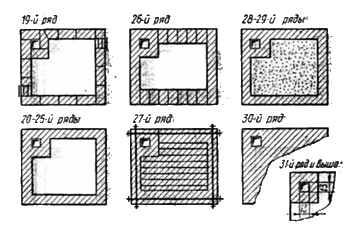

Take a look at fig. On it - drawings and orders of some of Kuznetsov's stoves: a bathhouse. heating and cooking. a double-circuit hot water boiler and an improved Russian with a stove bench. Not being an experienced stove-maker, it is clear that the amount of material per unit of released power (500 W * sq. M of the outer surface) in the Kuznetsov furnace is one and a half to two times less than in the traditional ones. In general, any bell-type furnace is "empty" inside a channel furnace of equal power.

The orders of some Kuznetsov furnaces

On the one hand, this is good, a brick with a masonry mortar costs money. But on the other hand, it requires careful development and adherence to the construction technology (see below). The heat load, from which the pile of cobblestones does not move, will destroy the thin brick wall already during the accelerating firebox.

For Kuznetsov furnaces, structural mechanics are also important. The strength of the wall on clay mortar decreases with decreasing its thickness much faster than on cement-sand. Therefore, the foundation for these furnaces must be carried out especially carefully in strict accordance with the recommendations of the author. They also need to be strictly followed during construction.

Note: I. V. Kuznetsov allows you to freely copy your materials for yourself, for construction, but objects to reprints. However, the pictures in Fig. small. An amateur can not build anything on them, but a master knows where to get full-fledged drawings. Therefore, we hope that Igor Viktorovich will forgive us for this small borrowing for the good of the cause.

Kuznetsov furnace

The design of this stove allows it to be installed in rooms with a wide variety of sizes, while the design can be whatever you like.

Advantages of Kuznetsov's two-bell ORP:

- high efficiency - 80%;

- a small amount of soot;

- the heat transfer source can be placed on the base of the lower hood in any places.

- any solid fuel can be used for heating;

- there can be installation of several sources of heat transfer;

- heated gases cannot escape until they give up a considerable part of their own heat;

- the stove is operational even with a low chimney.

The flue ducts of such stoves do not get dirty quickly; they need to be cleaned only once in a few years. This is due to the fact that there is always a high temperature in the bell near the combustion chamber. Those gaseous, liquid and solid substances, which in ordinary furnaces in most cases are drawn into the pipe and settle on it, burn out in the lower bell in the Kuznetsov furnace. In the end, the amount of soot becomes noticeably less. It is not necessary to close the valve as soon as the stove is heated, since heat does not escape through it.

There are a large number of varieties of Kuznetsov furnace designs, but the meaning of their work is the same - the free movement of gases through two or more bells, as has already been described before.

Two-bell furnaces Kuznetsova order and its features

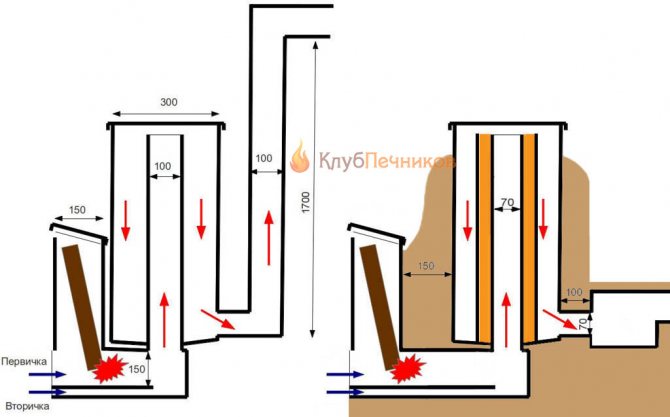

The principle of building furnaces in which it is possible to realize the law of free movement of gases has been known for a relatively long time. The most common and well-known option is a two-melt furnace.

The principle of its operation is that air from the environment enters the firebox through the blower. At the first stage of combustion, when the lightest fuel fractions are burned, the process is somewhat reminiscent of pyrolysis. This mode is the most effective. But before Kuznetsov, few people enjoyed these advantages. But the orders have a design that allows them to work in a pyrolysis mode. As a result, pyrolysis gases burn under the dome of the third bell. The process itself is interesting. Its peculiarity is that the combustion is self-regulating. If the flame has spread too much, then the draft deteriorates, and the combustion process slows down, if the heat is not enough, the draft increases, and the combustion process intensifies. Kuznetsov's two-bell furnaces (ordering) have a second dome so that the combustion process is not disturbed. The temperature in the second bell with an efficiency of about 80% reaches 300-400 degrees, and this is quite enough to transfer heat to the coolant.

Home option

Iron bell-type stoves are not suitable for heating a house. In the house, such a stove must be made of bricks. Newbie do it yourself do not fold the bell-top oven. Her ordering is very complicated. Because of this, it is best to entrust such work to the masters who will put together the "blacksmithing" of the desired configuration according to the prepared drawings. In addition, the master himself can prepare the necessary drawing.

Do not think that modern heating devices greatly bypass brick stoves in their characteristics. Perhaps they are more efficient in terms of heat transfer, but in terms of functionality they are inferior to “blacksmiths”.

Today bell-type stoves for the home are not very similar to their predecessors: "Swedes" and "Dutch". They use a different method of using hot gases.

Feature of the new ovens, which are popularly called "blacksmiths", is that heated gases circulate in them under their own weight. They do not need chimneys through which heat loss occurs. Heat in "blacksmiths" is collected under the dome of the hood. Naturally, the gas gradually cools, releasing heat into the surrounding environment, and slowly descends, where it collides with the hotter gas rising up. Because of this, cold air is forced out from under the hood by hot gases.

Heating polycarbonate greenhouses in winter: heating options

If in a traditional stove gas is drawn out through the chimney, then in a blacksmithing room it is pushed out. Moreover, the cap itself can be used for domestic needs. This can be a cooking area, a dryer, a container for heating water, etc. That is home owners receive a dual-use design.

According to their functional characteristics, "Kuznetsovki" are divided into the following types:

- Bathhouse.

- For cooking food.

- Fireplaces.

- Heating.

- Combined.

In Russia, preference is given to combined brick solutions. They can cook food, and at the same time they provide a long burning fuel and efficient heating of the house.

The main stages of arranging a brick oven in order with your own hands

When using ordering for heating and cooking ovens, a number of key steps must be performed. All of them have their own nuances of conducting and unique characteristics, knowing which you can ensure a high level of quality and minimize the cost of arranging a furnace with your own hands.

Next, an example of a furnace arrangement based on the Swedish order will be considered.

Work technology

In the design of a similar heating system. already in order, a blower is provided. This is especially necessary to remember when starting work on arranging the furnace with your own hands.

At the same time, it is important to take into account the peculiarities of laying the 1st row of bricks The fact is that here it is necessary to ensure compliance with the level and control of the corners, using a construction square for this purpose;

At the same time, it is necessary to pay attention to all the characteristics of the first row. The fact is that this largely affects not only the service life and reliability of the heating installation, but also the efficiency of its operation;

The technology of using the ordering provides, upon completion of the laying of the first furnace row, the installation of the door and the blower, after which they begin to lay the 2nd row;

When erecting the 3rd row of the cooking oven, it is necessary to adhere exactly to the ordering instructions.To create a blower, bricks should be chopped off on each side

And here it is necessary to take into account that the row being arranged must have the same height as the door;

For laying the 4th row of stove masonry, choose a place on the left side. This work begins with the installation of a door to ensure ash removal. This will prevent normal operation of the machine. As for the masonry itself, when it is performed, they adhere to the same order as in the scheme itself. Moreover, it is imperative to take care of overlapping the blower door. A square hole must be made above the ash pan. This idea is realized by laying bricks in a special way;

Starting to lay the 5th row, you need to follow that. so that the opening of the ash pan begins to narrow. In appearance, this row is similar to the 4th one. Therefore, the technology of its laying will be the same;

When starting the device of the 6th row, it is necessary to use a special brick with refractory properties as a material. Most often, a diagram developed by qualified stove-makers contains a note about this in the form of shading. Such a hint allows you to simplify the masonry process and avoid possible difficulties when performing these works;

The brick that will be laid in front of the grate must be chipped off. A detailed solution has a positive effect on the efficiency and quality of the placement of fuel on the grate during use of the stove. At the same time, the 5th row of the oven masonry will directly support the grate;

Bricks of the 6th row and the grate grate should create between themselves a sufficient space 10-15 cm wide, where sand or ash must be placed, and the presence of such a gap is necessary to create the effect of expansion of the grate metal when using a heating device;

After creating the U-shaped channel at the previous stages, it must be closed. Moreover, this is done with the expectation that as a result, three new ones arise. This stage provides for the installation of the furnace door, the support for which will be provided directly by the 6th row of the furnace masonry;

The process of laying the 8th and 9th rows of the Swedish stove masonry is carried out in the same way as in the case of the 7th. In this case, it must be remembered that it must have the same placement height as the door of the combustion chamber. Here, the processing of bricks is mandatory, with the help of which access to the partition of the combustion chamber and the left channel is blocked: they are cut on both sides, thereby ensuring the efficiency and smooth transition of combustion products from the furnace to the channel;

To create the 10th row of the furnace, refractory bricks are used. The laying technology provides for vertical placement, which should be complemented by regular checks carried out through the building level. The need for this is due to the fact that for such furnaces, when ordering, a special cooking deck must be placed on these bricks;

Next, you can start gluing the fire door. as a result, the final row will have two channels that differ in the presence of a perfectly square section.

Manufacturing procedure

Required tools

Double bell heating stoves are very different from the traditional designs that were used by our ancestors. Without going into the intricacies, it should be noted that for their design it is not necessary to involve a qualified stove-maker, the price of whose services is very high.

All work can be done independently, it is enough to have only the initial skills in handling bricks, mortar and trowel.

Before starting work, you should prepare the following tools:

- a trowel, which is needed for laying bricks;

A trowel is an indispensable tool for any stove-maker

- a mallet, with which it will be possible to level the laid stones;

- a bricklayer's hammer, without which you will not be able to give the bricks the required dimensions;

- the building level required to align the elements of the furnace horizontally;

- a plumb line, with the help of which the correct vertical installation is controlled.

Advice! The last two devices can successfully replace the laser level. This is the most accurate tool, however, its acquisition is justified only if large construction is to be done.

The laser level will help to make the oven level.

Materials used

The dimensions of the stove depend on the area of your country house. As a rule, a small structure is sufficient to provide an acceptable temperature in a room, the area of which does not exceed 50 square meters. meters. Otherwise, it is advisable to choose a more efficient heating system.

To build a furnace, you need to stock up on a sufficient amount of bricks (about 300 pieces). It must be fireproof, otherwise it may crack from exposure to high temperatures.

Clay is also needed, which is used for laying stoves. In addition, take care of the presence of sand, without which it is impossible to prepare a high-quality mortar.

Make sure you use refractory bricks

In a hardware store, you should purchase such structural elements in advance (it is impossible or very difficult to make them yourself):

- corners and steel strips - they are useful for arranging floors at various levels of masonry;

- hot water and drying boxes - their dimensions depend on the dimensions of the oven you have chosen;

- valves and doors - are elements of the firebox and protect the room from fire;

- hob - its design can be chosen depending on personal preferences.

Furnace masonry

Before describing the process of designing a furnace, it should be noted that during the construction of a country house, it is necessary to foresee the arrangement of the foundation for it in advance. Otherwise, the design will be unreliable. And casting the base after laying the finished floor will be either impossible or too costly.

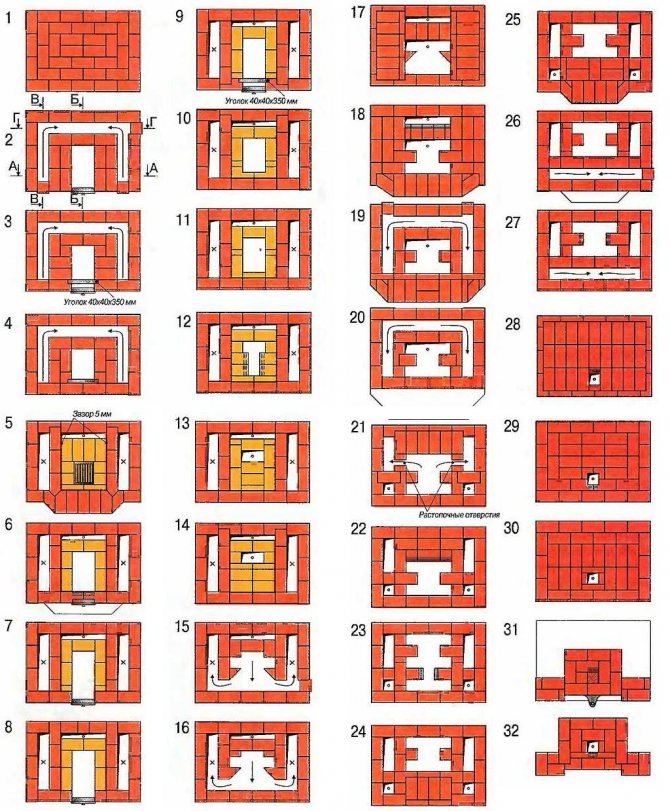

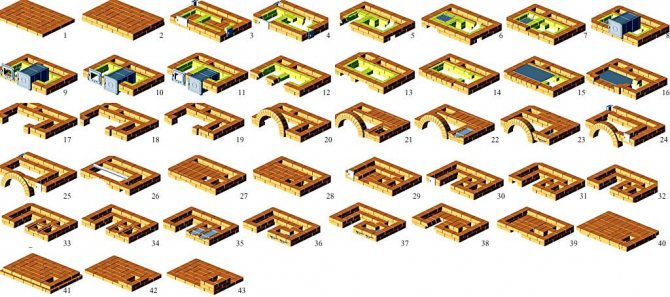

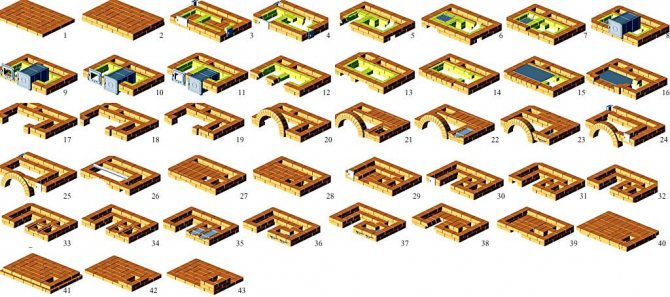

Layout of the masonry of a two-bell furnace

The work is done in the following sequence:

- The first and second rows are laid out. They will serve as a basis, therefore it is not recommended to use broken stones. In extreme cases, they can clog the middle. Moreover, broken brick at the edges of the masonry will spoil the appearance of the structure.

A start!

- The ash chamber is being constructed. It occupies layers of masonry from 3 to 5. In the front part, it is necessary to provide a place for installing the door. In addition, here you can leave the space used in the future for the installation of the drying chamber.

- The ash chamber is overlapped. To this end, the sixth row of masonry is built up inward, after which grate bars are mounted, which are fixed with bricks of the seventh row.

- A combustion chamber is being manufactured. It occupies rows from 8 to 10. The drying chamber is faced with the same bricks.

The manufacturing process of the two-bell furnace continues

- The overlap is being laid. To do this, before the installation of the 11th row, steel strips are laid on the brick, which are sealed from above with a screed made of clay mortar. When pouring the mixture, it is necessary to provide a place for arranging the chimney.

- A place for the hob is being prepared. For this, the 12th row of bricks is used, with which the previously hardened clay of the previous row is laid.

- A hob is installed. It is mounted on the 13th row of bricks. A tank can be installed on top, which uses the heat of the escaping smoke to heat the water.

- The chimney is being laid. It starts from row 14, and its dimensions depend on the height of the ceiling and other parameters of the room.

Various options for external design

Note! The dimensions of the oven can be larger. In this case, the order of work will not change, you just need to proportionally increase the rows of masonry.

We put the bell oven

In double-bell furnaces, the heat load on the materials is extremely high. Therefore, it is easy to make a mistake and implement a similar structure with massive walls. The fire will burn in it, but instead of the expected heat, you will receive smoke and soot.

Analysis of the order of Kuznetsov furnaces for various purposes, which are based on a 2-kolpaktovy version, (heating and cooking, for a bath, with the installation of a double-circuit hot water boiler, etc.), allows us to identify a very characteristic feature. On a unit Nout, equal to 500 W / m2 of the outer surface of the material, almost 1.5 times less is consumed than in products of traditional designs.

This has both a plus (cheaper construction due to the need for fewer bricks and mortar for masonry) and a minus. Such products make high demands on the development and strict observance of all technological nuances of masonry. Since the actual heat load, which is safe for a thick-walled furnace, is capable of destroying the thin wall already at the stage of the accelerating furnace.

Construction mechanics should also be close and understandable to a stove-maker who decides to lay out a bell-type stove with his own hands. The simplest confirmation of this thesis is that the strength characteristics of the wall laid with the use of clay mortar, if its thickness decreases, fall much faster than that of cement masonry. This places high demands on the foundation of such a furnace. The stove operator is obliged to strictly follow the recommendations of the author of the order with which he works. Moreover, not only when arranging the foundation, but further, at all other stages of the laying of the furnace.

Their primary basis is a floating firebox. It is laid out from refractory bricks (fireclay).The most popular brands are Ш-5 and ШБ-8. The rest of the furnace body is made of ordinary ceramic bricks, grades from M150 and above.

Recall floating, it is called because:

A dry seam is formed around the firebox from all sides, or in places strictly established by the order.

The technique for its implementation is as follows. After completing the laying of the last row of fireclay bricks, the masonry mortar is removed from all the joints between it and the ceramic brick. In the resulting voids, special gaskets are inserted, which are prepared from various types of mineral cardboard. The most commonly used are kaolin and basalt. It is possible to use other technologies, which are necessarily specified in the specifications available for a specific furnace.

Disconnected modules. This principle is subject to strict observance. Fireclay bricks in any version should not be inserted into the grooves between ceramic bricks (the opposite is also true), even if there are damping joints.

The heat capacity of fireclay bricks and its TCR are significantly different from those of ordinary ceramic bricks. Therefore, the firebox, if there is a connection with the main body of the stove, will simply tear the masonry already at the stage of kindling.

That is why it is required to make a firebox for such stoves as a fairly compact module inserted into a nest prepared from ceramic bricks. At the same time, there are a number of technical nuances of ensuring the removal of gases through the chimney.

It is very important to use in work only the material named in the specification for the furnace, as well as specified in the order. The designs of such furnaces are calculated and high-tech.

Therefore, replacement has a very negative effect on the performance of the finished product. In the best case, the oven will have to be repaired. At worst, disassemble completely and lay out in a new way.

Furnace types

There are several types of stoves for heating greenhouses, differing in the following parameters:

- The principle of heat radiation.

- The principle of heat propagation.

- Basic structural elements.

- Fuel combustion chamber type.

- Location and design of air supply channels.

- Convection shirts.

- Additional elements. As a rule, they have their own for each type of oven.

It is not difficult to make a furnace for a greenhouse with your own hands. At the same time, a long-burning sawdust oven will be able to effectively heat the air in a large greenhouse.

As fuel in greenhouse stoves, you can burn not only sawdust, but also the following types of fuel:

- Pellets.

- Peat granules.

- Ordinary firewood.

- Oil and other liquid fuels.

Heating a polycarbonate greenhouse with an infrared heater

It is worth notingthat the order of stoves for heating greenhouses of different sizes can vary significantly. Therefore, before starting work, it is recommended that you carefully familiarize yourself with the theoretical material.

Gallery: long-burning bell-type furnaces (25 photos)

Greenhouse bell furnace

If you need to quickly heat up the air in the room, then it is best to use a bell-type oven. It begins to give off heat intensively literally a few minutes after the start of warming up. At the same time, with its small dimensions, it is capable of heating a large room, as it provides prolonged fuel burning.

The bell system has one serious drawback - high heat losses. This heat loss does not depend on the type of fuel used.

Do-it-yourself bell-type sawdust stove is best made of metal. In this case, it will evenly heat the air in the room.

The main element of such a furnace is a metal body. Usually it is made from those materials that are at hand:

- Steel cylinder. It can be cooked by yourself.

- Empty gas bottle.

- Thick-walled metal pipe of large diameter.

- Metal barrel and water tank.

After selecting a suitable housing for the sawdust stove in the greenhouse, you need to purchase fittings and a strip of steel. Naturally, one must not forget about the chimney.

You can make do-it-yourself bell-type furnaces based on a barrel:

- You need to cut off the top of the barrel or the lid.

- Cut a groove in the resulting element and weld a piece of pipe into it. This will be the chimney.

- A door is cut through the wall of the barrel for storing the combustible material.

- The lid is processed in such a way as to pass freely into the barrel. It can then be compacted with a pre-prepared steel strip.

- At the final stage, another hole is cut in the lid, to which one pipe is welded to the food. This is blowing.

DIY greenhouse heating ideas

The principle of operation of such a furnace is very simple: the fuel inside it does not burn, but smolders. As the fuel burns out, the lid pushes the ash and smoothly drops down under its own weight.

The design of such a furnace can be complicated by adding a full-fledged ash pan and an independent firebox.

Advantages and disadvantages

The principle of hot air movement in a bell-type furnace

Kuznetsov's designs have many advantages. One of them is the increased efficiency - 93 percent. For comparison - in Russian stoves it is about 80. At the same time, “blacksmiths” have uniform heat transfer, less temperature fluctuations.

Other design advantages:

- There is no soot left, and therefore the stove and flue duct may not be cleaned for several years, which greatly simplifies maintenance.

- The device can be erected anywhere - in the corner zone, in the middle of the room, near the wall. Often, a two-bell oven heats several floors of a house on one tab.

- The stove chimney can be shortened to save bricks.

- "Kuznetsovka" is easily combined with a stove, fireplace, stove bench, differing in a variety of modifications.

- It is easy to connect a water circuit to the stove and pipe heated water for bathing or heating.

- Thanks to the increased level of pyrolysis, fuel is saved, which can be anything.

- The masonry will last longer, there is less risk of cracks.

- With the shutter open for a short time, it is almost impossible to cool the stove, because the cap is always filled with warm air, and the cold one is pressed downward.

Bykov's oven

Bykov's stoves are rectangular and have a simple laying. One of the largest is a stove with the following parameters: width 51 cm, depth 140 cm, height 215 cm (excluding the pipe). Its creator gave it the name of a thick-walled thick wall. This stove can be placed in a wall between two rooms.

Bykov's two-bell furnace

The design of the Bykov furnace is somewhat different from the two-bell one. The lower part - furnace, consists of ascending and descending channels. The upper one is made in the form of a cap, divided by five channels, made in the form of a sieve. This increases the area that comes into contact with hot gases. And this, in turn, significantly increases the efficiency of the furnace.

Double-bell ORPs are simple in design, but not easy to build. To build such a furnace, you need to have at least some experience, or choose a simpler structure, such as the name of Bykov. The best way to avoid trouble with room smoke or other problems is to consult a professional first.

Solution for two-bell furnace

The usual version of the kiln construction takes into account the clay mortar. Any specialist knows his own recipe for a wonderful mixture for bottom heating brick ovens. The building mass must necessarily include good clay of sufficient fat content, as well as sand with fine grains, which, simultaneously with the clay base, must have the consistency of sour cream of a thick consistency. As soon as the mixture is ready, a quality check takes place. Balls are rolled out of the mass and baked in the oven. If, after it cools down, the object is not cracked - the solution of possible parameters.When a similar ball is thrown from a height, and it does not lose shape and remains intact, then the mixture can be considered wonderful to work with.