If you do not seal the joint

When removing the chimney, a hole is made in the roof. The gap between the coating and the walls of the chimney is sealed with special aprons, collars and seals. You can buy them at any hardware store. These protective elements are easy to make with your own hands.

If you do not seal the seams on the roof in time, the following consequences are possible:

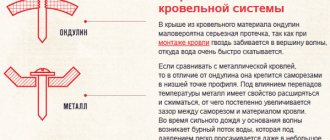

- Increased wear on the roofing material. Water entering the gap enters the inner surface of the roof, which causes deformation of the coating.

- Reduced service life of the building frame. Water, which is poured into the gap between the pipe and the roofing, promotes the gradual rotting of the wood. This is fraught with deformation and destruction of the rafters.

- Insulation loses its effectiveness. The heat-insulating materials with which the roof is equipped can quickly lose their properties when wet. If hard heaters are not very susceptible to moisture, then soft ones quickly begin to rot.

- Increased humidity in the attic. Increased dampness causes stale, heavy air. This can negatively affect the interior decoration of the attic.

The way to eliminate the gap between the pipe and the roof depends on its size and type of coating. Also take into account the shape of the chimney. At a distance of less than 5 mm, a heat-resistant sealant is used. If the gap width of 1 cm is exceeded, cement mortar, an apron or a special sealant are used.

It is necessary to close the gap between the pipe and the roof in order to:

- ensuring the isolation of the attic from atmospheric moisture;

- to improve the efficiency of thermal and waterproofing;

- increasing the service life of the rafter system and the entire roofing structure;

- exclusion of cold bridges.

Sealing the chimney on the roof avoids the destruction of the roof itself.

Where to remove the pipe on the roof from the corrugated board

In order for the roof to be reliable and moisture-proof, it is important to choose the correct outlet for the chimney or ventilation shaft. This will save time as much as possible, since in this case it will be much easier to seal the pipe on the roof made of corrugated board.

The following sections are considered the most optimal places for organizing the passage:

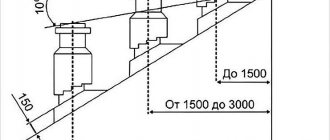

- On a skate... This is the most practical place to get the pipe out. In this case, snow pockets, condensation will not form and the risk of leaks will be minimized. At the same time, it is important to take into account that such a placement of the passage will lead to a violation of the solidity of the ridge beam. In this case, silicone sealant is used to fill the formed joint. To preserve the external aesthetics, a decorative apron is used.

- Not far from the ridge (50-7- cm). Also a good option is how to make a pipe on the roof from corrugated board. If you remove the chimney at a specified distance from the ridge, this will not violate the integrity of the rafter system. Joint protection is carried out with elastic gaskets and special additional elements.

There is a rule that with a decrease in the level of location on the roof of the outlet for the pipe, the complexity of its sealing increases.

Materials (edit)

The seam between the pipe and the roof can be sealed with silicone, acrylic, polyurethane and bitumen sealants. Special sealing tapes are also successfully used. Each of these types has its own advantages and areas of application.

Silicone sealant has become a kind of versatile material in construction. It is used both for working with the roof and for sealing window openings.Silicone sealant is often used when working with glass and wood. They are often treated with a gap around the chimney of a pipe on the roof. The material does not lose its properties with prolonged exposure to ultraviolet radiation and high temperatures. To seal the joints of roofing material, there is a special subspecies of it - roofing sealant.

Acrylic sealant is most commonly used to seal crevices in walls and floors. Also, acrylic compounds are used to repair windows. For outdoor work, it is rarely used - it is not elastic enough.

Polyurethane, unlike acrylic, is used almost everywhere for outdoor work. They are glued to metal, concrete, wood, stone. For minor repairs, the roof is ideal.

Bituminous mortars are ideally combined with roofing work. They are resistant to precipitation, temperature extremes, and chemical solvents. The only drawback of such a sealant is its toxicity. For this reason, no internal work is carried out with him. They are ideal for sealing a roof chimney.

The main advantages of bitumen:

- super-durability;

- low cost;

- elasticity;

- the possibility of staining;

- high moisture resistance;

- high level of adhesion to dry and wet surfaces.

There are several subspecies of bituminous mixtures that are specially designed for roofing. They are able to ensure complete tightness of the gap to be treated between the pipe and the roof covering.

Equipment for the junction of a rectangular pipe

It is easiest to seal the joint between the pipe and the roof made of corrugated board, if it is passed through the ridge. This increases the reliability of the connection. In such structures, the formation of snow pockets is impossible. The risk of leaks arises precisely when they are present. Such options also have one significant drawback - to pass the pipe through the top of the roof, the ridge element must be divided.

The upper abutment zone between should be sealed using a standard method - using the upper elements of the apron, sealed on top with sealant. The silicone composition is not afraid of high temperatures.

Tape sealant

Tape sealant is a hard material. Many builders consider it to be the most profitable option for roof sealing. Material Features:

- it is based on butyl rubber;

- the sealant tape is highly resistant to ultraviolet and high temperatures;

- it has high adhesiveness, due to which it is easy to install;

- ideal for sealing joints between chimney and roofing.

The tape has an aluminum coating, which increases the life of the sealant for outdoor use. The tape is easy to install and operate. The average service life of the product is 10 years. Due to its wide range of colors, the tape can be used for sealing various roofing coverings. The sealant has excellent adhesion to a variety of surfaces. The tape is used when it is necessary to seal wooden, plastic, metal surfaces. The tape is also successfully used for sealing translucent roofs.

How is it applied

The pipe and roof surface to which the tape is glued must be cleaned and dried. It is important that the area to be treated is level. To apply the tape, you need to cut a piece of a certain length, then remove the protective film and press the product tightly to the joint (gap). At temperatures below +5, the tape is first kept indoors at a temperature of 15 degrees for 12 hours.

The use of the tape in subzero temperatures involves heating the surface to be treated. The tape is not used for surfaces with a working temperature above 80 degrees or when the roof slope is more than 55 degrees.

How to seal a roof joint with an oval and round pipe

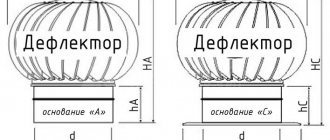

To organize the passage of the pipe through the roof of the corrugated board, a galvanized steel pipe with a round section can be used. In this case, the sealing of the abutment joints is not very difficult. It is for these purposes that elastic funnel-type penetrations are intended. The materials for their manufacture are usually latex and synthetic rubber. They are usually included with pitched and flat roofs.

The process of sealing a joint using elastic penetration looks like this:

- Selection of flexible penetration suitable for the size.

- Cutting off the narrow section to ensure a tight grip on the pipe.

- Removing the protective umbrella and deflector from the pipe, followed by careful tightening of the elastic penetration. The product must cover the entire pipe section.

- Fixing the base of the penetration to the roof surface is facilitated by the presence of a self-adhesive backing. You can also use silicone sealant or roofing screws.

- At the final stage, a decorative apron is mounted. It looks like a cap and is tinted to match the color of the roof. The apron is designed to protect elastic penetration from solar radiation and mechanical stress.

Elastic penetration sizing is key to ensuring a reliable joint seal. When the product lies loosely on the pipe, it is necessary to additionally use a sealant and a steel clamp. Small diameter passages can break when trying to fit over the chimney.

Sealing the gap

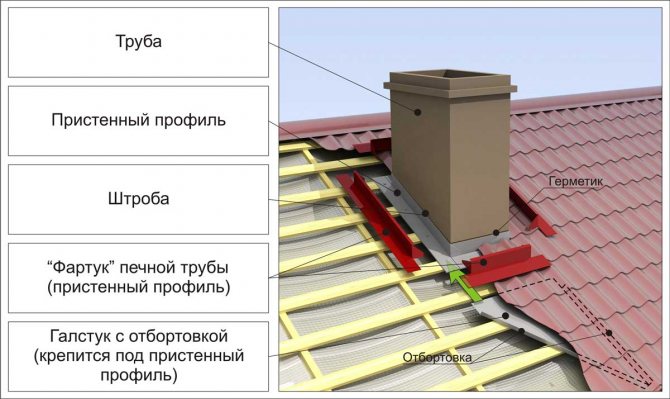

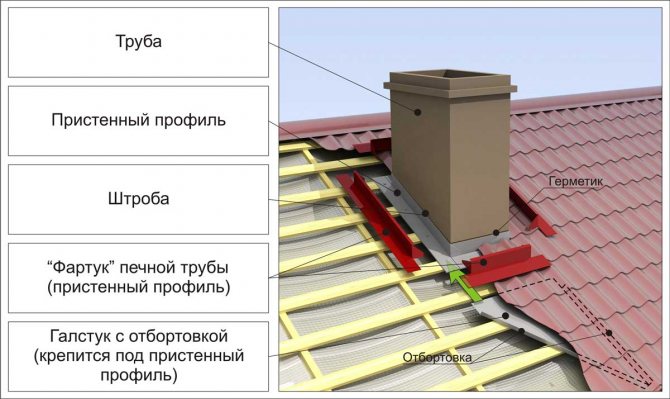

The traditional method of sealing the gap between the pipe and the roof involves an apron. For its construction, you will need abutment strips. They are placed at the bottom of the chimney pipe. They are applied to the pipe and marks are made on the top.

The grinder is used to perform the strobe. Subsequently, the remaining parts of the apron are overlapped around the pipe. The edges of the strip inserted into the groove must be covered with a heat-resistant sealant. The lower parts of the plank are trimmed and fastened with self-tapping screws. The gap between the pipe and the roof is sealed in such a way that water flows into the drainage elements.

A roofing part is mounted on top of the laid elements, and an external tie is constructed around the pipe. When setting it, it is important to take into account the inner tie pattern. The upper strips are not inserted into the groove, they are simply adjacent to the pipe.

If the pipe has a round shape, a special nozzle can be used. It is also used to seal antennas and ventilation outlets. It looks like a stepped pyramid. If the nozzle is rubber, it can be used in a temperature range from -50 to +130 degrees. Silicone models have a wider range - from -70 to +250 degrees.

There should be a distance of 25 cm from the chimney to the structures protected from fire. In the case of unprotected elements, it should not be less than 35 cm. The ideal option is to create an air gap. However, such a solution causes a large heat loss, which is disadvantageous from the point of view of thermal insulation.

For slate roof

Sealing a pipe on a roof made of corrugated board

This material does not have accompanying nozzles for the ability to close gaps. For slate roofs, other sealing options are possible. For a brick pipe, you can make an otter with your own hands - this is also an apron, only from a solution based on cement and sand. For round stove pipes there is a nozzle called "Master-Flash". It is made of rubber or silicone and resembles a stepped pyramid in shape. Such nozzles perfectly protect chimneys and are suitable for all roofing materials, even for corrugated roofs. After installing such a nozzle, all joints are firmly sealed with a sealant.

Important! The silicone nozzle serves at a temperature of -70 +250 degrees, and the Master-Flash made of rubber can withstand temperatures of -50 + 130 degrees.