Why are the pipes clogged and when is the heating system need to be flushed?

During operation, any heating system in one way or another experiences pipe contamination. This can be a rather small sedimentary layer, the accumulation limit of which is limited by the volume of the coolant in the isolated network. But in utility piping distribution systems, the amount of dirt can become so large that the water stops flowing completely. There are several reasons for this phenomenon:

- dirty coolant, land ingress into the heating network during pipeline repairs;

- accumulation of waste products of bacteria;

- the formation of a sedimentary layer of mineral salts, the concentration of which in the public heating structure is quite stable due to the constant addition of water to boilers;

- the consequences of the destruction of steel pipes, the remains of oxidized metal.

Advice! Determining that you need to purge the heating system with a compressor or another cleaning procedure is quite simple. The first sign of a clogged radiator is an uneven surface temperature. The second manifestation, speaking of clogged pipes, is the difference in the heating of the batteries in different rooms.

Do not think that owners of modern individual systems will never need a compressor for flushing heating. The isolated structure, where a limited volume of the coolant circulates, is generally stable without the addition of new portions of water with mineral impurities. However, the velocity of fluid passage, the so-called volumetric pumping of the working fluid per unit of time, plays an important role in it.

The warm floor is especially critical to a change in the nature of circulation. The effective cross-section of its thin tubes drops dramatically even when a modest plaque appears on their walls. In addition, even a thin layer of deposits that does not significantly affect the flow of liquid greatly reduces heat transfer in any system, with steel, cast iron, aluminum or bimetallic radiators. Therefore, a compressor for flushing heating can be useful not only for service companies that provide relevant services, but also for individuals.

Heating system cleaning methods

To clean the internal channels of heating networks, several methods are used: hydrochemical, pneumohydraulic and hydropneumatic impact.

Chemical washing

This is the most common cleaning method. Its essence lies in the fact that a chemically active liquid is supplied to the system for flushing the heating system together with a corrosion inhibitor. An aggressive solution dissolves deposits layer by layer and flushes them out of the pipes, and the inhibitor additionally passivates the pipes from the inside (creates a stable anti-corrosion coating, increasing their service life).

Important! After draining the reagent, the system should be flushed with a neutralizer or water, and then filled with a coolant.

Such work is performed using a pump for flushing the heating system, pumping a chemical fluid under pressure.

Important! Flushing work can be carried out in winter without interrupting the heating process. Flushing the pipes with a reagent, carried out on their own, is fraught with a major overhaul of the entire system. Contact the specialists!

Chemical cleaning will extend the operation of the heating system for 10-15 years and significantly reduce heating costs.

Bubbling: pneumohydraulic cleaning

The procedure will require a compressor that creates high pressure in the flushing hoses.The compressor delivers a water-air mixture to the pipes, which loosens deposits and removes scale, grease, sodium, calcium, magnesium salts, chemicals and rust from the walls. This method is widely used to remove sludge from cast iron radiators.

Battering ram: hydro-pneumatic cleaning

The method is based on the creation of a shock pulse passing through the highway at a speed of 1500 m / s. It is used on pipelines with a total length of no more than 60 m. The kinetic shock is produced by a special device. The result of the passage of the shock wave is the detachment of scale from the inner surface of the pipes.

Attention! Only a trained specialist can perform this operation!

A device for creating a shock wave in a pipeline

Compressor flushing methods

To do everything quickly and efficiently, it is recommended to use a compressor when flushing heating radiators, piping systems in order to restore the heat exchanger of a gas or other heating boiler. For some procedures, specialized equipment will be needed, for others, a conventional household (for example, automobile) compressor is sufficient.

Hydraulic and hydrochemical flushing

Hydraulic flushing is considered a classic of the genre. For its implementation, a water source is connected to the inlet of the heating circuit after disconnecting the corresponding pipe from the boiler or tapping in the outlet. This could be a communal water supply.

A hose is connected to the drain pipe of the heating system or a specially made cut-in to drain the dirty liquid into the sewer. In the simplest case, the procedure does not require any equipment. Water is fed into the pipeline.

Important! The minimum pumping volume for cleaning the system should be no less than five times the amount of the coolant.

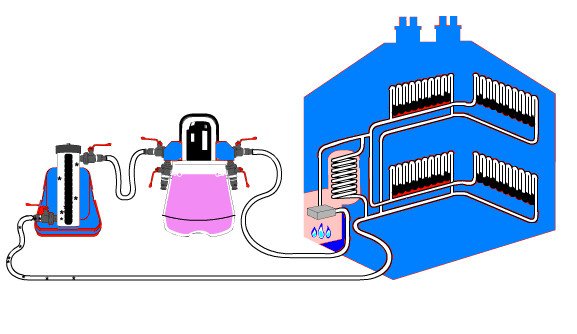

The procedure can be carried out with the addition of chemicals, in the simplest case - soda ash. In this version, it is called hydrochemical. Cleaning can be carried out either manually, with preliminary preparation of a large volume of the working composition and pouring it into the system, or using a compressor. The most difficult option in the context of the equipment used looks like this.

- A special flushing compressor creates pressure of the working solution and ensures its movement in the pipeline system. A circulation pump can be used instead.

- At the outlet of the drain pipe, a filter is installed that retains impurities.

- The circulation of the working solution is carried out for at least an hour.

Advice! To make sure that cleaning is nearing completion, it is recommended to install a transparent hose on the drain pipe of the heating network. In this case, flushing lasts until the working solution comes out practically clean.

The procedure can be done with a conventional car compressor. In this case, a container is mounted, a 19 liter polyethylene tank is quite suitable, into which purified water is poured. A removable sealing block with a tube equipped with a check valve is installed on its neck. A chemical solution will be fed through it. An inlet for the compressor is mounted in the bottom or wall of the tank. This is a fairly simple device that you can assemble yourself.

The chemical solution is poured into the tank. A tee is used to enter the system. It connects to a water supply or other source of liquid, the outlet tube of the tank. The outlet from the tee will be connected to the inlet pipe of the heating system. The procedure looks like this:

- water turns on;

- after some time, after preliminary flushing, the compressor turns on;

- the chemical solution enters the system as the pressure rises.

By adjusting the compressor capacity or by carrying out a short-term start-stop, it is easy to achieve a sufficiently uniform supply of the active substance. Best results are obtained when using a compressor with a low capacity. The completion of hydrochemical cleaning should be the flushing of the pipe network with clean water to remove chemical residues.

Advice! In order to achieve a really high-quality flushing by a hydraulic or hydrochemical method, it is recommended, after processing the system as a whole, to remove the radiators and carry out the cleaning procedure for each of them separately.

Hydrodynamic cleaning

The hydrodynamic cleaning procedure removes almost all contaminants from the heating system:

- limescale residues;

- carbon deposits;

- sediment of solids;

- corrosion products;

- organic fats;

- mineral bloom;

- waste products of bacteria.

The procedure is carried out using specialized compressors equipped with nozzles that emit water with high-energy pulses. The jet has a high speed and working pressure up to 200 atm.

However, such nozzles are difficult to operate inside pipelines. Therefore, hydrodynamic cleaning is mainly used for heating radiators. Services are provided by specialized companies, since for a private person the idea of buying equipment of this class is simply irrational, its price is very high.

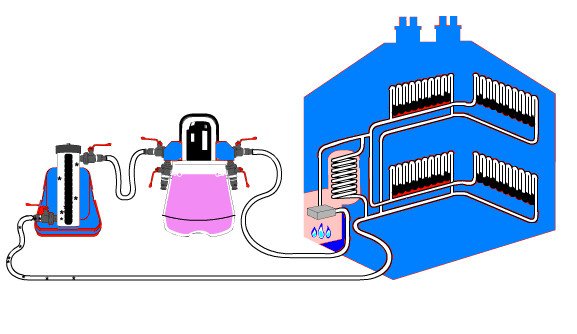

Bubble or hydropneumatic flushing

Hydropneumatic flushing is the most common way to restore the parameters of a heating system. It is the process of feeding an air-water mixture into pipes under significant pressure. Its effect literally tears off plaque, breaks precipitation and perfectly cleans both pipelines and heating radiators.

There are two ways to carry out this procedure.

- The system is filled with water and left for up to 1 hour. After that, an air compressor is connected to the inlet pipe and pressure is generated, which pipes and radiators can withstand. The system slugs again for half an hour. Finally, the drain pipe opens and the dirty water is discharged. Repeat the procedure if necessary. Any compressor can be used, including a car compressor.

- The system is supplied with an active air-water mixture. When carrying out this version of the procedure, you must use a special compressor. The device immediately delivers the finished mixture, allowing the washing procedure to be carried out as quickly as possible.

Hydropneumatic flushing is often referred to as purging. The procedure is carried out simply, quickly, without adding chemicals to the water, which can be immediately drained from the outlet pipe into the sewer.

Advice! It is recommended to carry out hydropneumatic cleaning before putting the heating system into operation.

Water hammer cleaning

Water supplied with a powerful impulse, at a speed of up to 1200 m per second, perfectly breaks up any deposits and dirt inside the pipelines of the heating system. This method has some danger for modern plastic pipes, non-welded joints, household heating boilers and boilers, thin heating radiators. However, water hammer is the most effective way to clean extremely clogged, old systems built on metal pipes and cast iron radiators.

For the procedure you will need:

- pneumatic gun, pressure accumulator with a pressure gauge and a valve opened by pressing the handle;

- a compressor that generates operating pressure for pulse shaping;

- source of liquid, plumbing can be used.

The mechanics of the work are quite simple. The heating system is supplied with water at a constant flow.The worker, monitoring the pressure indicator, launches the pneumatic gun.

The air pressure creates a hydraulic wave that breaks down the deposits in the pipes with an impulse. The time it takes to flush the system of a private house is an hour or a little more. For the fastest cleaning, you can use a specialized compressor, which is adjusted to certain parameters of the water hammer and the volume of fluid pumping.

Such an installation can be equipped with containers with chemical agents for automatic addition to the cleaning liquid, has a wide variety of protections, is able to combine water hammer with hydropneumatic mechanics, creating an air-water mixture.

Chemical cleaning

Cleaning with a concentrated active solution is a method that must be used with caution. Aluminum and silumin parts can be severely damaged when exposed to even relatively safe citric acid. However, for steel pipes, radiators, gas heat exchangers and other boilers, this is the most convenient way of cleaning.

The procedure looks like this:

- the volume to be cleaned is filled with a concentrated solution;

- after the lapse of time for which the maximum effect of the drug is achieved, it is removed from the system;

- the procedure is repeated for maximum thorough cleaning;

- the system is flushed with clean water to remove chemical residues.

In domestic conditions, a method with the movement of an active composition is used. For this, the liquid is pumped over. It is most convenient to use a special compressor.

However, you don't have to look for this type of equipment. You can get by with a conventional car compressor.

- For this, a container is made with two taps in the upper and lower parts. The ideal option is a plastic canister with a tightly screwed lid and a capacity of at least 5 liters.

- The compressor is connected to the upper outlet, and one of the heat exchanger pipes is connected to the lower outlet.

- A drain pipe is connected to the second pipe of the heat exchanger, the end of which is placed in an open container.

The procedure looks simple enough. 2/3 of the active solution is poured into the canister. After switching on the compressor, the delivery is started. The chemical mixture passes through a heat exchanger and is drained into a container. The fluid is pumped in portions for maximum impact.

After the canister is empty, the compressor is turned on in reverse. This provides a rarefaction, the reverse flow of the active composition occurs. The chemical mixture flows back into the canister. During the entire procedure, you need to ensure that the end of the drain tube is in the liquid. Finish the cleaning process by thoroughly flushing the heat exchanger.

The following types of active chemistry bring good results:

- alkalis;

- organic and inorganic acids;

- solvents.

Advice! If the pipes are slightly dirty, you can use citric acid and even a common toilet cleaner.

In order to flush not a separate radiator, but the system as a whole, specialized means are used. Their solution is pumped into pipelines and left for 6 to 10 hours to completely dissolve contaminants.

Purpose of the flush operation

If treated water is used as a working medium in the heating circuit, then you do not need to worry about its condition. But the possibility of using such a coolant is far from always available; in most cases, ordinary water circulates in heating systems. The salts of magnesium, calcium, sodium and other elements contained in it are deposited over time on the walls of pipelines and heating devices, just like in a regular kitchen kettle. In addition to deposits of inorganic nature, a sludge deposit consisting of grease, dirt and rust forms on the inner surfaces of the heating system components. The result of these processes is a number of undesirable effects:

- due to low thermal conductivity, dirt-salt build-ups impede the transfer of heat from the working medium to the walls of pipes and radiators;

- due to a decrease in the clearance of pipes and devices, a smaller volume of coolant enters the heating circuit;

- organic and inorganic contaminants contribute to the rapid destruction of the material of the circuit elements.

Heating system flushing process.

The consequence of the first two items of this list is a significant deterioration in the performance of the heating system, which is accompanied by a decrease in temperature in the heated rooms. The last of the negative effects leads to the appearance of leaks, which can lead to serious accidents with consequences in the form of expensive repairs or damage to human health.

The best way to restore the performance of the heating circuit and extend its life is flushing. This procedure can be carried out in one of three ways:

- chemical (special agents are used that dissolve dirt and scale);

- hydrodynamic (plaque is washed out by jets of water supplied with a high pressure);

- hydropneumatic pulse.

Let us consider the last type of heating flushing in more detail.

Compressor selection for flushing

Today on the retail market there are a huge number of models of equipment for various types of washing. It is almost impossible to formulate specific requirements for a compressor, since it is selected based on future operating conditions. This includes the volume of pumping, the ability to work in a specific mode, the ability to raise water to a height, and much more. However, there are brands that have earned a good reputation and offer devices with an attractive price and technical, functional indicators.

Ropulse

Compressors of this brand are characterized by a fairly high versatility, suitable for servicing pipes, individual radiators, heat exchangers. The models have a circuit for disinfection of the pumped liquid, which makes it possible to clean drinking water pipelines with their help. Ropulse compressors show good performance in maintenance procedures for underfloor heating systems and even solar collectors.

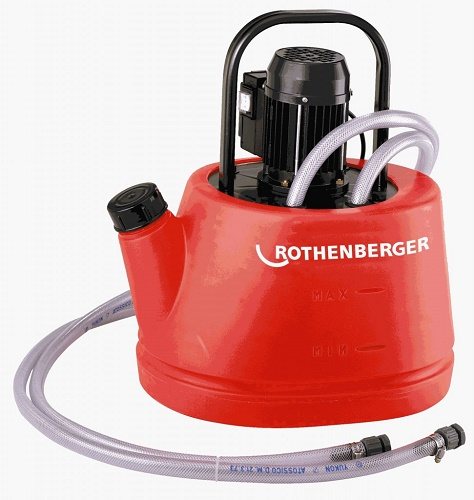

Rockal

Compressors of this brand provide gentle cleaning. The devices are of the manual type, lightweight, compact, and create a pressure of 1 atm in operating mode. Their low productivity (on average - 40 liters per minute) makes it possible to carry out procedures with a minimum consumption of the active composition.

Advice! Compressors of this brand are ideal for cleaning heating systems in a private house with a coolant volume of up to 300 liters.

Cillit-Boy

Compressors of this brand are able to solve almost any task. They are suitable for servicing steel and plastic pipe systems and show good results when cleaning underfloor heating. The functionality of the compressors includes disinfection, which allows them to be used for flushing the drinking water network.

The advantages of compressors include the ability to carry out hydropneumatic cleaning with a very uniform supply of air-water mixture for the most efficient operation. In addition, the devices are capable of operating in water hammer mode.

The control of the compressors is electronic, with convenient mechanics for setting and monitoring the operating parameters.

Flushing equipment

- Flushing chemicals... These chemicals are required for descaling work on copper and steel pipes. This concentrate prevents foaming of water (heat carrier), and this protects against corrosion, and also increases the service life of the pump.The spent chemical changes its color, so the active product has a red color, and the spent chemical has a yellow-orange color. To prepare an aqueous solution based on water, you will need from ten to thirty percent of the chemical. After the work related to descaling, the process of neutralizing chemical residues in the system takes place;

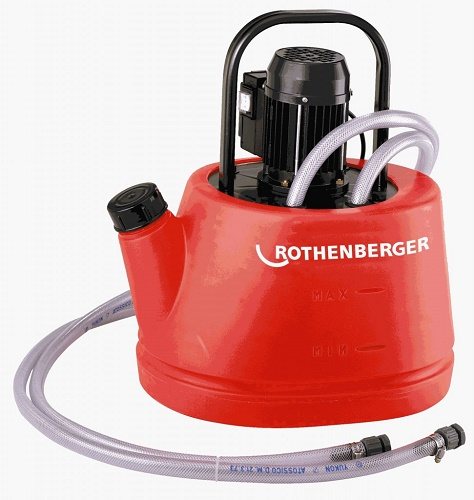

- Romantic 20 (descaling device). This device has an automatic regulation of the reverse flow interval and is used to remove heavy deposits and scale in installations with a volume of up to three hundred liters. As for the characteristics, such a technique has a pressure head of ten meters and a capacity of about forty liters per minute, and also maintains a pressure of one and a half bar. These devices can be equipped with work programmers, and the price for them is affordable;

- Ropulse... Microprocessor-controlled combined heating system flushing unit. It is also used for flushing water pipelines, including drinking ones, in accordance with existing requirements. In addition, it is used for washing: underfloor heating systems and solar collectors for home heating, which have been exposed to silt deposits; after repair or installation; cold water pipelines and hot water pipelines. This equipment can be used for the disinfection of drinking pipelines;

- Rockal... Hand pump for flushing the heating system. Its main task is to remove scale and deposits, and you can see photos and videos of this pump in the gallery of our website. It is used to remove deposits in installations and systems with a volume of up to three hundred liters. It has a high productivity, in the region of forty liters per minute, and a pressure slightly more than a bar. The device is well suited for descaling copper pipes and steel pipes.

Cillit-boy station

The heating flushing equipment, which is electronically controlled, provides a uniformly pulsating mixture of water and air, and compressed air is supplied from a connected compressor. Such a mixture passes through a heating system or a household gas heating boiler and then drains into the sewer.

The ripple can be adjusted and changed step by step depending on the goals. The device has an indication board.

The equipment is used for:

- flushing drinking water supply systems from sludge and other contaminants;

- for disinfection from bacteria in drinking water pipes;

- washing of heating systems and warm floors.

The principle of operation of this device is as follows. The device, controlled by an electronic unit, performs uniform flushing with a mixture of air and water. The compressor generates the required head. This mixture is passed through a heating circuit or heat source and cleans its interior surfaces.

Heating radiator flushing

- The beginning of the cleansing. The radiator should be taken to the bathroom and rinsed with clean water. Since it can damage and scratch the bathroom, it is advisable to place a wooden board under it. If washing is carried out in a private house, then for cleaning, it is best to take the radiator out into the yard.

- Unscrewing the end caps with a wrench. This procedure should be done in the bathroom or outside in the yard. Due to the fact that unscrewing the end caps causes the discharge of dirty liquid from the battery, and it can flood the floor and adjacent furniture. This will cause problems and damage your furniture and flooring.

- Flushing the radiator. Rinsing is carried out using a hose or shower. The hose is inserted into the pipe opening and water is supplied under pressure.

Equipment types

Timely cleaning of the system allows you to get rid of problems such as rust, scale and sediment. There are several types of heating flushing equipment used for varying degrees of blockage in the system.

Hydraulic flushing

This method is the supply of compressed air and water to the heating system. High pressure and frequent impulses allow small air bubbles, which actively fill a separate section of the system, to quickly and efficiently delaminate deposits on the walls.

It should be borne in mind that such a compressor for flushing the heating system allows you to clean the entire system, but this is done in stages.

To achieve the maximum effect, cleaning takes place in separate, relatively small areas (for example, one riser). Before starting the cleaning process, you should determine the amount and speed of water required for cleaning, as well as the amount and level of air pressure. When calculating, it is necessary to take into account both the length of the section of the system selected for flushing, and the diameter of the pipes used in this section.

Hydraulic flushing of heating systems can be carried out in two ways - flow and filling. The flow-through method involves the complete filling of the heating system with water. In this case, the air collector valve must be open. After the system has been filled to the maximum, the valve is closed, and compressed air is supplied to the system through the compressor. Hydropneumatic flushing of heating systems ends when exceptionally pure water without impurities begins to flow from the open pipe. For further operation, the system must be cleaned of water-air mixture.

When using the filling method, a certain procedure should be followed to achieve maximum effect.

First of all, the area of the system selected for cleaning must be filled with water. Further - the valve of the air collector is closed. After that, the supply of compressed air begins, produced through the second valve. The level of contamination should first be checked - the duration of the air supply depends on it, as well as on the length of the area to be cleaned. After stopping the air supply, close the shut-off valves. Next, the mixture formed in the system from water and sediment should be released into the drainage. After applying this method, the system must be flushed several times with water.

When system flush is required

Signs indicating the need to remove dirt and plaque:

- The temperature on the surface of the devices drops significantly.

- The interval between the inclusion of the heating system and the complete warming up of the radiators to the required values increases.

- The batteries do not warm up evenly, you can feel it to the touch: warm bottom, cold top.

- When the heating of the radiators is completely absent, only the pipes remain hot.

- Monthly heating bills are increasing.