The device for waterproofing walls is the most important element in the overall complex of construction work. The penetration of moisture from the outside into the structures and the loss of dew on the internal surfaces of the building always brings a lot of harm. Moisture destroys the structure of building elements, contributes to the development of mold and fungi. Moisture-saturated exterior surfaces of a home are most susceptible to deterioration during the winter. The water turns to ice and breaks the base of the walls. The waterproofing of the walls of the house must be of high quality. Sealing of fences is done both inside and outside the house.

Sources of moisture

From the outside, moisture can penetrate into the building from groundwater, during floods, from atmospheric precipitation. Poor thermal insulation of the building envelope can contribute to a sharp temperature drop on the surface of the walls inside the house. This causes dew to fall out inside the dwelling.

Inside the building, the presence of moisture is observed in basements, bathrooms and kitchens. Extensions to the building (garages, workshops, etc.) are also objects with a high level of humidity.

Horizontal shut-off waterproofing

This volumetric concrete protection, by the way, is one of the most effective. The method is based on the injection of chemically active liquids into the thickness of an artificial stone. As a result after hardening, a waterproof barrier is formed... The basis of the system can be silicates, organosilicon compounds, the latter being an order of magnitude more effective, since they fill the thinnest capillaries.

Benefits:

- low viscosity has a good effect on flowability;

- resistance to aggressive environments;

- high adhesion to concrete;

- excellent compressive strength, bending strength.

Disadvantages:

- high price;

- waterproofing is arranged only at positive temperatures.

Scope of application: force closure of cracks in concrete foundations of any load-bearing structures.

Brands: Penetron, Osnovit, Ivsil, Ceresit, Litokol

Specifications

| The foundation | Epoxy resin (or other polymers) |

| Density | 1.1 kg / dm3 |

| Viability | About 75 minutes |

| Polymerization time | 3-7 days |

| Compressive strength / tensile strength | 70/40 N / mm2 |

| Application temperature | +10 +30 degrees |

| Consumption | 1.1 kg / l |

Types of insulating materials

The types of waterproofing on the construction market are represented by many types of insulating materials. It can be liquid mastic or a film coating.

The most widespread use of materials as external waterproofing of walls was obtained by roofing material, roofing felts and bitumen mastic.

Bituminous mastic

Bitumen is one of the products of oil refining. Mastic serves as a means for gluing bituminous roll materials such as roofing felt and roofing felt. This is a homogeneous mass of bituminous binder with the addition of an antiseptic - sodium fluorosilicate.

The mastic is supplied in paper-wrapped sticks weighing about 20 kg. They use it in a heated liquid state, bringing the heating up to 1500C.

Warm-up conditions allow for open flames. When working with this material, you must strictly follow the fire safety rules.

Bituminous mastic has high adhesion and firmly "sticks" to any surface. This universal property and low cost of this substance make it one of the most attractive insulating materials.

Polymer mastics

In addition to bitumen mastic, there is a large selection of polymer-based lubricants.They are easily applied to the walls from inside the room with a spatula or brush. The mastic dries quickly (within a few hours), forming a surface with high adhesion.

This video demonstrates the use of such a mastic:

Roofing felt and roofing material

Roofing felt and roofing felt - roll insulating coatings intended for waterproofing building structures.

The basis of these coatings is technical board impregnated with soft bituminous compounds. A distinctive feature of roofing material is the presence on the outside of the dressing of asbestos crumbs, talc and quartz sand. This is mainly done to protect the upper layer of roofing material when laying it on the roof of the building.

Roofing felt and roofing material are "glued" to the walls with hot mastic. The resulting surface becomes a powerful barrier to moisture penetration. Thus, waterproofing of the concrete walls of the foundations is done from the outside.

Waterproofing the outer walls of the house with roofing material, laid on bitumen mastic, is considered one of the most optimal options for protecting the structures of the building from moisture.

Polyethylene film

Modern waterproofing materials include a wide variety of polymer coatings. They are used mainly indoors or in severe conditions of excessive humidity and for foundations, plinths and basement walls.

Polyethylene film is an irreplaceable material for waterproofing when performing many types of construction work. The film is absolutely waterproof, lightweight and durable. The thickness of the polyethylene coating can be between 0.5 and 3 mm.

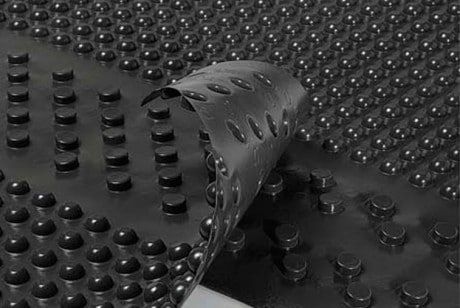

Polyethylene wall covering is called a waterproofing membrane.

The film is very flexible, it is easy to install it on any surfaces of complex configuration. An important advantage of the material is its low cost.

When waterproofing internal walls, the base of the fences is covered with a film, followed by the installation of a polymer or metal mesh under the plaster.

The basement walls and the outer surfaces of the basement walls are also covered with plastic wrap.

Polymer coating

The waterproofing polymer membrane is quite durable (up to 50 years), resistant to oxidation and decay, and is not subject to corrosion

There are insulating materials based on complex polymer compounds. Roll material is laid on the walls on special adhesives.

Injection waterproofing

These tools include various primers. They have a penetrating property. The liquid applied to the surface of the wall penetrates into the depth, filling microcracks and pores. This forms a waterproofing layer.

Penetrating insulating compounds clog the capillary pores of the array. Such tools are used for monolithic and precast concrete structures.

Plaster plaster of walls

Penetrating waterproofing application

The plastered surfaces with the gypsum mixture become absolutely waterproof. When dry, gypsum, in addition to creating a surface with high adhesion, also serves as waterproofing walls from the inside against mold.

How can walls be protected from moisture from the inside?

Protecting the walls from the inside

First you need to decide on the type of material used. The sequence of work will directly depend on this. Moreover, all materials can be divided into compositions:

- penetrating action;

- based on expanding cements;

- which are based on the principle of waterproofing membranes.

The first group of materials forms a crystallization barrier in the wall, thereby dramatically increasing its water resistance. Such compositions, after adding water, take the form of a batter. They are applied to a damp wall, providing a thin, hardened film on the surface.Materials of this group are able to penetrate 15 cm deep into the structure, leaving the capillaries permeable to air. Such formulations are sometimes called penetrating compounds.

The second group of compounds is relevant when it is necessary to make structures waterproof, crack resistance and durability. They have a high degree of adhesion to old concrete. This is true in the case of creating a hydro-barrier inside an old building. They can be used for underground and surface structures.

In addition to the above, you can use roll materials - polymer films. They are ideal when using insulation in the form of slabs. If the waterproofing of the walls inside the room is carried out with their help, then the sequence of work is as follows:

- the polymer film is fixed;

- insulation is being installed.

Also, if necessary, you can use a cement-sand mortar, into which various additives are introduced to ensure the required complex of properties. This plaster must be applied in three steps. In this case, the primer is applied first, and then the subsequent layers. Moreover, each layer can be applied only after the previous one has hardened. In this case, a dense crust will form, which will not allow moisture to penetrate inside for a minimum of financial investment.

Insulation cover location

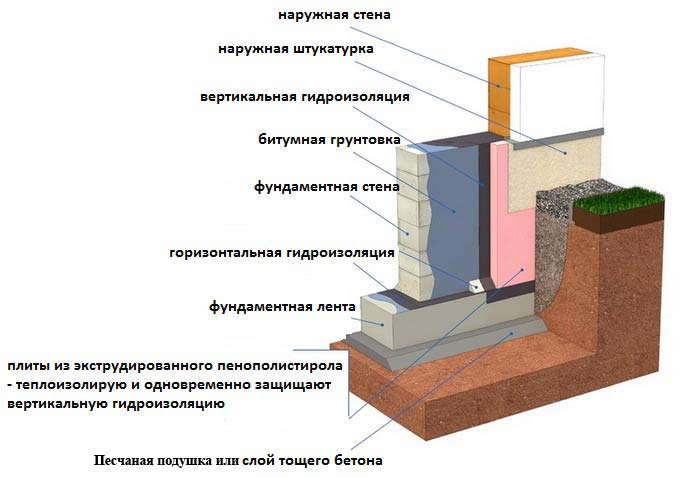

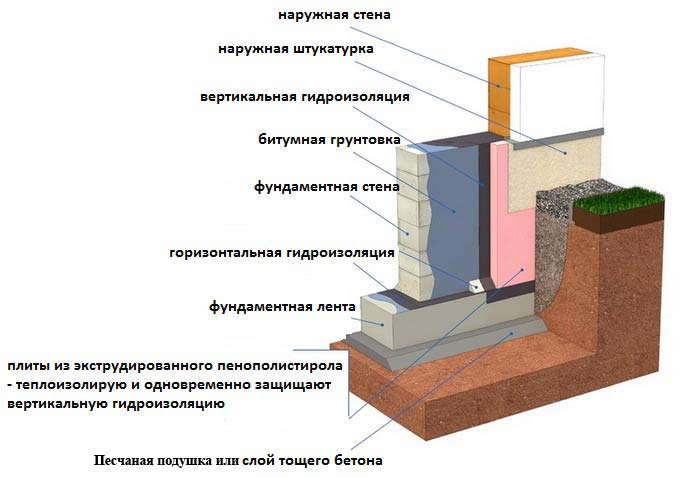

The wall waterproofing device can be horizontal and vertical.

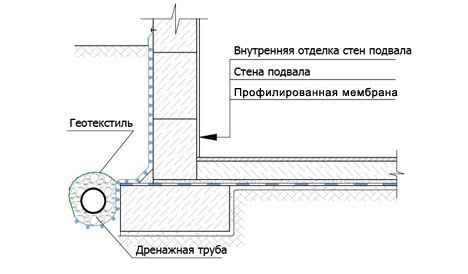

Vertical

This is a common method of waterproofing a wall in an apartment and on the outside of the house. The vertical insulating wall covering prevents moisture from entering the room horizontally.

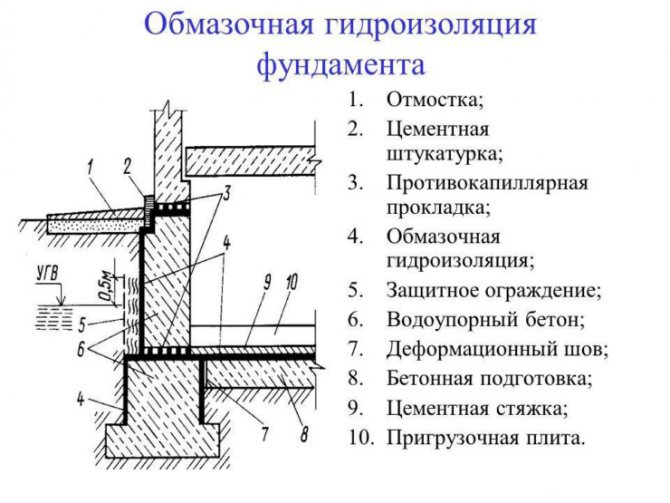

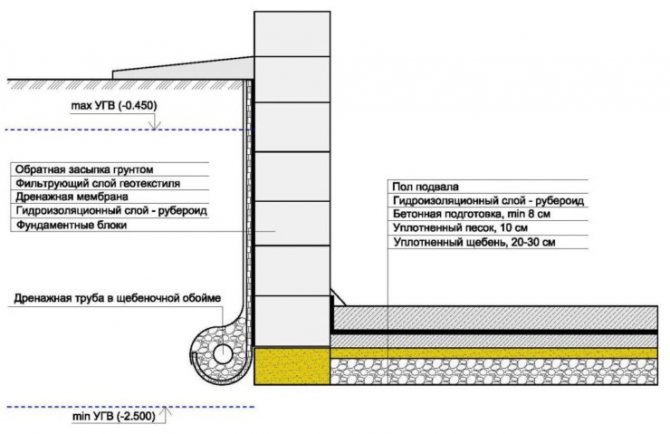

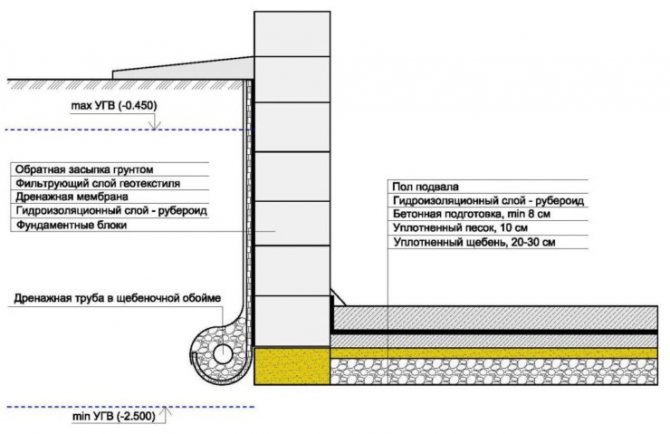

Basement vertical waterproofing device diagram

Horizontal

The purpose of the horizontal insulation device is to prevent the penetration of moisture into the premises from below, from the subgrade.

It is arranged by laying roll materials on top of the foundation and plinth before erecting the walls of the building. The upper horizontal surface of the foundation is covered with 2 layers of rolled waterproofing (roofing material, roofing felt or polymer membrane). Ground moisture tends to spread upward and penetrate into the structure of the building's ground structures.

Horizontal waterproofing becomes an insurmountable barrier to moisture penetration from the bottom up.

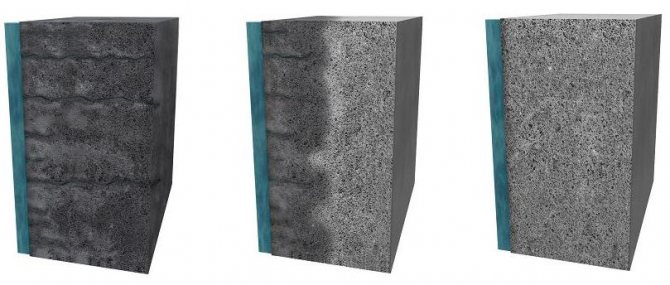

Coating waterproofing

This is surface insulation. We can say that thin-layer cement-based coating systems give very decent adhesion, becoming almost a single whole with concrete (in contrast to the same roll bitumen materials). Dry mixes are optimal for waterproofing foundations in static conditions, for example, tanks, basements... Rigid waterproofing is sealed with water and forms a durable, thin-layer coating.

After hardening, polymer coating waterproofing retains elasticity, which works well under dynamic and temperature loads... This method is best implemented in underground garages, on foundations, in residential and industrial premises (both inside and outside). In any case, after processing, the surface can be finished with tiles or plaster, depending on the purpose of the object.

Benefits:

- tear-proof watertightness, which is effective in buried rooms, basements;

- vapor permeability;

- crack resistance against the background of dynamic loads;

- ease of processing;

- durability.

Disadvantages:

- protection against mechanical wear is required.

Scope of application: vertical, horizontal structures of residential and industrial premises, foundations, basements, garages.

Specifications

| Life time | From 5 years |

| Water tightness | W6 |

| Consumption, 1mm / sq.m | 1.6-3 kg |

| Operating temperature | -50 +70 degrees |

Main brands of coating waterproofing agents: Osnovit, Litokol, Knauf

Preparation of walls for waterproofing

The whole point of preparing surfaces before any coating is to remove all unnecessary from the walls. Remnants of old cladding, sludge of various solutions, dust and dirt - all this can contribute to the detachment of the insulating coating.

In different cases, the vertical surfaces of the premises are cleaned with various hard brushes, spatulas. It happens that you have to use a sandblasting installation. In general, there are many options for preparing the base of the walls. The main thing is to achieve complete cleaning of surfaces.

Waterproofing concrete joints

The practice is that more than 70% of all concrete leaks occur precisely through the seams. Therefore, the purchase of waterproofing materials alone is clearly not enough - protection of the structure from unexpected water penetration should be comprehensive. To solve these problems, special waterproofing tapes have been developed.

Waterproofing tape is a high-strength, elastic material designed to strengthen joints, moisture protection of seams and joints... Plus, self-adhesive tapes can be used to conveniently seal corners, drain holes, utility inputs, floor-to-wall connections. As a rule, the material is used in combination with cement mortars, polymer mastics, epoxy and polyurethane adhesives.

No special tools are required to install the waterproofing tape

Benefits:

- versatility - mounting waterproofing tapes are produced with a bottom sticky layer, which guarantees reliable and instant fixation to any concrete structures;

- durability - modern belts are equipped with a durable metallized top layer. It works for high strength and protection;

- waterproofing characteristics - the material successfully repels moisture, preventing its penetration deep into cracks and joints;

- ease of use - it is most convenient to lay the waterproofing tape in rolls. No special tool is required for this;

- affordable price.

Disadvantages:

- not the simplest application technology.

Scope of application: waterproofing of seams, joints, abutments.

Brands: Penetron, Knauf.

Technical specifications

| Density | 1.5 g / cm3 |

| Tensile strength | 0.15 MPa |

| Elongation,% | 700 |

| Resistance to alkalis, acids | there is |

Features of insulation when insulating premises

When the walls of an apartment or a private house are insulated, it is imperative to arrange a waterproof covering of vertical fences. Roll materials are glued to the base of the walls before installing thermal insulation.

Insulation is a hygroscopic material, therefore a waterproof layer is especially important. Otherwise, the insulating layer will get wet and lose its properties. Raw materials are subject to fungal and mold contamination.

Application of liquid waterproofing

Polyurethane waterproofing concrete

The best option for high-quality waterproofing indoors is a one-component polyurethane mastic. Such material, after being applied to concrete, polymerizes and forms a durable seamless coating with moisture-insulating properties. It is gratifying that polyurethane can be used as moisture protection for laying tiles, screeds, and as an independent topcoat.

Polyurethane insulation does not interfere with the vapor permeability of concrete

Benefits:

- polymer forms a durable elastic seamless layer;

- excellent waterproofing properties;

- application to any concrete, regardless of the configuration of the structure;

- resistance to shock and abrasion loads;

- after the implementation of the work and polymerization, we can talk about the complete absence of toxicity;

- resistance to chemistry and biological effects.

Disadvantages:

- the material is applied under favorable conditions;

- contains toxic xylene, which is not very pleasant to apply;

- does not work for internal waterproofing of tanks in contact with chlorine, say, in swimming pools;

- does not work with negative water pressure, that is, it is not the best solution for waterproofing foundations.

Scope of application: industrial and household premises with high humidity, technical water treatment zones, insulation of interfloor floors in production, waterproofing for bulk polymer floors.

Brands: Hyperdesmo.

Technical specifications

| Operating temperature | -50 +90 | Adhesion | 30 kg / sq. Cm and above |

| Vapor permeability | 0.8 g * m2 * h | Water permeability | Not |

| Tensile strength | 55 kg / sq. Cm | Accelerated aging test | More than 2 thousand hours |

| Hardness | 70 units and higher | Elasticity | Over 600% |

Balcony and loggia waterproofing

In order for a balcony or loggia to be used as an additional room for storing any things or a recreation area, waterproofing of the premises is necessary. This process involves not only removing the seams, but also carrying out additional measures to protect the frame, treating the structure with water-repellent compounds, arranging an external ebb to prevent water leaks.

After the balcony or loggia is cleaned of contamination, you can proceed directly to protecting the floor of the premises, waterproofing is most often used of a coating or penetrating type. Processing is carried out in several layers, and then, after drying, foil insulation is laid on the floor. Next, you can carry out the installation of the topcoat, with the obligatory sealing of the joints.

For waterproofing walls and partitions, roll materials are used, which simultaneously play the role of insulation and insulation. For example, it can be rolled polystyrene foam. Further, the material is covered with a coating compound.

Roof waterproofing is also performed with coating materials, while great attention must be paid to joints, seams and other defects that are filled with sealed compounds.

Penetrating waterproofing technology

Work is carried out only on stable, dry or matt damp concrete. All loose layers, paint, grease are removed. The base must be moistened until it is completely saturated.

The cement mixture is mixed with water, in accordance with the manufacturer's recommendation. As a rule, 20 kg of mixture requires 5-5.4 liters of water.... A brush is taken to work to perform plastering work. the material is intensively applied to the surface at a rate of 1.5 kg / m2.

The second layer is realized after the first has been bound (after 4-8 hours). To avoid stress, do not exceed the standard consumption per layer. For three days, the base is protected with a polyethylene film from drying out too quickly, moistened with water spray, and protected from mechanical stress.