The principle of operation of the thermostat

It regulates the supply of electricity, which is converted in the heating elements into heat, heating. When the floor cools down or heats up to the temperature set for it, the device itself turns on or off the system. It works constantly, even when the floor is in an inactive phase, giving off the accumulated heat. This ensures that warm floors are safe from overheating and possible fire, although this is quite rare. This whole process is served by a temperature sensor that responds to the slightest temperature fluctuations.

Simple electronic and mechanical thermostats have proven themselves over time, they are more popular and stable in operation. Programmable ones are considered more complex and "capricious". But the connection of all types is almost the same, despite the filling.

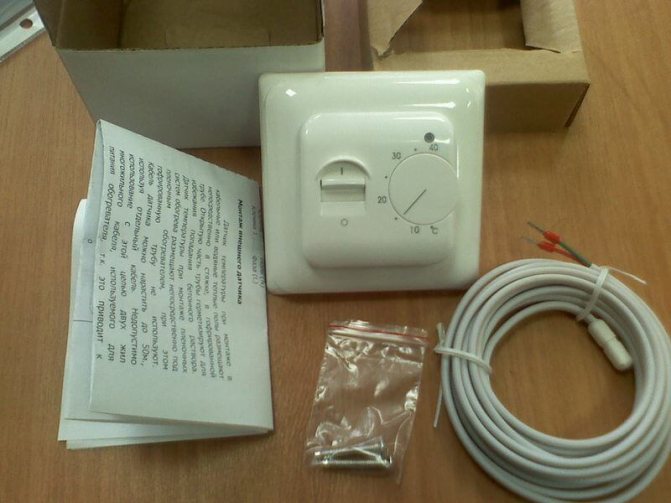

When purchasing a kit, make sure that all accessories are in place: temperature sensor, terminals, mounting box and installation instructions.

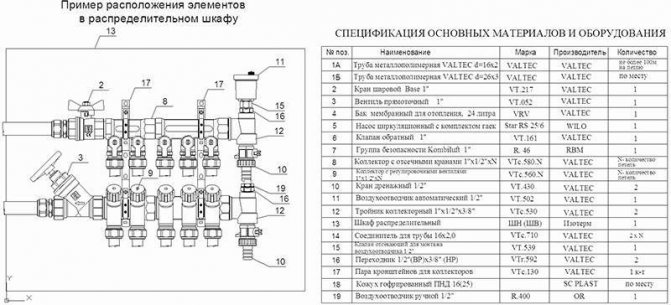

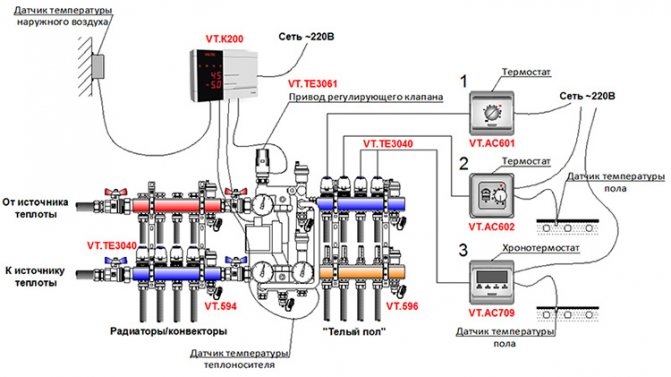

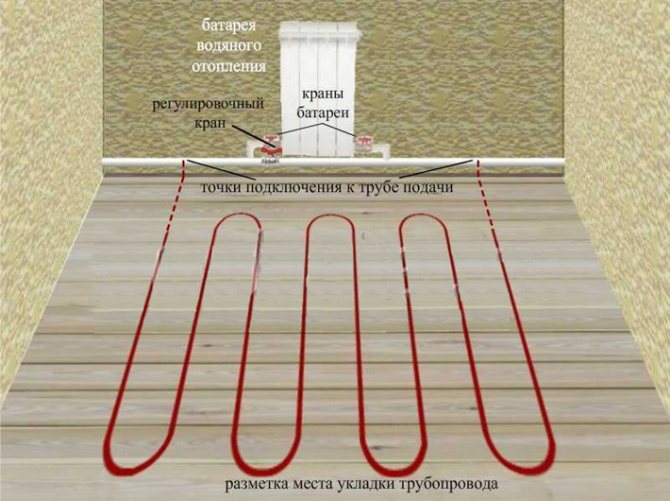

Connecting the system to the coolant supply and installing a collector

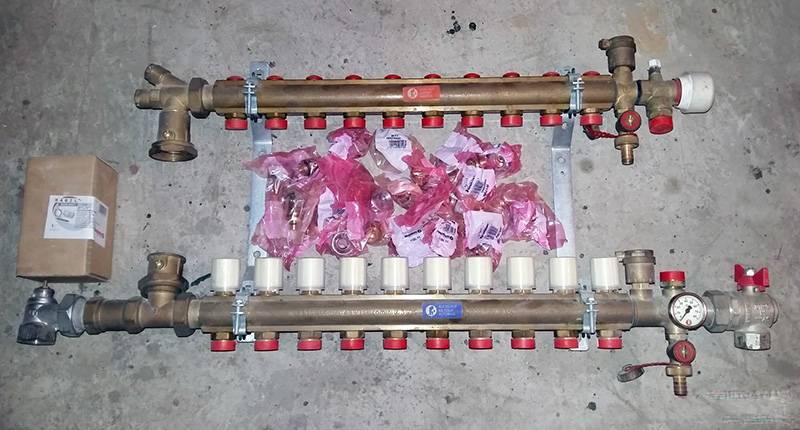

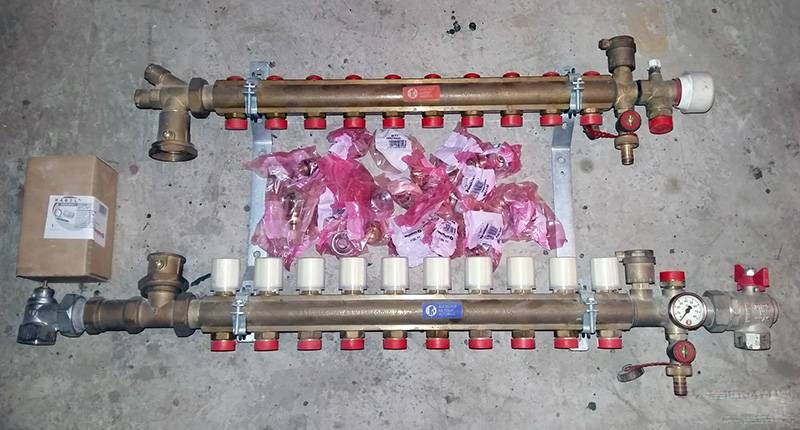

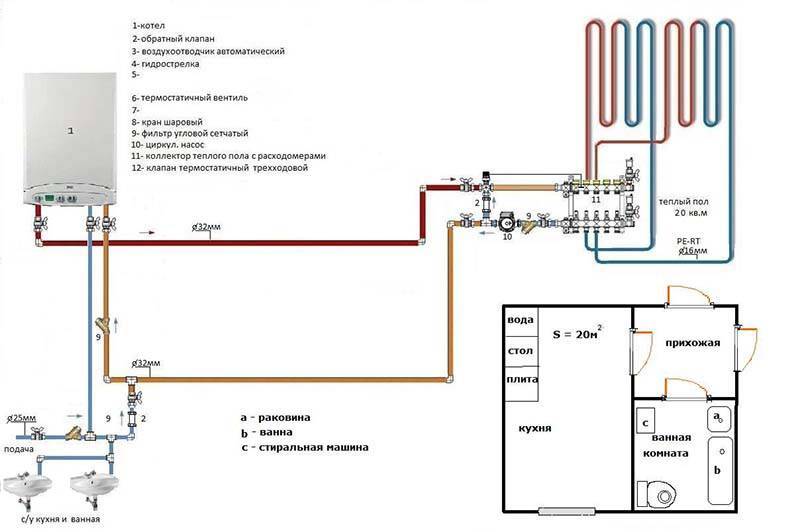

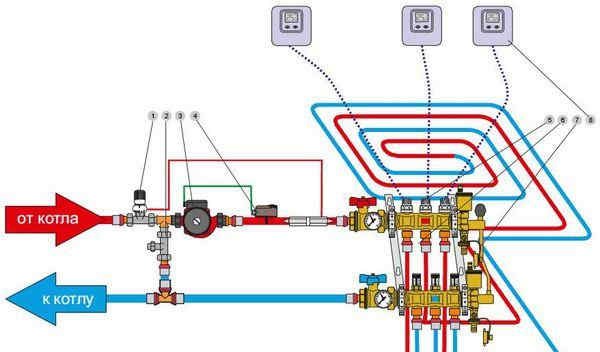

Manifold connection system

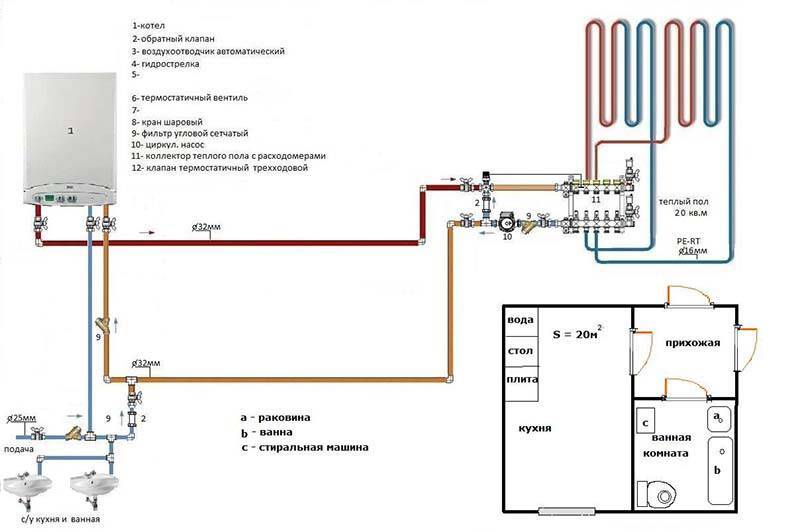

The collector connection scheme boils down to the fact that the boiler and the collector must be connected with a pipe line. If the boiler is installed near the gas pipe (in cases where the boiler is gas), then the collector can be mounted in any convenient place. It must be accessible for supplying pipes with supply and return, as well as for monitoring and controlling the system.

Before connecting the pipes, stopcocks must be installed on the manifold. To make it easier to control the temperature, a thermometer can be additionally included in the valve design.

So, a unit consisting of a manifold, a pipe and a valve is connected to each other by compression fittings. To connect pipes, special connections are used, which consist of a brass nut, a clamping ring and a support sleeve. If it is necessary to connect pipes of different diameters, then adapter fittings can be used.

Thus, we have the simplest scheme for connecting underfloor heating. This circuit has the following nodes:

- Simple manifold with shut-off valves.

- Supply / return pipeline, connected through taps with a comb.

Complete manifold set

https://www.youtube.com/watch?v=iSG92rSo27c

So, the coolant will be evenly distributed over the heating circuits.

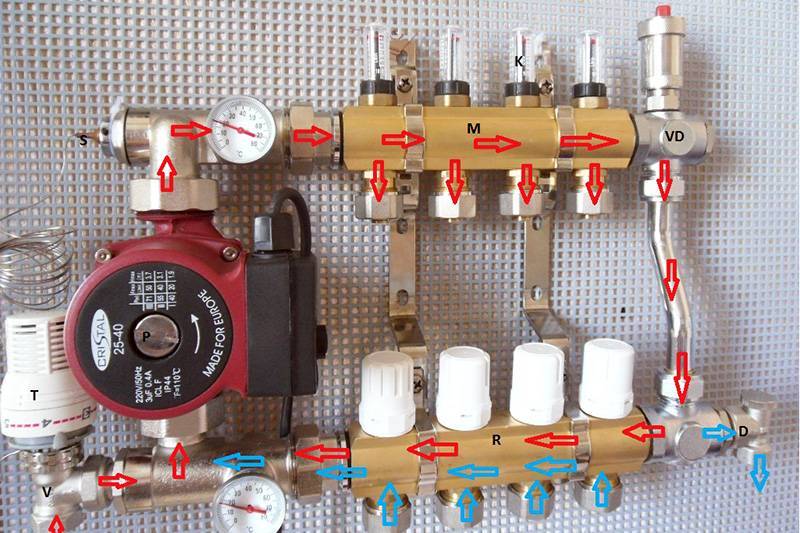

Thermostatic control valve

To organize full control of the warm floor in

will include:

- Pump and mixing unit.

- Drain cock.

- Circulation pump.

- Air vent.

- Shut-off valves and pipes.

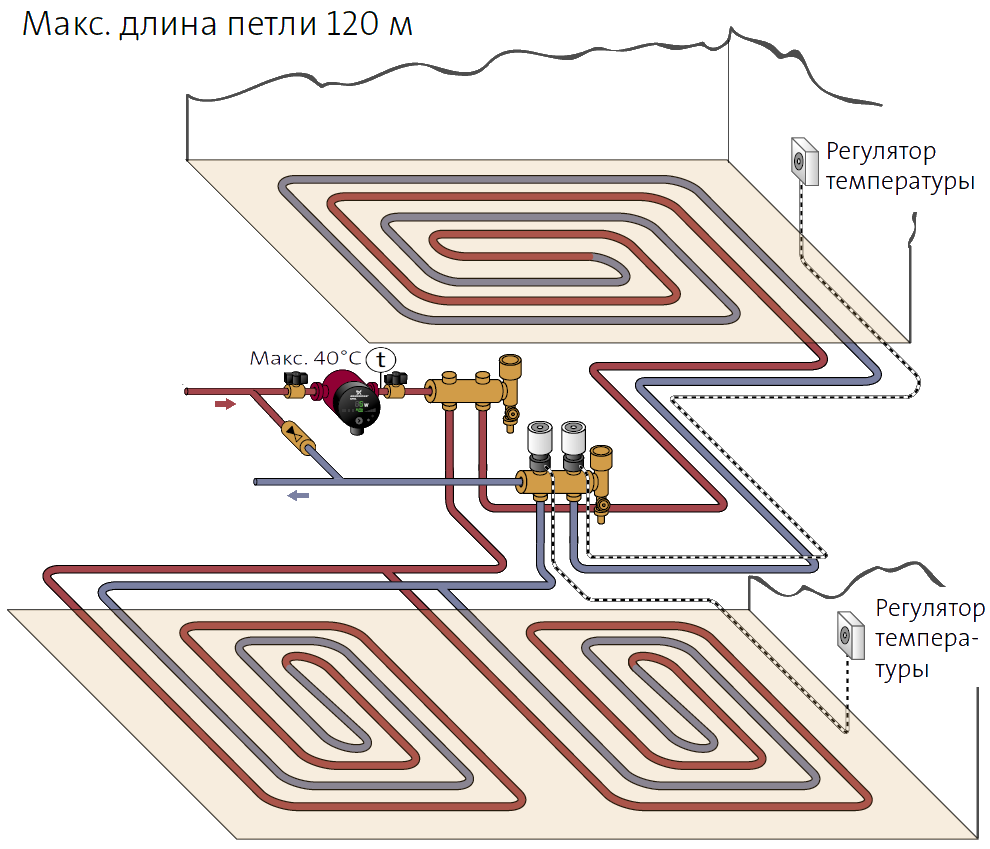

Thermostatic control valves can be installed at the outlet / inlet instead of conventional taps. Through them, you can set the throughput of the crane. This is achieved thanks to the paraffin wax, which expands or contracts under the influence of temperature.

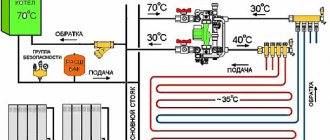

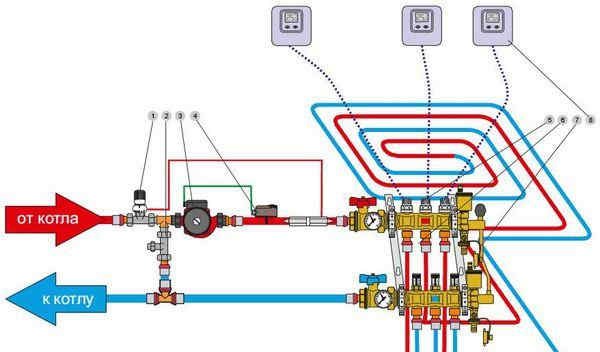

The mixing pump is installed between the supply of pipes and the supply of the collector. There is also a third outlet that goes to the return flow before the return flow in the manifold. If necessary, the pump will pump the cooled heat carrier into the supply to reach the set temperature.

Read more: Do-it-yourself ventilation in an apartment: how to make an effective system

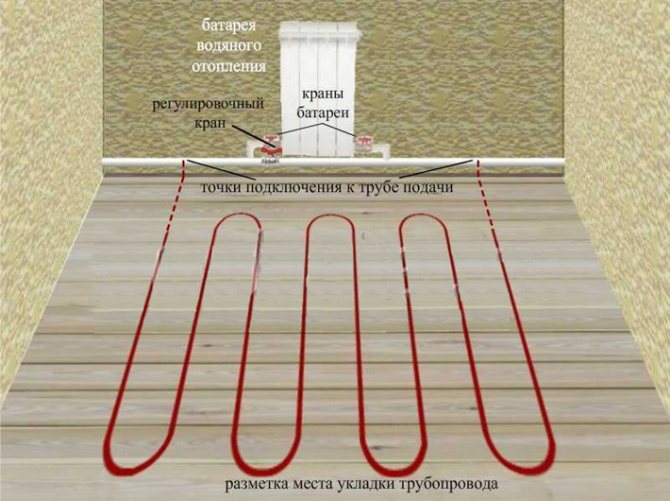

To figure out how to connect a warm floor to the heating system, you need to understand which elements of the system are involved in this. As in classic heating schemes, these elements are:

- heated coolant supply pipe;

- return pipe or return of the cooled coolant.

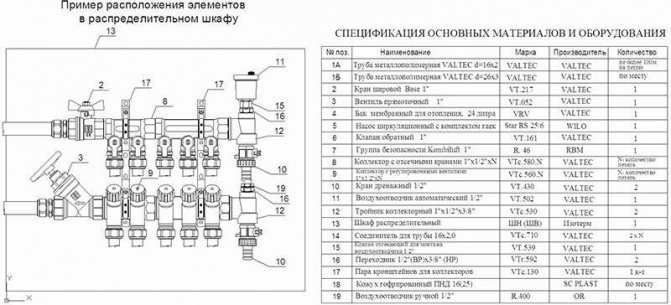

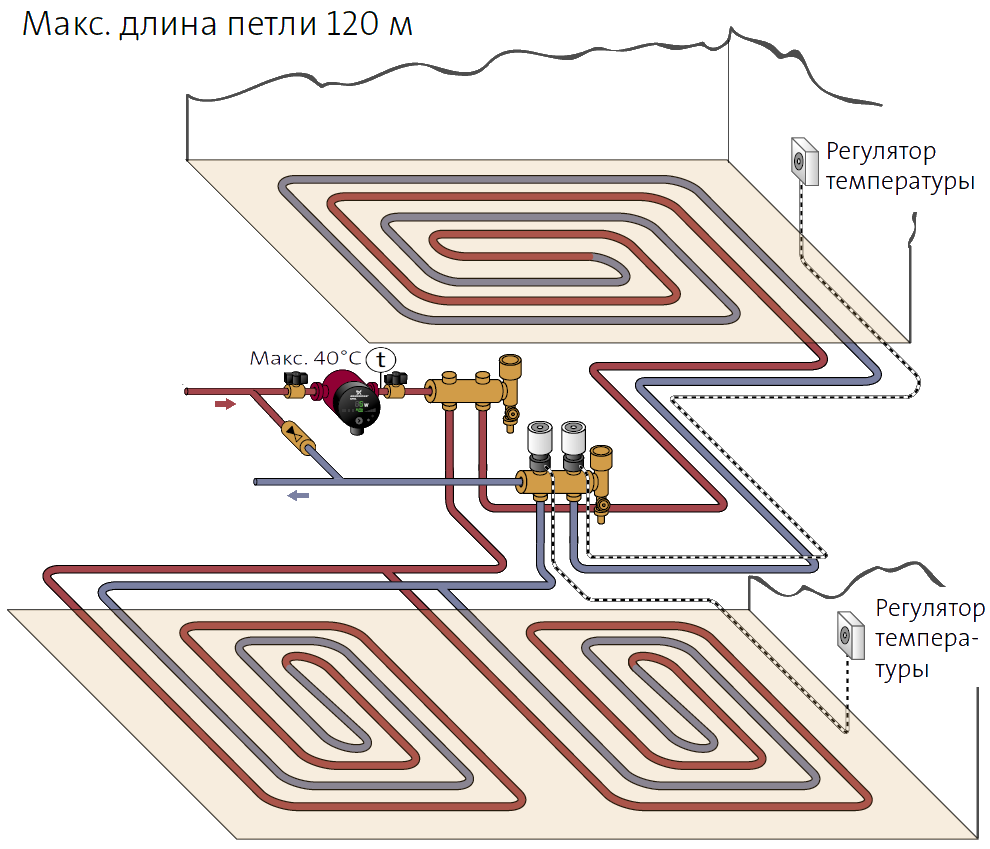

When the system consists of only one circuit, it can be connected directly to the boiler. If there is more than one circuit, to ensure uniform distribution of the coolant, it is necessary to connect the underfloor heating collector to the coolant supply. To it, respectively, the contours of the rest of the system are attached.

First, you need to choose the place of installation of the collector. There are several accommodation options:

- arrangement of the collector cabinet;

- installation in a niche in the wall;

- wall mounting in a suspended position.

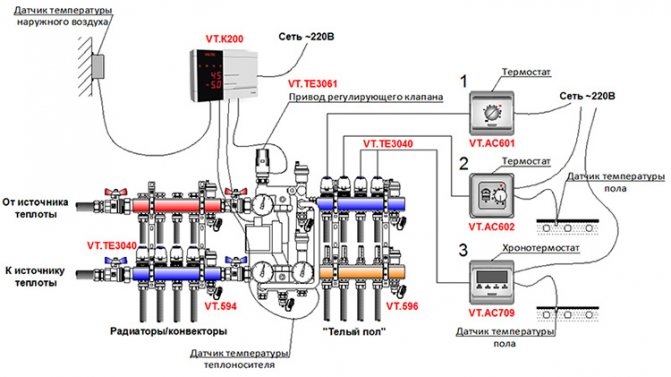

Popular collector models are equipped with automatic thermoregulation. The set will include temperature sensors and various measuring instruments. The process of distributing the coolant occurs automatically. The simplified scheme of the underfloor heating collector provides for a pair of thermometers and manual adjustment.

To begin with, two pipes are connected to the collector - return and supply. After that, "branches" of various pipelines are connected. To control and regulate heating, it is more accurately necessary to connect a circulation pump, a three-way mixer and control valves.

For ease of repair and maintenance, shut-off valves are mounted in the pipe connection zone, and a drain valve is provided at the end of the collector. Such a system operates on a boiler, and the temperature will depend on the temperature of the heating agent supply.

The collector, or more correctly, the collector cabinet, is the main element of the system, and is located in the wall. The best place is closer to the middle of the room. The classic size of the device is 60x40x12 cm. The wall niche in which it is placed should be placed near the floor surface.

The collector is responsible for the movement of the coolant. It is the "meeting point" of the supply and return pipes. Once in the boiler, the water heats up and flows back into the pipes under the floor. A circular pump is responsible for the automation of the process.

In the collector cabinet, both pipes have shut-off valves that are used to turn on / off the room from heating. A compression fitting is used to connect metal valves and plastic pipes.

The collector is actually a tube that collects the metal-plastic elements of the underfloor heating system. Their connection is ensured by using fittings. The number of outlets in the manifold must be equal to the number of contour elements. The collector is connected to the valve, and a splitter with a drain valve and an automatic air vent is placed at the outlet. The latter device eliminates the possibility of air bubbles in the system. I use the drain valve in case of need for repairs.

That is, if we consider a warm water floor, connecting to a collector will look like the most delicate and reliable way to organize the system.

The process of connecting a warm water floor with a comb is very simple and boils down to connecting the pipes of the heating circuits to the collector, and the collector itself to the boiler. However, there are differences in the configuration of the collector. This is what we will consider in this subsection.

The collector must be installed so that it is convenient to lead the heating circuit pipes to it. So, install shut-off valves on the manifold. Connect the side outlet to the pipe both for supply and return.

If you buy a ready-made manifold kit, then it will already have all the necessary valves even at the outlets of the pipes going to the boiler. The presence of taps will allow you, if necessary, to carry out repairs or temporarily disable one of the circuits. If you assemble the manifold yourself, then the assembly of the connection of each element is performed with a compression fitting. As a result, underfloor heating will be connected to the boiler through the collector.

So, instead of shut-off valves on the manifold, install thermostatic control valves.In their design, there is a thermal balloon with paraffin, which, pushing off from the air temperature in the room, narrows or expands. These actions set the capacity of the thermostatic valve. As for the pumping and mixing unit, the principle of its operation was described above.

Install and connect the device

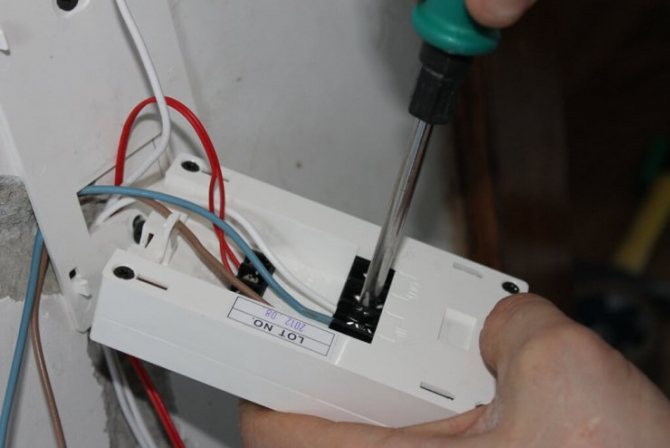

It is built into the wall like a regular outlet or switch. The place is selected closer to the existing wiring (for example, at the same switch). A hole is hollowed out in the wall where the junction box is inserted, and the wires of the power supply (+ and -) and the temperature sensor are connected to it, then the thermostat itself is connected.

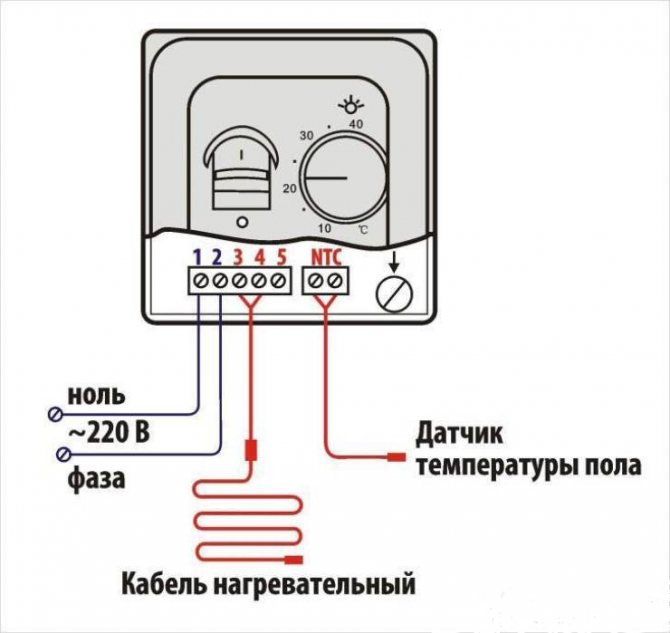

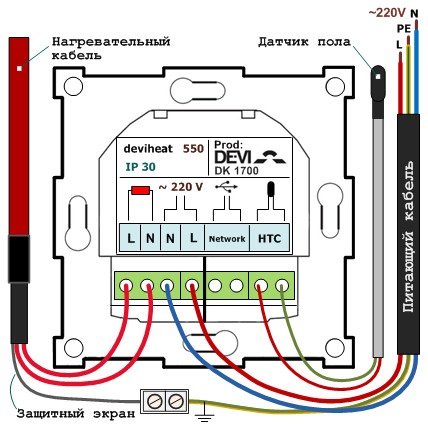

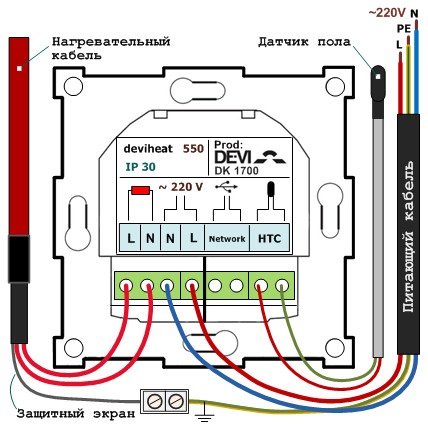

On the side, 200 V mains wires, heating cables and a temperature sensor are connected. They differ in color (phase - brown, white or black, zero is marked in blue, and the ground is marked in yellow-green).

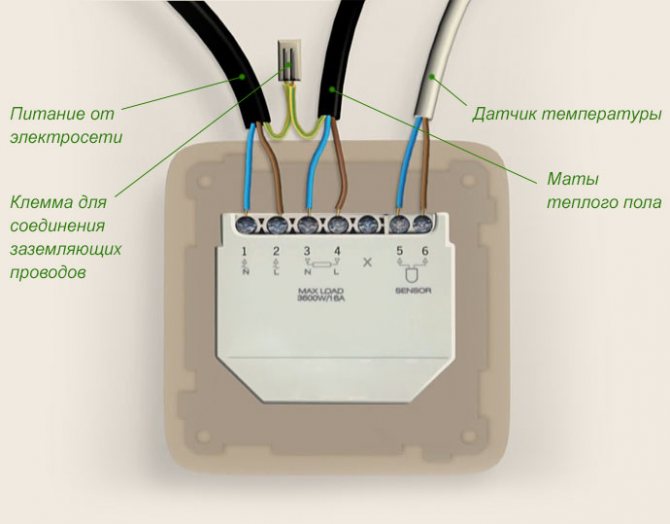

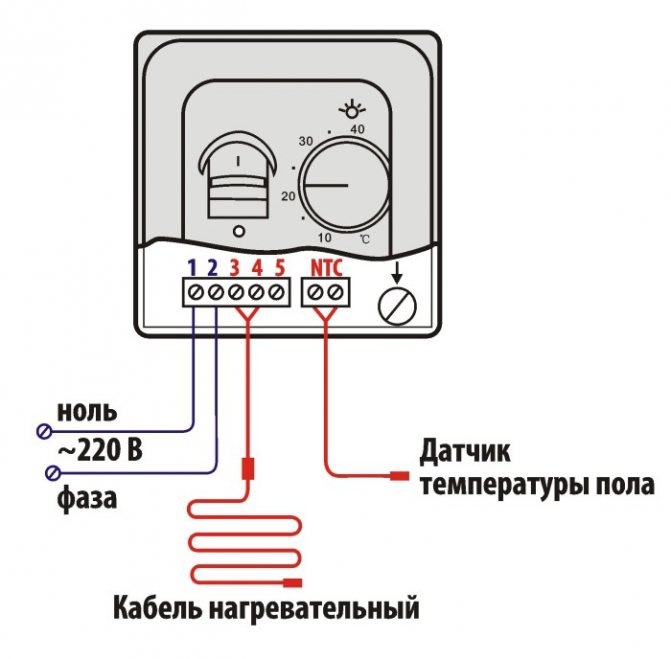

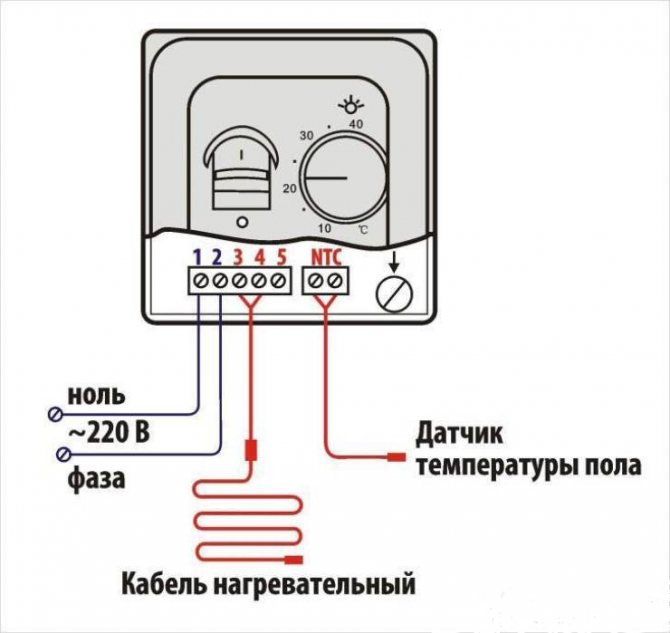

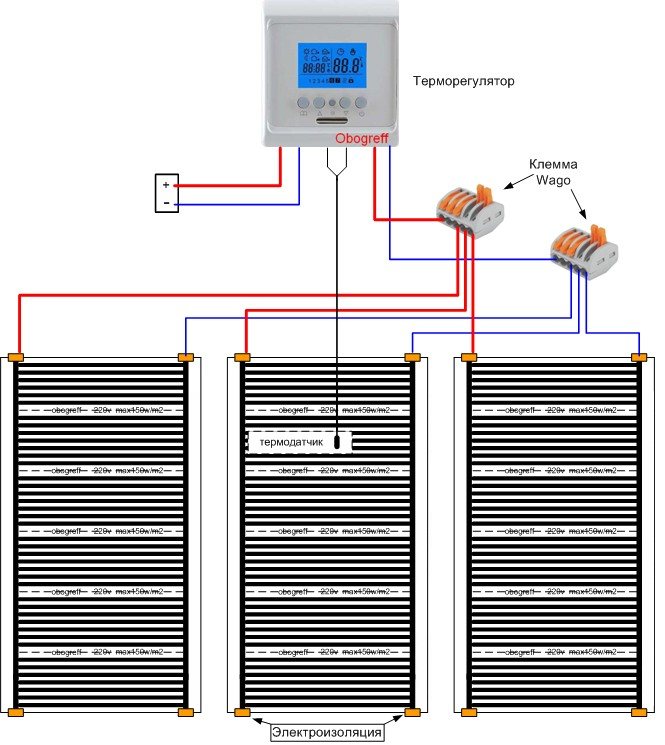

Connecting the thermostat to the warm floor

- The electrical wires (220 V) are connected strictly according to the scheme: 1 - phase L, 2 - zero N.

- Underfloor heating cables are led as follows: zero N - socket 3, phase L - socket 4.

- The temperature sensor is connected to slots 6 and 7, the polarity can be disregarded.

- And at the end, a check. After turning on the network, the minimum temperature is set on the device. Next, set the maximum, which will indicate to the thermostat that the system needs to be turned off. If everything is done correctly, you will hear a click - the network has closed and started its work.

Depending on the types of thermostats, the circuits may vary slightly. To avoid connection errors, the manufacturer prescribes all the names directly on the device. Underfloor heating cables have some differences, which affect the connection. They are single- and two-core, let's talk about them in more detail.

- Two-core cable.

Under the outer sheath there are 2 conductors and 1 earth wire. It is more convenient than a single-core one, since it is connected at one end. - Single core cable

hides two wires under the sheath. White is current and green is ground.

In this article, we have provided general installation tips that will make it easy to read and parse the manufacturer's instructions. You just have to take care of safety when working with electricity. You should know, even without our reminder, that all work must be carried out after having disconnected the entire apartment or house in the switchboard.

The device of the underfloor heating system consists in the installation of heating elements under the floor covering and their further connection to the power source. This does not happen directly, but through a thermostat - a device that serves to regulate the temperature regime. Connecting a warm floor to a thermostat (thermostat) and electricity is a simple operation, so it can be done without the involvement of professional electricians. Moreover, caring manufacturers usually depict an electrical installation diagram on the housings of their thermostats. However, if you are a person who is not at all versed in the wilds of electricity, some of the nuances may not be clear to you. We will try to take into account possible controversial nuances and describe the process of connecting the thermostat to the underfloor heating system in as much detail as possible - for "dummies".

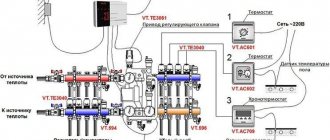

Features of connecting a water heated floor

As you can see, electrical floor systems can be connected quite easily. But what about water heating? Connecting a warm floor to a thermostat in this case is also justified, although not necessary. The device controls a servo drive, on which the flow of the coolant in the pipeline depends. That is, you have an additional opportunity to save money.

So, the work on connecting the thermostat consists of the following actions:

- When arranging a warm water floor, the height of the sensor above the floor must be taken into account. It should be about 1 meter.Remember, the sensor must be located away from any other heaters or batteries to adequately reflect temperature readings.

Wire the regulator and sensor.

Temperature control circuit in the water underfloor heating system

- Next, a regular room thermometer should be attached next to the sensor.

- Set the required heating temperature on the thermostat. For a couple of hours, the system must maintain the specified parameters.

If you did everything correctly, then the device will regulate the heating operation without failures and problems. Self-connection of the thermostat must be done very carefully and carefully. In the event of an incorrect connection, the underfloor heating system will not function adequately and can quickly fail. If you are not confident in your abilities, it is better to contact a specialist. Leave your opinions, wishes, additions to the article in the comments!

How does the thermostat work?

The thermostat is used to maintain a stable temperature in a "warm" system, as well as to turn on and off heating mats (films). The device "reads" the readings of the temperature sensor and automatically cuts off the power supply as soon as the floor heats up to the required limit. At the same time, he himself remains in working mode and continues to control the situation. If the sensor notifies about deviations in the temperature mode, the thermostat will again put electricity into the system and the floor will begin to heat up.

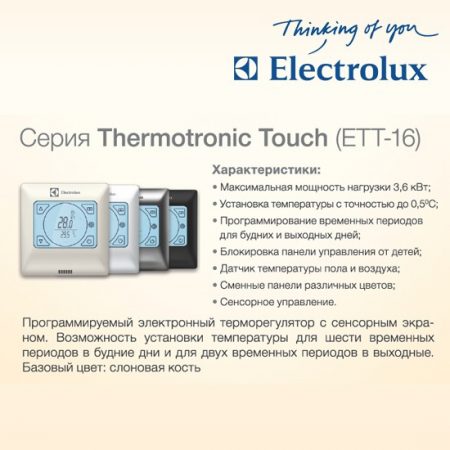

The most popular and reliable thermostats are mechanical and conventional electronic. More complex ones are electronic programmable. Despite the significant difference in its "stuffing", the principle of connecting thermostats is very similar.

The kit for the thermostat includes a temperature sensor, a junction box, terminals, installation and operating instructions

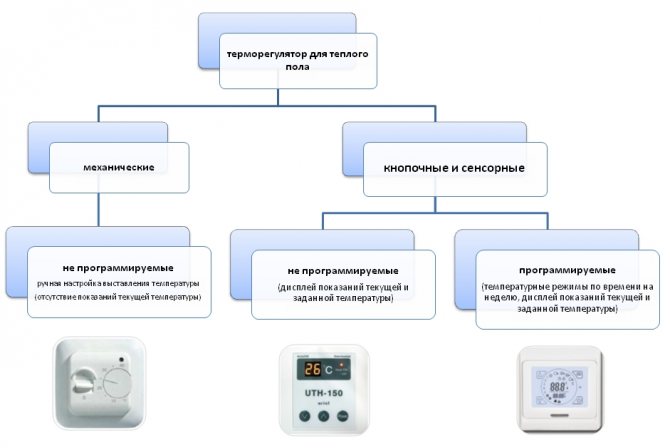

Types of thermostats

Thermostat (thermostat) Is a device that maintains a specified temperature within certain limits.

In the underfloor heating system it detects the temperature by signals from a sensor located in the screed between the heating elements. The device then compares the sensor reading to the user-specified temperature.

If the temperature exceeds the set temperature, the thermostat turns off heating... When the temperature drops below the set limit, the device switches on the current again. The household thermostat maintains the temperature with an accuracy of ± 1 ° C.

Distinguish two types of thermostats:

- mechanical;

- electronic.

Mechanical ones are equipped with a rotary knob, with which they set the desired temperature. The current is switched on and off in it by an electromechanical relay, which emits a characteristic click during operation.

In electronic thermostats no mechanical moving parts. The switching on and off of the current in them is produced by an electronic relay, which does not emit sounds. Some of these devices have push-button control and a liquid crystal display panel, which indicates the set temperature, the temperature at the moment and the operating mode (heating or cooling).

State-of-the-art thermostats equipped with a touch-sensitive display and no buttons. Mechanical thermostats are not programmable. They constantly maintain the temperature set by turning the knob.

Electronic devices are divided into two groups:

- without software control (maintain a certain temperature);

- programmable (automatically change the heating mode during the day according to a given program).

Programmable thermostats reduce heating costs regardless of the user's forgetfulness.

Installing and connecting the thermostat

The thermostat is usually wall-mounted like a conventional switch. For it, a place is chosen near the existing electrical wiring, for example, near an outlet.First, a recess is made in the wall, the thermostat junction box is installed there, the wires (phase and zero) of the supply network and the temperature sensor are connected to it. The next step is to connect the thermostat.

On the side of the thermostat there are "nests". The wires of the network (220V), the sensor and the heating cable are connected here.

It is useful to know that the wires that are connected when installing the thermostat are color-coded:

- white (black, brown) wire - L phase;

- blue wire - N zero;

- yellow-green wire - ground.

Connecting the warm floor to electricity is performed in the following order:

- To "sockets" 1 and 2 connect the mains wires with a voltage of 220V. The polarity is strictly observed: the L (phase) wire is connected to contact 1, and the N (zero) wire to contact 2.

- A heating cable for underfloor heating is connected to contacts 3 and 4 according to the principle: contact 3 - wire N (zero), contact 4 - wire L (phase).

- The wires of the temperature sensor (usually built into the floor, that is, determining the temperature in the floor) are connected to "sockets" 6 and 7. The principles of polarity do not need to be observed here.

- Check the health of the thermostat. To do this, turn on the -220V power supply, set the minimum temperature on the device and turn on the heating element system (by turning the knob or pressing the button). After that, the heating mode is changed to the maximum, that is, the thermostat is “programmed” to the highest temperature that is possible for it. Correct operation of the device will report itself with a click, which will indicate a closure of the heating circuit.

Connection diagrams may differ slightly, depending on the types and models of thermostats. Therefore, so that the user does not make a mistake, as a rule, all contacts are written on the device case.

Installation and commissioning of hidden heating systems is a fairly simple process, if we are not talking about water structures. Electric heating circuits are suitable for rooms of any configuration and purpose, and unlike more complex water systems, there are practically no restrictions on their use.

Installation and arrangement of such a heating element consists in laying the heat carrier itself and connecting it to a power source. This is not a difficult job that does not require special knowledge and colossal experience, but if the installation of the source itself does not cause many problems, then not everyone knows how to connect a warm floor to a thermostat.

Warm floor

The main function of such heating floors is to heat directly the floor and / or the room. There are two types of such heaters: water and electric. The first involves laying pipes into the base of the floor, through which warm water is started up. This is a cheaper and not entirely safe option, since in case of damage to the pipes, not only will you have to remove the entire coating in order to repair the leak, but there is also a very real risk of ruining the repair completely.

Read the same: about the features of the operation of an electric floor heating.

As for the electric variation, everything is much more favorable here, although the cost of such a heating project will be more expensive. However, the costs will quickly pay off, because such a system:

- safe;

- very comfortable;

- economical;

- in the event of a breakdown, repairs are much easier.

Some fear that electrical heating options consume a lot of electricity, but this is actually not the case. After all, it should be borne in mind that the main expense is only for warming up. Further, electricity is required only to maintain a given temperature. And a high-quality and competently mounted and tuned heater will not be a very greedy consumer.

The mixed type of heating will allow to further reduce the consumption of electricity, that is, when the room will have both underfloor heating and main heating. Although without the latter, power consumption will not be a big problem.

In this video, you will learn how to connect a cable underfloor heating to a thermostat:

Features of the device and installation

Despite the seeming complexity of the underfloor heating installation, in reality it is extremely simple, like the installation itself.At the heart of its work is the transformation of electricity into heat by means of a conductor with a high resistance. As such, a cable or mat can act, which are connected to a 220 volt network. The thermostat monitors the degree of heating and temperature.

The thermostat will help maintain the required temperature without overheating the floor

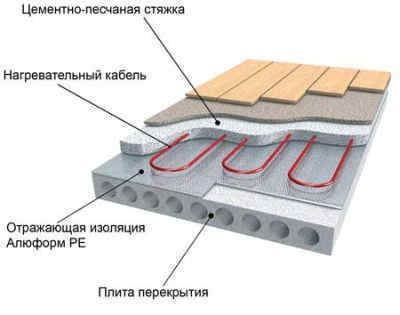

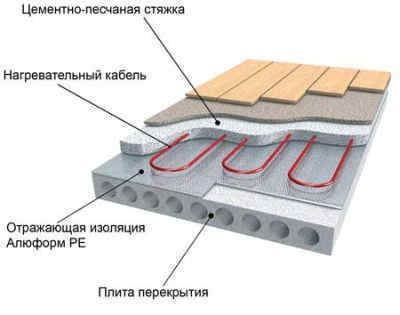

The selected conductor is laid on a foil, which covers a rough screed 1 cm thick. Under it, in turn, there is a heat insulator, which can be placed directly on the floor. The wire itself is fixed with a special mounting tape and connected to the thermostat. A temperature sensor is also attached to it, which will record the degree of heating.

Once laid and secured, a base screed with a thickness of 2 to 5 cm can be applied, on which a finishing coat will subsequently be laid. When choosing it, you should pay attention to the admissibility of using it with a "warm floor" system.

Thus, a floor heating device includes:

- heater;

- thermostat;

- temperature sensor.

All installation and commissioning work can be carried out even by a person who does not have special knowledge in this area.

Types of electrical systems

This hidden heating option is the most common among people who want to create comfortable temperature conditions in their home. Despite the fact that electric floors operate from the same power source, they differ in the heating element. To find out how to connect a warm floor to a thermostat, you need to clarify what type of heating system you are dealing with.

So, among all the variety of heat sources, the most common ones can be distinguished:

- cable with the property of self-regulation of temperature regime;

- resistive one- or two-core heating cable;

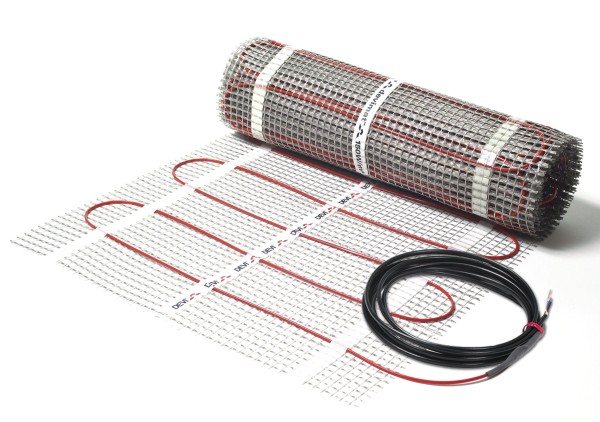

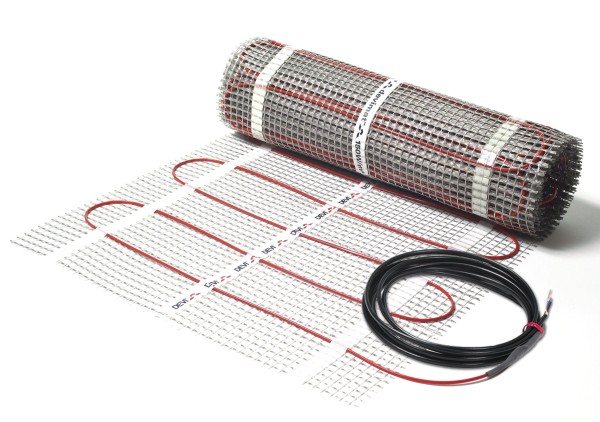

- thermomats are thin, rolled material, in which the heat source is sealed in several layers of a special cloth;

- a film based on carbon, bimetallic heat-transfer fibers, as well as carbon rods.

For each of these types of electric flooring, its own individual wiring and connection diagram has been developed. When installing thermal cable elements, it is necessary to correctly calculate the laying pitch, which will eliminate excessive heat generation or uneven heating of the floor covering.

So, what types of electric floors are, we have already found out, now let's figure out how the temperature regulator works.

VIDEO: How to connect a warm floor to a thermostat

What is the principle of thermostats

This device, as mentioned above, is used to maintain a stable temperature in a hidden heating system. Also, by means of a thermostat, a cycle of on / off operation of thermal elements is carried out. How does he do it?

So, during the pouring of the screed, the sensor is laid, which will read its thermal data from the floor surface. Further, when the cement base is completely dry and the decorative coating is laid, the warm floor should be correctly connected to the thermostat. As a rule, it is located in the wall covering, according to the principle of the device of sockets and switches. But if the latter are installed, according to the European standard, 80 cm from the floor covering, then the regulator should be easy to use. Most trained professionals recommend placing the thermostat at eye level for comfortable use and protection from unnecessary actions by small children.

So, back to how this device works. The thermal sensor, located in the screed, "transmits" the heating data to the auto-thermostat, which, when the set temperature is reached, turns off the heating system.In this case, the device itself remains in operation and continues to monitor the situation. When the device detects deviations in the temperature of the concrete base and the one set by the program, it re-energizes the system and the floor starts warming up again.

Today the market in this segment offers a huge number of regulators, among which mechanical and conventional electronic models are the most popular and reliable. More complex - electronic thermostats with the function of programming the cycle of switching off / on, as well as other additional features. Despite the significant difference in their "stuffing", and, accordingly, in cost, the principle of their connection to the network is almost identical.

Connecting thermostats

Before connecting the warm floor to the thermostat, you need to decide which method you will use to connect. Creatures have two options:

- Stationary supply of the power source from the main meter.

- Using an outlet.

Many models in their configuration already have a scheme, thanks to which the procedure for putting the device into operation will not cause difficulties. And if you are at least a little versed in electrics, then, most likely, you can independently carry out this procedure without resorting to the help of specialists.

After you have installed the underfloor heating thermostat in the place you need, phase, ground and zero must be connected to the junction box. Now let's start preparing the place for the output of the wires from the data meter. In the wall covering, we cut a small groove in which two plastic tubes for wires should fit - the power wire of the heat source and the connection of the internal sensor. Based on this, you should understand that the connection of the underfloor heating regulator is carried out before finishing work, otherwise you will simply ruin the finished, beautiful walls and you will have to deal with their improvement again.

As soon as a number of these measures are completed, you can proceed with the installation and connection of the electric underfloor heating.

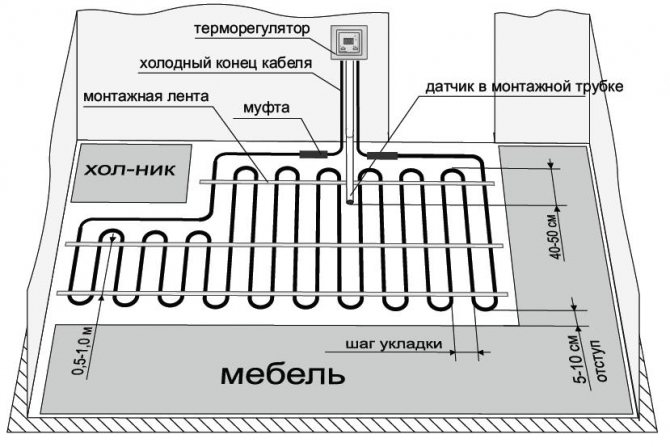

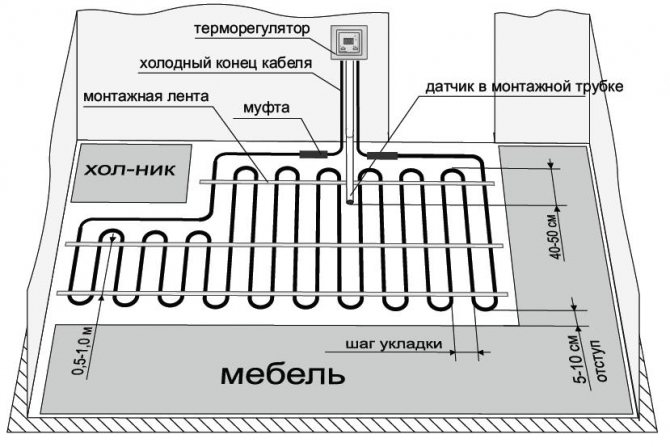

How to connect the cable floor?

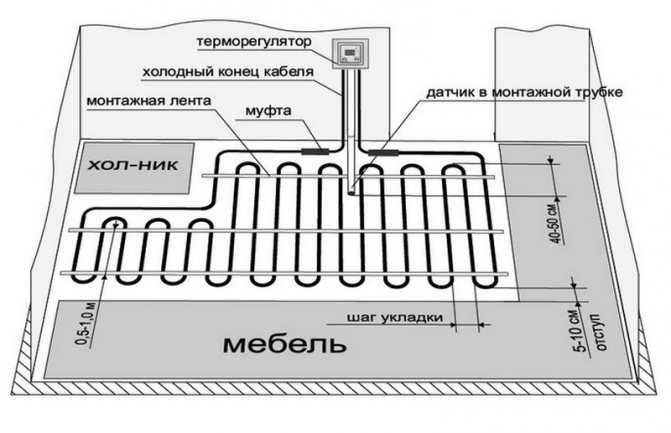

Before proceeding with the installation of the cable, it is necessary to stretch the power wires to the thermostat, while the heating element itself and the wires passing to the regulator are connected with a special coupling, which will later be located in the screed.

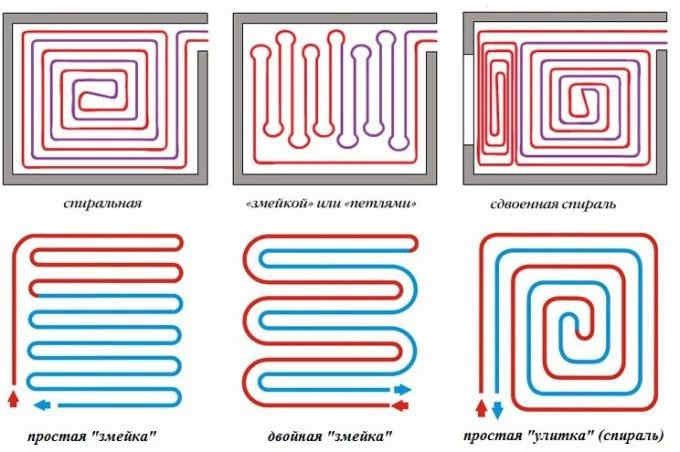

The next step is to lay the cable directly. There are many schemes that help create uniform heating of the floor plane, but whichever you choose, it is important to remember that the cable lines should not intersect in any case.

Next comes the installation of the sensor, which is placed in a plastic pipe of a suitable size. And, before pouring the screed, you need to make sure that the laid heat source is working, using a special tester for this. After this device has shown resistance identical to the passport data, you can start pouring the concrete base.

The connection of the bonded underfloor heating to the thermostat is carried out only after the base has completely solidified.

Connecting thermomat

Connecting this heating system to a thermostat is not so difficult, especially since the process is almost identical to the previous version. Therefore, it makes sense to point out only the differences.

Due to the fact that in this case there is no need for a concrete screed, an additional opening in the floor surface will be required to place the sensor. Once the mats and data meter are positioned, fix them with a thin adhesive backing. That's the whole difference.

VIDEO: Installation of underfloor heating based on heating mats

Connection to the network of the film structure

At the edges of the heating film there are copper rods, which are connected to the network.The thermostat is connected to the film variety according to the same scheme as the thermomat device. The difference lies in the use of a special substrate, which is laid out over the entire insulated surface, which is a foil sheet.

VIDEO: Warm film floor connection instructions 220 watts

Modern technologies allow you to equip a warm floor in several ways, depending on which connection you plan to use. Water-based underfloor heating systems have proven themselves to be highly reliable and economical. Electric underfloor heating is easy to install, the wide popularity of which is due to the possibility of placing it under any cover. Of course, all the positive aspects take place only when using high-quality equipment and its correct installation. Since part of the work on energy saving and convenience is assigned to the thermostat, special attention should be paid to its installation and connection.

Varieties of electric floors

Electric floors have a common power source, but differ in the design of the heating elements. To find out how to properly connect a warm floor, you need to clarify which kind of floor you plan to install.

The following can act as a heating base:

- resistive heating cable (one- or two-core);

- self-regulating cable;

- thermal mats (thin conductor laid on a mesh);

- heating film (carbon or bimetallic);

- carbon rods.

There is a separate wiring diagram for an electric underfloor heating for each of the above options.

When installing a cable floor, it is necessary to calculate the laying spacing correctly in order to avoid excessive heat generation or uneven heating of the surface.

Heating mats and films are purchased following the manufacturer's recommendations, which are usually indicated on the packaging.

The need to install a thermostat

A modern thermostat can be programmed to change the temperature not only by the hour, but also by the days of the week

The use of a thermostat allows you to use any heating device without the danger of overheating and failure. That is why thermostats are built into electric irons, kettles and water heaters. Cable, rod, and film warm floors were no exception. Thanks to the installation of an adjustment device, you can not only change the temperature under your feet, but also program the operation of additional heating to save energy.

In systems with a heating liquid, the principle of underfloor heating is different, since the thermostat controls the operation of a three-way valve and / or a circulation pump. This allows you to obtain the required degree of heating regardless of the temperature of the coolant.

All existing thermostats can be divided into two types:

The electronic thermostat sensor is installed in the controlled area, and the control unit is mounted separately

Rack layout on a wooden base

By the type of material in which pipes are laid, the main types of installation can be distinguished:

- in a concrete screed;

- on a polystyrene base;

- on wooden slats.

The first type is the most reliable and widespread. A layer of heat and hydro insulation is laid on a flat surface. To strengthen the structure, a reinforcing mesh is laid. Next, pipes are laid and fixed with special brackets. The mounted system is poured with a mortar of a mixture of cement and sand, and you can also add plasticizers that strengthen the screed. The best decorative coating option would be tile or stone.

You can not use the warm floor until the screed is completely dry, it may crack.

The next option is installation on a polystyrene base. This option is the easiest to install. The pipes are installed in special ready-made forms. To mount a single base on them, engagement locks are provided and additional fixation is not needed. After laying the pipes, the heat distribution plates are attached from above, and then the finishing floor covering.

The last option is installation on a wooden base. The material is different - edged board, plywood or other wooden products. Strips are made of them and laid on a wooden floor, with gaps for pipes. In these gaps, the pipeline is attached using special brackets. Next, the surface is covered with polyethylene and a layer of gypsum fiber, it will distribute the temperature evenly and the topcoat is attached to it.

To perform the correct calculation of a warm floor of a water type, you need to take into account a lot of parameters and conditions:

- main or secondary heating;

- installation is planned in the house or apartment;

- what is the topcoat;

- what is the volume of the room;

- what is the purpose of the premises;

- what is the heat loss of the room.

Calculation of the heat loss of the room is very important, especially if the warm floor is the only heating system. To do this, you need to take into account the nuances:

- type of building materials for walls and floors;

- type of window frames and glazing;

- number of doors and size of windows;

- peculiarities of the climate in your region;

- availability of alternative heating systems.

For premises of various types, a certain heating temperature of the coating is provided, namely:

- living rooms - 30 degrees;

- in rooms where strong heating is needed - 36 degrees;

- with high humidity - 33 degrees;

- for natural wood - 27.

The choice of the material for the topcoat must be made at the costing stage, in advance. Otherwise, the heating power will not be enough or it will be excessive.

The peculiarities of heating with underfloor heating imply an accurate thermal calculation of the power of the system. This is especially true for rooms with wooden floors. Such a surface has low thermal conductivity and heating will be weaker at the standard system power. Having studied all the nuances and paying attention to important points, you need to make an accurate calculation of the performance of the warm floor, heating equipment and calculate the step between the pipeline, taking into account the selected layout scheme. All this information will help you make heating with underfloor heating in a private house with your own hands.

Water floor installation errors (2 videos)

Water floor schemes (25 photos)

Articles others read:

- Servo drive for underfloor heating collector: automation of underfloor heating

- The right choice of screed in a new building: features and specifics

- Engineering or parquet board: how to choose?

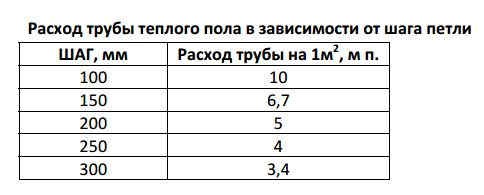

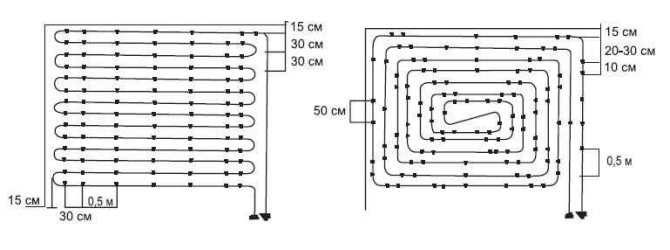

The room should be divided into sections depending on the configuration. Draw a preliminary sketch of the heating scheme on paper. In this case, two conditions must be met: the number of heating pipes in each section should be approximately the same, sharp turns should be avoided if possible. The maximum area of one section cannot exceed ≈20 m2, the length of pipes on it is not more than 100 m. The specific values depend on the pump power and the technical characteristics of the heating pipes.

Wiring diagram for connecting a water-heated floor to the boiler

Wiring diagrams can be made of plastic (the cheapest and rather durable option), corrugated stainless (in all respects they occupy middle positions) and copper (the most expensive and most reliable option) pipes.

Underfloor heating pipes

Corrugated stainless steel pipes

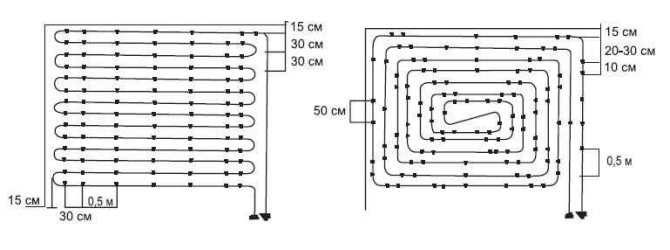

Next, you need to draw a pipe layout on paper, taking into account the above conditions.The distance between the pipes is 15–30 cm, depending on the required indoor temperature. It should be borne in mind that floor coverings cannot heat up to more than 30 ° C.

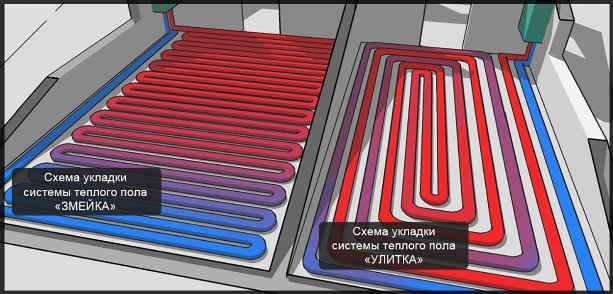

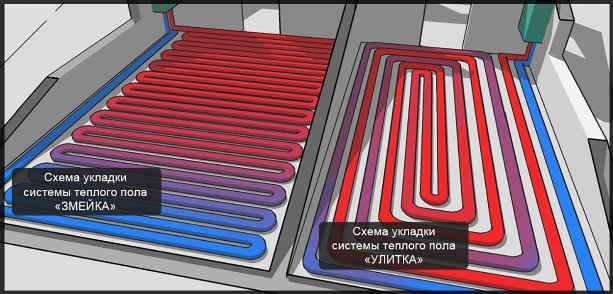

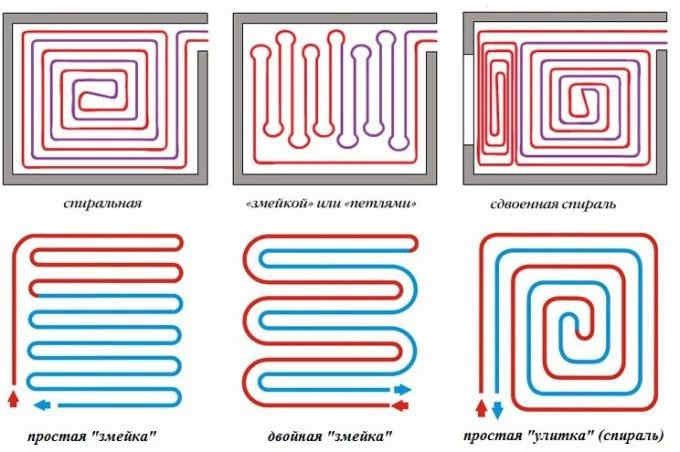

When drawing up a diagram, one more condition must be fulfilled. In the room, each circuit should have the same pipe length and approximately the same number of bends. The schemes provide for laying the pipe using a spiral method, a zigzag and a snake, it is allowed to use several methods in one room, it all depends on the features of the floor configuration. It is recommended to increase the density of heating pipes near windows, otherwise the floor under them will be much colder.

Floor heating connection diagram

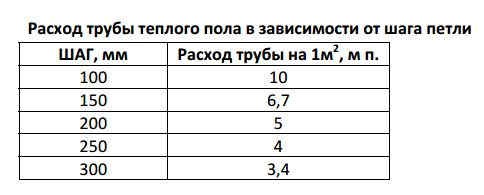

Pipe consumption depending on the step

The length of each circuit is increased by about two meters, they will be required for piping to the riser. If you can make a little mistake with plastic pipes, then copper ones are too expensive to cut them into pieces, unproductive waste increases the cost of the heating system. It is possible that you will have to draw several sketches, change the appearance and dimensions of the outline.

Pipe Laying Options

Methods for laying out pipes for a water-heated floor

Having found the optimal solution, the layout of the contour can be marked on the basis with a felt-tip pen. Further development of the installation depends on the type of base.

Scheme of a water-heated floor on a concrete base

Installation of a water-heated floor with a concrete screed

A hot water heating installation on a concrete base contains several layers of cake.

Insulation layer

It is laid on a cleaned base, if it has large irregularities, then a screed must first be made. It is advisable to use foam concrete, it reduces unproductive heat losses. The thickness of the insulation must be more than three centimeters, the density of the insulation must be at least 35 kg / m3.

Insulation layer

It is recommended to put foam or pressed mineral wool of increased physical strength into the circuit. In the implementation there are special mats for water floor heating systems, they have installed clamps, which greatly facilitate the process of pipe laying. If the room is large, the thickness of the insulation increases.

Read next: Nursery design basic principles

Pipe laying

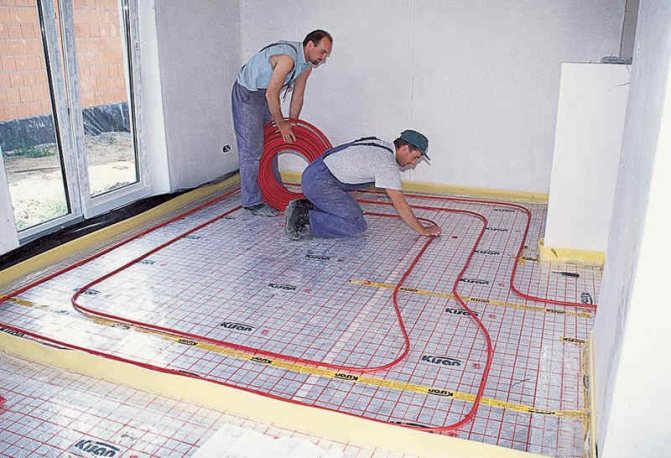

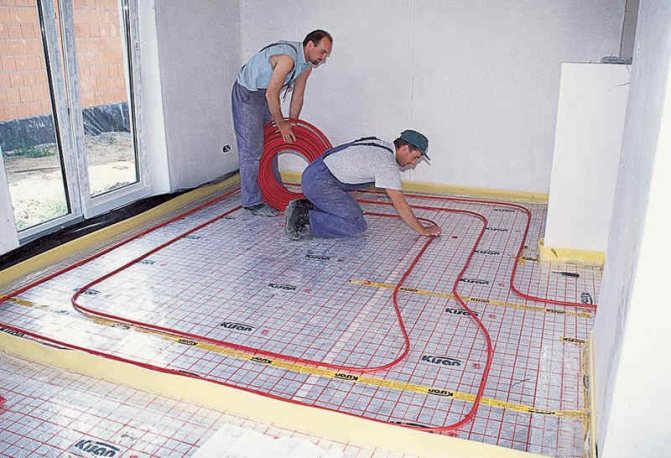

Fixing underfloor heating pipes

On average, approximately five running meters will be needed per square meter of the room at a step of 20 cm. These indicators may vary taking into account the calculated power of the heating system.

Pipe laying

After connecting all sections, it is imperative to conduct a hydrotest of the tightness of the connection. To do this, plug one end of the pipe, and connect a water pump to the other. The water pressure during the tests should be twice the operating pressure. Such tests will make it possible to detect and eliminate leaks in a timely manner.

Damper tape for underfloor heating

Damper tape and insulating film

A damper tape is provided along the contour of the room, which compensates for the thermal expansion of the upper cement screed. A layer of waterproofing is provided between the pipe contour and the screed in the diagram. For these purposes, you can use a cheap plastic film with a thickness of at least 30 microns.

A metal or plastic mesh for reinforcement is laid on top of the waterproofing.

Insulation film and mesh

The screed is 3–10 cm thick above the pipe surface. The screed is done in the usual way, you can use wet or semi-dry material. After cooling down, the final flooring is installed.

Screed over a water-heated floor

All layers of the warm floor are drawn on the diagram, indicating the materials of manufacture and linear parameters.

Provides for the use of ready-made OSB boards with saw-cut grooves for pipes and metal plates.The thickness of the slabs is not less than 22 mm; in the diagram, the installation of thermal insulation is provided in the floor. The variety of modules in configuration allows you to put them in the desired sequence according to the developed scheme.

Warm floor on a wooden base

Photo of laying pipes for underfloor heating

The diagram is drawn taking into account the use of wooden or OSB slats with a thickness of at least 28 mm. The slats should be laid on the floor joists, the distance between them is slightly larger than the diameter of the pipes. Metal profile plates are used as clamps, there are latches on top. The system is covered with gypsum fiber boards.

Warm floors on a wooden base

When considering the problem of how to connect a warm floor to the heating system, it is immediately worthwhile to clearly understand the difference between the device for heating it in a private and an apartment building. In the first case, the owner is free to carry out the improvement without any restrictions, based only on the characteristics of the boiler and the layout of the premises. In high-rise buildings, connecting a water-heated floor to the heating system causes much more problems.

The main ones are the following:

- the difference in hydraulic resistance in heating radiators and floor heating pipes;

- the quality of water in the central heating system is poor and can have a tangible effect on the operation of underfloor heating;

- water hammer and pressure drops can lead to premature failure of the underfloor heating system.

Types of thermostats

Depending on the design and purpose, thermostats are divided into several types:

- devices with a saving mode that reduce the degree of heating in the absence of people in the room;

- devices combined with a timer, which help to save energy due to the ability to program the periods of turning on and off the system;

- intelligent programmable devices that control the operation of heating both according to a given algorithm and depending on other factors: temperature and humidity outside the window, the presence of people, etc.;

- limiting thermostats that are triggered when the set heating limit values are reached.

In small rooms, it is more rational to use a simple electronic thermostat or a device with a timer. The use of intelligent devices is justified in complex heating systems and large rooms.

Some thermostat models are equipped with a pair of temperature sensors and two separate load control channels.

Purpose of thermostats

Depending on the purpose of the room, it can be different, but not higher than + 27 ° С. Although in some cases, when heating large rooms, heating up to + 33 ° C is allowed.

Even a novice specialist can connect a thermostat

There may be several main reasons for maintaining the temperature within such limits:

- Providing comfortable conditions for a person, because when the floor is heated above + 27 ° C, the sensations for the legs can be far from pleasant.

- Floor covering also requires maintaining certain temperatures, non-observance of which can lead to various unpleasant moments - deformation, drying out, seam divergence.

- And the constant unregulated work of the heating element will result in a noticeable overspending of electricity.

It is in order to maintain the temperature within certain parameters that the systems of electric underfloor heating are equipped with thermostats. Moreover, the scheme for connecting a warm floor to a thermostat is quite simple and will not cause problems even for a person who first encountered such a need. This is clearly seen in the figure.

Floor connection diagram to thermostat

Choosing a place to install the thermostat

Built-in type programmable electronic thermostat is the most popular model

When choosing a place to place a thermostat, several factors are guided.

- Device type.In the retail network, most often you can find built-in thermostats, however, if it is impossible to install it, you can find a structure designed for surface mounting.

- Ergonomic considerations. The regulator is placed in a convenient place, at a height of 10 - 80 cm from the floor.

- Availability. It is best to install a thermostat near doors.

In this case, you do not have to worry about the fact that after a while access to the device will be impossible due to standing furniture or equipment. - Rational use of materials. When choosing a location, you should take into account the distance from the electrical panel and the location of the cable outlet, since these factors affect the consumption of electrical wiring.

In the case of using underfloor heating, a thermostat with a built-in sensor is often used as the main heating. Since the device works depending on the air temperature in the room, then it is installed at a height of about 150 cm from the floor.

Installation of additional automation

Scheme - boiler - metal circuit - collector - warm floor - the simplest. It is not complicated by additional equipment.

If several circuits are laid in the house, the coolant in each system must warm up to a certain temperature, then an additional control unit is used. It is a three-way valve with a thermal head and a circulation pump.

Automation will allow you to withstand different modes in individual rooms. The optimum air temperature in the bedroom is 18-20 ° C, in the living room 22-24 ° C, in the bathroom 30 ° C.

The automation is connected to the distributor comb. A bypass is installed between the supply and return collectors. Additional equipment is connected to it. A rotameter is installed on each outlet of the supply manifold. Return outlets are equipped with thermal heads.

- The hot coolant enters the floor line. If the temperature of the liquid in the system rises, then the three-way valve closes the outlet of the supply circuit, opens the outlet for the return.

- In the mixing chamber, cold water is mixed with the hot liquid from the boiler.

- When the temperature in the underfloor heating decreases, the valve closes the return outlet. A hot coolant is injected into the floor circuit.

You can connect the floor heating system from the boiler with your own hands. It is necessary to choose the right boiler, to determine the diagram of the water circuit. A separate circuit is displayed for each room.

Additional automation is installed on the distributor comb. Experts recommend adhering to the technology of connecting plastic pipes to collectors.

YouTube responded with an error: Access Not Configured. YouTube Data API has not been used in project 268921522881 before or it is disabled. Enable it by visiting https://console.developers.google.com/apis/api/youtube.googleapis.com/overview?project=268921522881 then retry. If you enabled this API recently, wait a few minutes for the action to propagate to our systems and retry.

- Similar posts

- What is a self-leveling underfloor heating?

- What is National Comfort underfloor heating?

- What kind of warm floor to lay under the parquet board?

- Do you need a mixer for an underfloor heating?

- How to install a water-heated floor with your own hands?

- How to choose a material for a warm water floor?

Features of connecting the thermostat to the mains

The power of the installed heaters can be calculated based on the passport data or found in a practical way by multiplying the current consumed in amperes by 220, which corresponds to the voltage in a two-phase network.

The color coding of the terminals is designed to facilitate the task of connecting the thermostat to electricity.

In accordance with generally accepted standards, the phase wire corresponds to black or brown, and zero to blue. Ground is connected to the yellow-green conductor.

The supply voltage that is supplied to the device is life-threatening, therefore, the circuit must have a grounding circuit and a residual current device. When installing the thermostat, you should not ignore the safety requirements, and in the absence of experience, it is better to contact a professional electrician.

Connecting the thermostat to the system

Insulation layer

Insulation layer

Pipe laying

Pipe laying

In floor heating systems, the presence of a thermostat allows you to control the servo drive and regulate the supply of coolant to the system. This will allow you to automatically adjust the temperature in the room, as well as significantly save. In rooms with several heating systems, the presence of a thermostat is encouraged.

They are electronic and mechanical. The supplied temperature sensor measures the heating of the air. It is mounted at a height of up to a meter, not far from the thermostat. The main thing is that there are no extraneous sources of heating near the sensor. After fixing the sensor, attach it to the thermostat. After starting the heating, fix the desired room temperature on the thermostat.

Now let's move on to the main question: how to connect water underfloor heating to heating? The scheme of operation of a water-heated floor is simple: the pipes are heated, the heat is distributed to the material that surrounds the network of pipelines, and then moves to the floor covering, through which the entire room is heated.

The material that surrounds the pipelines is a sand-cement screed. Its use is due to the fact that the system will be reliably protected, since the screed is able to withstand significant loads.

It is important to understand how to properly connect a water heated floor. After all, the correct installation is a guarantee of a well-heated room and cost savings.

Air is an excellent insulator, and if it were not for placing pipes (the area of which is actually very small) in a cement-sand mixture, then the efficiency of the system would be so low that no one would even think to use a warm floor for heating.

Now there are two types of electric underfloor heating:

- cable or sectional;

- mats, infrared film systems.

Cable underfloor heating

Each of these types has its own characteristics and is used in specific cases. So, if the warm floor is mounted in a concrete screed, then it is better to use the cable type. Mats or foil heating elements are best suited for tiles.

Read more: Borehole pump Aquarius characteristics device connection

Naturally, the main part of the underfloor heating is the heating element itself. But it works fully thanks to the thermostat, which is the heart of the system.

A thermostat for a warm floor is a device that, without human intervention, automatically regulates and maintains the optimal air temperature

It allows you to maintain the desired surface temperature. It is not a problem to buy a thermostat: it can be either mechanical, with manual adjustment and temperature control, or fully automatic, with the measurement of the surface temperature, air in the room and the selection of the most optimal parameters.

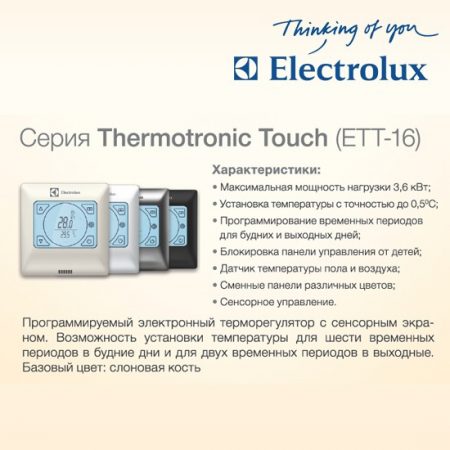

Thermoregulator for warm floor Electrolux ETT-16 Thermotronic Touch

Installation schemes for film underfloor heating

Before connecting a warm floor, regardless of its type, you need to decide on the location of the thermostat. This device is used to maintain a stable set indoor temperature. In addition, through the thermostat, the underfloor heating is directly connected to the network.

It is better to install the thermostat near the existing electrical wiring.

Before connecting the thermostat, you must first decide by what method it will be done: powering from the panel or using an outlet. It should be noted right away that these two methods involve the additional inclusion of a circuit breaker in the circuit, which will be triggered in case of breakdowns, overheating or short circuit. Its maximum shutdown power is selected depending on the type of underfloor heating.

In most cases, a connection diagram is indicated on the thermostat, which greatly simplifies installation without the help of an electrician.If there is no circuit, then the following wires must be connected to the following terminals:

- 1 terminal - mains phase;

- 2 terminal - network zero;

- 3, 4 terminals - wires of the heating element;

- 5 terminal - timer;

- 6, 7 terminals - floor temperature sensor.

This distribution is standard, but it should be understood that different manufacturers can create circuits that require a different connection. It all depends on the design and additional capabilities of the system.

We prepare a place for the installation of a thermostat: we supply power to it (hidden or open, if desired)

Before connecting, you need to drill a small ditch in the wall. It will house two plastic tubes. In the future, the wires of the heating element will be passed into one, and the temperature sensor will be located in the second. At the end of these activities, you can proceed with the installation and connection of the entire underfloor heating system.

Technology for connecting the thermostat to the underfloor heating

Depending on the type of underfloor heating and the method of laying the heaters, its connection diagrams may differ.

Single core heating cable

Laying a single-core cable underfloor heating is carried out in such a way that both ends are as close as possible to the installation site of the thermostat. In this case, the connection is performed in the following order:

- the wires of the temperature sensor are connected to the corresponding terminals (without observing the polarity);

- a power cable is connected to the L and N contacts from the outlet or shield, while L corresponds to the phase wire, which can be detected using an indicator screwdriver;

- the output terminals of the power relay are connected to the underfloor heating element.

Wiring diagram of the thermostat to a single-core cable for an electric underfloor heating

After installation, check the correctness of the connections with a multimeter, apply voltage and test the system in all modes.

How to connect a single core cable floor (video)

Two-core cable

Due to the two current-carrying conductors, this type of cable is connected only on one side. A typical connection scheme is no different from a single-core design, except that the output of such a cable has three wires.

In the absence of a grounding terminal of the thermostat, the yellow-green lead of the heating cable is connected to the neutral power wire.

Connection diagram of a two-wire cable to the thermostat

Installation and connection of a warm floor, consisting of two-core mats (video)

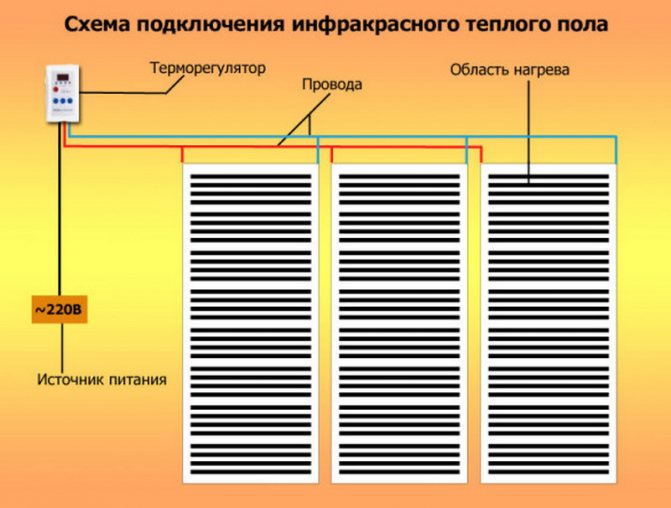

Rod and film heating systems

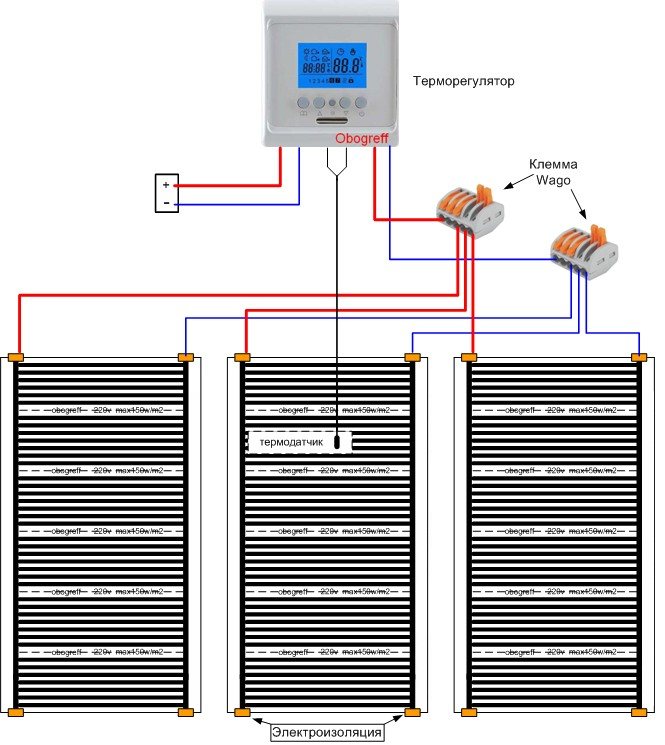

Rod and foil heaters are connected to the thermostat in a parallel way

When arranging underfloor heating equipped with infrared or rod heaters, a scheme is used according to which several panels are connected to the thermostat in parallel.

The same principle is observed in the case of using a heating cable in mats, when several parallel strips are required.

In this case, the connection of heaters to the temperature controller is possible in two ways.

Installation and connection of film heaters (video)

Temperature control of water-heated floors

Heating of water floor systems is carried out by transporting the hot coolant along the contour laid in the floor screed, therefore, the temperature can be adjusted in two ways:

- a change in the flow rate of the coolant;

- a change in its temperature. This is the most commonly used method. It involves the installation of a three-way valve that controls the mixing unit. In this case, the relay output of the thermostat is connected to the solenoid of the electric locking device. As soon as the temperature exceeds the set value, the valve opens. After that, the cooled water from the return line begins to mix with the incoming liquid, reducing its heat capacity.

The scheme with a three-way valve allows you to control the temperature of a water-heated floor

The thermostat connection includes several sequential steps.

After that, all elements of the system are tested for operability. Cold areas or areas with uneven heating are disconnected from the circuit, after which their resistance is measured. The detected defects eliminate and restore the performance of the warm floor.

Thanks to my versatile hobbies, I write on various topics, but my favorites are engineering, technology and construction. Perhaps because I know a lot of nuances in these areas, not only theoretically, as a result of studying at a technical university and graduate school, but also from the practical side, since I try to do everything with my own hands.

Warm floors are increasingly used in private houses and apartments. They help to obtain the optimal and comfortable temperature for a person. The stores sell both separate components for the warm floor and ready-made kits. Installing a warm floor is not so difficult. A home master can handle this task. One of the most important stage of installation is connecting the floor to the control system - the thermostat. We will tell you how to connect the warm floor to the thermostat correctly.

The warm floor can be water or electric. In water-heated floors, pipes with hot water supplied from the heating system are the heating element. The power supply of electric floors is the same, however, they are distinguished by the heating elements used: cable or foil.

The heating element can be:

- one- or two-core heating resistive cable;

- self-regulating cable;

- heating film (bimetallic or carbon);

- carbon rods.

Types of warm floors

The warm floor can be water or electric. In water-heated floors, pipes with hot water supplied from the heating system are the heating element. The power supply of electric floors is the same, however, they are distinguished by the heating elements used: cable or foil.

The heating element can be:

- one- or two-core heating resistive cable;

- thermal mats;

- self-regulating cable;

- heating film (bimetallic or carbon);

- carbon rods.

Thermostat: purpose, types and methods of connection

The underfloor heating system is controlled through a thermostat. Manufacturers offer two types of thermostats:

- Mechanical. The temperature that you want to maintain in the house is set using a mechanical rheostat.

- Electronic. They work on the basis of a programming device. There are touch and push buttons. The operation of the system through such a thermostat is initiated at a given time and at a given temperature.

Types of thermostats

The thermostats are installed at a height of about 1.5 meters from the floor surface. The place for installing the thermostat must be protected from direct sunlight and the action of any additional heat sources. The thermostat is connected permanently, powered from the electrical panel or through the sockets already in the room.

Usually, the manufacturer draws a connection diagram on the thermostat case. This enables the home technician to connect this device on their own.

Connecting the thermostat

Regardless of the type, thermostats are designed to control the following types of electrical heating elements:

- Heating cable.

This is a high resistance conductor. It is housed in secure insulation. When current flows, the cable heats up. - Thermal mat.

This device uses the same high resistance cable, but it is fixed to the mat with a pre-set pitch. - Special film

that emits infrared rays. The thickness of such a film is no more than 5 mm. A semiconductor flat heating strip is installed in its layer.

If underfloor heating is installed in several rooms, then it is more advisable to install thermostats on each heating circuit. This will protect the power grid from overloads, allow you to use different operating modes for different rooms and turn on the systems independently of each other.

Installation of the thermostat

After installing the thermostat, a phase is connected to the junction box, and zero and ground are connected. In the wall, you need to make a groove in which the plastic tubes are placed. The power wires of the heating cable are laid in one of them, and the wire from the sensor is in the other. The sensor is placed under the floor finish. After that, you can proceed with the installation and connection of the electric floor.

The difference between the connection diagram of a single-core warm floor from a two-core circuit

Preparatory work

Before proceeding with the connection of the regulator, it is necessary to carry out a number of preparatory steps. To begin with, determine where it will be located, taking into account a number of nuances:

- The device is not installed where it can be exposed to direct sunlight, and it is not recommended to install it in drafts. This is especially true for models with a built-in sensor, which will regulate the temperature according to the air flow of the room.

- It is undesirable to install the regulator on external walls in contact with the street, as this can lead to incorrect reading.

- The installation height of the device is an equally important point. Installation at a height of at least 400 mm is prescribed.

- It is forbidden to install temperature control devices in rooms with high humidity, since almost no model is equipped with a waterproof case. Therefore, if the underfloor heating is in the bathroom, shower or bath, then the regulator itself must be taken out to the next room, where it will not be exposed to excess moisture.

- The temperature sensor must be located at least 500 mm from the wall, in the case of a cable floor model - between the turns in the center. If the film version is used, the thermometer head is centered on the carbon heating strip.

For a more convenient and comfortable installation, it is recommended to use an extended 60 mm socket. This will allow you to freely arrange all the wires connected to the device.

For underfloor heating, it is recommended to have a separate dedicated power line with a copper cable with a cross-section of 2.5 mm wires, which can easily withstand a load of up to 3.5 kilowatts. Moreover, the line must be equipped with a separate 16 amp circuit breaker.

Before starting the connection, it is necessary to make a strobe from the installation site of the device to the floor. It should fit two corrugated pipes with a diameter of 10 mm. In one of them the wires will run to the "cold ends", in the other - the line of the temperature sensor. It is especially useful to place a sensor in a corrugated tube, since they can often fail, and in order not to open the cover every time, it will be enough to simply pull out the old one and just as easily insert a new one.

If the screed is calculated to be rather thick (35–50 mm), then the corrugated tubes need not be immersed in the groove on the floor. Otherwise, you will have to prepare the corresponding groove here too. The ends of the corrugation should be plugged so that the solution does not get there during the process.

When the thermostat is connected to a warm floor of a film type, the corrugated tubes are not used, since here the principle of measuring the temperature will be different.

Wiring diagram for underfloor heating to the thermostat

The connection diagram for a warm floor is selected depending on the type of floor.

Connecting the cable floor

Before installing the cable, the floor is leveled using one of the methods, depending on its type. Before laying the cable, it is necessary to extend the power wires to the thermostat. In the diagram below, it can be seen that after the installation is completed, the connecting sleeve will be in the floor screed.A mounting tape is laid out on the surface of the subfloor, which will help fix the cable. Most often, the cable is laid with a snake or snail.

An example of installing a heating cable for underfloor heating

Consider!

When laying underfloor heating, the cable sections must not be crossed.

After the cable has been laid, the sensor is placed in a plastic tube. With the help of a special tester, the quality of the installation and the compliance of the cable resistance with the passport data are checked. The warm floor is ready for screed filling.

Floor temperature sensor

Depending on the type of screed used, the floor is maintained until it hardens completely. Only then can all the wires be attached to the thermostat. For connection, screw terminals are used.

Connecting heat mats

The principle of connecting thermal mats differs little from the analogous process for a cable floor. Let's dwell only on the differences.

A thermal mat is the same cable, but fixed with a certain pitch on a heat-resistant film. This makes installation easier. The film with the cable is laid out on the prepared base of the floor and poured with mortar or tile glue. After that, the topcoat is mounted. Thermal insulation is not used for this type of floor to avoid overheating of the system.

In its finished form, such a structure has a thickness of no more than one and a half centimeters. To place the sensor in such a floor, you have to make a recess on the surface.

Applying a screed to thermal mats

Sometimes the so-called cold ends are not enough to connect the mats to the thermostat. In this case, a piece of cable is cut out of the mat. The coupling is poured with a coupler.

Installation of this type of floor gives significant savings in materials: thermal insulation, screed, fasteners. In addition, the amount of work is significantly reduced. Such a system has practically no restrictions in use, since it slightly raises the floor surface and can be used in rooms with low ceilings.

Connecting the film floor

The basis of the film floor is represented by carbon or bimetallic heating elements sealed in a heat-resistant film. Copper conductors are located along the edge of the heating foil, with the help of which the system is connected to the mains.

A foil-coated substrate must be placed under the heating film, which will reflect infrared rays towards the room. In this case, the plastic tube with the sensor is placed in the made recess or is attached to the surface of the film.

Infrared floor heating connection diagram - standard installation

If necessary, the film can be cut along special lines. On the one hand, the conductive strips are insulated, and on the other, they are left open for connection to the wires. The strips of film are laid out and connected to one another in parallel.

Such a warm floor is the most versatile, as it can be mounted under any floor covering.

Connecting a water underfloor heating

The scheme of a water-heated floor is slightly different from an electric floor. First of all, you need to determine with the connection method.

Underfloor heating with a low loss header

An important stage in the installation of a warm water floor is the installation of a water collector. All circuits of the system are connected to this device. The manifold device allows individual regulation of pressure and temperature in each circuit.

Wiring diagram of the underfloor heating collector in a private house

Warm water floor can be an additional source of heating or used as an independent option. In the first option, radiators are installed on the forward run, and a warm floor is connected to the reverse.

The diagram below shows:

- Circulation pump.

- Heating radiators.

- Boiler.

- Storage tank.

- Control device.

- Shut-off valves.

Connecting a heated floor according to a combined scheme

Underfloor heating is increasingly used in the residential sector. This pleasure is not cheap, but by doing the installation yourself, you can save a lot. The advice of our website will help you to carry out a competent installation.

We connect the cable floor

First, we level the surface, then we attach a damper tape along the wall and install thermal insulation. The cable can also be installed on a sub-floor, provided that there is a heated room below. Before laying the cable, we stretch the power wires to the thermostat box (the connecting sleeve will eventually have to be in the body of the concrete screed).

An example of installing a heating cable for underfloor heating

Further, the installation and connection of the warm floor is done according to the following scheme: we place the mounting tape on the surface of the subfloor or thermal insulation. It is needed in order to fix the cable. The most convenient way of laying is the so-called. snake.

Important: when laying, the cable lines must not cross!

The fasteners on the mounting strap will help to position the conductor evenly. After the cable is unfolded, we install the sensor by placing it in the plastic tube, which was described above. The final stage of installation is to check the quality of its implementation: using a tester, we make sure that the cable resistance corresponds to the passport value. Now everything is ready to pour the screed.

Installing a thermal sensor

Before connecting the electric underfloor heating, you need to make sure that the screed has hardened. When the cement-sand mortar is sufficiently solid, we connect the power wires from the heating sections and the sensor, as well as the electrical wiring that feeds the entire system to the thermostat using screw clamps. This stage is the most difficult, so it will be best if it is done by a professional.

Recommendation: For ease of installation, a mounting tape for a warm floor is used.