The metal tile gives the building a very attractive appearance and insulates it well.

Insulation of a roof made of metal tiles is a rather important stage of construction. Compared to other roofing materials, metal tiles are more convenient - their use gives multiple advantages. The material is produced in the form of sheets - it is quite lightweight, about 4.5 kg per square meter. Such material allows you to easily and quickly carry out all the necessary installation work, to carry out thermal insulation. Metal tiles can be used on pitched roofs where a small angle of inclination is expected.

If the roof has a simple structure, the use of metal tiles will be economically justified. When buying metal tiles, everyone wants to have high-quality material for the roof in order to ensure the longest possible service life for the roof. It is also important to pay attention to the fact that the correct method is chosen for insulation, which will not later allow you to regret an overly hasty decision - if, for example, you were attracted by its cheapness. When the joy of the saved money subsides, it is immediately replaced by disappointment from the poor quality of the chosen method. For example, the thickness of the metal used for the manufacture of roofing material should be 0.5 mm.

It is also important to have a complete set of fasteners available. With a complete set, you will be able to carry out the installation of metal roofing tiles quickly and efficiently, and in the future you can not be afraid of leaks. You should also take care of the system of snow retention, the movement of precipitation on the roof. So that when installing the roof, a lot of material does not go to waste, you should order cutting of sheets of metal tiles.

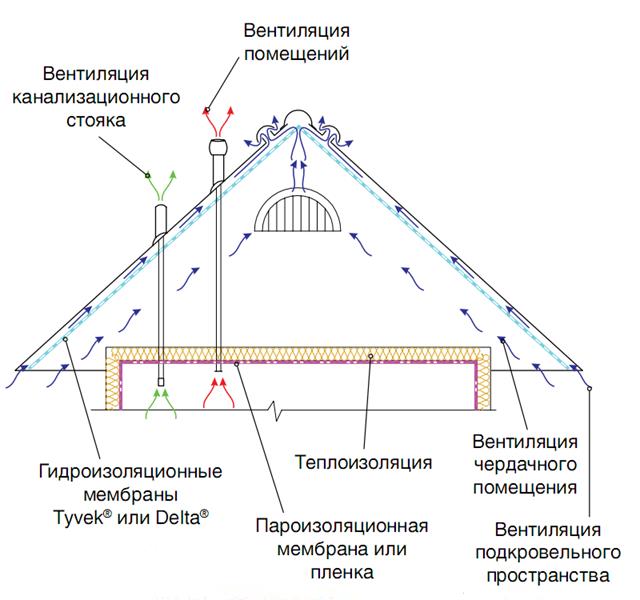

How a warm roof works and why is it called that

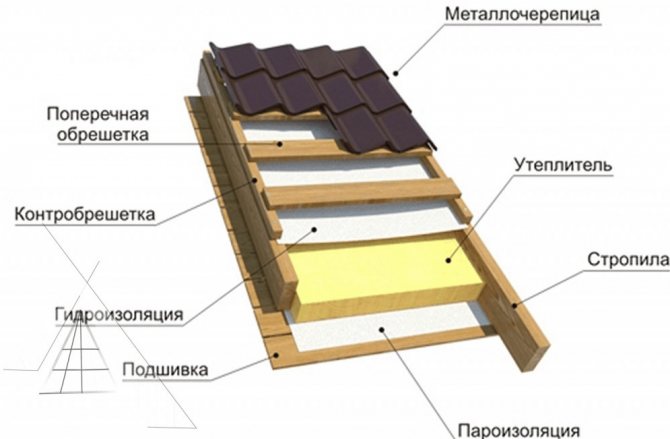

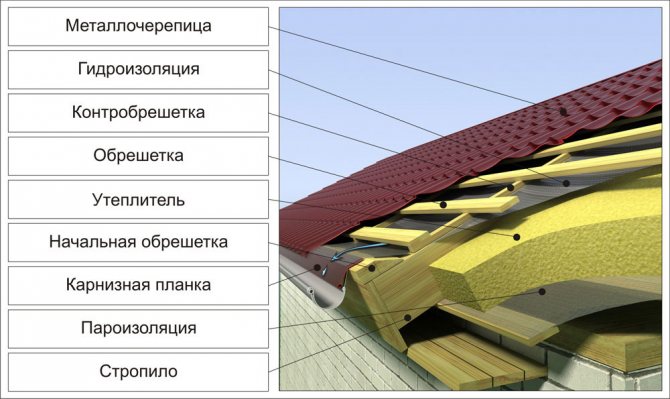

Such a roof has insulated roof slopes, thanks to which it is quite possible to arrange a comfortable living space in the attic - an attic. But this requires a series of operations to create an entire roofing system. Let's study the structure of such a roof.

Water resistant

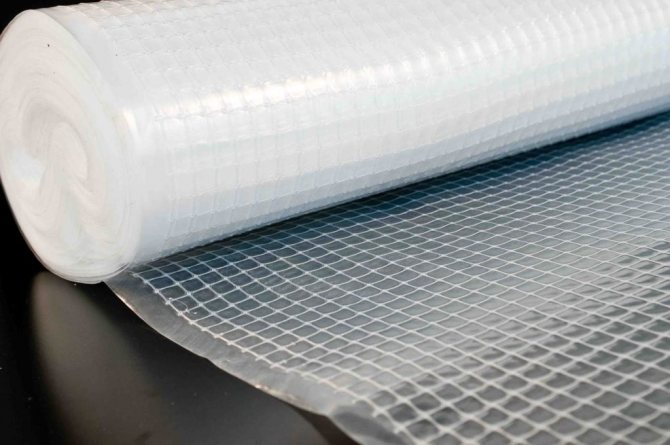

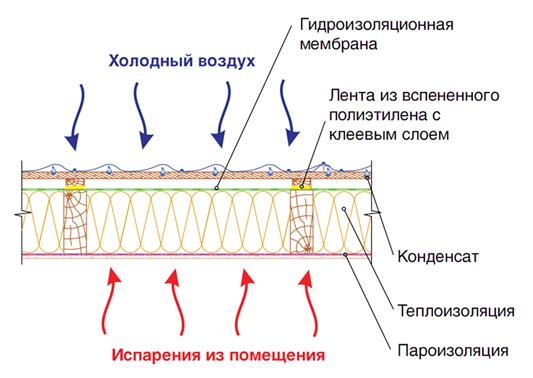

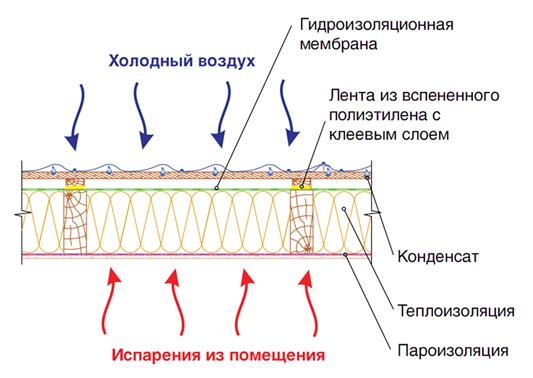

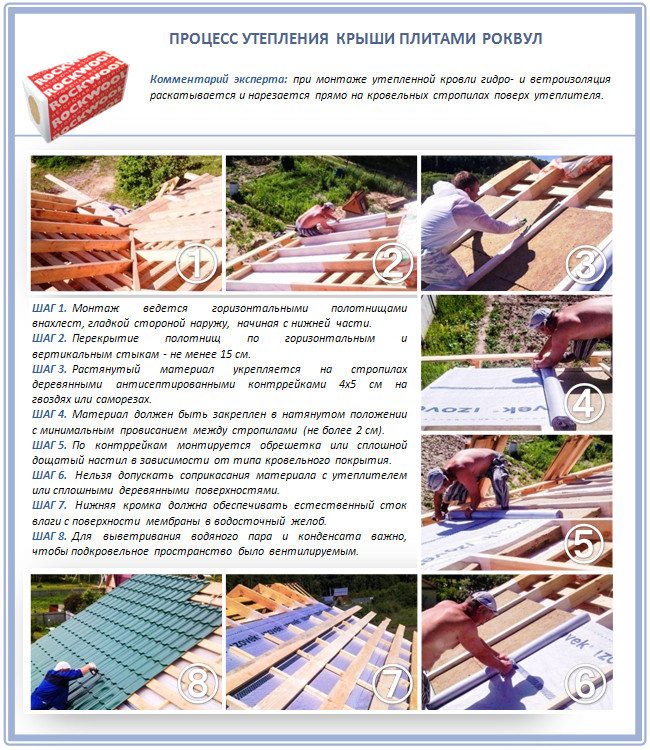

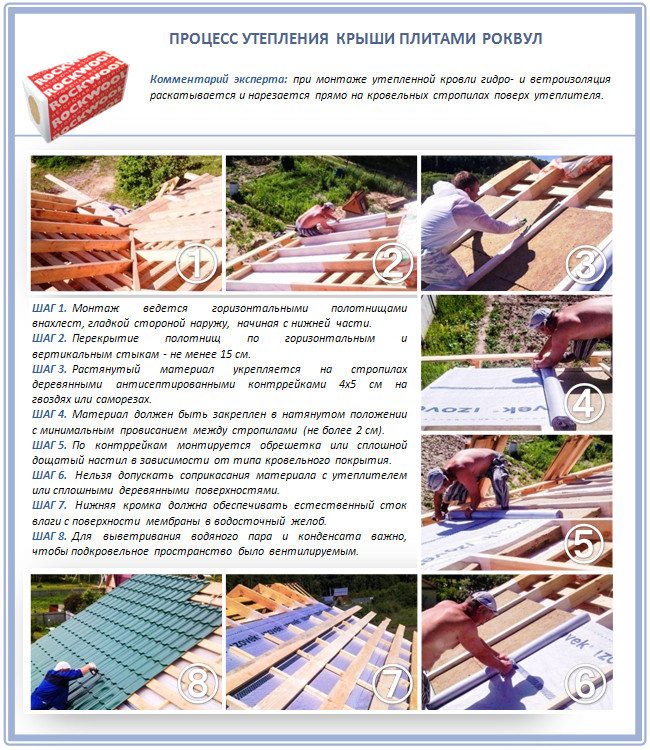

Condensation can collect on the reverse side of the metal tile, and in order to prevent it from getting on the insulation and wetting it, it is necessary to consider waterproofing. Membranes are well suited for these purposes, they are better than polyethylene film, since they are permeable to steam. Accordingly, moisture will calmly go outside, not accumulating anywhere. Thanks to such super-diffusion properties, the membranes are functional, moreover, they save space (they can be laid directly on the insulation without any gap).

The first thing to do is to isolate the valley. Starting from the top, the membrane is laid along its entire length, and the joints on the valley and abutments are glued with construction tape from the same manufacturer as the membrane. The waterproofing is laid along the rafters, starting from the eaves to the ridge, the rolls are rolled horizontally. It is necessary to ensure that the joints of individual rolls fall on the rafters, the rolls are placed with an overlap of 15 cm. The membranes must not be allowed to sag, they must be well tensioned.

We insulate the roof and put a vapor barrier

We continue to work on the creation of a metal roofing tile. On the inside, after the waterproofing membrane, insulation is laid. As a rule, basalt wool mats are used for this, but other types of insulation are also possible.

Insulation is placed between the roof rafters. When laying more than one layer, the joints between the mats of the first layer must be covered with the mats of the second, otherwise cold bridges may appear. A vapor barrier membrane is placed on top.It is necessary so that the fumes from the inner rooms do not accumulate on the insulation.

Protection of insulation from moisture penetration both from the inside and outside.

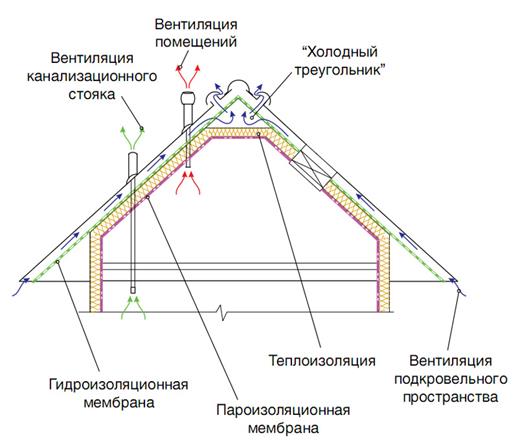

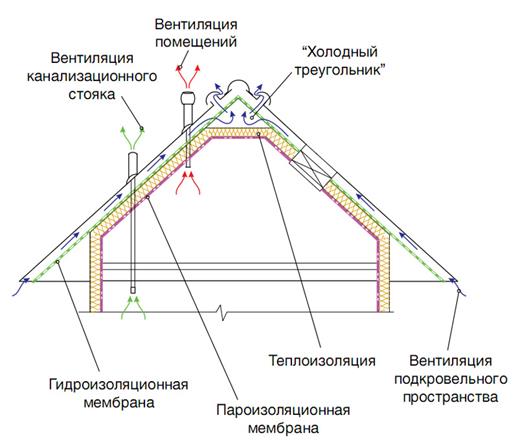

General arrangement of a warm metal roofing.

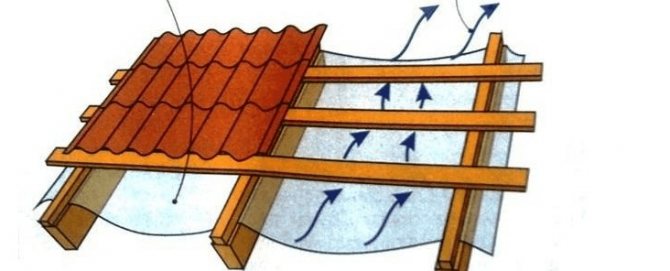

Ventilation device, roof insulation

Important! The more intensively the air moves in the space under the roof, the faster the condensate evaporates. Natural ventilation may be sufficient, but with a large roof area or a difficult shape, forced ventilation will be required.

When installing a heater with your own hands, it will be useful to know:

- The distance between the rafters should be 2 cm narrower than the width of the sheets of insulating material. The insulation is thus pressed tightly to the structures, without the formation of cracks. Otherwise, the corners will need to be sealed with small pieces of heat-insulating material - to prevent the formation of "cold bridges".

- Do-it-yourself insulation should be done only in dry weather in the absence of precipitation.

- When the insulation is in place, cover it with a waterproof film or put waterproofing.

- If the insulation is laid in several layers, it is necessary to make sure that the joints do not coincide - they must be displaced relative to each other.

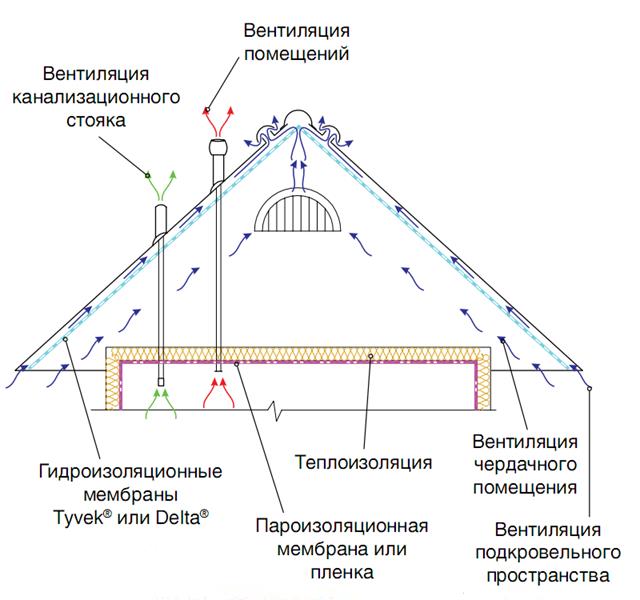

Cold roof differences

The main difference between such a roof is the lack of insulation on the slopes. Insulation is placed only in the lower part of the attic. Thanks to this, the house is always warm, and the slopes are ventilated at the same time.

How to protect the insulation from moisture?

In addition to the membranes that have already been mentioned above, cold metal roofing also allows the use of a waterproof film. But, unlike membranes, it must sag a little between the rafters (by about 20 mm) in order for the condensate to drain off. Waterproofing, as well as for a warm roof, must be laid horizontally, from the eaves to the ridge, making an overlap of 15 centimeters.

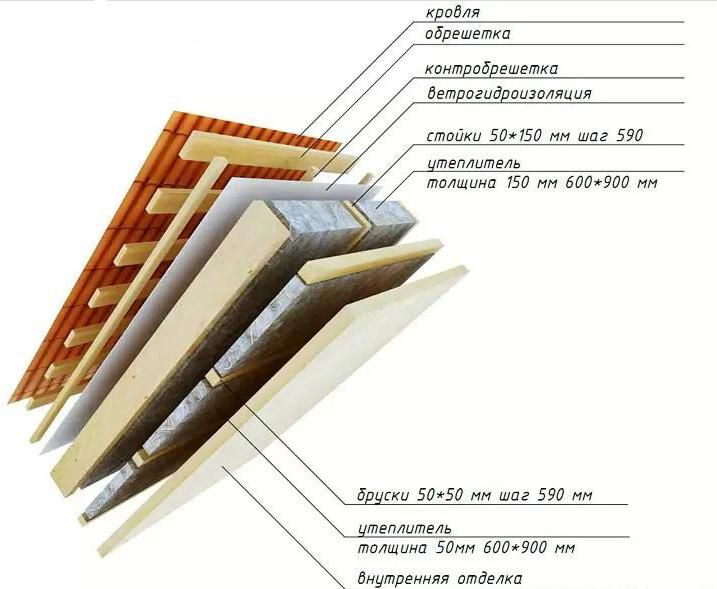

The general arrangement of the cold metal roofing.

Thermal insulation of the operated roof

A roof made of metal tiles can also be strengthened with your own hands.

A roofing material such as metal tiles will need high-quality insulation. Basically, roof insulation is carried out during the construction phase. Depending on personal preferences, materials of various characteristics can be used as insulation.

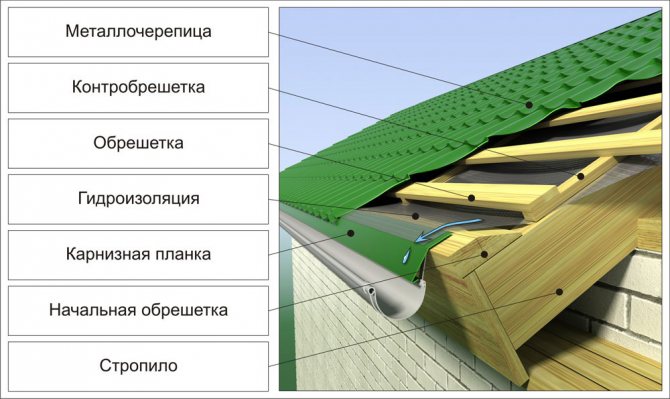

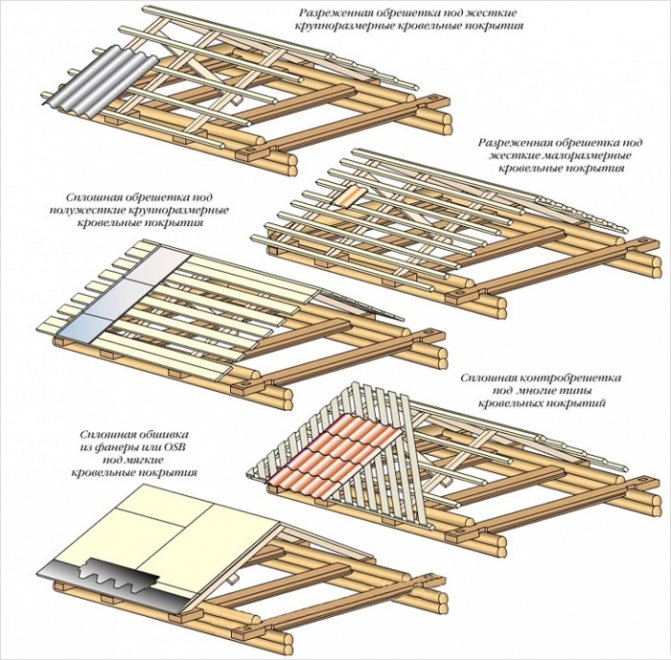

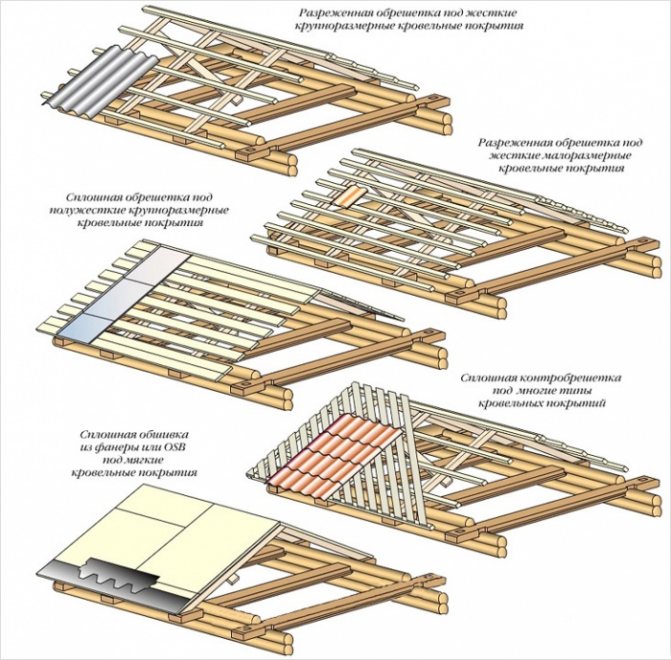

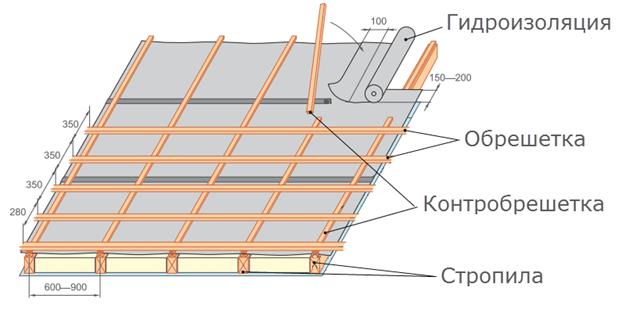

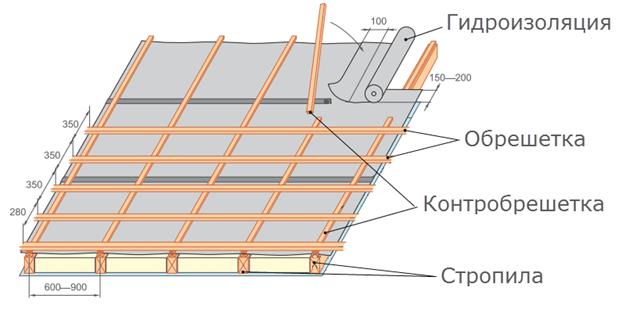

The lathing is an important element of the roof

When creating the lathing, wooden blocks with a section of 50x50 mm are used, as well as edged boards with dimensions of 32x100 and 50x100 mm. In the lower part of the roof slope, along the eaves, you need to nail two boards 50x100 mm. Further, from the bars of 50x50 mm on top of the waterproofing, you need to fill the counter-lattice, nailing the bars along the rafters, starting from the ridge to the bottom. On top of it, with an equal pitch, the sheathing boards are horizontally fixed. The fastening step depends on which type of metal tile profile, which will cover the roof, will be chosen.

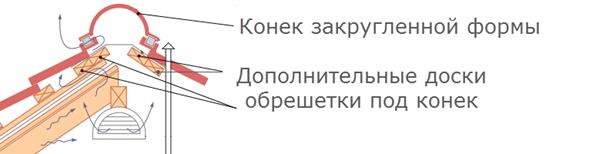

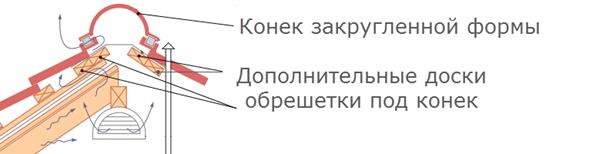

Sheathing for the ridge

The top-most part of the roof must be reinforced. For this purpose, a pair of boards are nailed on each side of the ridge strip.

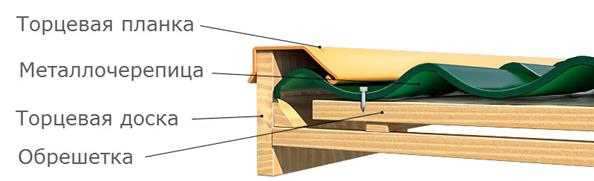

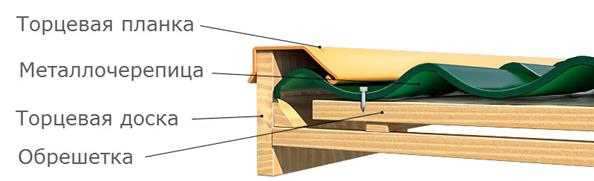

Roof ends

From the end side of the roof, boards must be nailed to the height of the metal tile profile - larger than the sheathing itself.

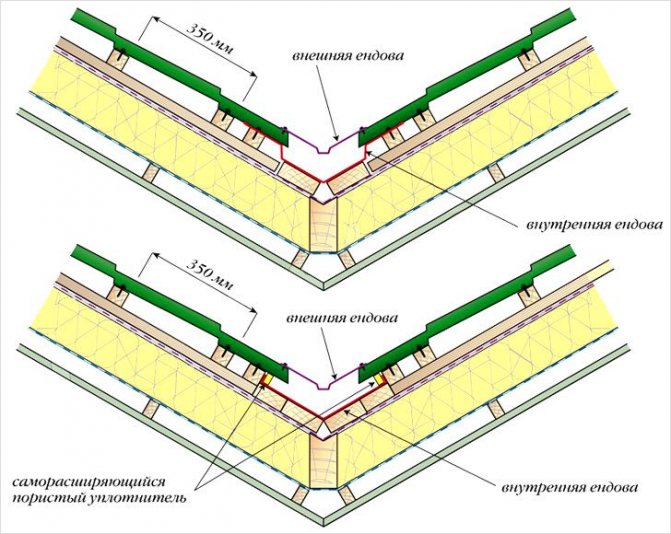

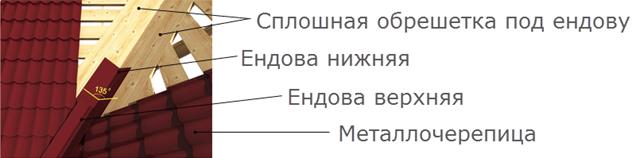

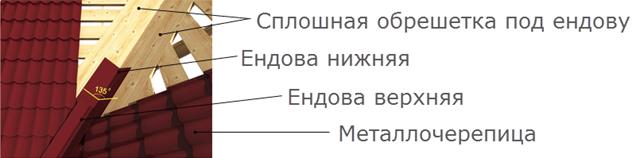

Lathing for the valley

Endova is the inner joint of two roof slopes. On sections of the valley, the crate must be made continuous.

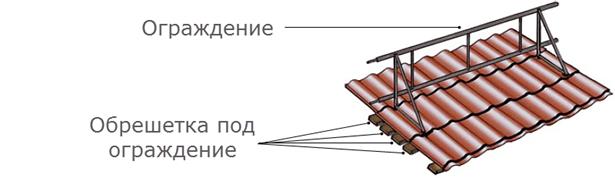

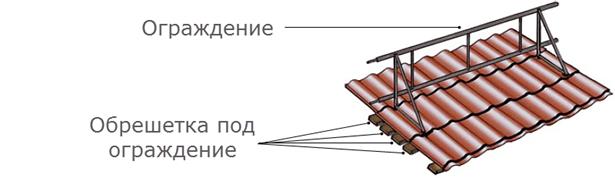

Roof fencing

Such a fence must be reliable, therefore it is made above the eaves overhang. The height of the load-bearing wall can be used as a guide. In these places, a solid crate is also needed, therefore, several additional boards are added between the usual crate to make a solid base.

Roofing from metal tiles on wooden crate

The main purpose of the crate is roof frame supportformed by the rafters. Waterproofing and metal tiles are attached to it, it creates natural ventilation the inner space of the roof.

There are two types of lathing - solid and sparse. In a solid construction, all boards are adjacent to each other, which provides increased frame strength, but significantly increases material costs.

In a sparse crate, the boards are at a certain distance from each other.

When installing a roof made of metal tiles, the second type is most often used, since the cladding material is strong enough by itself and does not require additional strengthening of the frame.

IMPORTANT!

Distance between parallel boards of the main direction of the sheathing determined by the interval between the waves of the tiles, since the troughs of the waves are the strongest parts of the profile.

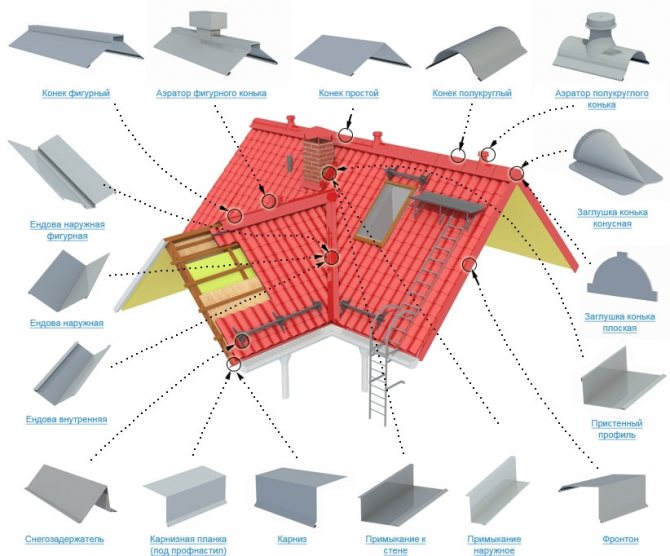

Structural elements of the roofing system

The construction of a metal roofing tile assumes that all elements of the roofing system are attached to the mounted lathing. Let's consider these elements in more detail.

Eaves strip, gutter and gutter holder

First of all, the gutter holders are fixed, and then the gutters for the water drain. After that, you can fix the curtain rod. It is attached to the crate with self-tapping screws so that the edge of the gutter does not protrude from under it.

Endovy roofs made of metal tiles

The number of such elements depends on the shape of the roof. The lower valley is attached to the lathing under the roof, and the upper valley (decorative strip) - above the roof. When joining the planks of the lower valley, an overlap of about 10 - 15 cm must be made.

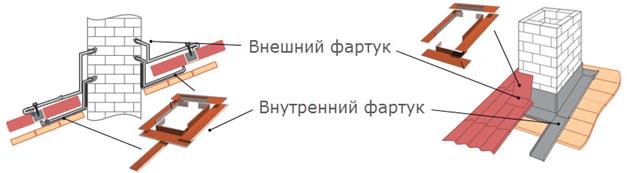

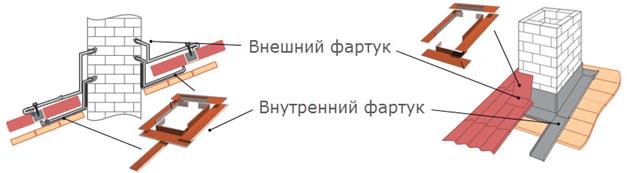

Adjacencies

Such elements are needed for a tight abutment of the roof to pipes and walls. Just like valleys, abutments consist of upper and lower planks. A so-called apron is made from the lower slats, after which a tie is placed under it, which is necessary to drain water into the valley or to the outer cornice. After that, the roofing is fixed, and the upper abutment strips are mounted on top of it.

Choosing the right insulation

So we come to the main question. For convenience, let's break it down into separate important points.

Sorption moisture of insulation

Do you know why wet insulation quickly loses its thermal insulation properties? The fact is that the thermal conductivity of water is exactly 25 times greater than that of air - this time, and the water itself, as it were, glues the fibers together - these are two. That is why, when choosing a roof insulation, carefully study such three of its main qualities: an indicator of sorption moisture content, vapor permeability and water absorption. Indeed, at a roof with metal tiles as a roofing, the issue of dampness is acute. Not to mention the constant condensation on the metal surface, which always finds how to get to the insulation through imperceptible gaps in the waterproofing.

So, sorption moisture is the hygroscopic moisture of the insulation under certain conditions. Those. the higher this value, the worse, because water-repellent properties are important for roofing insulation first of all. And they are directly affected by the presence of special hydrophobic additives in the material.

For clarity, let's take a closer look at the issue of humidity in a typical home. So, according to the sanitary requirements for residential premises, normal humidity is 30-45%, and 30% is the threshold below which the air becomes too dry and even unfavorable for health. But in European countries, 45-60% is considered normal humidity. But keep in mind that the humidity level in the house can reach 80%, especially if not two people live together and the wall decoration is almost vapor tight.Moisture simply has nowhere to go, and it rises up to the roof, from where the problems with the insulation come from, if you think over the roofing pie well. Do you remember how a metal roof loves to collect condensation under it?

Of course, all responsibility can be immediately shifted to the vapor barrier. So, for example, aluminum is considered one of the best:

Water-absorbing properties of insulation

But you have to upset you a little: not a single vapor barrier in the world can protect the insulation by 100%. The real figures are in the range of 70-80%, if the vapor barrier is of high quality, and 50-60%, if the simplest. And, if we take into account the fact that such insulation is still affected by condenser moisture on the other side (again, metal tiles), then both high-quality vapor barrier and insulation are needed, which, as far as possible, is not afraid of water and retains its properties for a long time even in such extreme conditions.

And this is already such a quality of insulation as water absorption - this is the disposition of the material to absorb moisture in contact with water and hold it. The lower the water absorption of the insulation, the better - this way it will be dry as long as possible, even with high dampness. Polyfoam in this regard, for example, is the leader among other heaters.

So, in addition to foam, stone fiber naturally has water-repellent properties, which only have to be slightly reinforced. Here is a step-by-step instruction on how to insulate such a roof with them:

Vapor permeability of insulation

And, finally, vapor permeability is the ability of an insulation to pass water vapor through itself and bring them out into the ventilation opening. This is one of the most important factors that affect roof insulation. And in such a roofing cake, vapor permeability should also be at its best!

Modern ecowool in this regard is one of the best:

Insulation cleanliness

There is one more problem: some heaters get dusty, and their lint particles, together with warm air, rise and gradually clog vapor-permeable holes. As a result, over the years, the quality of even the best "breathable" membrane deteriorates. Therefore, it is better not to insulate such a roof with sawdust at all, as with cheap mineral wool. Only from renowned manufacturers!

And in this regard, special subcranial fastening systems that are just beginning to appear on the Russian market, but have long been recognized abroad, are well suited:

To summarize: the lower the water absorption and sorption humidity, and the higher the vapor permeability, the better the thermal insulation qualities of the material for insulating the roof made of metal tiles. Choose the right material, study our photo instructions - and off you go!

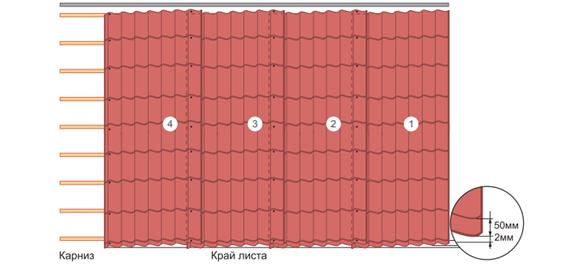

Installation of metal tiles

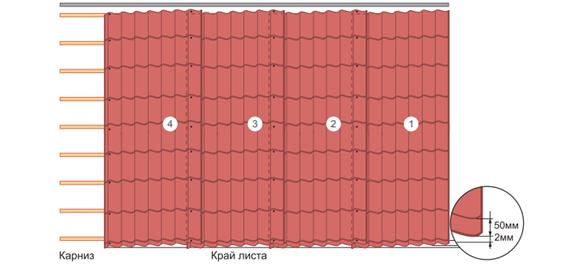

In cases where a sheet of metal tile completely covers the entire roof slope, installation begins from the ridge. It is necessary to check the location of the first sheet in relation to the end and the cornice (it should protrude 5 centimeters above the cornice). It is possible to mount metal tiles both from right to left (making an overlap of the next sheets on the previous ones), and from left to right (with an overlap of the previous sheets). After laying 3 sheets, you need to check their parallelism to the cornice. Self-tapping screws must be screwed into the side of the overlap (to the upper point), but not allowing the crate to be caught.

Consider a metal roofing scheme for situations where the roof slope is longer than the sheets of material. First you need to dock the sheets along the length, and then align the first 4 sheets along the end. Each square meter of shingles is fixed with self-tapping screws (with EPDM gasket) - 6 or 8 pieces are required. In places where the material is adjacent to the crate, the lower part of the sheet must be fixed in the bend of the wave. Installation is carried out through the wave, and the subsequent rows of self-tapping screws should be shifted in a checkerboard pattern.

Roof insulation technology from metal tiles with the use of the best thermal insulation

The insulation material should be lightweight and easy to install. Its ability to block sound is just as important as its low thermal conductivity. Insulation must be resistant to moisture and time.

Among the thermal insulation on the building materials market, mineral wool has all these parameters. Its characteristics do not change over the years, and the properties of retaining heat and protecting the room from the penetration of sound waves fully meet the requirements of current international standards.

Whatever material is used for insulation (foam board, mineral wool or other), the installation technology is similar. Consider the device of a roofing pie on mineral wool... It is mounted on the supporting structures of the roof frame. This method of protection from cold weather is the most effective due to the fact that it creates obstacles for cooling the under-roof space.

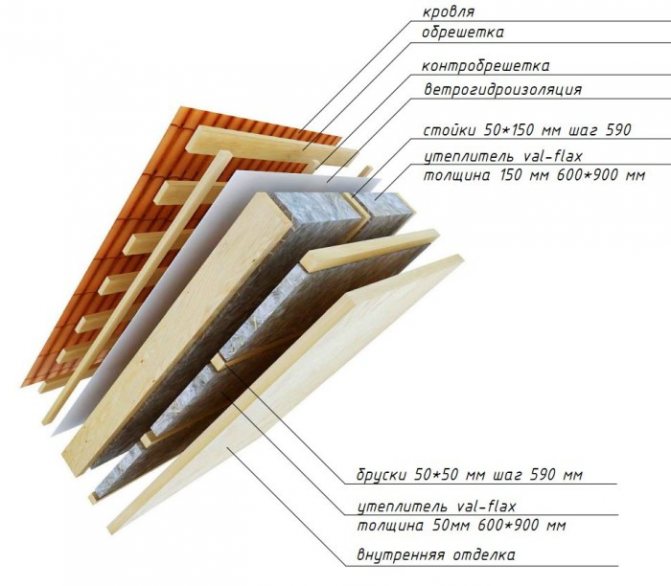

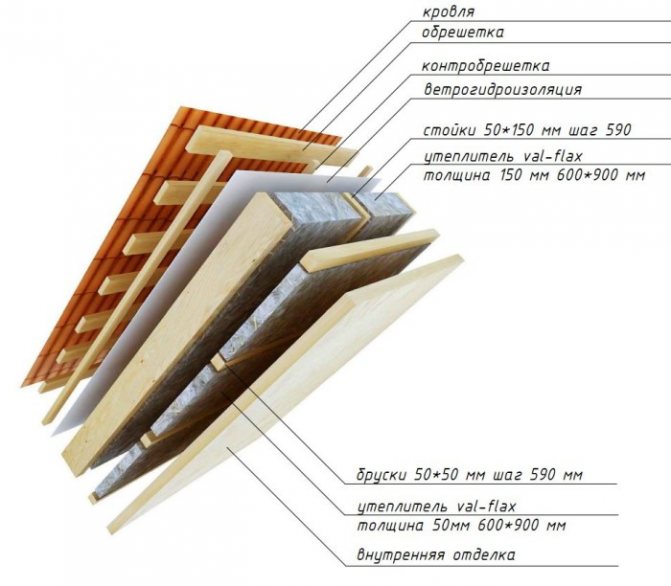

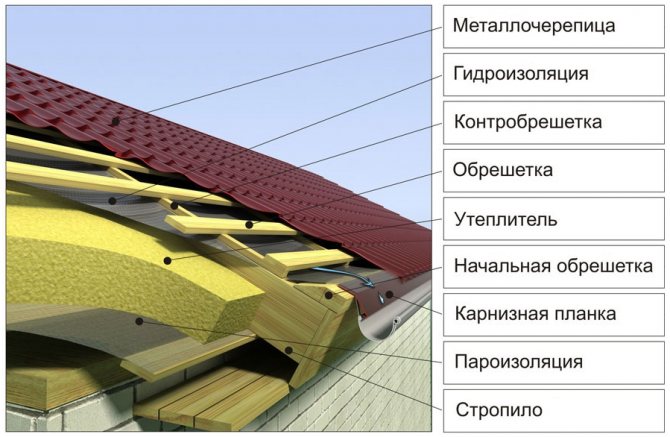

The number of layers of "pie" depends on the type of roof.

Each layer performs its own function. The cut looks like this:

- the metal tile itself - protection against atmospheric influences;

- vibration isolation - dampens all types of vibrations, including sound waves;

- lathing made of wooden slats and beams - forms a frame base;

- counter-lattice (from the same materials as the previous item) - forms ventilation gaps of the lathing;

- waterproofing layer - protection of rafters and insulation layer from condensing moisture;

- ventilation space - ensures the drying of the insulation;

- insulation (mineral wool) - retains heat in the under-roof rooms and provides additional protection against the penetration of sound waves;

- rafter system - supporting structure;

- vapor barrier - protection against condensation from the air contained inside the room;

- sheathing - hides the structure from view from inside the room.

When installing rafters, it is necessary to take into account that a load of 200 kg will act on 1 square meter - and this is without the weight of the snow cover and people who will be on the roof for repair and maintenance. For outbuildings, a simplified package is used.

Completing parts of the roof system

End strips

End strips are installed from the end side of the roof. They are fastened with self-tapping screws every 50-60 cm. It is necessary to make an overlap between adjacent strips of about 50 mm.

Ridge strips

Such elements can be flat or rounded. The latter must be additionally attached to their end caps. It can be simple or conical, it is fastened with self-tapping screws or rivets. Before installing the strips, you need to put a universal or shaped seal under the ridge. These strips are mounted using ridge screws.

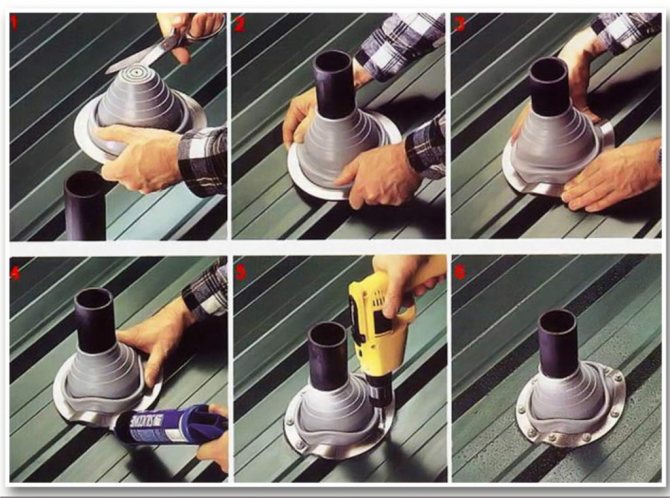

Ventilation device and passages

The following additional metal roofing elements are necessary for ease of installation of air ducts, antennas and other elements.

Ventilation outlet

For normal air exchange in each span of the rafters, ventilation outlets are required. However, if the roof itself has an uninsulated “cold triangle”, then one exit for every 60 m2 of the roof will be enough. You need to make a hole in the metal tile and fix the knot to its edges with self-tapping screws. If silicone sealant is not included in the vent outlet kit, apply additionally.

Sewer outlet

The sewer outlet must be connected to the riser, usually a corrugated pipe is used for this. On the roof, for the installation of such a passage element, you need to cut out a fragment of the metal tile. The sewer outlet must be inserted into the passage element and attached to the metal tile with self-tapping screws after the installation of the waterproofing, sealant and sealant is completed.

Outputs for antennas and electric cables

In order to seal the joints of antennas, cables and sandwich-type chimneys, special antenna outputs must be used. It is necessary to cut off the rubber top of the antenna outlet so that it is 20% smaller than the diameter of the passing pipe, and pull it over the pipe. After giving the base of the antenna outlet the shape of the metal tile profile, it is coated with silicone sealant and attached to the metal tile with self-tapping screws.

In the photo (from left to right): 1. Ventilation outlet; 2. Sewerage and exhaust outlet; 3. Antenna output.

Design and purpose of safety elements

Stairs

To climb to the roof, you need a stable ladder, consisting of wall and roof fragments with brackets. Requires 4 brackets per section. They are mounted in the section of the lower wave bend, where there is a solid crate. The brackets themselves and the upper part of the roof ladder are fixed with bolt-screws. The wall ladder is mounted in such a way that its top step is opposite the edge of the eaves. The wall ladder must be positioned in alignment with the roof ladder.

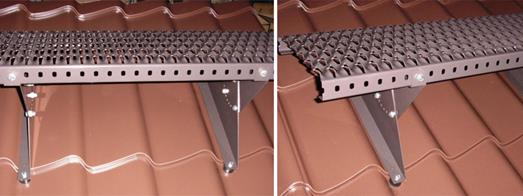

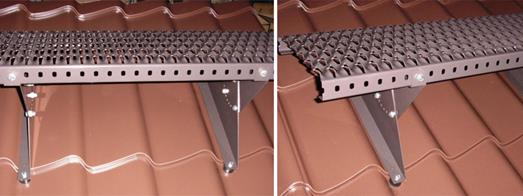

Roof railing

Such metal barriers are essential for roof work. They are attached with special supports to the solid crate through the lower part of the wave and are sealed with rubber gaskets.

Transition bridge

In order to safely walk on the roof from an attic window, hatch or staircase, walkways are necessary. They are fixed in the same way as fences, but a solid crate is not required in this case.

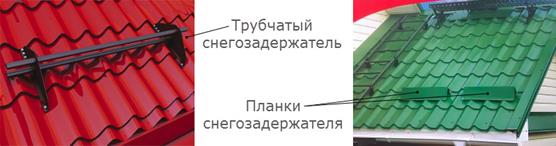

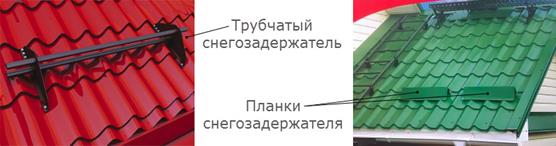

Snow holders

The most popular are tubular metal snow guards and are usually painted black, brown, green or red. They are mounted around the entire perimeter of the roof above the eaves. Also, they must be placed above the entrance, dormers and above each level of a multi-tiered roof.

Roofing system diagram

Below you can see a diagram of the roofing system. On it, all the nodes discussed above are connected into a single roof.

Gutter system

A competent roof structure for metal tiles is impossible without a reliable drainage system. It consists of several elements.

Gutter

According to the rules, no more than 10 meters of gutter is required for one downpipe. A V-shaped hole 10 cm wide is cut out on it, into which the outlet funnel will be inserted. You need to fix it 15 cm from the edge of the gutter.

Holders for gutters

They must be installed before the eaves and metal tiles are finally installed. The holders are fixed every 0.4-0.5 m. They need to be marked so that a slope of up to 5 mm per meter comes out, after which they are bent with a strip bender. You can also bend the already installed holders by marking them using a stretched cord.

Gutter plugs

They are installed at both ends of the gutter and are tightly hammered inward with a mallet.

Outlet funnel

The front edge of the outlet funnel is brought under the outer folded edge of the gutter and is fixed with a carved flange, which is folded against the trailing edge of the gutter.

Connectors

When fastening gutters or their corners together, an overlap of 2.5 to 3 cm must be made. For this, connectors are used. They have rubber gaskets, as well as a lock, which consists of a tongue in the front and a rear flange. Using such a lock, it is easy to connect the gutters both in a row and at an angle.

Spider

This part is installed in the funnel of the downpipe. It is designed to keep out debris and leaves. The spider must be cleaned at least once a year to continue performing its functions.

Connection pipe and its elbow

Two transition elbows and a connecting pipe are installed between the funnel and the drainpipe. They are sawn off directly on the spot, having determined the desired size.

Downpipe and its holders

There are two types of holders.They are versatile and suitable for all surfaces and materials. They need to be fixed to the wall every meter. You also need fasteners at pipe joints. During installation, pieces of pipe of the required length are cut, they are inserted into the holders and snapped into place with locks. At the bottom of the drainpipe, 30 cm from the blind area, a knee is attached to drain the water.

Downspout tee

It is required if one outlet is provided for two funnels. In the lower part it is compressed, and on the side it has a sufficiently wide socket that allows you to change the angle of entry of the side pipe.

Funnel for collecting water

Seam and other complex types of roofing involves the use of a funnel instead of a gutter. It is inserted into the pipe, which is attached to the eaves with a clamp. It is made from a strip of metal and connected with a self-tapping screw.

The main ingredients of a roofing pie

Such a name as a pie is based on the fact that several layers are present simultaneously in the composition of an insulated roofing structure. They are related to each other and perform specific functions. insulated roofing cake usually consists of layers such as:

- Metal tiles;

- High-quality lathing made of high-quality edged boards;

- An element such as a counter-lattice made of bars, planks;

- High quality waterproofing film;

- Special ventilation gap;

- Unique thermal insulation material;

- Special vapor barrier film;

- Professionally constructed rafter system.

The roof, which is not insulated with special materials, is installed much less often, because the heat-insulating layer used in this process seriously reduces the material costs for heating the room. this is based on the fact that "cold bridges" are almost completely excluded in this design.

If the building is located in a warm region, it will be much more expedient to install such a coating, which consists of the following layers:

- Metal tiles;

- High-quality lathing made of boards and bars;

- You will need a counter-lattice made of wood bars and planks;

- Ventilation gap;

- High quality rafter system.

After that, in direct proportion to whether there is a special room in the attic, whether the attic is present in the structure, and whether the space that is located inside the building is arranged strictly under the roof. Below, each of the layers of such a structure as an insulated roof will be discussed in more detail.