How to properly insulate the attic from the inside

Published by: Artur Kanapatsky 0

Having correctly insulated the attic from the inside, you can use the attic all year round. This solution allows you to save on heating your home. The technology for creating an insulated attic is selected based on one main factor - at what stage of the construction of the house the attic was laid. It is also worth figuring out how to choose the right insulation material, how to lay it, what tools will be needed during the work.

For this, there are step-by-step instructions that allow you to figure out what actions to perform at each stage of the attic insulation. If a warm attic space was planned at the design stage of the building, the type of insulation should be correlated with the tasks assigned to it. To understand how to properly insulate the attic, it is worth understanding the work algorithm and calculated data.

Errors when insulating the attic

Ninety percent of homeowners save literally everywhere when setting up an upper floor on their own. Trying to reduce the cost of insulation technology, they make it absolutely unsuitable for winter living. As a result, they have to spend an impressive amount of money to correct the error. Haste is the second critical oversight, leading to the same problems, but with a hassle.

What exactly are the savings? In an effort to preserve the family budget, the overwhelming majority of individuals avoid expert advice. They replace them with the advice of supposedly experienced neighbors who have a Finnish cottage with an insulated room on top. The deliberate reduction in the density of the building material initiates the loss of heat from the inside out. Even a minor miscalculation of 5 centimeters can worsen microclimatic conditions.

Making adjustments to the installation technique is unacceptable. The ventilation system plays one of the main roles in the process of thermal insulation of the space. Wealthy consumers are trying to do without grout and putty. Meanwhile, incorrectly performed grouting leads to the formation of a cold bridge, as a result of which the dew point increases. The rooms are getting cold. This is especially felt by Siberians, residents of the western and northern regions of the Russian Federation.

How can you avoid such mistakes? Very simple. Talk to a consultant from a well-known metropolitan company specializing in insulation works for country houses, brick or wood buildings, and other objects. Take advantage of the free service of the visit of the master to the construction site. Get comprehensive answers to your own questions regarding the insulation of floors, walls, roof ceilings with a building material of a separate brand.

Attic insulation methods

Today, there are two ways to insulate the attic. The first is to try to do it yourself. The second is to entrust the turnkey work to the experts of the Moscow organization "Ekovata-MSK". The administrator of the official website will accept the order, form a work order and send the measurers to the place of the proposed installation of thermal insulation. After the application, the foreman will arrive within 60 minutes, measure the area, draw up and agree on an estimate.

Based on the measurements made taking into account the design features of the house or cottage, you, as the owner, will make a responsible decision about fruitful cooperation. Along with this, the foremen will carry out preparatory measures, clean the territory, take out solid household waste and construction waste upon completion.For all types of work, the company provides a 10-year guarantee of the result.

In addition to mineral wool, we use foam and ecological cellulose insulation. A complete list of serviced objects (garages, hangars, industrial buildings), you can find on the main page of the official website. We provide a discount of up to five percent for purchased building materials. The amount of the discount for a particular case, check with the manager when drawing up an application for the purchased insulation.

The right choice of insulation

If the attic will be used only in summer, it is enough to cover only the floor area with a layer of insulation. When planning year-round housing, multilayer insulation of the attic is performed from the inside. The process includes the processing of walls, gables, floors and ceilings. In addition, the heating of the attic will have to be integrated with the heating system of your home.

The difficulties that arise when choosing insulation for the attic are often associated with the non-standard architecture of the attic floor. The choice of material also depends on such factors:

- climatic conditions;

- rafter system design;

- tasks of using the attic.

The attic floor is insulated with both hard and soft materials. Polyurethane foam is often used. The use of each type of insulation for the attic requires compliance with certain rules, which should be considered in more detail.

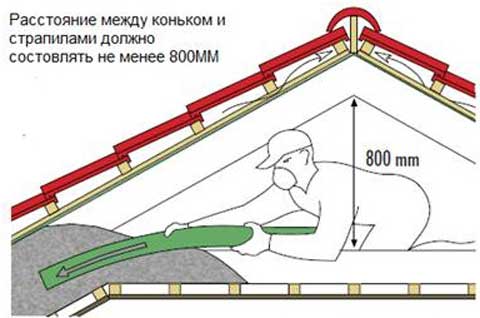

Professional recommendations ↑

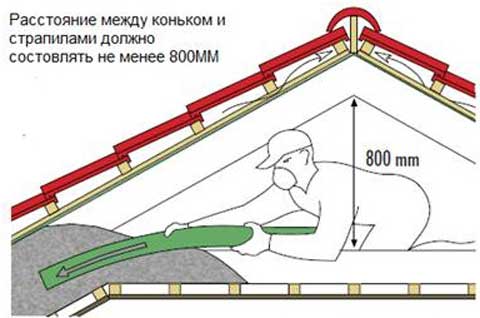

- If the distance between the ridge and the attic ceiling is more than 80 cm, this allows work to be carried out through the attic room.

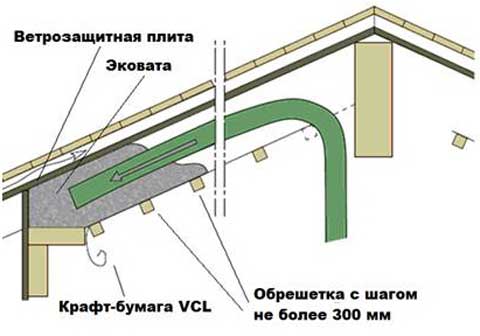

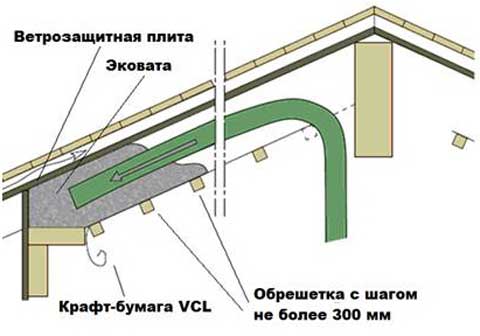

- Insulation can also be applied from the side of the ceiling using the technological holes in the inner lining.

- If the distance between the ridge and the attic ceiling is too small for work, installation is carried out using the technological holes in the inner lining, from the side of the ceiling.

- The exit of the chimney to the roof is carried out taking into account the fact that ecowool will begin to smolder at high temperatures.

© 2020 stylekrov.ru

Insulation options

The most economical option is the option of thermal insulation of the attic with sawdust. When combined with cement mortar, a non-combustible mixture is formed, which does not attract small rodents at all. In addition, sawdust can be used to fill any hard-to-reach places. You can understand how to insulate a living room in the attic in the process of choosing a material for thermal insulation.

This attic insulator is a cheap and lightweight material that can be used on flat surfaces. Polyfoam has a number of disadvantages:

- low vapor permeability creates conditions for the appearance of dampness;

- air can freely penetrate between the insulation plates, which is fraught with drafts;

- one of the most significant drawbacks of the material is that mice like to arrange in it they love their moves and nests.

In addition, the foam produces toxic gases during combustion. For a gable roof, such insulation is optimal - it is easy and inexpensive to install it.

Expanded polystyrene

One of the advantages of expanded polystyrene is that it does not form joints during installation, which excludes the appearance of cold bridges. The material does not attract pests and has good noise and sound insulation properties.

Extruded polystyrene foam is another popular type of expanded polystyrene. Due to its many positive properties, the use of the material allows you to exclude the appearance of moisture. The material provides a sufficiently high degree of thermal insulation of the attic. Extruded polystyrene foam is durable and practical. With the same success, you can insulate a residential attic with penoplex.

Insulation of the attic with penofol allows you to create excellent heat and sound insulation protection of the attic.In addition, it has waterproofing properties. Its big disadvantage is its insufficiently high strength.

Polyurethane foam

It is sprayed onto the selected surface of the attic from a balloon. The advantages of polyurethane foam:

- high speed of surface treatment;

- excellent thermal insulation properties;

- not attractive to small rodents.

Other advantages include low cost of the product, resistance to high temperatures and acids. Also, spraying with polyurethane foam allows you to achieve good tightness.

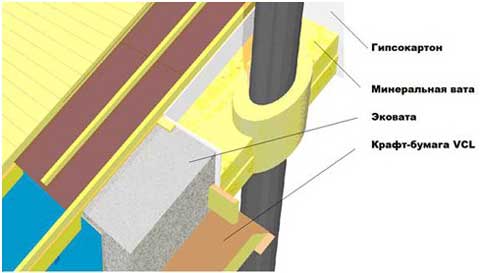

Mineral wool

If you list all the parameters of high-quality thermal insulation for the attic, this will turn out to be a list of the advantages of mineral wool. The material retains heat well, does not burn, provides a sufficient degree of noise insulation, is easy to install and is able to easily fill voids of various sizes.

It is made from processed cellulose. The material is shipped to the point of sale. Ecowool is applied to the surface of the attic using a special device. The advantages include seamlessness, ease of installation, high environmental friendliness, provision of steam and heat insulation. In addition, ecowool is not afraid of pests and does not burn. When working with the material, you need to have certain construction skills.

Necessary calculations

When figuring out how to properly insulate the attic from the inside, and what material to choose for this, you should pay attention to such an indicator as the coefficient of thermal conductivity. This information will allow you to correctly calculate the quantity and cost of the material. Indicate the coefficient of thermal conductivity in the quality certificate.

Advice! To keep the attic warm, you should pay attention to materials with an indicator of 0.05 W / m * K.

Calculation of the density of the insulator for the attic is also necessary for the correct choice of material. The heat transfer resistance of the walls (R req) is calculated as follows:

R req = (1 / A1) + (L / k) + (1 / A2)

Here A1 is the heat exchange rate of the attic wall from the inside. This indicator is equal to 8.7 W / m 0оС.

A2 shows how the heat exchange of the wall takes place from the outside (23 W / m 0оС).

L is the thickness of the wall material in meters and k is its thermal conductivity coefficient.

Having performed these calculations, you can calculate the thickness of the attic wall, taking into account the insulation used. The indicators that are obtained as a result are compared with certain building codes, and their difference is the thickness of the insulation.

Ecowool characteristics

The material in question is natural and safe. This is evidenced by its composition.

| Name | Content | Properties |

| Recycled waste paper | 80% | The basis of the material and the insulating substance |

| Boric acid | 12% | Antiseptic |

| Sodium tetraborate | 8% | Fire retardant |

Heaters, Ekovata brands

The advantages of such insulation over other similar types:

- complete absence of possible seams;

- the possibility of erecting an even, continuous layer;

- insulation of structures with any geometry, due to the high adhesion of the composition;

- the possibility of using for roof surfaces;

- even in an upright position, the material does not slip or cake. The layer remains the same over the entire height. This is important for sloping attic walls;

- enveloping metal elements prevents their corrosive destruction;

- minimum air permeability;

- low heat transfer coefficient from 0.036 to 0.042 W / mK. This is achieved due to the woody origin of the material and its capillary structure;

- moisture drainage. The material has the ability to absorb water from the air and penetrating moisture. But he just as quickly gives it back, drying out. The main thing is to provide a ventilation system for the insulation layer;

- good soundproofing qualities. A 15 mm layer is capable of absorbing 9 dB of sound.While a 50 mm layer of ecological wool will provide 63 dB of sound insulation, 100 mm of mineral wool will give only 37 dB;

- category G2 for flammability. The substance smolders and does not ignite. In this case, there is no release of substances harmful to humans;

- ecowool is resistant to microorganisms. The material is not subject to decay and is not a hotbed of fungus or mold;

- The approximate service life is about 50-80 years.

But, like any material, ecowool has several disadvantages. These include:

- reduction in layer thickness with wet application. As a result, a decrease in heat-saving properties;

- dry installation produces a lot of dust. Work should be carried out in a respirator;

- with the wet method of injection, in the case of insulation of the attic with ecowool with your own hands, voids may appear in the layer. You need to pay attention to the density indicator. For each type of work: for walls about 68 kg / m³, for ceilings about 38 kg / m³.

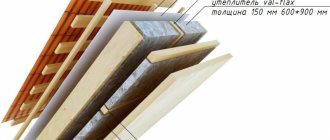

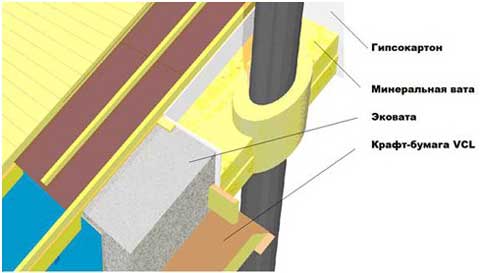

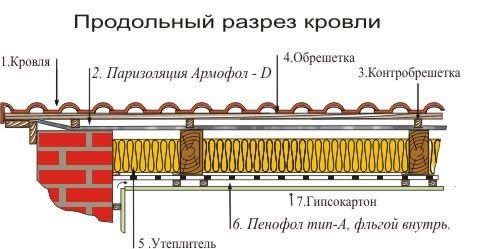

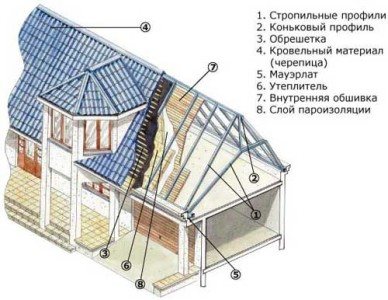

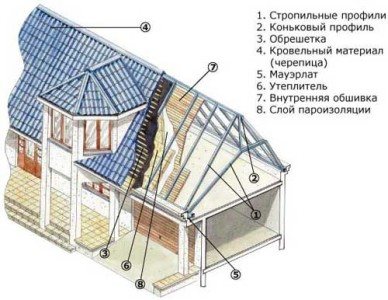

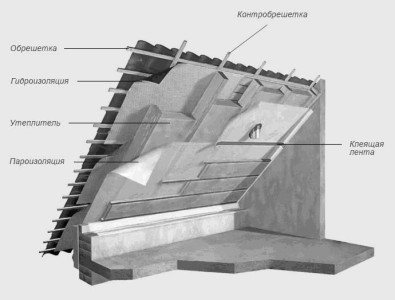

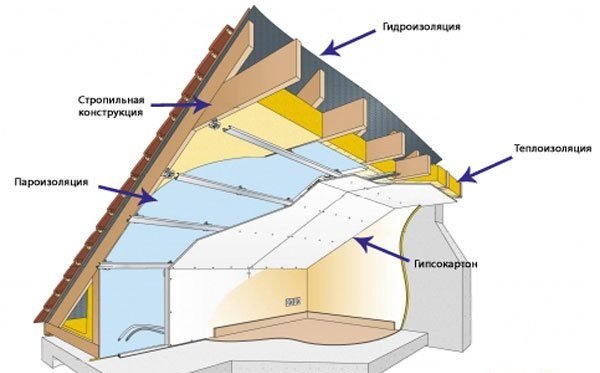

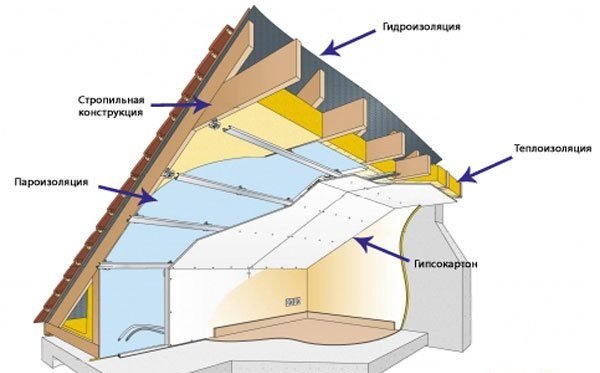

What does the insulation layer consist of?

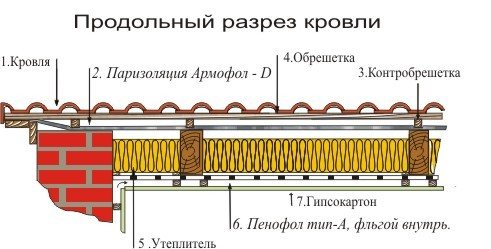

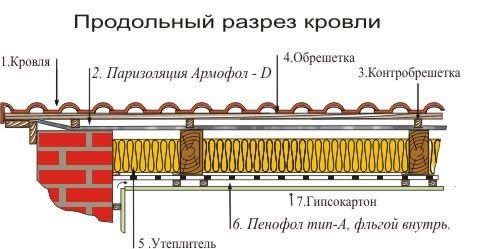

When insulating the attic floor, you can significantly save on heating. Subject to the correct sequence for the construction of a thermopie, all work on equipping a warm attic can be done by hand. The layers of warm roofing cake include:

- roofing material;

- counter-lattice (nailed from the outside to the racks of future walls);

- a layer of waterproofing material;

- ventilation gap;

- thermal insulation layer;

- vapor barrier membrane;

- lathing;

- interior finishing materials.

Insulation of the gables, floor and ceiling of the attic is performed as the main insulation. When icicles form on the roof in winter, one can argue about improperly performed thermal insulation. The snow on the roof begins to melt from the warm air rising from below, which causes the formation of icicles.

Ecowool as the most effective insulation

Ecowool is a cellulose heat and sound insulation material that is widely used in both individual and industrial construction. Ecowool usually consists of 80% crushed newsprint, 12% borax and 8% antiseptic (boric acid is used as the latter).

The appearance of ecowool is unremarkable

All ecowool components are absolutely harmless to humans (The conventional wisdom that newsprint contains typographic lead is incorrect, since newspapers have been printed exclusively in offset printing for many years).

By the way, at the International Competition for Environmentally Safe Products, ecowool was entered in the register of natural products and was awarded a corresponding medal.

Why is it recommended to use ecowool for insulating the attic?

Here, one should take into account following its advantages

:

- ecowool ensures the seamlessness of the coating, which is of particular importance for insulation in the places where the wall passes to the roof of the house;

- ecowool has excellent soundproofing properties (romantics who like to enjoy the sound of raindrops on the roof, please do not read this);

- ecowool protects the room well from overheating in the summer;

- ecowool does not require a vapor barrier, which is especially important for the attic floor, because the walls and ceiling of this room are active remove water vapor out. As a result, ecowool most effectively regulates the relative humidity in the attic.

We recommend watching a voluminous and very detailed video about ecowool, comparisons, prices, installation, and of course a full description of the material are waiting for you:

Insulation of vertical walls

To start insulating the vertical walls of the attic floor, it is worth filling up large gaps with jute. The scheme for performing thermal insulation of the attic walls includes:

- Creation of a lathing (outside), on which waterproofing will be laid from the inside.The slats are nailed from the outside of the wall posts.

- Implementation of a waterproofing layer from the inside of the attic. A vapor barrier membrane is more suitable for this purpose. It will let steam out, but prevent moisture from penetrating into the insulation.

- Next, a layer of insulation is laid.

- Vapor barrier is performed. It is a reliable protection against steam penetration into the insulation.

- Creation of a layer of finishing material.

Walls should be insulated only after thorough processing. Anti-fungal and fire-fighting compounds are applied to the wooden elements of the rafter system. Along the perimeter of the windows, it is necessary to build a special structure, which will serve as a place for joining the heat-insulating cake and dormer windows.

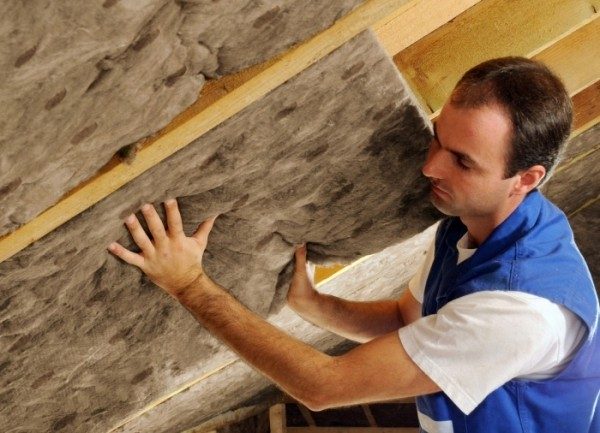

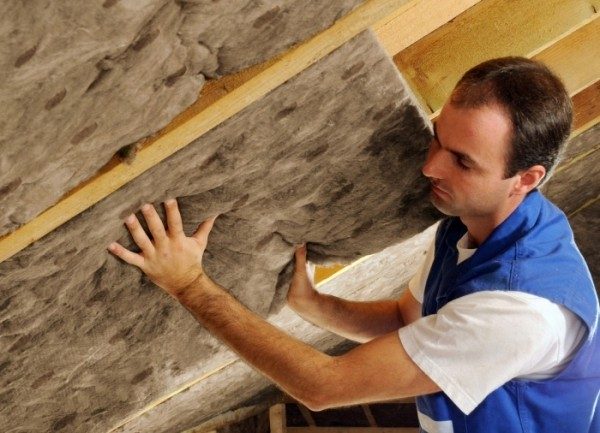

Waterproofing must be overlapped by 150-200 mm. It is better to fix the insulation between the beams close to them (as in the photo). This will eliminate the formation of cold bridges and unnecessary heat loss. When choosing mineral wool, it should be laid with a small margin on each side. It should adhere well between the beams.

When insulating an attic in a cold climatic zone, after performing a vapor barrier, another layer of insulated material is laid. A vapor barrier is again mounted on top.

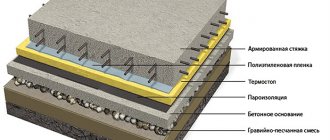

Floor insulation

First, the entire surface of the future floor must be cleaned of any debris. Irregularities and cracks should be repaired with a cement-sand mixture. The next step is waterproofing. If it is a concrete slab, it is coated with bitumen mastic. When waterproofing a wooden floor, roll waterproofing is laid.

Next, a heater is mounted. It is placed in a continuous layer or between the floor beams. Vapor barriers are placed on the insulation. Then perform a reinforcing screed. Then you can start finishing. In the case of a wooden floor, instead of a screed, it is worth finishing with an edged board.

Advice! Before starting work on the insulation of a wooden floor, the surface is treated with refractory and antiseptic solutions.

If necessary, the attic ceiling is also hemmed with a layer of insulation. The work is identical to the wall insulation procedure. A crate is made outside, then a layer of waterproofing is created (from the inside), insulation and vapor barrier are laid. Next, a fine finish is carried out.

To make insulation of the attic from the inside with your own hands, you will need to carry out simple calculations. It is also necessary to choose materials for waterproofing, insulation and vapor barrier. It is also worth reading the instructions on how to properly insulate the attic.

Preparatory work

Ecowool properties.

Before proceeding with the insulation of the attic space with ecowool, the roof should be waterproofed. Next, you need to analyze the state of the rafter system: if its bearing capacity does not meet regulatory requirements, reinforcement work will have to be done by installing additional rafters and steel elements.

The space must have a good ventilation system, for this you can install air ducts. If there is a floor covering in the attic, it will have to be temporarily disposed of, this will provide space for blowing the material.

Before the process of warming, the room must be well dedusted. In those areas where the electrical cable runs or the components of electrical appliances are located, protective screens should be installed, this will provide access to them after applying the insulation material.

Back to the table of contents

Roof insulation with foam foam - convenient, effective, affordable

Insulation of the roof with penofol. If you are looking for a high-quality and inexpensive insulation for arranging a roof, attic, attic or ceiling, then our company will be happy to offer you Foil Penofol - a new universal thermal insulation product that has a lot of obvious advantages.

By purchasing Penofol for the roof, you will simultaneously solve several issues at once, because it is not only an insulating material, but also a product that is widely used in waterproofing, soundproofing and vapor barrier modern structures.

Thus, by correctly installing reflective foil and polyethylene foam, you get the opportunity to create a high-quality and energy-efficient attic and at the same time receive significant savings in time, effort and money.

The main modern heaters are in many ways inferior in terms of characteristics to Penofol, therefore in the assortment of our store there are different types of material based on foamed polyethylene, but for roofing work, there is no alternative to Penofol A-05, and type C can be used for finishing the ceiling surface inside the premises. ...

Insulation of the roof with Penofol will allow you to achieve excellent results with minimal time and financial costs. When building a summer house, cottage, laying in the roof and on wooden floors will provide you with a comfortable temperature inside the room at any time of the year. Penofol insulation is carried out in attics, installed in attics, verandas, gazebos, summer kitchens, etc., and also Penofol is installed on the ceiling, thereby ensuring reliable thermal insulation of the house or garage structure.

- Do you know how to fix Penofol?

- How to glue Penofol to Penoplex?

- Is Penofol harmful to health?

- How to fix Penofol to the ceiling?

- Which side to stack?

- Penofol or Tepofol which is better?

Experts of our production will be happy to advise you on any questions, tell you about roof insulation with foam foam, installation and technical characteristics of our products. Reflective insulation is suitable for construction work in any residential, commercial or industrial setting. Heat, hydro, noise and vapor insulation for the roof using reflective insulation along GOST, today is in great consumer demand, since this unique insulating material is characterized by such important consumer qualities as:

- strength - resistant to light mechanical stress;

- reliability - firmly attached to the false ceiling in flat roofs;

- practicality - performs several functions at a low cost;

- multifunctionality - has the effect of insulation and vapor barrier;

- versatility - it is used in any truss structures and roofs;

- resistance to temperature extremes, ultraviolet light and other negative factors

- ease of installation - it is enough to nail Penofol with a stapler and glue it with tape;

- Penofol insulation is very economical and does not require large installation costs;

- durability - Penofol service life is up to 50 years;

- environmental friendliness - absolutely environmentally friendly material.

Insulation of a private building, a country house, or any other types of premises using Penofol does not require special training, complex tools or additional installation elements and specific tools. The main thing is to provide a ventilated gap on the side of the foil of at least one centimeter and glue the joints with aluminum tape LAMS.

Penofol - what is it?

What is Penofol or Tepofol better? Often unscrupulous manufacturers of analogs think that it is enough to take foamed polyethylene and foil it. Such as Penoflex, Neofol, Megafol, Magnoflex, etc. Far from it! The production technology is unique and complex. Beware of counterfeits! Our products are manufactured in accordance with GOST, have a fire certificate, which indicates the flammability factor "G1". The goods are made only of the highest quality and have no analogues. Minimum costs, maximum effect - this is how the work of the original Penofol can be described - a heater of a new formation. You can buy wholesale and retail without intermediaries on favorable terms at.

Penofol types

There are three main types of penofol. Made with the use of foil - foil, and without its use - non-foil. Perforated.

Non-foiled is less popular due to the fact that the foamed base without foil has much less thermal insulation compared to the foil counterpart. Used for domestic purposes as rugs in sheds, baths, etc. It is an obsolete building material.

Foiled penofol is divided into several classes:

- class A. The base layer is covered with foil on one side only. Most often used in the process of complex thermal insulation.

- class B. The base layer is covered with foil on both sides. it is used as insulation of pipeline mains, saunas, thermal insulation of industrial equipment.

- class C. The base layer is covered with foil on one side, and with an adhesive layer on the other. During the installation of class C penofol, the use of additional crimping tools is not required.

- class R. Similar to class A, but the foil coating has a relief shape. It can be used in the process of creating thermal insulation consisting of several layers.

- ALP class. The base layer is covered with foil on one side and laminated with polyethylene film on the other. It is used in the manufacture of greenhouses and incubators.

- NET class. Has the properties of class B, but more elastic.

- SuperNet class. Particularly resistant to aggressive external meteorological conditions.

Perforated penofol is a novelty among building materials. Has a lot of breathable pores. Popular for working with wood surfaces.

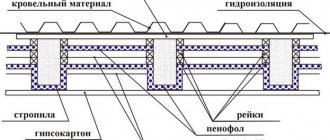

Insulation of the attic with penofol

Summer resident

Joined: 7/17/2006 Posts: 1465 From: Moscow

Summer cottage in Sands (across Novoryazanka)

In this article, I tried to popularly explain the basic principles of the attic insulation device. The easiest way is to initially make the correct insulation. But any restructuring must be approached individually. If your case is not similar to the standard one, then I am waiting for questions, preferably with photographs.

Insulation.

General requirements for insulation used for attics: 1. Insulation should be of low density from 30 to 70 kg / m3. A denser one will make the vapor more difficult to escape. 2. Insulation must be hydrophobic. After getting wet, it must dry out and restore all its properties. 3. The insulation must be resilient enough to fit snugly between the rafters. Foaming of cracks is unacceptable. 4. It is possible to combine insulation, but it is imperative that the more dense should be lower than the less dense. 5. Dense insulation such as penofol can be used to insulate attics, but it should not be laid between the rafters, but with a solid plane above or below the rafters. The presence of grooves in the plates of such insulation is mandatory. Any gap between the plates is a cold bridge and a free passage for steam.

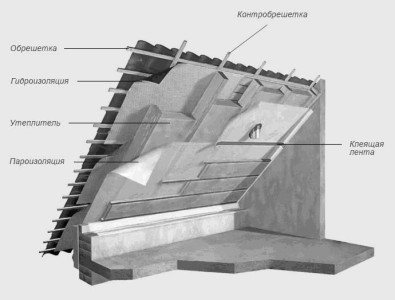

Around the insulation.

The insulation separates the two zones. He, in fact, is needed in order to isolate the space comfortable for a person from the external environment. These two zones have different temperatures (the difference can exceed 50 degrees), different humidity and different pressures. The thickness of the insulation is usually 15 - 20 cm. In order to preserve the properties of the insulation for many years, several rules must be observed when installing it. 1. The humidity in the room is always high. If water vapor penetrates into the insulation and begins to move in it, tending to the outside, then sooner or later the temperature of the steam will reach the lower critical point at which condensate forms. That is, water droplets will appear in the thickness of the insulation. And a wet insulation is no longer a heater. In order to block the way for the steam, from the side of the room, a vapor barrier film is laid close to the insulation. The lower the vapor transmission capacity of this film, the better. There should be no defects, gaps or cracks in this film.The seams of the film, the joints with the wall, with pipes extending to the roof, are carefully glued with tape. If you damage this film during the filing of the ceiling or carelessly seal the passage through the film of a pipe, then your insulation will have a hard time. 2. That small amount of moisture that still gets into the insulation should leave it as soon as possible. In insulators of low density, this moisture quickly reaches the outside. And on the outside, it should not meet obstacles. Ideally, it would be to leave the insulation on top open and ventilated. But you still have to close it. From the side of the roof, the insulation can get wet from small leaks, from condensation that drips from the metal roofing. Therefore, from above, the insulation is also protected with a film. But the upper film must contain water droplets and at the same time release vapors from the insulation. She must have high vapor permeability. Such films are called diffusion films.

If the roof is already covered: insulation of the attic from the inside according to all the rules

Reading time: 7 minutes No time?

We will send the material to you by e-mail

Whether you are building a new structure or remodeling the roof for additional rooms, you need to take care of how to make high-quality insulation of the attic. If the roof is already covered, all work from the inside is carried out taking into account the geometry of the roof and the climatic characteristics of the region. In this material, we have collected all the necessary information about possible methods of insulation and will provide you with practical recommendations from professionals.

A well-insulated attic can serve as a bedroom or even a children's room.

Thermal insulation of the attic with ecowool

Home for every person is his family nest, filled with comfort and warmth. Own houses, cottages very often have an attic - a room in the attic. You can use it in different situations, for example, make it habitable or for storing any unnecessary things. In any situation, it is very important to carry out insulation of the attic with ecowool... This method of keeping heat in the house has long been popular and in demand.

Useful information and video on how to insulate an attic for winter living

A lot depends on the quality insulation of the attic roof. If you plan to use this room during the winter, you need to think carefully about what materials to use for thermal insulation. Another important aspect is the construction of the roof.

If the geometry of the roof is very complex, you may have to sacrifice part of the area to keep warm.

The peculiarity of the under-roof space is not only in geometry, in winter it is colder here than in other rooms, and in summer it is hotter. To maintain the optimum temperature, roofers recommend forming a multi-layer "cake" of waterproofing, vapor barrier and insulation under the roofing.

High-quality thermal insulation will prevent heating of the roofing material and the formation of ice

And now a small video to get a general idea of the attic insulation:

A little about the choice of tools

If you ask an experienced roofer what tools are needed to insulate the attic roof of a private house, he will shrug his shoulders and say: hammer, knife, head and hands. For the most part, this is true, but there are professional secrets that not everyone wants to share.

The most important trick is choosing a knife. If you take a simple construction and assembly knife, then throughout the entire process you will suffer, unevenly shredding the insulation. The blade of such a tool is too short, it does not cut through the thick layer of insulating material. In addition, the assembly knife will quickly become blunt on mineral wool or foam.

You can get by with an improvised cutting tool (a hacksaw for wood) or use a wide kitchen knife for cutting bread with a toothed sharpening for work.

Professional cutting tool - wide long carbon steel knife. Blade length - 35 centimeters, durable plastic handle is very comfortable to work

In addition to a good knife, you really need a hammer, and also screws and a screwdriver, a strong cord, protective clothing, a respirator and goggles.

Tips for cutting insulation:

- the room in which you will cut the mineral wool should be well ventilated;

- hands, head and especially eyes and respiratory tract must be protected from the penetration of volatile fibers;

- after working with insulation, you need to take a shower, wash your hands and face thoroughly;

- the material must be cut across the fiber - this way there will be less flying dust;

- in order not to be mistaken in the size of the pieces, you should carefully measure their locations.

It is better not to unwind the rolled insulation, but to cut it right in the roll

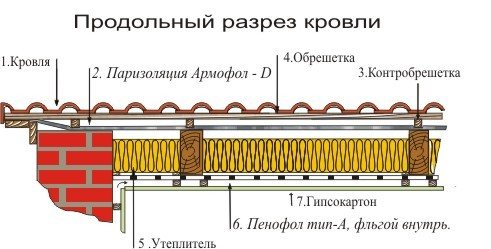

How to insulate a house with penofol

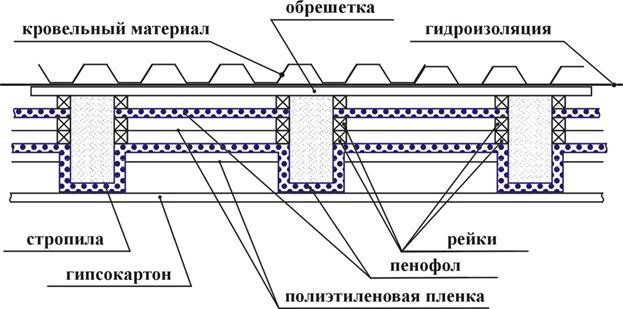

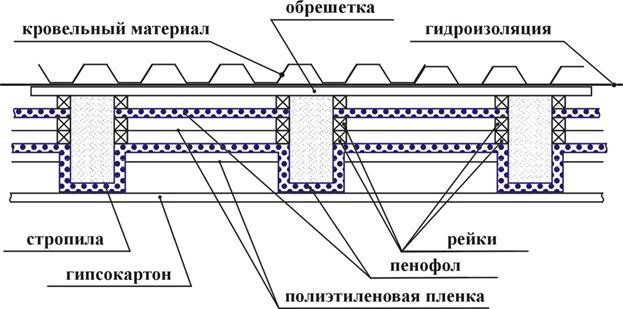

Penofol is a union of foil with foamed polyethylene. Sold in rolls. Roll length can be 5, 10, 30, 50 m. Roll width is 580, 600, 1000, 1100, 1200 mm. This allows for virtually waste-free work.

Thermal insulation scheme for a simple unexploited roof.

This material is suitable for insulation of walls, roofs, attic, floor and ceiling from inside the room.

All insulated works are carried out according to the same principle:

- The required strip length is measured and cut.

- With the help of a construction stapler, it is fixed to the insulated surface in such a way that the foil layer looks inside the room, attic.

- The strips are joined edge to edge, without overlap.

- For additional insulation, the joint is closed with self-adhesive aluminum tape.

- On top of the insulation layer, the slats should be fixed for ventilation and the creation of an air heat-insulating layer. And already on the slats, finishing materials are mounted.

Roof longitudinal section diagram.

This method is suitable for insulating a house or attic from the inside. If you plan to carry out insulation work outside, then you need to purchase a profile penofol. In this case, it is mounted with foil outward, and is closed from above with finishing materials.

The advantages of penofol include its complete environmental friendliness. Insulation of the attic or house, created with the use of penofol, is durable and does not require repair work. Absolutely does not absorb water. If you use fiberglass for insulation, penofol prevents it from penetrating into the room. Protects the house and the attic from freezing and dampness.

Ecowool insulation technology: three ways of applying insulation ↑

The process and result of thermal insulation is interesting. This is not the familiar laying of any roll materials, mats or slabs, but the blowing of ecowool using special blowing installations. This technology, on the one hand, makes it possible to speed up the process of performing insulation, and on the other hand, it makes it possible to isolate hard-to-reach places.

Moreover, the material can be blown into the finished frames of attics, attics, and even over an existing insulation layer.

Dry method ↑

Dry application is carried out in two versions.

Manual option

It is often used when insulating attics. The essence of the thermal insulation process is as follows:

- ecowool, laid out in a large bowl, is loosened with a construction drill;

- laid out on a surface to be insulated and carefully tamped.

When insulating floors, it is necessary to achieve a packing density of about 30 kg / m3, and walls - 50 kg / m3.

It will be difficult to provide the required degree of density or licentiousness by this method, and it is these parameters that determine the quality of thermal insulation.

Using blow molding equipment

This is perhaps the ideal version of the attic insulation device. It is effective when working with structures of a complex nature: under-roof spaces, inclined planes, etc. By the way, this method is also more popular, as it combines the speed and quality of insulation.

From the packaging, the ecowool is poured into the bunker of the installation and fed onto the insulated surface, covering it with a layer. Depending on the slope of the roof, a stacking density of 60-70 kg / m3 can be achieved.

Wet (wet): soundproofing solution ↑

This is an open way to perform insulation, and on any surface. Here the decisive role is played by a natural binder - lignite, which is part of the ecowool, which has good adhesion to various types of substrates. Wet application involves the use of a special set of equipment for high-quality wet application of the material. Before application, the material is sealed with a binder - either ordinary water or a glue + water solution. This option completely solves the problems associated with poor sound insulation. The paving density when using this technology is 60 kg / m3.

Joint-combined ↑

The process of performing thermal insulation in this way is divided into two stages:

- the first layer: using a wet-glue ("wet") method, a layer of ecowool is applied with a thickness necessary to achieve maximum sound insulation, that is, all cavities and holes are, as it were, "sealed";

- second coat: the remaining unfilled volume required for blowing is filled using the dry method of application.

Roof insulation

In order to insulate the roof with foam foam from the inside, it is necessary to take into account the heat and moisture protection properties of the roof. The roof protects the dwelling from the penetration of atmospheric moisture; moreover, the formation of condensation is unacceptable. And if moisture does occur, then it is necessary to provide excellent ventilation of the attic space so that water does not lead to irreversible consequences.

Mansard roof insulation scheme.

Condensation occurs due to the temperature difference between the room and the outside. Warm air, rising upward, reaches the surface of various roofing elements, the temperature of which is lower. As a result, warm, moisture-laden air settles as condensation. Because of this, the rafters and the insulating roofing material become unusable.

It is recommended that when installing the roof, create two ventilation layers. The first is located between the roof cladding materials and the thermal insulation layer. Here ventilation takes place due to technological holes in the facing material. The second ventilated layer is created between the waterproofing and thermal insulation materials.

Previously, foam rubber or mineral wool was used to create roof insulation. At the same time, the layer thickness was over 20 cm. Penofol 4 mm thick, laid out in two layers (below and above the thermal insulation), makes it possible to reduce the layer thickness to 8 mm. At the same time, it combines both heat and moisture insulation of the roof.

How to insulate an attic?

Experts advise using mineral wool based on basalt, glass particles or slag. What are their differences? Basalt wool is obtained by melting a certain rock, which is then mixed with clay, limestone compounds, dolomites. The adhesive is usually replaced by formaldehyde. The resinous structure of the reactive substance binds the ingredients, resulting in a finished product.

Slag analogs are obtained in the same way. Industrial waste from the production of cast iron, zinc, copper alloy is placed in the smelting tank. The high degree of toxicity does not allow the use of slag wool in the processing of buildings for residential use. Glass wool is a product of processing limestone, sand, borax, soda. Mineral wool is a natural fiber insulation material.

How to create a warm attic

Attic spaces are increasingly being used for the arrangement of residential premises. This is economically justified. A slight increase in the cost of construction work leads to a tangible increase in the area of residential premises.

But, if you want to use the attic all year round, it must be insulated. You can insulate the attic from the inside with penofol with your own hands. Even if you did not have experience of such work, do not despair, it is not difficult to do it!

Attic roof insulation scheme from the inside.

- We create a ventilated space between the insulation and the lower elements of the roof. A ventilated space will help prevent condensation from forming inside the attic and also keep the indoor temperature. Since warm air, according to the laws of physics, rises upward, no matter how you insulate the walls and floor, the heat from the attic will leave you with an improperly insulated roof. Additionally, warm air has high humidity, which will be released from the air and settle in the form of condensation on cold roofing elements. In addition, roof insulation will help save heating costs. In order not to be mistaken in the correctness of the thermal insulation layer, you must use the regulations (SNiPs) of your region.

- The main facing materials are waterproofing materials, practically not allowing vapors and moisture to pass through themselves. Because of this, accumulated condensation will lead to the formation of mold and mildew inside the attic. In order for the thermal insulation material not to be negatively affected by high humidity, it must be additionally protected. For this, vapor-proof materials are used, with a mandatory ventilated layer between them. All properties for high-quality vapor permeability and thermal insulation are penofol in combination with the use of mineral wool. Penofol is laid below the mineral wool, leaving a gap of at least 2 mm.

- Due to the use of the latest materials, the layer used for roof insulation has been reduced by almost a third, while retaining all its functions.

All stages of work will allow you to equip a warm attic without the formation of moisture. And if this happens, then due to the ventilated layer, it will quickly disappear.

Design features of thermal protection

Since the roof covering of the building is a layer of waterproofing, it can poorly pass vapors and moisture through itself, which will contribute to the formation of condensation on the inside of the roof.

Such formations can cause negative consequences:

- the lower part of the roof will be covered with wet spots and formed mold, although the roof waterproofing can be done correctly with this;

- the quality of the insulation due to moisture may deteriorate;

- a large amount of condensation formed can lead to the fact that water will simply drip from the ceiling of the room.

Roof design features. Click to enlarge.

Since moisture can negatively affect the insulation material and worsen its properties, such a heater should be protected from possible moisture ingress on it.

For such purposes, a vapor-proof material is used, which is located on the inside of the insulation. Also, do not forget to make a ventilation layer between the insulation and the roof so that moist air can escape through it.

Very often, the attic is made from an ordinary attic space. This is done in order to preserve the roof truss system. Also, in order to lighten the load on the load-bearing parts of the structure, lighter types of insulation with low density are used.

Very often, such heaters, with poor-quality material and carried out insulation work, are blown through by air currents from drafts, and, accordingly, the heat from the room will leave along with the draft.

In order to preserve the thermal characteristics of such a heater, an additional vapor-proof and windproof material should be used.

If you want to insulate the attic, then do not forget that heat loss is possible not only through the roof, but also through the end walls. Therefore, the pediment should also be very well insulated. Any attic has a rafter system, which should be filled with insulation very carefully and without gaps.

Today it is possible to insulate the attic from the inside with polystyrene foam, mineral wool, foam foam, free-flowing mixtures, etc.

It all depends on the requirements for a particular type of insulation and the financial capabilities of the buyer.

The easiest way to use slabs of mineral wool, which are produced on the basis of basalt fiber and fiberglass.